Capturing CO

2

in a Bubble-Column Scrubber Using Blended Amine

Solvent

Pao Chi Chen

*

, Huan Sheng Tseng, Zi Qi Lai and Zi Xiang Liao

Department of Chemical and Materials Engineering ;Lunghwa University of Science and Technology, Taiwan, China.

Email: chenpc@mail2000.com.tw

Keywords: Carbon dioxide, amine, bubble-column scrubber, Taguchi, mass transfer coefficient

Abstract: Carbon dioxide emissions are the major climatic change issue in the world. In order to reduce the CO

2

emissions, several technologies have been explored, in which absorption is found to be a powerful method.

The key factors for an effective absorption are the structure of the scrubbers and solvents adopted. Therefore,

this study aimed at absorbing carbon dioxide through a bubble column using AMP+MEA blended amine

solution as an absorbent. The reason for using MEA+AMP as the absorbent was that its absorption capacity

can be improved and the price was cheaper for both. In addition, the scrubbing factor for a bubble-column

scrubber was higher. In the experiment, CO

2

absorption was performed by simulating the temperature of the

flue gas and the concentration of CO

2

in the coal-fired power plant. The liquid flow rate (A), gas flow rate

(B), temperature in the column (C) and solution concentration (D) were chosen as the operating factors.

There were 4 factors in total, and 3 levels of each were taken for Taguchi design L

9

(3

4

). There were a total

of 9 groups of experiments. In order to explore the effect of operating variables on the absorption efficiency

(E), absorption rate (R

A

) and overall mass transfer coefficient (K

G

a), the parameter significance and target

operating condition (E=90%; R

A

=1x10

-3

mol/s-L; K

G

a=0.4 s

-1

) could be obtained by Taguchi design and

Taguchi analysis, so as to serve as a reference for future scale-up design. The results showed that E was in

65.79-98.7%; R

A

was in 3.54 x10

-4

-13.9 x10

-4

mol/s-L; and K

G

a was in 0.1743-0.3950 s

-1

. After Taguchi

analysis, A and B were found to be significant parameters, and the target condition was confirmed to be

A1B1C2D3. In addition, the best condition was also discussed in here.

1 INTRODUCTION

Currently, the CO

2

emissions in industry are mainly

from coal-fired power plants, steel-making plants,

petrochemical industry and cement plants, etc.,

among which coal-fired power plants are the most

concerned. In order to reduce CO

2

emissions, a lot

of studies for the capture, storage and reuse of CO

2

were explored, mainly focusing on the post-

combustion using absorption method (Yang et al.,

2008; Yu et al., 2012), which is to use an alkaline

solution to capture CO

2

(Chen et al., 2015).

Therefore, the improvement of absorbent efficiency,

absorbers and solvent regeneration efficiency has

become important in research. How to effectively

reduce the cost of electricity becomes the key to the

success of CO

2

capture and storage (CCS).

According to literature reported, the MEA is widely

used in various amines (Chen et al., 2015; Versteeg

et al., 1996). However, due to the high energy

consumption required using single amine, the

development of blended amine was valued (Vaidya

and Kenig, 2007; Adeosun et al., 2013;

Rinprasertmeechai et al., 2012), such as

MEA+AMP, which has development space based on

absorptive capacity and lower energy consumption

(Choi et al., 2009; Khan et al., 2015; Aroonwilas

and Veawab, 2009). A similar viewpoint for lower

energy consumption was reported by Gomes et al.

(Gomes et al., 2015), who found that diethyl amine

was more competitive in price and loading capacity

as compared with other amines. However, the

reaction rate of blended amines with CO

2

can be

expressed below (Versteeg et al., 1996; Xiao et al.,

2000; Vaidya and Kenig, 2007):

76

Chen, P., Tseng, H., Lai, Z. and Liao, Z.

Capturing CO2 in a Bubble-Column Scrubber Using Blended Amine Solvent.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 76-81

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

r

k

RR

NH

K

K

R

RN

CO

1)

where (RR’NH) and (R

2

RN) represent the

concentration of MEA and AMP, respectively. This

equation shows that the absorption rate is influenced

by the concentration of MEA, AMP and OH

-

, which

also indicates that the CO

2

emitted by the plant can

be treated with absorption mode in alkaline solution

(Xiao et al., 2000; Chen et al., 2008). In addition,

the efficiency of absorption process is usually set to

90%, it is also desirable to have a high mass transfer

coefficient to make the scrubber smaller (Weiland

and Hatcher, 2011; Idem et al., 2006). Due to the

fact the mass transfer coefficient for the use of

scrubber is approximately in the range of 0.1-1.0 1/s

(Chen et al., 2015; Tontiwachwuthikul et al., 1992;

Aroonwilas et al., 1999), it is difficult to achieve

both higher efficiency (90%) and higher mass

transfer coefficient (0.4 1/s), simultaneously.

In absorption experiment, the packed column,

tray column and bubble column were often used. As

the operation of the packed column is complicated,

and its operating cost is high, while the bubble

column is characterized by the merits such as

controllable pH value, high mass transfer coefficient,

high absorption factor and easy operation. Therefore

in this study the absorption experiment is performed

using the bubble column with a blended amine

solution (MEA/AMP) as the absorbent. This study

planned to conduct an experiment to absorb CO

2

by

the bubble column with MEA+AMP as a solvent to

search for and confirm the target operating condition

and parameter significance, and predict the

feasibility with absorption efficiency of 90%,

absorption rate of 1.0x10

-3

mol/L s, and mass

transfer coefficient of 0.41/s. In order to compare,

the best condition analysis was also explored.

2 EXPERIMENTAL DESIGN AND

PROCEDURE

2.1 Absorption Experiment Design

The experiment aimed at absorbing carbon dioxide

using MEA+AMP blended amine in a bubble

column. The results were expected to be applied to

the absorption of CO

2

emitted by coal-fired power

plants. Therefore, the carbon dioxide of flue gas in

the coal-fired power plant with the concentration of

15% and temperature of 55℃ was simulated to enter

the column. Taking liquid flow rate, gas flow rate,

liquid temperature, and solution concentration as

the condition factors, three levels of each condition

factor were taken respectively, i.e. liquid flow rate

(A:0.1-0.3L/min), gas flow rate (B:3-9L/min), liquid

temperature (C:30-50℃), and solution

concentration (D:4-6M) . Theoretically, a total of

81(=3

4

) experiments needed to be done, but due to

the high cost and time-saving in this way, this

experiment used the Taguchi experimental design to

reduce the groups of the experiment to L

9

(3

4

)=9 to

save time and experimental costs. The value

obtained in the steady state was adopted to obtain

the absorption rate, absorption efficiency and overall

mass transfer coefficient, and then the statistical

software was used to find out the sequence of

significance and target condition. Table 1 shows the

condition factors and levels, Table 2 shows the

orthogonal arrays, and there are 9 groups of

experiments under different conditions needed to be

conducted.

Table 1: Factors and levels in this work.

Factor level

1 2 3

A(L/min) 0.1 0.2 0.3

B(L/min) 3 6 9

C(℃) 30 40 50

D(M)

4 5 6

Table 2: Orthogonal table, L

9

(3

4

).

No. A B C D

No1 1 1 1 1

No2 1 2 2 2

No3 1 3 3 3

No4 2 1 2 3

No5 2 2 3 1

No6 2 3 1 2

No7 3 1 3 2

No8 3 2 1 3

No9 3 3 2 1

The Taguchi method uses the signal and noise

ratio (S/N) as the process optimization objective

function (Chen et al., 2015; Hvalec et al., 2004). The

target value is:

2

1

)(

1

log10 my

nN

S

i

n

i

(2)

Capturing CO2 in a Bubble-Column Scrubber Using Blended Amine Solvent

77

In addition, the best condition for larger-the-

better is:

n

i

i

y

nN

S

1

2

11

log10

(3)

where y

i

is experimental data for ith level, n the

number of level, and m the target value. Using the

two equations and experimental data obtained, the

objective condition, best condition and parameter

importance could be determined.

2.2 Calculation of Experimental Data

Experimental data including absorption efficiency,

absorption rate, and overall mass transfer coefficient

are listed in Table 3. In these equations, V

L

, Q

y

, P

A

and T

1

represent the final solution volume, gas flow

rate, inlet gas partial-pressure and inlet gas

temperature, respectively. In order to determine

overall mass transfer coefficient, a two-film model

and mass balance are adopted (Chen et al., 2015; c).

In addition, it is assumed that the concentration of

CO

2

gas in the liquid phase is extremely small,

which can be ignored (C

A

≫HC

AL

). Therefore, the

overall mass transfer coefficient can be calculated

from the following Eq. (6), in which K

G

a can be

calculated from known inlet and outlet conditions.

Table 3: Equations evaluated in this work (

Chen et al.,

2015

).

E

100%

4)

1

1

1

1

5)

6)

2.3 Experimental Devices and

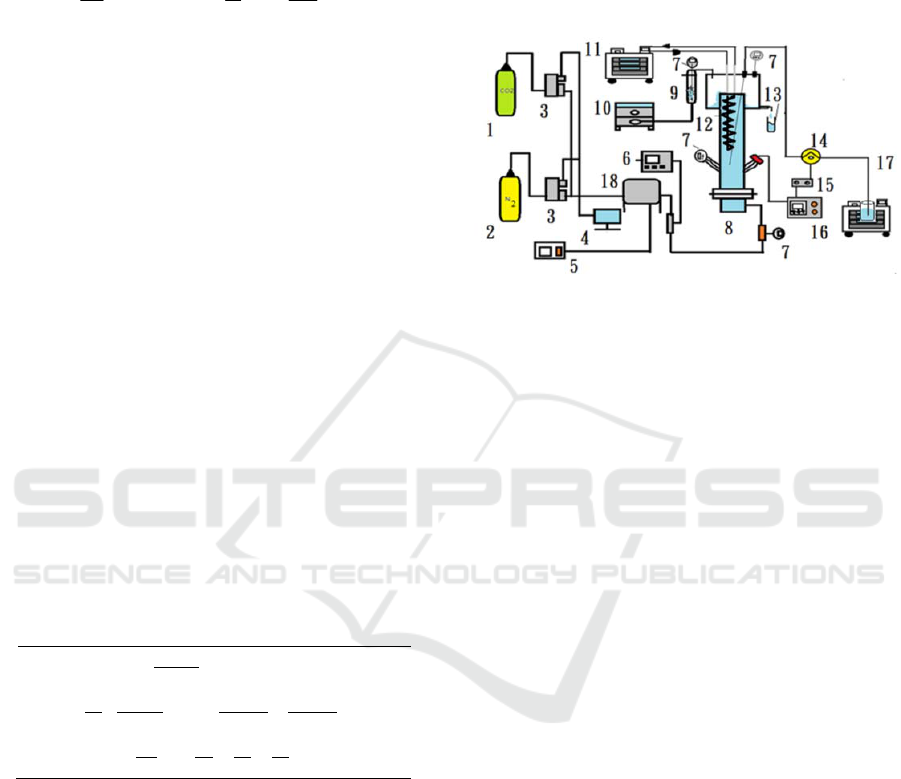

Procedures

The devices required for this experiment are shown

in Figure 1, including the bubble column, gas-liquid

feed system, pH detector, CO

2

detection system, gas

heating system and liquid cooling system. In this

experiment, the blended amine (AMP/MEA) was

used as an absorbent, among which the AMP

accounted for 30wt% of the total amine

concentration, which was reported in the previous

work. In order to achieve the desired concentration,

the required blended amine concentration was

prepared by using distilled water. Second, the flow

rate of carbon dioxide and nitrogen was input based

on the proportion of 15% of CO

2

, and the gas inlet

temperature was maintained at 55℃. The

experiment was started after the blended amine was

put into the column.

1. CO

2

-tank 10. CO

2

-meter

2. N

2

-tank 11. Cooling system

3. Mass flow controller 12. Coil

4. PC 13. Sampling vessel

5. Heating adjuster 14. Tubing pump

6. Pressure gauge 15. Pump controller

7. Digital thermometer 16. pH controller

8. Bubble column 17. Thermal stat tank

9. Drying vessel 18. Heater

Figure 1: Experimental device.

3 RESULTS AND DISCUSSION

3.1 Operation and Data Calculation at

the Steady State Condition

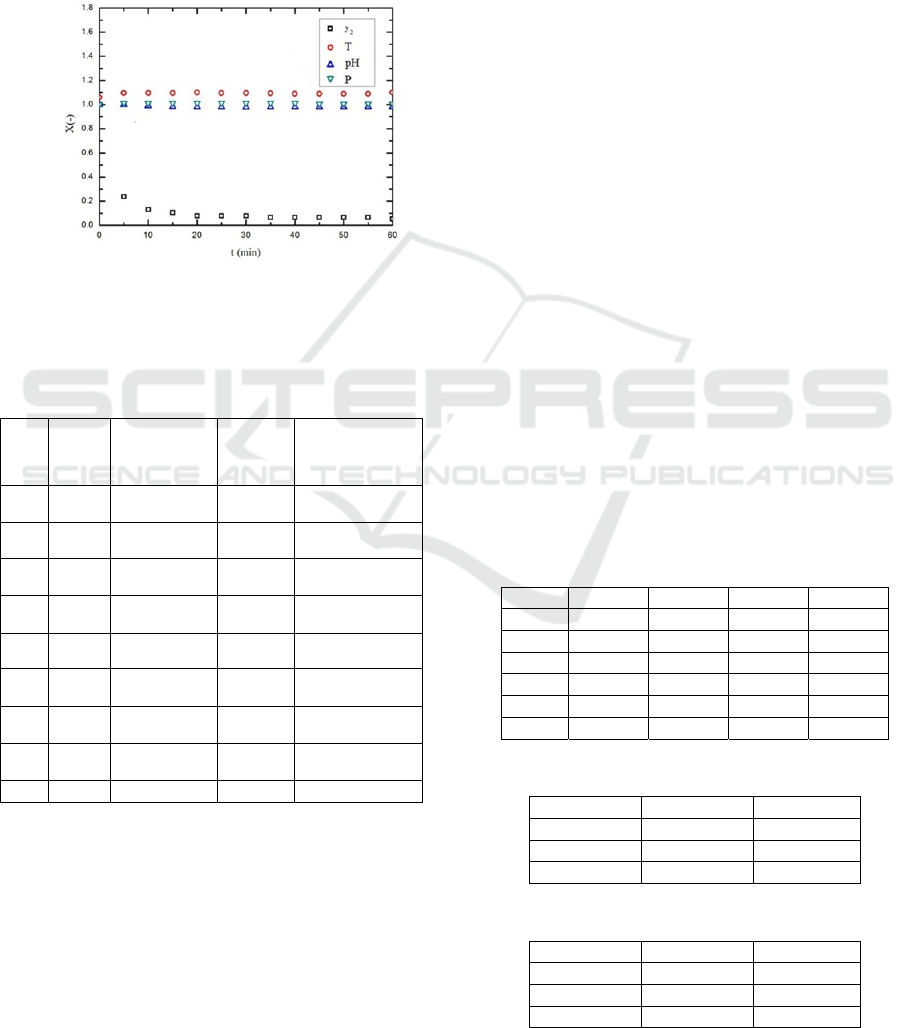

In order to understand the relationship of the outlet

concentration of gas, liquid temperature, pH, and

inlet pressure against time during operation, the

measured value divided by the initial value was

defined as X (-) value, which was taken as the Y-

axis; the time (t) was taken as the X-axis, as shown

in Figure 2; after 1 hour of experiment, it was found

that the X values kept constant after 20 minutes,

showing that the system reached a steady state.

Therefore, all data can be evaluated at the steady

state condition. The experimental results may be

divided into two parts. Part 1 used the Taguchi

method to design 9 groups of experiments, and

calculated the data of absorption rate, absorption

efficiency and overall mass transfer coefficient as

shown in Table 4. Part 2 searched for and confirmed

the target operating condition and the sequence of

IWEG 2018 - International Workshop on Environment and Geoscience

78

significance based on the results of the data

calculated in Part 1 and Taguchi analysis. Table 4

shows the values calculated by Eqs. (4)-(6), where E

is in 65.8% - 98.7%; R

A

is in 3.54×10

-4

- 13.9×10

-4

(mol/s.L); K

G

a is in 0.1743- 0.3950(s

-1

), and in

addition, the pH is in 10.45 - 11.25 in the steady

state. These data are comparable with literatures

(Chen et al., 2015; Vaidya and Kenig, 2007).

Figure 2: A plot of X vs. t, showing the steady state

operation (No.1).

3.2 Taguchi Analysis

Substituting the absorption efficiency and target

value into Eq. (2) for Taguchi analysis, the results

were shown in Table 5. It was found that the

parameter significance affecting the absorption

efficiency was B>A>C>D, and the combination of

the target value was A1B1C2D3. The data showed

that B was the main factor. After conducting the

Taguchi target analysis for the absorption rate, it

was found that the parameter significance affecting

the absorption rate was B>D>C>A, and the

combination of the target value was A2B3C3D2. It

was found that B was the main influence factor. In

addition, Taguchi target analysis for the overall

mass transfer coefficient showed that the parameter

significance affecting the overall mass transfer

coefficient was B>D>A>C, and that the best

combination was A3B3C2D2. It was also found that

factor B was the main influencing factor. Table 6

showed the parameter significance analysis and

target conditions obtained through S/N analysis for

the three types of calculation data. Regarding the

overall influence effect, B was the most significant,

followed by D, and it was also found that the impact

of C was the least significant.

Alternatively, the best condition and parameter

significance through the Taguchi analysis were

shown in Table 7. It was found that the parameter

significances affecting E (No. 13), R

A

(No. 14), and

K

G

a(No.15) were B>D>A>C, B>A>C>D and

B>A>D>C, respectively. It was also found that B

was the main influence factor, while C was the

minor factor. The result was similar to that target

analysis. Except B, D is the second significant in

Target condition, while A is the second significant

in the best condition. In addition, the conditions for

Nos. 12 and 15 are the same, but the parameter

importance is slightly different.

T a b l e 5: S / N r a t i o a n a l y s i s f o r E .

LevelA B C D

1 (-20.24) (-16.16) -22.39 -24.75

2 -25.24 -24.06 (-21.06) -22.27

3 -22.23 -24.93 -24.85 (-21.46)

Delta 5.00 8.77 3.76 3.29

Rank 2 1 3 4

Target 1 1 2 3

Table 6: Target condition and significance.

Target Significance Condition

NO.10(E) B>A>C>D A1B1C2D3

NO.11(R

A

) B>D>C>A A2B3C3D2

NO.12(K

G

a) B>D>A>C A3B3C2D2

Table 7: The best condition and significance.

The best Significance Condition

NO.13(E) B>D>A>C A1B1C2D2

NO.14(R

A

) B>A>C>D A3B3C2D3

NO.15(K

G

a) B>A>D>C A3B3C2D2

Table 4: Experimental data obtained in here.

NO E(%)

R

10

/∙

a

pH

1 93.42 3.54 0.1743 10.64

2 82.89 7.3 0.2564 10.45

3 74.03 11.99 0.3525 10.16

4 96.05 4.23 0.2444 11.20

5 65.79 6.62 0.1769 10.43

6 70.51 11.6 0.3058 11.18

7 98.70 4.4 0.3153 10.82

8 78.67 7.35 0.2337 11.25

9 72.73 13.9 0.3950 10.73

Capturing CO2 in a Bubble-Column Scrubber Using Blended Amine Solvent

79

3.3 Confirmations of the Target

Conditions and the Best Conditions

Table 8: Confirmation for target condition and the best

condition.

NO

E

(%)

R

A

(10

4

)

/∙

a

1/

p

H

10 (92.11) 12.25 0.5723 10.82

11 97.33 (3.34) 0.2160 10.93

12 82.67 11.86 (0.403) 11.00

13 (94.74) 3.74 0.1924 10.62

14 80.52 (13.48) 0.4415 10.72

15 82.67 11.86 (0.403) 11.00

Table 6 showed the analysis results of the target

condition and the best condition obtained by

Taguchi analysis. According to the target conditions,

three experiments were carried out and the results

were shown in Table 8. It was found that No. 10, its

E, R

A

and K

G

a, were all up to standard, indicating

that the target conditions is obtained in here. In

addition, the best condition confirmation showed

that No. 13 was not reached the best, while the Nos.

14 and 15 all reached the best as compared with

Taghchi experiments listed in Table 4. From both

analyses, it was hard to obtain higher E and K

G

a

simultaneously. Therefore, how to use effective

experimental design to obtain the desired conditions

became significant. In this study, the condition of

A1B1C2D3(No. 10) can satisfy not only a higher E,

but also a higher K

G

a.

4 CONCLUSIONS

A continuous bubble-column scrubber was

successfully used to investigate the process variables

on the absorption efficiency, absorption rate, and

overall mass transfer coefficient. Under Taguchi

experimental design, a total of 9 runs were carried

out in here. It was found that the system could reach

a steady state after 20 minutes, while the final pH

was in the range of 10.16-11.25, depending on the

operating condition. In addition, the absorption

efficiency was found to be in the range of 65.79-

98.7%; the absorption rate was in

4

1054.3

-

Lsmol

/109.13

4

; and the overall mass

transfer coefficient was in 0.1743-0.3950 1/s. From

Taguchi analysis for target and the best modes, it

was found that the gas flow rate (B) was major

factors influencing the outcome data, while the

influence of the temperature in the column (C) was

the minor. In addition, the target condition was

found to be A1B1C2D3. Through the confirmation

of target conditions, it was known that the E

(92.11%), R

A

(1.225x10

-3

mol/s L) and K

G

a (0.5723

s

-1

) all reached the set target value.

REFERENCES

Adeosun A, Goetheer N E H, Abu-Zahra M R M 2013

Absorption of CO

2 by Amine Blends Solution: An

Experimental Evaluation International Journal of

Engineering And Science 3 12

Aroonwilas A, Veawab A 2009 Integration of CO2

capture unit using blended MEA-AMP solution into

coal-fired power plants Energy Procedia 1 4315

Aroonwilas A, Veawab A, Tontiwachwuthikul P 1999

Behavior of mass-transfer coefficient of structured

packings in CO

2 absorbers with chemical reactions

1999 Ind Eng. Chem. Res. 38 2044

Chen P C, Luo Y X, Cai P W 2015 Capture of Carbon

Dioxide Using Monoethanolamine in a Bubble-

Column Scrubber Chemical Engineering &

Technology 38 274

Chen P C, Shi W, Du R, Chen V 2008 Scrubbing of CO2

green-house gases, accompanied by precipitation in a

continuous bubble-column scrubber Ind. Eng. Chem.

Res. 47 6336

Choi W J, Seo J B, Jang S Y, Jung J H, Oh K J 2009

Removal characteristics of CO2 using aqueous

MEA/AMP solutions in the absorption and

regeneration process Journal of Environmcntal

Scicnccs 21 907

Fan L S 1989 Gas-liquid-solid fluidization engineering

Butterworths USA Ch. 9 600

Gomes J, Santos S, Bordado J 2015 Choosing amine

based absorbents for CO2 capture Environmental

Technology 36 19

Hvalec M, Gorsek A, Glavic P 2004 Experimental design

of crystallization processes using Taguchi method Acta

Chim. Slov. 51 245

Idem R, Wilson M, Tontiwachwuthikul P, Chakma A,

Veawab A, Aroonwilas A, Gelowitz D 2006 Pilot plant

studies of the CO2 capture perforance of aqueous MEA

and Mixed MEA/MDEA solvents at the University of

Regina CO2 capture technology development plant and

boundary dam CO capture demonstration plant Ind.

Eng. Chem. Res. 45 2414

Khan A A, Halder G N, Saha A K 2015 Carbon dioxide

capture characteristics from flue gas using aqueous 2-

amino-2-methyl-1-propanol (AMP) and

monoethanolamine (MEA) solutions in packed bed

absorption and regeneration columns Int. J. Greenh.

Gas Control 32 15

IWEG 2018 - International Workshop on Environment and Geoscience

80

Rinprasertmeechai S, Chavadej S, Rangsunvigit P,

Kulprathipanja S 2012 Carbon dioxide removal from

flue gas using amine-based hybrid solvent absorption

World Academy of Science, Engineering and

Technology 64 410

Tontiwachwuthikul P, Meisen A, Lim J 1992 CO

2

Absorption by NaOH, Monoethanolamine and 2-

amino-2-methyl-1-propanol Solutions in a Packed bed

Chem. Eng. Sci. 47 381

Vaidya P D, Kenig E Y 2007 Absorption of CO

2 into

aqueous blends of alkanolamines prepared from

renewable resources Chem. Eng. Sci. 62 7344.

Vaidya P D, Kenig E Y 2007 CO

2-alkanomine reaction

kinetics: A review of recent work Chem. Eng. Technol.

30 1467

Versteeg G F, Van Dijck L A J, van Swaaij W P J 1996

On the kinetics between CO

2 and Alkaloamines both

in aqueous and non-aqueous solutions. An overview

Chem. Eng. Comm. 144 113

Capturing CO2 in a Bubble-Column Scrubber Using Blended Amine Solvent

81