Low-cycle and High-cycle Fatigue Properties of Austenitic

Stainless Steel at Room and Liquid Nitrogen Temperature

F P Yang*

School of Naval Architecture, Ocean and Civil Engineering, Shanghai Jiao Tong

University, Shanghai 200240, PR China

Corresponding author and e-mail: F P Yang, yangfp@sjtu.edu.cn

Abstract. A kind of strain hardening austenitic stainless steel widely used in cryogenic

pressure vessels was adopted. A series of systematic experiments were performed and the

results were presented concerning the monotonic tension and fatigue mechanics properties of

stainless steel at room and liquid nitrogen temperature (-196°C ). The fatigue life of low cycle,

and high cycle, and the monotonic stress-strain curve were tested and discussed. The results

were compared and found obviously different at room temperature and ultra-low temperature.

The strength and fatigue life of the stainless steel were improved, while the ductility and

plasticity decreased visibly at ultra-low temperature. The curve of the maximum stress S

max

versus the cycle number to failure N

f

at -196°C was obtained and contributed to safety design

of the cryogenic vessels.

1. Introduction

The design concept that safety and economy are equally important for pressure vessels has become

the development trend of pressure vessels design method. Along with the development of low-

temperature technology, austenitic stainless steel is an ideal material for the cryogenic vessels and

has more and more wide applications, which has with excellent toughness and plasticity [1-2].

However, low yield strength of the austenitic stainless steel restrains its development and application,

material and recourse waste [3]. Cold working hardening austenitic stainless steel is one of the most

useful stainless steels. It has the characteristic advantages of high strength at room and intermediate

temperatures [4], and combined ductility and toughness, high corrosion resistance and useful weld

ability [5], short term loading capacity over re-crystallizing temperature [6-7]. The mechanics

property of the strain hardening austenitic stainless steel shows strong dependency of temperature

environment. The yield strength and tensile strength of the stainless steel increase with the decrease

of the temperature [8-10]. The effects of some low temperatures from -60°C ~150°C were discussed

[11-13]. Sometimes, strain hardening austenitic stainless steels were used for some cryogenic vessels

at ultra-low temperature, such as liquid nitrogen (-196°C ) and Liquid hydrogen (-253°C )

environment. It is very important for nuclear engineering and some pressure vessel fields to study

and understand the mechanics property of the cold working hardening austenitic stainless steel at

ultra-low temperature.

Yang, F.

Low-cycle and High-cycle Fatigue Properties of Austenitic Stainless Steel at Room and Liquid Nitrogen Temperature.

In Proceedings of the International Workshop on Materials, Chemistr y and Engineering (IWMCE 2018), pages 31-37

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

31

In the present study, a kind of strain hardening austenitic stainless steel widely used in ultra-

cryogenic pressure vessels was used. A series of systematic experiments were performed concerning

the monotonic tension mechanics and fatigue properties. The monotonic stress-strain curve and the

fatigue life of low cycle, and high cycle were compared and discussed at room and liquid nitrogen

temperature (-196°C ).

2. Materials and experimental procedure

2.1. Test material and specimens

In order to compare the mechanics property of strain hardening austenitic stainless steel at room and

liquid nitrogen temperature (-196°C ), Stainless steel X5CrNi18-10 was chosen for the experiments

due to its wide range of the ultra-cryogenic vessel applications. Its chemical composition is given in

Table 1. The mechanical properties are summarized as follows: yield strength Rp

0.2

=305MPa, tensile

strength R

m

=781MPa, elongation A

k

=453MPa. The strengthened

materials from the actual cryogenic vessels were chosen for all the specimens and experiments in this

paper.

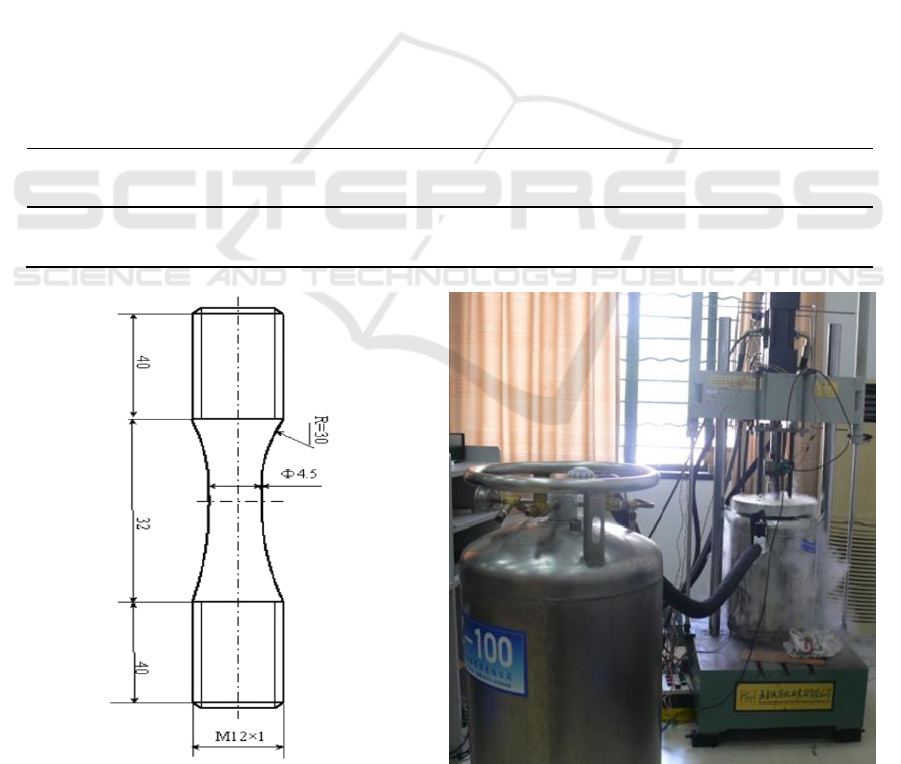

According to the standards of ASTM E466 [14] and ASTM E606 [15], specimens with circular

cross section were used and the geometric configuration of the specimen employed was shown in

Figure 1. The diameter D and the length L of the gage part are equal to 4.5mm and 12mm

respectively.

Table 1. Chemical composition of X5CRNI18-10.

Components

C

Si

Mn

S

P

Cr

Ni

N

(wt.%)

0.048

0.61

0.93

0.002

0.023

18.22

8.05

0.041

Figure 1. Details of the specimen geometry.

Figure 2. Specimen installed in fatigue

machine.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

32

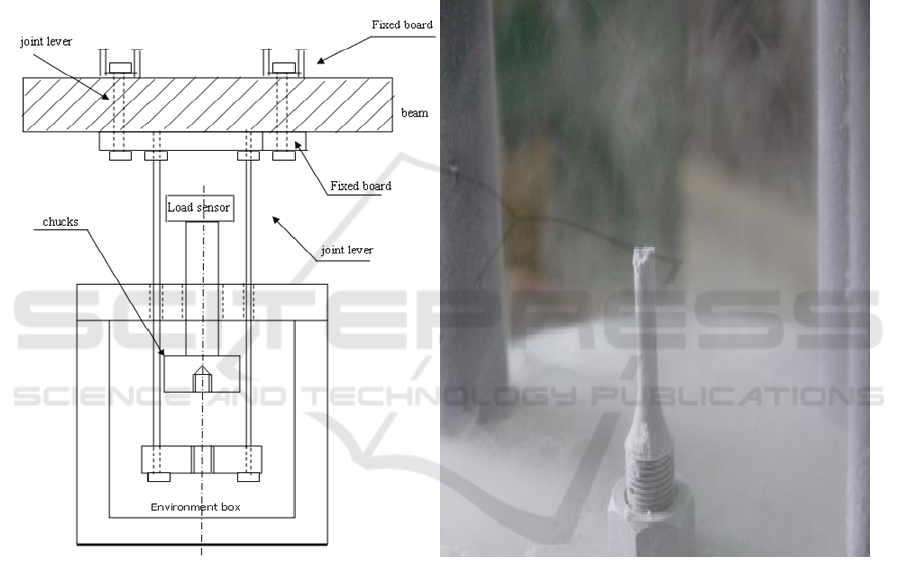

2.2. Experiment Equipment

SDS20 fatigue test system made in China was selected as shown in Figure 2. The maximum axial

static and dynamic output load: ±20kN. Dynamic frequency range: 0.001Hz-100Hz. In this research,

the specimen is required to test under fatigue loading in liquid nitrogen temperature environment,

namely about -196°C ultra-low temperature. However, the corresponding device is seldom found to

satisfy the condition. A set of new equipment has been designed and produced to achieve the

environmental requirement. The sketch of the equipment is shown in Figure 3, and the assembled

experimental device is shown in Figure 2. During the whole test, the liquid nitrogen can

automatically be put into the environmental chamber when the liquid nitrogen is not enough and be

stopped when the chamber is full. The specimen is sure to be in the liquid nitrogen all the time.

Figure 4 shows the broken specimen under fatigue loading.

Figure 3. The ultra-low temperature

environment equipment.

Figure 4. The broken specimen (some parts

removed).

3. Results and discussion

3.1. Tensile tests

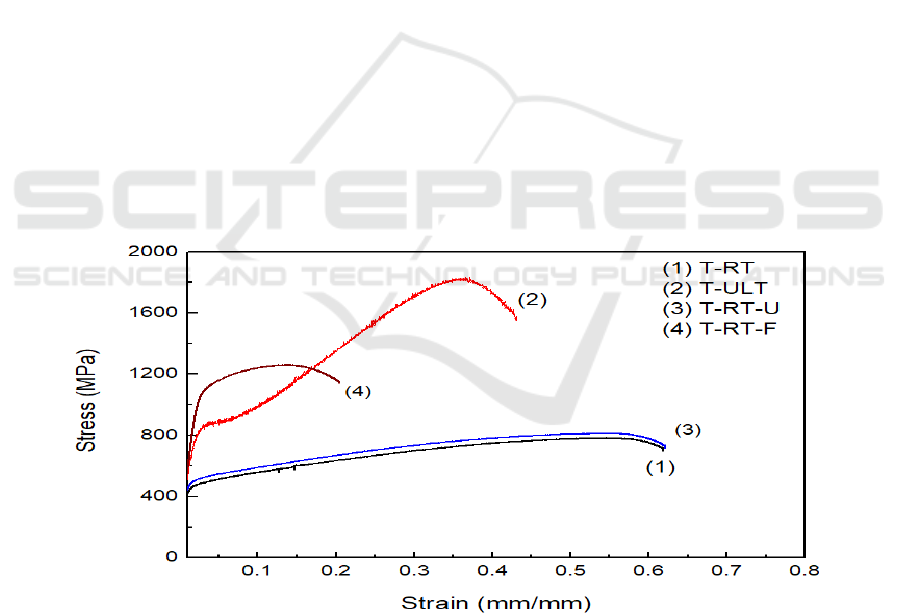

To obtain and compare the monotonic tensile mechanics property of the strain hardening austenitic

stainless steel at room and liquid nitrogen temperature, a series of experiments have been performed

and researched as follows.

T-RT: the monotonic tensile test at room temperature.

T-ULT: the monotonic tensile test at liquid nitrogen temperature.

T-RT-U: the monotonic tensile test at room temperature after the specimen has been in liquid

nitrogen environment for 5 hours.

Low-cycle and High-cycle Fatigue Properties of Austenitic Stainless Steel at Room and Liquid Nitrogen Temperature

33

T-RT-F: the monotonic tensile test at room temperature after the specimen has been under fatigue

loading in liquid nitrogen environment for 300,000 cycles. The maximum stress is 500MPa, which is

lower than the yield stress at 196 °C .

Figure 5 shows the monotonic stress-strain curves under different condition and Table 2 gives the

detail test results. For the case of T-RT, it shows a common tensile curve of strain hardening

austenitic stainless steel at room temperature. The strengthened yield stress is 453.2MPa and the

elongation is 61.87%. When the specimen is in the liquid nitrogen, the stress-strain curve of the test

T-ULT appears obvious difference. The yield stress is up to 863.1MPa and improves 90.4%.

However, the elongation is reduced to 43.18%. It shows that the strength of the stainless steel

increases and the elongation decreases under low temperature, which is corresponding to the result of

[6].

T-RT-U shows the monotonic tensile curve at room temperature after the specimen has been in

liquid nitrogen environment for 5 hours. The obtained stress strain curve is very similar with the case

of T-RT. The mechanics parameters are almost the same: The yield stress is 477.5MPa and the

elongation is 61.93 %. It shows that the mechanics property of stainless steel alters obviously at ultra-

low temperature. However, once the specimen leaves from the liquid nitrogen environment, the

property will turn to similar with that at room temperature.

T-RT-F shows the monotonic tensile test at room temperature after the specimen has been under

fatigue loading in liquid nitrogen environment for 300,000 cycles. The maximum stress is 500MPa,

which is lower than the yield stress at 196°C . The curve shows that the strengthen effect is further

improved and the yield stress is up to 1132MPa and the elongation is also reduced to only 20.43%.

From the four stress strain curves under different conditions, the conclusion can be guessed that

the lower temperature will decrease the ductility and plasticity of the stainless steel and improve the

strength of the material. In addition, the effect of the temperature is also dependent on the effect time

and the environment at the time of loading.

Figure 5. Stress-strain curves under tension and compression loading.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

34

Table 2. Mechanics properties of four tensile tests.

No.

Spec

Rp0.2(MPa)

Rm(MPa)

A(%)

Description

1

T-RT

453.2

781.3

61.87

Tensile test at room temp.

2

T-ULT

863.1

1810

43.18

Tensile test at -196 °C

3

T-RT-U

477.5

808.4

61.93

Tensile test at room temp. after 5h

in liquid nitrogen

4

T-RT-F

1132

1262

20.43

Tensile test at room temp. after

300,000 cycles in liquid nitrogen

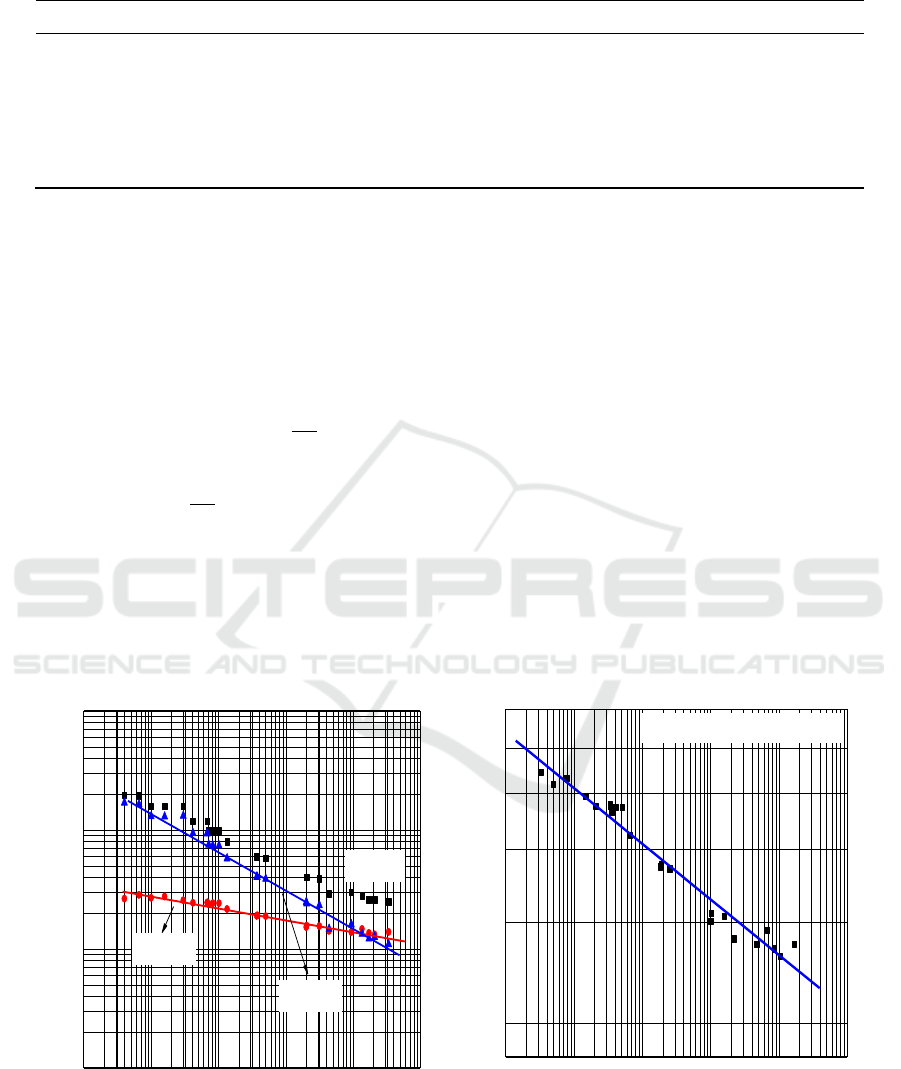

3.2. Fatigue Tests at room temperature

At room temperature, the austenitic stainless steel shows good plasticity and ductility. When the

structure is under fatigue loading, the relationships of the strain ε vs. fatigue cycle number N

f

and

stress S vs. N

f

are important for evaluating the fatigue life of the structure made of the material. In

order to obtain the low-cycle fatigue life curve, the specimen geometry as shown in Figure 1. was

utilized. All the tests were under strain control at stress ratio R=-1 and total 21 specimens were

selected. The fatigue strain-life curve is presented in Figure 6., and the fitting formula is as follows:

bc

f

e f p f f

/ 2 2 ; / 2 2NN

E

(1)

b c 0.0959 0.331

f

t f f f f f

/ 2 2 2 0.0043 2 0.068 2

N N N N

E

(2)

Where the variables are: is true stress range;

-

is the total strain range,

is true elastic strain range,

is true plastic strain range,

is the number

of cycles to failure; and the constant

is fatigue strength exponent,

fatigue ductility exponent,

fatigue strength coefficient,

fatigue ductility coefficient,

10

1

10

2

10

3

10

4

10

5

10

6

10

-4

10

-3

10

-2

10

-1

t

vs. N

f

p

vs. N

f

e

vs. N

f

2N

f

10

1

10

2

10

3

10

4

10

5

10

6

400

600

800

1000

1200

1400

logS

max

=3.202-0.0963logN

f

S

max

N

f

Figure 6. The curve of vs. N

f

for low cycle

fatigue.

Figure 7. The curve of S

max

vs. N

f

for low cycle

fatigue.

Low-cycle and High-cycle Fatigue Properties of Austenitic Stainless Steel at Room and Liquid Nitrogen Temperature

35

In order to study the relationship of stress and the number of cycles to failure, the fatigue stress-

life curve is obtained and presented in Figure 7. The fitting formula of the maximum stress S

max

vs.

fatigue life N

f

is as follows:

max f

log 3.202 0.0963logSN

(3)

Where S

max

=F/A

0

is the maximum engineering stress, the ratio of the application load F to the

original cross sectional area A

0

.

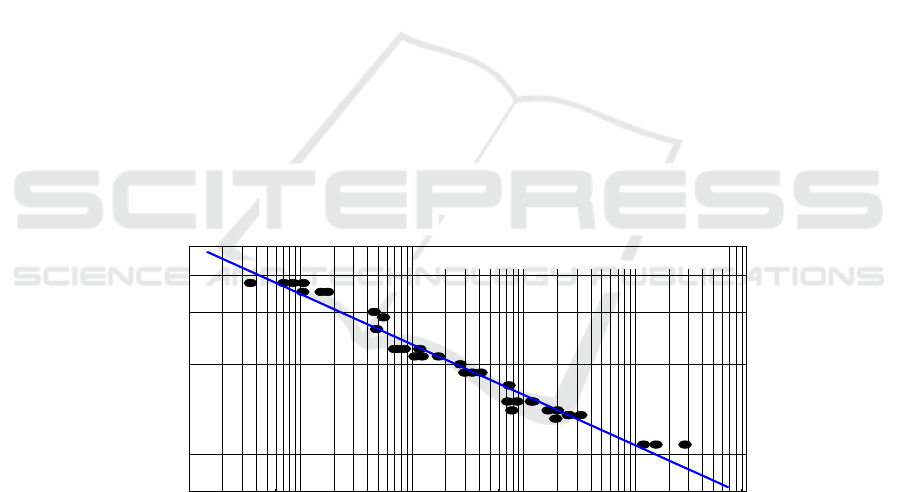

3.3. Fatigue Tests at -196°C

The fatigue life tests were also performed under load control at stress ratio R=-1 in the liquid nitrogen

environment. Ten groups of stress levels and total 36 specimens were selected. For each stress level,

three to four specimens were chosen to obtain the fatigue life. All the fatigue life data of the

specimens and the relationship curve of the maximum stress S

max

vs. the number of cycles to failure

N

f

is presented in Figure 8. The fitting formula is as follows:

max f

log 3.647 0.169logSN

(4)

From the curve, it can be seen that the fatigue life is greatly improved in the liquid nitrogen

environment. When the maximum stress S

max

is 600MPa, the fatigue life is only 10,000 cycles at

room temperature, but 87,500 cycles at liquid nitrogen temperature. Due to the effect of the ultra-low

temperature, the tensile mechanics property is increased. Correspondingly, the fatigue life limits and

fatigue failure resistance are improved. However, once the austenitic stainless steel leaves the liquid

nitrogen environment, the tensile property and fatigue life will become more complex and difficult to

predict as the test cases of T-RT-U and T-RT-F. A more detailed study on the alternate influence of

temperature will be conducted in next paper.

10

2

10

3

10

4

10

5

10

6

10

7

400

800

1200

1600

2000

logS

max

=3.647-0.169logN

f

S

max

N

f

Figure 8. The curve of S

max

vs. N

f

in the liquid nitrogen environment.

4. Conclusions

In the present paper, a kind of strain hardening austenitic stainless steel widely used in ultra-

cryogenic pressure vessels was used. A series of systematic experiments were performed and the

results were presented concerning the monotonic tension mechanics and fatigue properties of

stainless steel at room and liquid nitrogen temperature (-196°C ). Some conclusions are shown:

(1)The strain hardening austenitic stainless steel has good plasticity and ductility at room

temperature. The ultra-low temperature reduces the elongation obviously and improves the

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

36

mechanics strength. However, it is guessed that the effect of the temperature is also dependent on the

effect time and the environment at the time of loading.

(2)The stress-life curve was obtained at -196 °C and compared with that at room temperature.

The fatigue life was greatly improved in the liquid nitrogen environment.

Acknowledgements

The financial supports from the National Natural Science Foundation of China (Grant No. 11102107

and No. 11172165) are gratefully acknowledged.

References

[1] Müller-Bollenhagen C, Zimmermann M and Christ H J 2010 Very high cycle fatigue

behaviour of austenitic stainless steel and the effect of strain-induced martensite Int. J.

Fatigue 32 936-42

[2] Simmons J W 1997 Strain hardening and plastic flow properties of nitrogen-alloyed Fe-17Cr-

(810) Mn-5Ni austenitic stainless steels Acta Materialia 45 2467-75

[3] Zhang F, Harsch D, Manopulo N, Gorji M and Hora P 2018 A comprehensive investigation on

temperature dependent plastic deformation behavior of one austenitic stainless steel J.

Maters Proc. Tech. 255 55-65

[4] Xie X, Ning D and Sun J 2016 Strain-controlled fatigue behavior of cold-drawn type 316

austenitic stainless steel at room temperature Maters Characterization 120 195-202

[5] Fan S, Jia L, Lyu X, Sun W, Chen M and Zheng J 2017 Experimental investigation of

austenitic stainless steel material at elevated temperatures Construction and Building

Maters 155 267-85

[6] Angella G 2012 Strain hardening analysis of an austenitic stainless steel at high temperatures

based on the one-parameter model Mater. Sci. Enging. A 532 381-91

[7] Ceschini L and Minak G 2008 Fatigue behaviour of low temperature carburised AISI 316L

austenitic stainless steel Surface & Coating Technology 202 1778-84

[8] Byun T S, Hashimoto N and Farrell K 2004 Temperature dependence of strain harening and

plastic instability behaviors in austenitic stainless steels Acta Materialia 52 3889-99

[9] Li Y, Xu H, Zhu F and Wang L 2014 Low temperature anodic nitriding of AISI 304 austenitic

stainless steel Maters Letters 128 231-34

[10] Borgioli F, Galvanetto E and Bacci T 2016 Low temperature nitriding of AISI 300 and 200

series austenitic stainless steels Vacuum 127 51-60

[11] Kim J W and Byun T S 2010 Analysis of tensile deformation and failure in austenitic stainless

steels: Part I-Temperature dependence J. Nuclear Maters 396 1-9.

[12] Hahnenberger F, Smaga M and Eifler D 2011 Fatigue behavior and phase transformation in

austenitic steels in the temperature range -60°C °C Procedia Engng 10 625-30

[13] Kain V, Chandra K, Adhe K N and De P K 2004 Effect of cold work on low-temperature

sensitization behaviour of austenitic stainless steels J. Nuclear Maters 334 115-32

[14] ASTM E466 2002 Sandard practice for condition force controlled constant amplitude axial

fatigue tests of metallic materials

[15] ASTM E606 1998 Standard practice for strain-controlled fatigue testing

Low-cycle and High-cycle Fatigue Properties of Austenitic Stainless Steel at Room and Liquid Nitrogen Temperature

37