Testing of Basic Characteristics of Pepper Fresh Fruits and

O

p

timization of Mechanical Parameters

Yuan Zhang

1

, Lijiao Wei

1*

, Yiguo Deng

1,2

, Mingfu Li

1

, Yeqin Wang

1

and Shengli Liu

3

1

Tropical Agricultural Machinery Research Institute, Chinese Academy of Tropical Agricultural Sciences, Zhanjiang,

China

2

Agricultural Science and Technology Co., Ltd. of YIWU, Zhanjiang,China

3

The Center of CangLong Agricultural Technology Service for Zhanjiang City, Zhanjiang, China

{zhang198414}@126.com,weilijiao2008@163.com,dyg7810@21cn.com,lmf6306@21cn.com,441213852@qq.com,1051568

484@qq.com

Keywords: Pepper, physical properties, mechanical properties, testing, analysis.

Abstract: By measuring the physical properties of fresh green peppers and measuring the mechanical properties of the

epidermis, the crushed and damaged data of the peel and the nucleus under different working conditions

were analyzed. The results showed that using 3% 7.0, soaking in heated waters within 24h with the

pretreatment of broken machine and peeler peeling peel fruit of the process steps. Obtained the base of the

working clearance of 5.5-6.5mm, the cavity is three times the size of the gradual change model and the

mechanical properties of the control in the 5 ~ 40N, you can get better peeling effect and the core is not

damaged basic conclusions , Which provided theoretical basis for upgrading and processing of pepper initial

processing machinery.

1 INTRODUCTION

Pepper fresh fruit is picked after sterilization,

peeling, washing, drying, and vested white pepper.

white pepper products as one of the most popular

products, it needs to remove the peel, pulp and

drying the pepper seed process, peeling is the most

crucial step.

Pepper fresh fruit peeling methods are the

traditional water immersion method, mechanical

peeling method, chemical peeling method and

biological enzyme method. The traditional method

of soaking for a long time (the shortest 5-7d),

resulting in a long processing cycle, covers large

area, But wastes a lot of water during the processing,

labor-intensive production of white pepper has a

serious odor. Processing quality is not stable, the

cost is higher and higher. Chemical peeling pepper

will consume large amounts of chemical raw

materials, high cost, resulting in waste water

pollution of the environment, while the chemical

reagents used in food processing makes the law

difficult to promote (Li Mingfu, 2015; Wu Huasong,

2006; Wang Xiulan, 2004). Although enzymatic

peeling process shorter, less pollution, but also can

play a role in water conservation to some extent, but

the cost of enzyme preparation is too high, the

cultivation of enzymes for shorter cycles peeling

pepper is also more complex, related research work

also remain in the laboratory stage, it is difficult to

promote; mechanical peeling method mainly by

means of mechanical working principle, the use of

peeling parts and pepper fruit friction, collision,

hitting the role of peeling. At present, many

domestic and foreign researchers have reported on

the development of peeling machine and washing

machine, but the process should be in accordance

with threshing (artificial or mechanical), fan to

stems, green ripe fruit sorting, soaking pool or river

immersion, machinery Rinsing, natural drying or

drying, cleaning, grading and other implementation

in order to get better quality finished products. The

process involves more equipment, complex

conditions, the cost is higher, while friction or hit

peeling machine also exists incomplete peeling, high

nuclear damage rate and waste more serious issues

such as the entire peeling process and ancillary

equipment Improve the optimization of space is still

larger.

Throughout the status of pepper processing,

enzymatic, biological and water immersion, etc.,

aside processing costs, cycles, product quality and

Zhang, Y., Wei, L., Deng, Y., Li, M., Wang, Y. and Liu, S.

Testing of Basic Characteristics of Pepper Fresh Fruits and Optimization of Mechanical Parameters.

In 3rd International Conference on Electromechanical Control Technology and Transportation (ICECTT 2018), pages 627-631

ISBN: 978-989-758-312-4

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

627

other factors, the final peeling still need to be

manually assisted. However, with the gradual lack of

rural labor force in recent years, no one is willing to

continue to engage in first-line agricultural

production, and the rural areas are facing the

situation of having no labor force. As a result,

people become the biggest bottleneck in the

development of agriculture (Vaidyanatha Lyer

Thankamani, 2004; Li Mingfu, 2015; Du Zhihao,

2011; MR. BINU, 2013). Although the mechanical

peeling method can alleviate the shortage of rural

labor force to a certain extent, it has some help, but

the huge unit or the product quality, waste and other

factors still restrict the pace of its mechanized

production.

Based on the requirement of scale and

industrialization of pepper processing, the key

technologies of peel peeling of peppers are still

difficult to meet the relevant international standards.

The lack of adequate market competitiveness of

peppers has not yet been fundamentally solved,

which limits the sustainable development of peppers

industry to a large extent development of. Therefore,

by measuring the physical properties of pepper fresh

fruit, the mechanical properties of the test, will help

strengthen pepper peel peeling key technology

research, to focus on carrying out efficient, high

quality, non-polluting, low-cost processing

technology research and ancillary equipment

research Provide basic reference indicators.

2 OVERALL RESEARCH

METHOD

The overall method for the study is as follows: First,

the pretreated pepper fruits are pretreated with a

pretreatment machine to damage most of the

pericarp, but the damage is not damaged. Then, the

pretreated pepper fruits are treated with a biological

enzyme for a certain period of time, Machine

peeling, and finally washed and dried to get white

pepper (P.K Ravi, 2013).

The chemical constituents of pepper epidermis

were tested by phytochemical pretreatment system.

The chemical constituents of pepper fresh fruits

were studied qualitatively by water extraction,

ethanol extraction and petroleum ether extraction.

According to their chemical composition and related

experiments The corresponding enzyme preparation

is screened; pepper physical properties of the

measurement of the use of electronic scales, vernier

caliper, respectively, hundred-weight and two-axis

size measurement, multiple sets of data to determine

the average to determine the mechanical properties

of fresh pepper test using electronic universal testing

machine The anti-stress of pepper fruit was

measured many times, the value of anti-stress was

recorded, and the average value of multiple

measurements was taken. The friction test method

was used to conduct several tests to record the peel

adhesion strength of pepper and the average value of

multiple experiments. After analyzing its physical

characteristics And mechanical properties, based on

the design of mechanical pretreatment equipment to

provide a theoretical basis.

Pepper fresh fruit peeling best enzyme

preparation screening and peeling process to the

peeling effect as an indicator, the use of single factor

test results comparison analysis, screening of

suitable enzyme preparation, the use of response

surface analysis of enzymatic peeling process

conditions further Analysis and optimization, to

determine the best process parameters for the design

of peeling machine provide a reference.

3 PHYSICAL PROPERTY

MEASUREMENT AND

MECHANICAL PROPERTIES

TESTING

3.1 Physical property measurement

Pepper ear harvest picking string yellow ear or more

than four cooked fruit, this method is the traditional

practices and experiences of farmers, but also

recognized by the market, so the pepper grains have

green, ripe fruit points, understand the pepper fruit

hundred-grain weight, two-axis size of the indicators

help to quickly complete the mechanical method of

pepper fruit epidermal premature damage. It has a

direct guiding significance for the design, working

principle and shaping of key components of pepper

fresh fruit pretreatment machine (Piper nigrum L,

2013; Piper nigrum L, 2013; V.Thirupathi., 2009; Li

Mingfu, 2012).

Hundred-weight measurement of electronic

balance as the main tool, points green ripe fruit,

artificial selection of hundred weighing and

recording, each sub-100 were weighed separately.

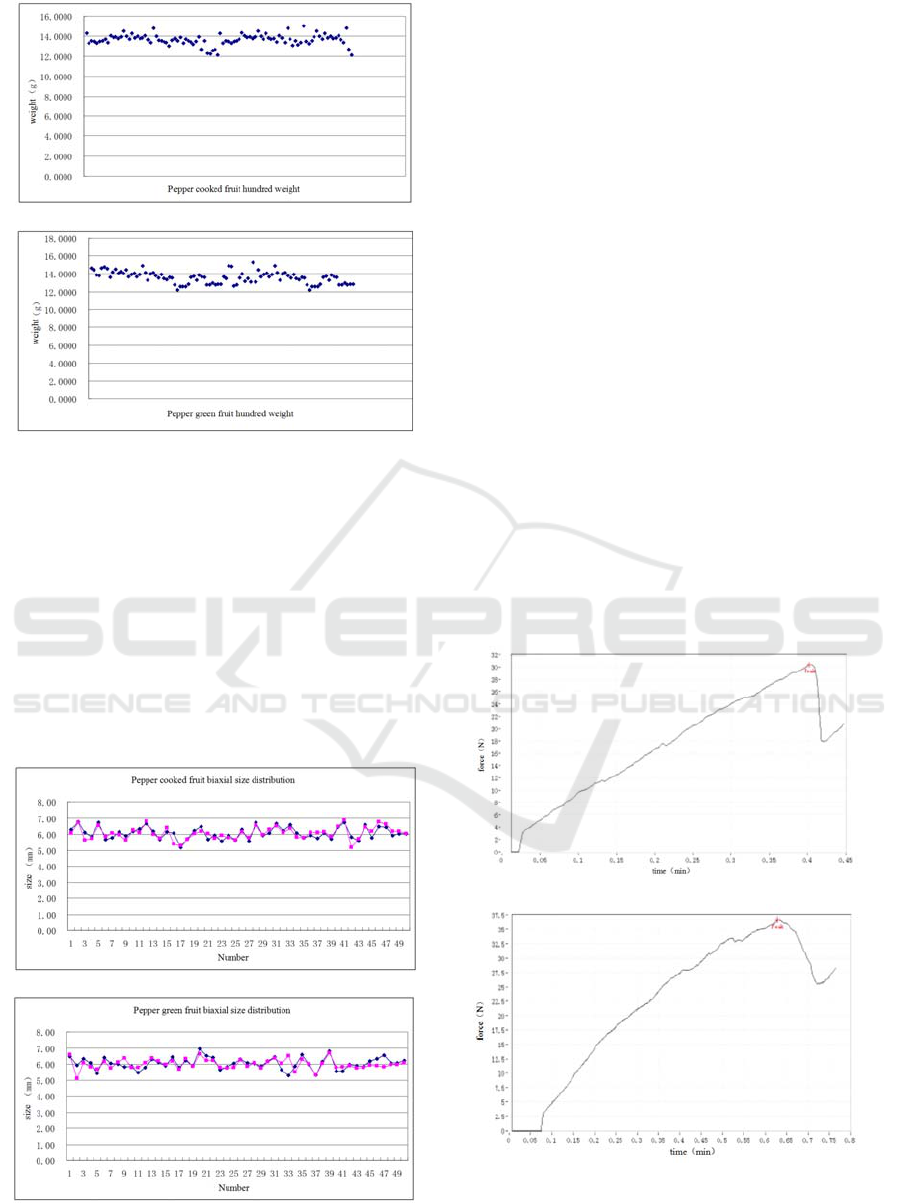

Pepper fruit mass distribution shown in Figure 1 (a,

b).

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

628

(a)

(b)

Figure 1 Pepper green ripe fruit hundred redistribution

map

As can be seen from Figure 1, pepper ripe fruit

hundred gravimetric distribution of the relative law,

the ripe fruit hundred weight in 13-14g; green fruit is

still in the growth stage, and the growth rate varies,

the distribution of hundred weight more Wide range,

between 12-15g.

Two-axis size using electronic vernier caliper,

points green ripe fruit, artificial selection of the 100,

were measured. The bifacial distribution of pepper

fresh fruit is shown in Fig.2.

(a)

(b)

Figure 2 Peppers two-axis size distribution

As can be seen from Fig. 2, the distribution of

the biaxial size of the cooked pepper is regular and

the size of the biaxial axis is basically the same. The

biaxial size of the bred fruit is between 5.5 and 6.5

mm. The green fruit is still in the growth stage. The

biaxial size Yet irregular, and basically distributed

between 5.5-6.5mm, the shape of green fruit has not

yet formed, but the size of the final shape after the

formation of ripe fruit basically the same.

3.2 Mechanical properties test

Pepper fresh fruit mechanical properties of the test

can be further understanding of the green peel

pepper skin damage, stress resistance of the nuclear,

Pepper peel peeling machine design, mechanical

properties, peeling principle selection provides a

theoretical reference to help peel fruit peel Pre-

broken machine and peeling machine model

optimization and improve pepper processing

quality(Li Mingfu, 2012; Zhang Yuan,2015).

Pepper mechanical properties of fresh fruit,

divided into green ripe fruit, artificial thresholding,

the selection of maturity, color, shape close to the

sample of 100 each, the use of TE-XWW-20

electronic universal testing machine (Shanghai

RIXIN data analysis and image processing software)

test. Mechanical curve shown in Figure 3.

(a)

(b)

Figure 3 Pepper fresh fruit anti-stress test map

Testing of Basic Characteristics of Pepper Fresh Fruits and Optimization of Mechanical Parameters

629

From Fig. 3 (a), we can see that there are two

turning points on the strength and time chart of

pepper green fruit, the first time the external force

reaches 3 ~ 4N and the second time is 31 ~ 32N; (b)

There are also two turning points on the time chart,

when the external force reaches 3 ~ 5N for the first

time, the second time is 36 ~ 37.5N. The above can

be expected to damage the epidermis of pepper

about 3 ~ 5N external force, while the damage of the

nuclear fruit about 30 ~ 40 external force, that

pretreatment and peeling machine theoretical hitting

force should be controlled below 40N.

3.3 Chemical Analysis

A clear chemical composition of fresh peel peel for

rapid and safe screening of enzymes suitable for

biological peeling process is of crucial significance,

but also the enzymatic and mechanical methods

combined with the peeling process theory basis. The

test and analysis of the chemical constituents in the

peel The chemical composition of the pepper fresh

fruit was qualitatively and quantitatively analyzed

by the method of phytochemical composition system

pre-test, the extraction method of water extraction,

ethanol extraction and petroleum ether extraction.

According to the results of the test and analysis,

it was found that the peel of pepper fruit contains

chemical components such as carbohydrate, flavone,

organic acid, saponin, lactone, alkaloid and

coumarin and does not contain cardiac glycoside,

amino acid, anthraquinone, protein, Volatile oil, may

contain phenolic substances.

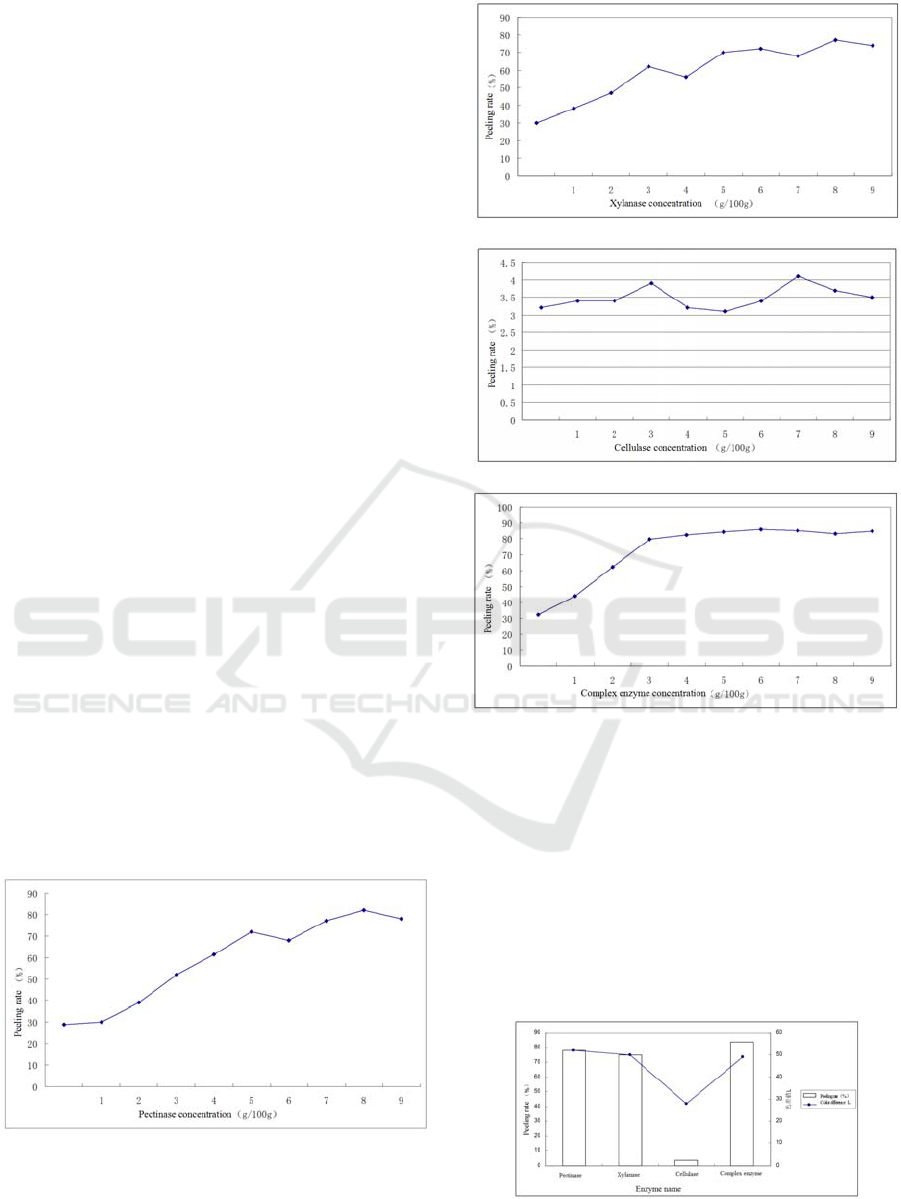

Based on the above chemical composition

analysis, the choice of enzyme preparation mainly

selected pectinase, xylanase, cellulase, enzyme

solution four kinds of specific peeling effect shown

in Figure 4 (a-d).

(a)

(b)

(c)

(d)

Figure 4 Different enzyme concentrations lead to peeling

effect map

Analysis of Figure 4 (ad) shows that the peeling

effect of pectinase and xylanase can reach more than

75%, and pectinase and xylanase dosage of 5% or

more to achieve better results, while the fiber

Enzymes do not affect pepper peel peeling the main

enzyme preparation. Figure d complex enzyme

solution, the concentration of 3% or more to achieve

the effect of the above single enzyme effect,

showing a good economic value.

Figure 5 Different enzyme conditions under the effect of

comparison

ICECTT 2018 - 3rd International Conference on Electromechanical Control Technology and Transportation

630

As can be seen from Fig. 5, the optimal peeling

effect of different enzyme preparations is compared

with the color difference value L, the peeling effect

of the composite enzyme solution is best, and the

color difference value L is close to that of pectinase

and xylanase, Chromatic aberration value L of

recognition, at the same time, in the amount, cost,

peeling time, etc. have shown better economy,

preferably pepper fruit pretreatment after the

enzyme preparation.

4 CONCLUSIONS

a.According to the principle of ball dynamics and

the rules of contact between the friction surface and

the solid body, the working gap of the pre-treated

damage machine is 1 to 3 times the biaxial size (5.5-

6.5mm) according to the physical characteristics

measurement. The peeling machine is from top to

bottom The taper gap range is 3 times the cardinal

taper of the biaxial size.

b.According to the principle of friction

mechanics, the mechanical properties of peeling

parts in the working chamber of the peeling machine

should be controlled at 5 ~ 40N to ensure the peeling

of the fresh fruits of the pepper and the kernels are

not damaged.

c.Using complex enzyme preparation. The whole

peeling process according to the screening of the

composite enzyme solution concentration of 3%, PH

value 7.0, heated water immersion within 24h with

the pretreatment damage machine and peeling

machine to achieve the optimal process steps.

ACKNOWLEDGEMENTS

This work was financially supported by the Central

Public-interest Scientific Institution Basal Research

Fund for Public Welfare Research and Capacity

Building of Guangdong Province

(2017A020208009); Chinese Academy of Tropical

Agricultural Sciences(1630132017003)and

Collaborative innovation and platform environment

construction special of Guangdong Province

(2017A040406003).

I would like to thank the members of the

research group for their selfless help, especially the

communication author Wei Lijiao.

REFERENCES

Li Mingfu,Zhang Yuan,Ge Chang.etc.Study on Pepper

Decorticating Technology and

Equipment[J].Engineering Solutions for

Manufacturing Processes vol.741(2015)pp577-581.

Wu Huasong,Wen Huiting.Ripening and softening effect

of ethephon on pepper fruit[J].Chinese Journal of

Tropical Agriculture,2006,26(6): 4-6.

Wang Xiulan,Liu Hongsheng.Effect of Various

Ingredients in Pepper on Quality[J].Chinese Journal of

Tropical Agriculture,2004,(4): 25-28.

Vaidyanatha Lyer Thankamani, Raghavan Nair Giridhar.

Fermentative Production of White Pepper Using

Indigenous Bacterial Isolates[J]. Biotechnology and

Bioprocess Engineering, 2004, 9 : 435-439.

Li Mingfu,Ge Chang,Zhang Yuan.etc.Qualitative Study on

Chemical Constituents of the Piper nigrum L.

peel[J].China Condiment,2015, 40(6):109-110,114.

Du Zhihao,Zhang Ronghe,Feng Jiancheng.etc.Screening,

Identification and Preliminary Application of Efficient

Debinding Bacteria of Pepper Peel[J].China

Condiment, 2011, 4: 51-55.

MR. BINU. Design and fabrication of pepper

thresher[EB/OL]. [2013-09-09].http://www.

kscst.iisc.ernet.in/spp/30series/pdf/project_synopsis_4

09.pdf.

P.K Ravi. Technology for reducing the drudgery of

women: Pepper thresher: P.K Ravi[EB/OL]. [2013-

09-09]. http://www.pdslandtolab.org/

html/journey.htm.

Mechanical thresher for black pepper (Piper nigrum L.)[

EB/OL]. Tamil Nadu Agricultural University, [2013-

09-09]. http://www.tnau.

ac.in/aecricbe/aetc/proc9.htm.

Mechanical thresher for black pepper (Piper nigrum

L.)[EB/OL]. Tamil Nadu Agricultural University,

[2013-09-09].http://www.tnau.ac.

in/aecricbe/aetc/proc10.htm.

V.Thirupathi.A hand operated white pepper peeling

machine[J].Agricultural Mechanizati- on in Asia,

Africa, and Latin America, 2009, 40(4): 57-59.

Li Mingfu,Li Yulin,Zhang Yuan.etc.Pepper pre-treatment

peeling machine[P]: China,201210368105.3,2012-9-

28.

Li Mingfu,Zhang Yuan,Li Yulin.etc.Simple peeling

pretreatment equipment[P]:China,

201220501854.4,2012-9-28.

Zhang Yuan,Ge Chang,Li Yulin.etc. Design and

Experimental Analysis of Pepper Fruit Preprocessing

Machine[J]. Advanced Materials Research Vols.1061-

1062(2015)pp687-691.

Testing of Basic Characteristics of Pepper Fresh Fruits and Optimization of Mechanical Parameters

631