Experimental Study on Desorption Characteristics of Methane in the

Soft and Hard Layer Coal of Stratified Structure in the Northwest of

Guizhou, China

Xijian Li

1, *

, Kegang Ling

2

and Peng Pei

1,3

1

School of Mining, Guizhou University, Huaxi, Guiyang, Guizhou 550025, China;

2

Department of Petroleum Engineering, University of North Dakota, 243 Centennial Dr., Upson II Room 366, Grand

Forks, ND 58202, USA;

3

Institute for Energy Studies, University of North Dakota, 243 Centennial Dr., Upson II Room 366, Grand Forks, ND

58202, USA.

Email: 575914635@qq.com

Keywords: Soft and hard coals of stratified structure, coal gas outburst, coal gas mining, coal gas desorption

characteristic

Abstract:

Based on the importance of coal gas desorption characteristics to coal bed methane mining, extraction, and

prevention and control of coal and gas outburst, the coal samples from the soft and hard layer of stratified

structure in the northwest of Guizhou were selected as research subjects, and a High Capacity

Adsorption(HCA) device using high pressure capacity method was utilized to perform research on

adsorption characteristics of the soft and hard layer coal under different temperatures and pressures.

Seventy-two experiment groups have been carried out. The characteristics and rules of gas desorption of the

soft and hard layer coal were analyzed comprehensively. The results showed that the gas desorption rate of

the soft and hard layer coals was highest within the first minute after coal body was exposed or gas pressure

was relieved, and gas desorption volumes increase almost linearly, then leveled off. The gas desorption of

the soft and hard layer coals took place in the first 30 minutes after coal body was exposed or gas pressure

was relieved, and the first minute gas desorption volumes accounted for 62.67-86.06% of the first two- hour

gas desorption volumes. The initial gas desorption rate, the cumulative volume, and the desorption

proportion of different time periods were affected by temperature and pressure, and increased slightly with

the increase of temperature and pressure. Under the conditions of same temperature and pressure, the initial

gas desorption rates of the soft layer coal were 1.282-1.892 times of the hard. The cumulative gas

desorption of the hard layer coal would exceed that of the soft at the end of desorption. The shortest

desorption process can happen in 10 minutes. The results provide a reference and guideline to coal gas

mining and gas outburst control in the northwest of Guizhou.

1 INTRODUCTION

Although there are vast amounts of coal resources

and tremendous coal mining projects in Guizhou

province of China, the coal seams distribute in

complex geological settings, and disasters due to

coal and gas outburst accidents occur more

frequently than other places (

Li, 2013; Heng et al.,

2015). A critical overview of a large number of coal

and gas outburst cases shows that occurrences of

these outbursts are closely related to complicated

geological structure (

Li and Shi, 2013; Li and Lin, 2010;

Liu et al., 2015). Numerous investigations done by

scholars around the world have shown that

tectonically deformed coal has a strong gas diffusion

ability, high gas desorption rate, high porosity,

various strength, and favorable dynamic and

mechanical conditions of gas accidents(

Li et al., 2013;

Li, 2011; Wei et al., 2008; Cao et al., 2013; Wang and Sun,

2015; Liang et al., 2014; Gao and Tan, 2015; Liu and Liu,

2015

). Therefore, to prevent or control gas outburst

in tectonically deformed coal, understanding the gas

desorption characteristics of the coals is the key to

gas control work (Li et al., 2010; Li et al., 2014; Xie

304

Li, X., Ling, K. and Pei, P.

Experimental Study on Desorption Characteristics of Methane in the Soft and Hard Layer Coal of Stratified Structure in the Northwest of Guizhou, China.

In Proceedings of the International Workshop on Environment and Geoscience (IWEG 2018), pages 304-313

ISBN: 978-989-758-342-1

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

and Chen, 2007; Li et al., 2011; Liu et al., 2010).

There are many coal seams in the northwest

coalfield of Guizhou, and most of them consist of

layers of stratified structure. Many of these coal

seams are thin and interlayed with layers of different

lithology. Most coal seams have high gas contents

and are close to coal seam group with coal and gas

outburst dangers. These coal seams merge and

bifurcate frequently, and their structure is

complicated with low matrix permeability and

interlayed by soft and hard intervals. In the mining

process, the volume of coalbed gas emitted in

Xiaotun coal mine in Dafang county, Qinglong coal

mine in Qianxi county and Xinglong coal mine in

Xishui county is large. Because the emission

mechanism is complicated and the control of gas

outburst is difficult, gas burst seriously threatens the

safety of underground workers. It is noted that the

gas emission from coal depends mainly upon gas

desorption characteristics. In this paper, the

experiments on gas desorption from the samples

retrieved from Xiaotun, Qinglong, and Xinglong

coal mines were conducted under different

temperatures and pressures. By contrastive

analysis on gas desorption characteristics of the

samples from the soft and hard layer coals, the

desorption mechanism and the factors that influence

desorption characteristics were revealed. The results

provide a reference and guideline to coal gas mining

and gas burst control.

2 EXPERIMENTAL METHODS

AND PROCESSES

2.1 Sample Collection and Preparation

The coal samples were collected from the soft and

hard layers of the sixth coal seams of Xiaotun coal

mine, the No. 16 coal seam of Qinglong coal mine,

and the No. 18 coal seam of Xinglong coal mine.

The coal samples were prepared according to the

sample preparation standard, GB/T212-2008, issued

by China. The coal samples were crushed, sieved,

and then put into the bottle with ground stopper and

sealed. Standard analysis, true density (TD),

apparent density (AD), initial speed of gas emission

(

△

P), speed of gas diffusion (

△

D), and firmness

coefficient ( f) of the samples are shown in Table 1.

Notes: QLSC-The soft coal of Qinglong coal mine;

QLHC-The hard coal of Qinglong coal mine;

XTSC-The soft coal of Xiaotun coal mine; XTHC-

The hard coal of Xiaotun coal mine; XLSC-The

soft coal of Xinglong coal mine; XLHC-The hard

coal of Xinglong coal mine

2.2 Experimental Methods and Steps

The selected experimental equipment was the high

pressure and capacity adsorption device HCA,

which was manufactured by Chongqing Research

Institute of China Coal Technology Engineering

Group. According to the standard MT/T752-1997,

experiments were conducted as follows:

The fresh coal samples were crushed,

sieved by the 0.2-0.25 mm standard sieve,

then the particles of sizes between 0.2-0.25

mm were put into the bottles with ground

stopper and sealed with a label.

Fifty grams of samples, with an accuracy to

0.0001 grams, were weighed and put into

dry containers and numbered, then dried for

8 hours under temperature of 85 ℃ and

pressure of 13 Pa, and then were cooled

down.

One of the dried samples was loaded into a

coal sample tank and vibrated, and the tank

was sealed and filled with high pressure gas

of 4MPa. Then the tank was put into a

water bath and checked for air-tightness.

The valve was slowly opened to release

high-pressure gas in the tank, and the tank

was connected to the degassing system,

then put into the water bath.

The temperature of water bath was

increased to 60±0.1 ℃, then the vacuum

pump was started, and the vacuum

degassing valve was slowly opened to

remove the gas from the coal sample.

After the vacuum gauge showed the

pressure was below 4 Pa, the coal sample

tank was continuously pumped for at least

4 hours, then the valve was closed, and the

vacuum unit and vacuum gauge were

turned off.

When gas desorption experiments of coal

samples were carried out, experimental methods and

steps were as follows:

Experimental Study on Desorption Characteristics of Methane in the Soft and Hard Layer Coal of Stratified Structure in the Northwest of

Guizhou, China

305

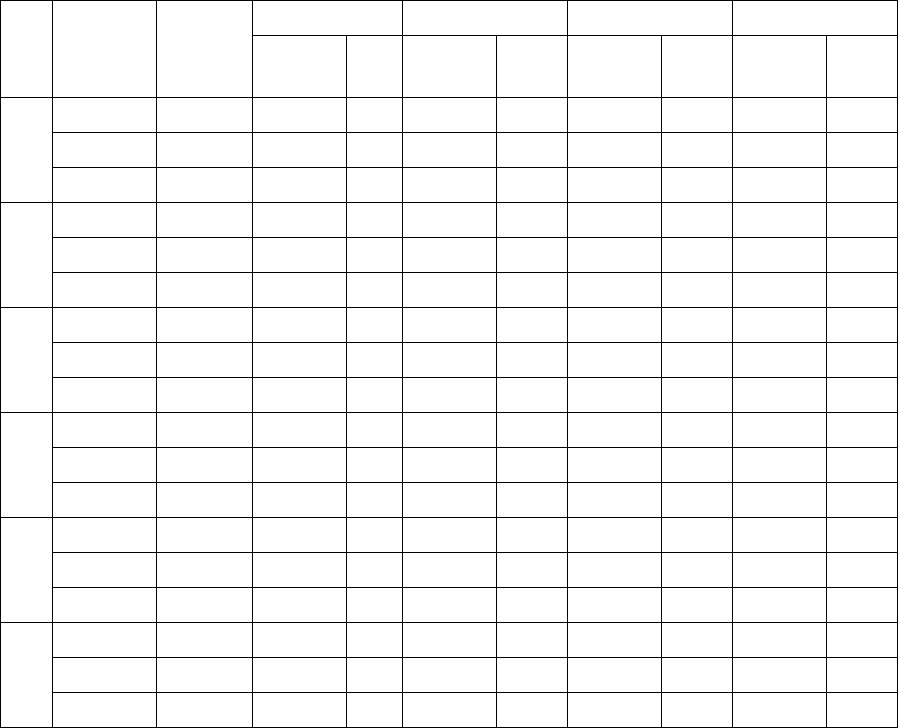

Table 1: Basic parameters of coal samples.

Coal sample name

Water content

(Mad)%

Ash content

(Aad)%

Volatile content

(Vdaf)%

TD

(g/cm

3

)

AD

(g/cm

3

)

△ P

(mmHg)

△ D

(ml)

f

QLSC 3.42 22.96 8.75 1.61 1.54 15.209 1.520 0.78

QLHC 2.18 10.06 7.14 1.51 1.43 10.053 0.850 1.223

XTSC 3.58 19.99 7.86 1.57 1.49 19.779 2.100 0.303

XTHC 1.66 12.86 6.59 1.57 1.48 12.533 1.018 0.707

XLSC 5.42 10.41 8.10 1.56 1.49 15.904 1.411 0.333

XLHC 3.15 7.58 7.50 1.43 1.37 4.961 0.470 0.673

The temperature of water bath was adjusted

to 25±1℃, and the coal sample tank was

put into the constant temperature water bath.

The inflatable tank was filled with a certain

volume of high purity gas with

concentration of 99.99%, then the valve of

gas tank was closed.

The coal sample tank was connected to the

inflatable tank and the gas pressure data

acquisition instrument. The valves of coal

sample tank and the inflatable tank were

opened, then the high purity gas flowed

into the coal sample tank.

When gas pressure of the coal sample tank

reached a set value, the valve of the coal

tank was closed, then the gas was fully

adsorbed by the coal sample at a set

temperature.

The gas pressure inside the tank was read

from the gas pressure data acquisition

instrument, and the tank was filled with gas

immediately when the pressure inside the

tank was less than the set value, until the

pressure reached the set value.

When the gas adsorption on the coal sample

lasted more than 12 hours, the gas adsorption

equilibrium experiment was finished. The

temperature of water bath was adjusted to set

values(20±1℃、30±1℃、40±1℃) before the gas

desorption volume was measured. When the

temperature of water bath reached a set value and

became constant, experiment could begin.

The cylinder scale that was used to measure the

gas desorption volume was read and recorded every

10 seconds within 1 minutes, and data were read and

recorded every 1 minute from the beginning to 30

minutes, every 5 minutes from the 31 to 60 minutes,

and every 10 minutes from the 61 to 120 minutes.

The cumulative gas desorption volume per gram per

minute measured from the beginning to 10 seconds

is the initial gas desorption rate V1(ml/(g-min)), i.e.

the gas desorption rate of coal after 10 seconds of

exposure.

3 ANALYSIS OF

EXPERIMENTAL DATA

3.1 Desorption Experiment Under

Different Experimental

Temperatures

The experiments of 6 coal samples (soft and hard

layers) from 3 coal mines were carried out under

1.5MPa at 20℃, 30℃, 40℃, respectively. The

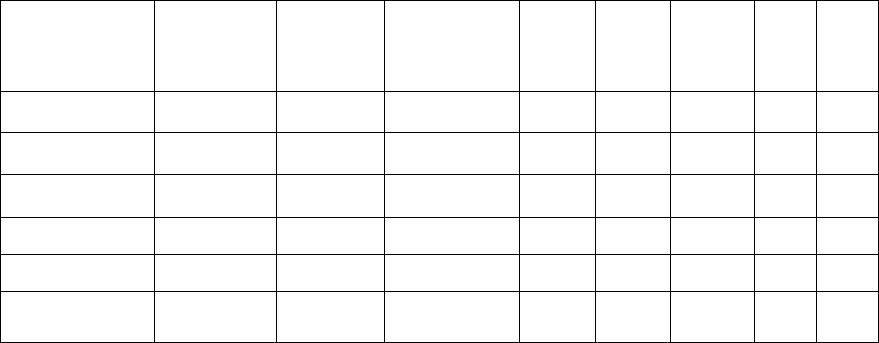

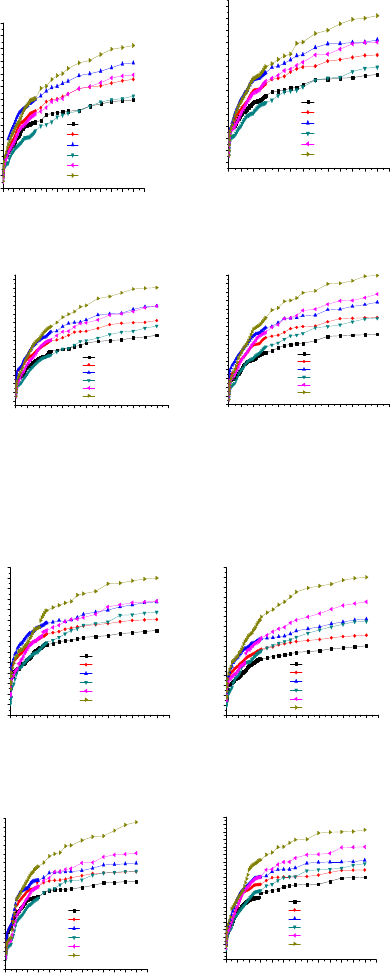

results were shown in Figures.1 to 6.

In order to study the relationship between the

initial gas desorption rates of the soft and hard coals

and the desorption temperature, the statistics

analysis were performed on the desorption data of

the soft and hard coals from Xinglong mine. The

results were shown in Table 2.

IWEG 2018 - International Workshop on Environment and Geoscience

306

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

t=20 ℃

t=30 ℃

t=40 ℃

Cumulative Volume (ml/g)

Time (s)

Figure 1: Desorption curves of QLSC at different

temperatures.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Cumulative Volume (ml/g)

Time (s)

t=20 ℃

t=30 ℃

t=40 ℃

Figure 2: Desorption curves of QLHC at different

temperatures.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

1

2

3

4

5

6

7

8

9

10

11

12

Time (s)

Cumulative Volume

(

ml/g

)

t=20 ℃

t=30 ℃

t=40 ℃

Figure 3: Desorption curves of XTSC at different

temperatures.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Cumulative Volume

(

ml/g

)

Time (s)

t=20 ℃

t=30 ℃

t=40 ℃

Figure 4: Desorption curves of XTHC at different

temperatures.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Time (s)

C um ulative V olum e (m l/g )

t=20 ℃

t=30 ℃

t=40 ℃

Figure 5: Desorption curves of XLSC at different

temperatures.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Cum ulative V olum e (m l/g)

Time (s)

t=20 ℃

t=30 ℃

t=40 ℃

Figure 6: Desorption curves of XLHC at different

temperatures.

Experimental Study on Desorption Characteristics of Methane in the Soft and Hard Layer Coal of Stratified Structure in the Northwest of

Guizhou, China

307

Table 2: The cumulative gas desorption volumes and percentage of XLSC and XLHC within 5 minutes (at pressure of 1.5

MPa).

Samples Temperature

0-1 min. 2-5 min.

Cumulative gas

desorption volume

(ml/g)

Percentage

(%)

Cumulative gas

desorption volume

(ml/g)

Percentage

(%)

XLSC

20±1 ℃ 2.877 29.20 2.085 20.45

30±1 ℃ 2.990 27.07 2.413 21.84

40±1 ℃ 3.154 25.64 2.89 23.50

XLHC

20±1 ℃ 2.054 17.39 1.985 16.51

30±1 ℃ 2.080 15.97 2.091 16.85

40±1 ℃ 2.192 14.71 2.579 17.31

Figures.1 through 6 showed that the curves fitted

the monotonically increasing function relationship,

in which the cumulative gas desorption volume of

the soft and hard interlayered coals increased with

the time. However, gas was desorbed quickly within

the first minute, and the desorption volume

increased almost linearly with desorption time, then

increased slightly. The gas desorption rates of the

samples from different coal mine were different. The

cumulative desorption volume increases when

temperature increases for all coal samples. ,

Table 2 showed that when desorption pressure

was kept constant, the cumulative gas desorption

volume of soft coal was 11 percentage higher than

that of hard coal. The gas desorption rate is the

highest in the first minute, and then decreased later.

Therefore, the increase of cumulative desorption

volume slowed off gradually. The cumulative

desorption volume from 2 to 5 minutes was

obviously smaller than that of the first minute under

the same temperature, but the decline rate decreased

with the increase of temperature.

3.2 Desorption Experiments Under

Different Desorption Pressures

The HCA experimental device was used, and

desorption experiments were carried out under the

temperature of 25 ℃ and the pressures of 0.74 MPa,

1.5 MPa, 3.0 MPa respectively. The experimental

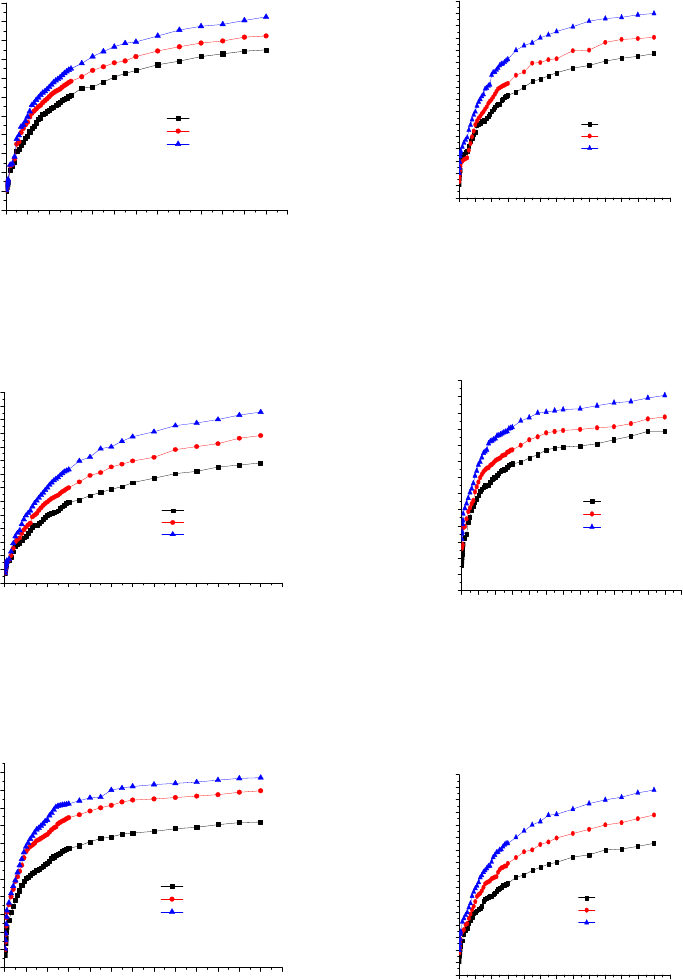

results were shown in Figures.7 through 12.

In order to study the relationships between the

initial gas desorption rate (V1), cumulative gas

desorption volume and gas adsorption equilibrium

pressure, the data of desorption time from 0 to 2

hours at 25±1 ℃ were analyzed by for the soft and

hard coals from Xinglong mine, which are shown in

Table 3.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

1

2

3

4

5

6

7

8

9

10

11

Time (s)

Cumulative Volume (ml/g)

P=0.74 MPa

P=1.5 MPa

P=3.0 MPa

Figure 7: Desorption curves under different desorption

pressures, QLSC.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Cumulative Volume (ml/g)

Time (s)

P=0.74 MPa

P=1.5 MPa

P=3.0 MPa

Figure 8: Desorption curves under different desorption

pressures, QLHC.

IWEG 2018 - International Workshop on Environment and Geoscience

308

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

1

2

3

4

5

6

7

8

9

10

11

12

Time (s)

Cumulative Volume (ml/g)

P=0.74 MPa

P=1.5 MPa

P=3.0 MPa

Figure 9: Desorption curves under different

desorption pressures, XTSC.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Cumulative Volume (ml/g)

Time (s)

P=0.74 MPa

P=1.5 MPa

P=3.0 MPa

Figure 10: Desorption curves under different

desorption pressures, XTHC.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

Cumulative Volume (ml/g)

Time (s)

P=0.74 MPa

P=1.5 MPa

P=3.0 MPa

Figure 11: Desorption curves under different desorption

pressures, XLSC.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Cumulative Volume (ml/g)

Time (s)

P=0.74 MPa

P=1.5 MPa

P=3.0 MPa

Figure 12: Desorption curves under different desorption

pressures, XLHC.

Table 3: The 0-2 hours cumulative gas desorption volumes and percentage of the soft and hard coals from Xinglong coal

mine (25 ±1 ℃)

Samples Soft coal Hard coal

Gas equilibrium pressure 0.74 MPa 1.5 MPa 3 MPa 0.74 MPa 1.5 MPa 3 MPa

The initial gas desorption rate(V1)(ml/(gꞏmin)) 9.066 12.074 12.918 7.542 8.196 8.478

0-1 min

Cumulative volume(ml/g) 2.541 2.997 3.264 1.963 2.152 2.298

Percentage(%) 26.96 26.13 25.81 18.69 17.03 15.71

0-30 min

Cumulative volume(ml/g) 7.676 8.765 10.13 7.266 8.846 10.45

Percentage(%) 78.42 82.28 83.21 69.18 70.00 71.48

0-2 h

Cumulative volume(ml/g) 8.792 9.909 11.398 8.970 10.90 12.85

Percentage(%) 89.82 93.02 93.63 85.40 86.22 87.90

Experimental Study on Desorption Characteristics of Methane in the Soft and Hard Layer Coal of Stratified Structure in the Northwest of

Guizhou, China

309

Figures.7 to 12 showed that the higher the gas

equilibrium pressure, the higher the gas desorption

rate was at constant temperature, and the gas content

increased as the pressure increased. The gas

desorption rate decreased with desorption time. The

decline of desorption rate was the highest during the

first minute. The initial gas desorption rates of the

samples from the soft coals were larger than those

from the hard coals. The attenuation of gas

desorption rate of the soft coals was faster than that

of the hard coals as well.

Table 3 showed that the percentage of 0-1

minute cumulative volume decreased when gas

equilibrium pressure increased for both soft and hard

coals from Xinglong coal mine. The cumulative gas

desorption volume of the soft layer coal within the

first 30 minutes accounted for 78.42-83.21 % of the

cumulative desorption volume within 2 hours, and

the cumulative gas desorption volume of the hard

coal within the first 30 minutes accounted for 69.18-

71.48% of the total cumulative desorption volume

within 2 hours. Therefore, for both soft and hard

coals, the amount of gas emission in the early stage

of coal exposure or gas pressure relief changes

dramatically, and the gas desorption rate decreased

rapidly. Under the same gas equilibrium pressure,

the initial gas desorption rates (V1) of the soft coals

were 1.202-1.524 times of those of hard coals. The

0-1 minute cumulative volumes of the soft coals

were 1.294-1.420 times of those of the hard coals.

The percentages of 0-1 minute cumulative volumes

in total desorption volumes of the soft coals were

1.442-1.643 times of those of the hard coals. For the

same desorption time period, the cumulative amount

of desorption increased with the increase of gas

pressure. For example, the 0-2 hours cumulative

volume of the soft coal at 3 MPa increased by 2.606

ml/g than the volume at 0.74 MPa. This explained

that gas content in the coal mine increased as the

pressure increased, and the probability of gas

disaster increased.

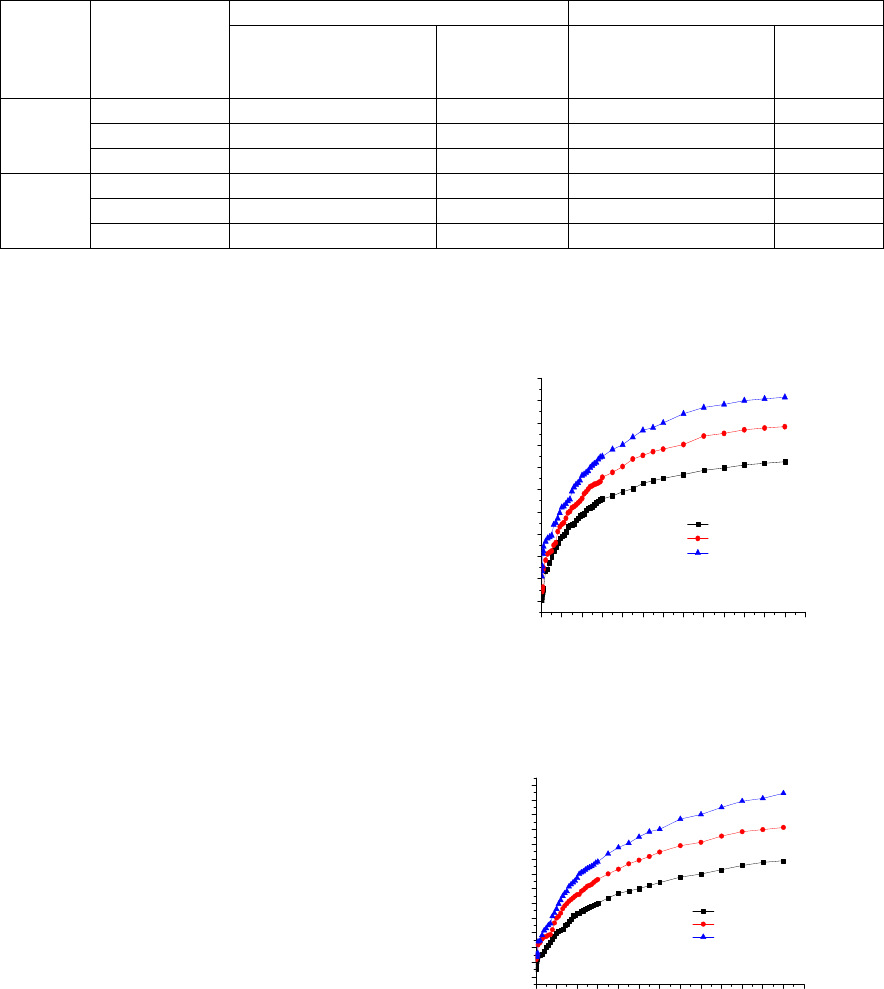

3.3 Desorption Experiments Under

Different Temperatures and

Equilibrium Pressures

In order to study the desorption characteristics of

soft and hard layer coal under different temperatures

and pressures, the experiment on gas desorption

characteristics of coal samples were carried out at

different temperature and pressure combinations.

Experiment pressures were set at 0.74MPa, 1.5MPa,

3MPa, and temperatures were set at 20℃、25℃、

30℃、35℃、40℃.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

C um u lativ e V o lu m e (m l/g)

Time (s)

(a) 20℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Cumulative V olume (m l/g)

Time (s)

(b) 25℃

0 600 1200 1800 2400 30 00 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Cumulative Volume (m l/g)

Time (s)

(c) 30℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Cumulative Volume (ml/g)

Time (s)

(d) 40℃

Figure 13: Desorption curves of QLSC and QLHC under

different temperatures and pressures.

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Time (s)

Cum u lative V olu m e (m l/g )

(a)20℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

C um ulative V olum e (m l/g)

Time (s)

(b)25℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Cumulative Volume (ml/g)

Time (s)

(c)30℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Cumulative Volume (ml/g)

Time (s)

(d)40℃

Figure 14: Desorption curves of XTSC and XTHC under

different temperatures and pressures.

IWEG 2018 - International Workshop on Environment and Geoscience

310

Figures.13 to15 showed that the 2-hour

cumulative gas desorption volumes of both soft and

hard coals from three different coal mines increased

slightly with the increase of temperature and

pressure. The 30-minute cumulative gas desorption

volumes of most soft coals were larger than those of

hard coals. However, the 2-hour cumulative gas

desorption volumes of the soft coals were smaller

than those of hard coals.

Table 4 showed that the 30-minute cumulative

gas desorption volumes of most soft coals were

larger than those of the hard ones from the same coal

mine under same experimental conditions. The

initial gas desorption rates (V1) of the soft coal were

7.116-12.94 ml/(gꞏmin) while those of the hard coals

were 3.762-10.09 ml/(gꞏmin). This explained that

there would be a large volume of gas emission of the

soft coal at the beginning of sudden pressure relief,

and the risk of coal and gas outburst in the soft coals

would be higher than that in the hard coals.

The percentage of 1-minute desorption volume

in total desorption volume of the soft coals were

much higher than that of the hard coals. The 1-

minute desorption volumes of the soft coal samples

from Qinglong coal mine were 1.367-1.652 times of

the hard one. The percentage of 1-minute desorption

volume in 2-hour desorption volume of soft coals

were 1.592-1.865 times of those of the hard ones

from same coal mine. For Xiaotun coal mine

samples, the 1-minute desorption volumes of the

soft coal samples from were 1.442-1.659 times of

those of the hard ones, and the percentage of 1-

minute desorption volume in total desorption

volume of the soft coals were 1.780-1.985 times of

those of the hard coals. The 1-minute desorption

volumes of the soft coal samples from Xinglong

coal mine were 1.368-1.481 times of those of the

hard ones, and the percentage of 1-minute

desorption volume in the total desorption volume of

the soft coals were 1.686-1.729 times of those of

hard coals. The 30-minute cumulative gas

desorption volume of the hard coals were larger than

those of the soft ones under the same temperatures

and pressures. These showed that the gas desorption

rate decays quickly in the soft coals after the first

minute. At the 30th minute, the cumulative gas

desorption volumes of the hard coals were larger

than those of the soft ones, and the difference in

cumulative gas desorption volumes between the soft

and the hard coals slowly increased afterwards.

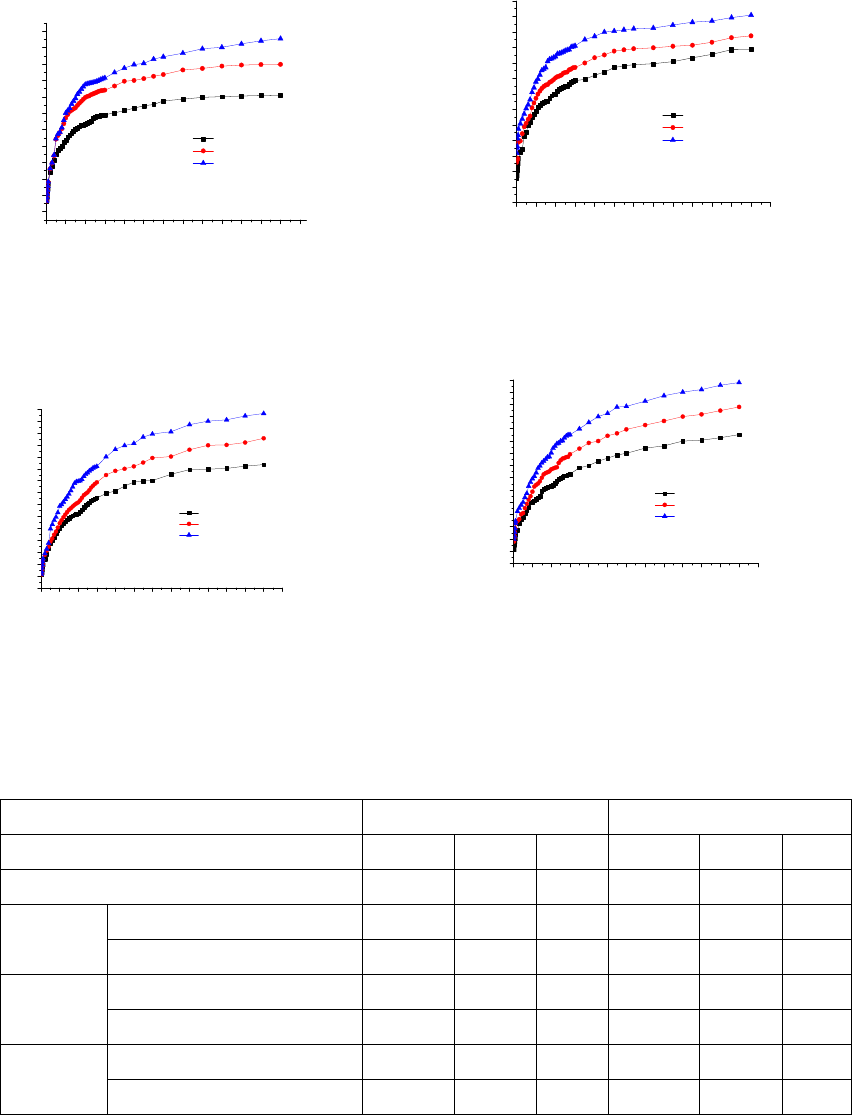

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

Time (s)

Cum ulative V olum e (m l/g)

(a)20℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

C u m u lativ e V o lu m e (m l/g)

Time (s)

(b)25℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

C u m u la tiv e V o lum e (m l/g )

Time (s)

(c)30℃

0 600 1200 1800 2400 3000 3600 4200 4800 5400 6000 6600 7200 7800

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

P=0.74 MPa

(

)

The soft layer

P=1.5 MPa

(

The soft layer

)

P=3.0 MPa

(

The soft layer

)

P=0.74 MPa

(

)

The hard layer

P=1.5 MPa

(

The hard layer

)

P=3.0 MPa

(

The hard layer

)

C u m u la tiv e V o lu m e (m l/g )

Time (s)

(d)40℃

Figure 15: Desorption curves of XLSC and XLHC under

different temperatures and pressures.

The 30-minute cumulative gas desorption

volumes of the soft layer coal accounted for 72.74-

86.06 % of the 2-hour volumes. Meanwhile, during

the same time period, it accounted for 62.67-72.79 %

for the hard coals. The percentages of the soft coals

were 1.161-1.182 times of those of hard coals. These

indicated that the gas desorption of the soft and hard

coals mainly occurred in the first 30-minute, and the

gas desorption rates were decline significantly in the

interval from the 30

th

minutes to the 2

nd

hour. The

gas desorption rates of the hard layer coals were

larger than those of the soft coals during this time

interval, and the declines of the desorption curves of

the hard coals were less than those of the soft ones.

With the increase of the equilibrium pressures

and temperatures, the time for the desorption

volumes of the hard coals to exceed those of the soft

coals became shorter, and the shortest time observed

in the experiment, which was 10 minutes, took place

in samples from Xiaotun coal mine under the

conditions of 40±1℃ and 3MPa.

Experimental Study on Desorption Characteristics of Methane in the Soft and Hard Layer Coal of Stratified Structure in the Northwest of

Guizhou, China

311

Table 4: The initial gas desorption rates and the cumulative gas desorption volumes of the soft and hard layer coal at

different time periods(30±1℃).

Samples

Gas equilibrium

pressure(MPa)

The initial gas

desorption

rate(V1)

(ml/(gꞏmin))

0-1 min 2-30 min 30 min-1 h 1 h-2 h

Cumulative

volume(ml/g)

Percenta

g

(%)

Cumulative

volume(ml/g)

Percentage

(%)

Cumulative

volume(ml/g)

Percentage

(%)

Cumulative

volume(ml/g)

Percentage

(%)

QLSC

0.74 7.116 1.754 23.07 3.818 50.22 1.072 14.10 0.958 12.61

1.5 8.316 2.003 21.59 4.842 52.20 1.304 14.06 1.157 12.47

3 10.69 2.445 22.54 5.391 49.70 1.571 14.48 1.441 13.28

QLHC

0.74 3.762 1.062 12.37 4.320 50.30 1.567 18.25 1.638 19.08

1.5 5.692 1.465 13.56 5.584 51.67 1.913 17.70 1.844 17.06

3 5.962 1.623 12.27 6.909 52.24 2.461 18.61 2.233 16.88

XTSC

0.74 11.72 3.088 31.56 5.259 53.76 0.868 8.873 0.568 5.806

1.5 12.19 3.266 29.83 6.131 56.01 0.934 8.532 0.616 5.627

3 12.94 3.438 29.14 6.692 56.92 0.994 8.424 0.675 5.521

XTHC

0.74 6.950 1.988 17.73 6.166 54.99 1.784 15.91 1.274 11.36

1.5 7.500 1.969 15.03 7.501 57.26 2.004 15.30 1.626 12.41

3 10.09 2.385 14.94 8.854 56.53 2.373 15.15 1.750 11.17

XLSC

0.74 10.81 2.737 28.54 5.316 55.44 0.936 9.761 0.600 6.257

1.5 11.84 2.890 26.16 6.413 58.05 1.075 9.731 0.669 6.056

3 12.92 3.328 25.76 7.457 57.71 1.370 10.60 0.766 5.928

XLHC

0.74 6.918 1.848 16.93 5.983 54.81 1.678 15.37 1.407 12.89

1.5 7.812 1.970 15.13 7.179 55.13 2.091 16.06 1.781 13.68

3 9.990 2.433 15.09 9.299 57.70 2.498 15.50 1.787 11.09

4 CONCLUSIONS

The gas desorption characteristics of the coal

samples that came from the soft and hard coals of 3

coal mines in the northwest of Guizhou were studied

by the experiments under different temperatures and

pressures. Based on the analyses of the experimental

data, following conclusions can be drawn:

The curves fitted the monotonically increase of

the cumulative gas desorption volumes of the soft

and hard coals with the desorption time.

The gas desorption rates of the soft and hard

coals were high at early stage, then slowed down.

Gas was desorbed quickly within the first minute,

and desorption volumes increased linearly, then

leveled off.

The gas desorption of the soft and hard coals

mainly took place in the first 30-minute, and the gas

desorption volumes within 30 minutes after coal

exposure or gas pressure relief accounted for 62.67-

86.06% of the 2-hour desorption volumes.

The initial gas desorption rate, the cumulative

desorption volume and the desorption percentages

of different time periods were affected by

temperature and pressure. The desorption volume

was proportional to both temperature and pressure.

Under the conditions of the same temperature

and pressure, the initial gas desorption rates of the

soft coals were 1.282-1.892 times of those of the

hard coals.

Given enough desorption time, the cumulative

gas desorption volumes of the hard coals would

exceed those of the soft ones. The shortest time

observed in the experiments is 10 minutes.

IWEG 2018 - International Workshop on Environment and Geoscience

312

ACKNOWLEDGEMENTS

This research was supported by National Natural Sci

ence Foundation of China (No.51874107, and

No.51864008) and Major Applied Basic Research

Project of Guizhou province (JZ (2014)2005)

and Joint Funds of Department of Science &

Technology of Guizhou Province and Guizhou

University (No. LH [2017] 7282).

REFERENCES

Cao S G, Zhang Z G, Li Y 2013. Experimental study of

deformation properties of outburst-prone coal

induced by gas adsorption and desorption.

Journal of China Coal Society 38(10) 1792-1799

Gao Y, Tan G W 2015

. Analysis on influence of fault

structure upon coal and gas outburst in

Zhaozhuang mine.

Mining safety & environmental

protection 42(3) 104-107

Heng X W, Li Q S, Han Z L 2015.

Structural control

features of coal and gas outburst in Shuicheng

mining area.

Safety in Coal Mines 46(07)186-190

Li S G, An Z F, Lin H F, et al. 2014. Research on

characteristics of methane adsorption in coal

seam under the conditions of multiple factors.

Coal Science and Technology 42(6) 40-44

Li S G, Zhao Y, Zhang T J 2010.

Test systems of the

coal sample adsorption /desorption

characteristics based on low-frequency

vibproportionn.

Journal of China Coal Society 35(7)

1142-1146

Li X C, Nie B S, He X Q 2011.

Influence of gas

adsorption on coal body.

Journal of China Coal

Society 36(12) 2035-2038

Li X J , Shi T H 2013.

Experimental study on pore

structures of outburst coal and its adsorption

properties at typical mining fields in Guizhou

province.

Journal of Mining & Safety Engineering

30(03) 416-420

Li X J 2013. Expermental study on physicochemical

properties and molecular simulation on methane

adsorption properties of gas-outburst coal in Guizhou

area [D]China University of Ming and Technology

Li X J, Lin B Q 2010.

Status of research and analysis

on coal and gas outburst mechanism.

Coal

Geology & Exploproportionn 38(1) 7-13.

Li Y B 2011. Experimental study on gas desorption of

tectonic coal at initial stage [D] Henan Polytechnic

University

Li Y B, Zhang Y G, Zhang Z M 2013.

Experimental

study on gas desorption of tectonic coal at initial

stage.

Journal of China Coal Society 38(1) 15-20

Liang J, Kang Z Q, Yao H F 2014.

Experimental study

on gas adsorption capacity of tectonic coal in

Hancheng mining area.

Safety in Coal Mines 45(12)

6-10

Liu D M, Wu L Y, Yang Y Z 2015.

Research on the

safety evaluation of coal mine production

logistics based on AHP-entropy method.

Journal

of Safety and Environment 15(3) 33-36

Liu Y B , Cao S G, Li Y, et al. 2010.

Experimental

study of swelling deformation effect of coal

induced by gas adsorption.

Chinese Journal of

Rock Mechanics and Engineering 29(12) 2484-2490

Liu Y W, Liu M J 2015.

Effect of particle size on

difference of gas desorption and diffusion

between soft coal and hard coal.

Journal of China

Coal Society 40(3) 579-587

Wang G Z, Sun G Z 2015.

Experimental research on

influence of porosity on tectonic coal gas

permeability.

Safety in Coal Mines 45(7) 1-4

Wei J P, Chen Y C, Wen Z H 2008.

Study of gas

desorption laws of tectonically coal. Safety in

Coal Mines 39(8) 1-3

Xie Z H, Chen S J 2007.

Effect of moisture and

temperature to CH

4

adsorption of coal. Journal of

University of Science and Technology Beijing 29(2)

42-44

Experimental Study on Desorption Characteristics of Methane in the Soft and Hard Layer Coal of Stratified Structure in the Northwest of

Guizhou, China

313