High-temperature Creep Tests and Analyses for T23 and T24

Steels

J P Pan

1, *

S H Tu

1

, X W Zhu

1

, L J Tan

2

and B Hu

3

1

Jiaxing Special Equipment Inspection Institute, Jiaxing 314051, China

2

Shanghai Jiao Tong University, Shanghai 200240, China

3

China Special Equipment Inspection and Research Institute, Beijing 100029, China

Corresponding author and e-mail: J P Pan, jxlpjp@foxmail.com.

Abstract. T23 and T24 heat-resistant steels are ideal metal materials for high-temperature

and high-pressure boilers of ultra-super critical (USC) power plants. In the present work, the

creep activation energy of T23 and T24 steels was studied based on the relationship between

creep rate and temperature under different stresses. Long-time creep tests at high

temperatures were carried out for T23 and T24 steels. Manson-Haferd model was adopted to

predict the creep life of the two steels, the results of which demonstrate that the data from the

creep tests were in good accordance with the data from Manson-Haferd model prediction.

Manson-Haferd model is useful in the high-temperature creep study for the T23 and T24

steels.

1. Introduction

Ultra-super critical (USC) power plants have been developing rapidly under urgent demands for

clean energy and global environment protection. Construction of USC power plants requires

materials with excellent high-temperature creep strength and resistance to hot corrosion [1].

Generally, creep rupture lives of 100,000 hours under a stress of 100 MPa at temperatures of 650°C

or above are expected [2]. T/P23 and T/P24 steels are relatively new steel grades that allow welding

without post weld heat treatment [3]. These steels are preferable materials for fabricating large water

wall panel used in boilers. Since safe and economical operations of power plants are extremely

important, life prediction becomes a major concern for the steels serviced in boilers [4, 5]. In this

study, the creep activation energy of T23 and T24 steels was investigated by analyzing the

relationship between creep rate and temperature under different stresses. In addition, long-time high-

temperature creep tests were performed and Manson-Haferd (M-H) model was utilized to predict the

creep life of the two steels.

2. Experimental

2.1. Materials

The T23 and T24 steels sampled from new boilers of a power station were studied. The chemical

compositions of the two steels were determined using an Optical Emission Spectrometer (ARL 4460,

Thermo Scientific), and the results are shown in Table 1.

52

Pan, J., Tu, S., Zhu, X., Tan, L. and Hu, B.

High-Temperature Creep Tests and Analyses for T23 and T24 Steels.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 52-55

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Table 1. Chemical compositions of T23 and T24 steels (at.%).

Steel

C

Si

Mn

P

S

Cr

Mo

Nb

V

N

W

Ti

T23

0.054

0.349

0.336

0.011

0.003

2.33

0.152

0.057

0.210

0.011

1.55

/

T24

0.079

0.293

0.504

0.010

0.003

2.51

0.959

/

0.219

0.006

/

0.068

2.2. Creep tests

Tensile creep tests at different temperatures were conducted in the open air using an electronic high

temperature creep & rupture testing machine (GWT2105, MTS) with constant loads to investigate the

creep properties of the two steels. Standard cylindrical samples according to DIN50125 B 4×20 were

used.

3. Results and discussion

3.1. Creep activation energy

Creep activation energy is an important parameter for studying the high-temperature creep behavior

of steels [6]. Arrhenius equation is often used to calculate the creep activation energy. For most steels,

Arrhenius equation can be expressed as:

(1)

Where

is the minimum creep rate; A is a material-dependent constant; n is the stress exponent;

σ is the applied stress (MPa); Q is the creep activation energy (kJ/mol); R is the gas constant; T is the

absolute temperature (K).

When the stress keeps constant, the creep activation energy can be calculated by the following

equation:

(2)

The

of T23 and T24 steels has been determined through creep tests at varied temperatures and

stresses, based on which the creep activation energy of T23 and T24 steels can be calculated,

respectively. The results are listed in Tables 2. and Tables 3.

Table 2. Creep activation energy values of T23 steel at different temperatures and stresses.

T (°C )

σ (MPa)

180

160

140

120

80

60

550-600

795.3

764.1

659.4

601.0

--

--

600-650

--

718.2

675.3

588.1

527.4

--

650-700

--

--

--

606.8

547.5

462.3

Table 3. Creep activation energy values of T24 steel at different temperatures and stresses.

T (°C )

σ (MPa)

180

160

140

120

80

60

550-600

810.4

788.5

671.3

611.6

--

--

600-650

--

730.4

692.0

600.9

531.0

--

650-700

--

--

--

615.7

555.2

463.9

High-Temperature Creep Tests and Analyses for T23 and T24 Steels

53

It is evident that for both of the steels, the creep activation energy increases with the increase of

temperature under the same stress. At the same temperature, the creep activation energy decreases

with reduced stress. Moreover, the high-temperature creep performance of the T24 steel is better than

the T23 steel, as reflected by the fact that the creep activation energy of the T24 steel is higher than

that of the T23 steel at the same temperatures and stresses.

3.2. Manson-Haferd model

As a popular model in life prediction of heat-resistant steels, the Manson-Haferd (M-H) model was

adopted to predict the creep rupture life of T23 and T24 steels. This model can be described by the

following equation:

(3)

Where σ is the applied stress (MPa); lgt

a

and T

a

are two characteristic parameters of the M-H

model. In this model, the lgt

r

is linear with the T when the σ is fixed. It is crucial to determine the

optimal values of lgt

r

and T for creep rupture life prediction. In this study, the lgt

r

and T were

calculated according to the point whose distance from the isostress lines is minimal. The distance of

the optimal point from the isostress lines can be calculated according to the following equation:

(4)

Where d is the distance between a point and the isostress lines; n equals 8 herein. a

i

, b

i

and c

i

are

the coefficients of the isostress lines; (x, y) is the coordinate values of the optimal point. The x and y

values were limited within a certain range based on the characteristic properties of the T23 and T24

steels. Eq. (3) can be further expressed as:

(5)

Where a

0

, a

1

, a

2

and a

3

are all constants. MATLAB was used for calculation and fitting, and the

resultant optimal parameters are listed in Table 4.

Table 4. Manson-Haferd model parameters for T23 and T24 steels.

a

0

a

1

a

2

a

3

lgt

a

T

a

T23

0.2401

-0.4706

0.2749

-0.05937

14.52

733.89

T24

0.2436

-0.4821

0.2791

-0.05886

14.67

765.33

3.3. Creep curves

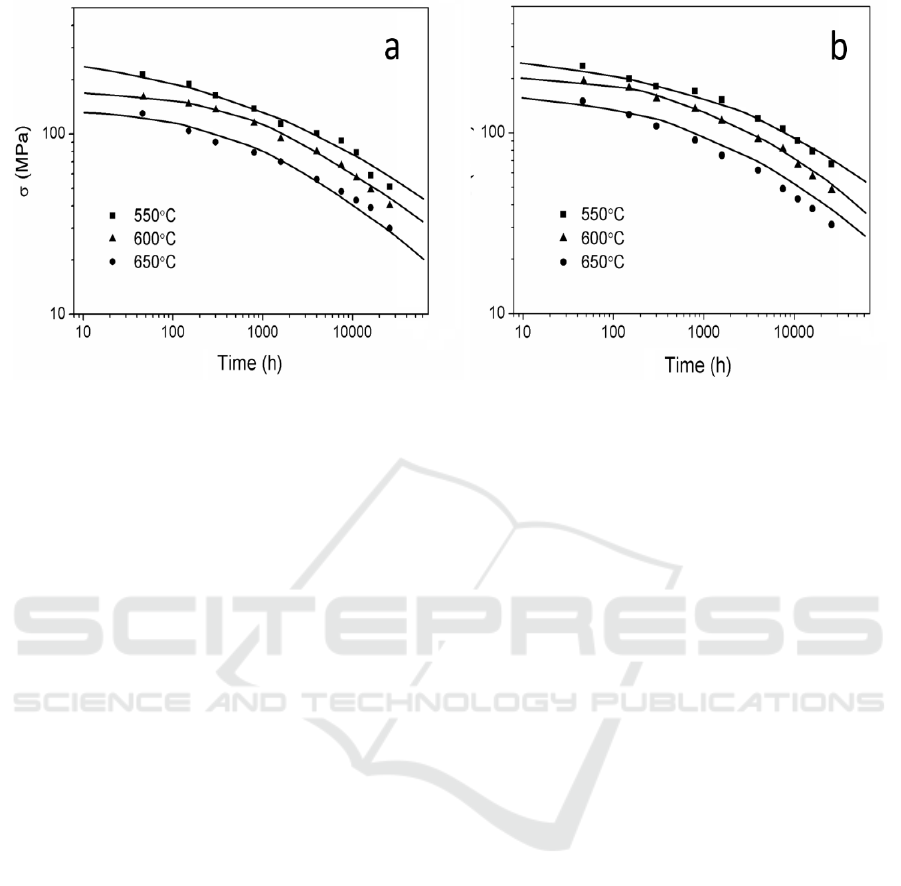

The experimental data of stress versus creep time as well as the M-H model predictions for the T23

and T24 steels at different temperatures over a long period are shown in Figure 1. It is clear that the

M-H model prediction curves agree with the experimental data fairly well for both T23 and T24

steels at the selected temperatures, demonstrating the high prediction accuracy and applicability of

the M-H model for the T23 and T24 steels. The T23 steel has similar creep behaviour to the T24 steel

at 650°C , but has a little lower creep performance than the T24 steel at 550 and 600°C . Both T23 and

T24 steels maintained ca. 30 MPa stress at the temperature of 650°C after a creep time of over 20,000

hours, indicating that the steels may have long high-temperature creep life and can meet the demands

of high-temperature and high-pressure boilers in USC power plants.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

54

Figure 1. Changes of stress with creep time (scatter) as well as M-H model predictions (curve) for (a)

T23 steel and (b) T24 steel at different temperatures.

4. Conclusions

To sum up, the creep activation energy of T23 and T24 steels has been evaluated and their high-

temperature creep performance was examined by long-time creep tests at selected temperatures and

Manson-Haferd modeling. The T24 steel has higher creep activation energy than the T23 steel. The

data from long-time creep tests at high temperatures agreed well with the data from Manson-Haferd

model prediction. It was also found that both of the steels have long high-temperature creep life and

can serve well for high-pressure boilers in USC power plants.

Acknowledgment

This work is financially supported by the Quality and Technology Supervision of Zhejiang Province

(Grant No. 20170251), the AQSIQ Science and Technology Project (Grant No. 2017QK037) and the

National Key Research and Development Program of China (Grant No. 2017YFF0210702).

References

[1] Aghajani A, Somsen Ch and Eggeler G 2009 On the effect of long-term creep on the

microstructure of a 12% chromium tempered martensite ferritic steel Acta Mater. 57 5093-

5106

[2] Rojasa D, Garciab J, Prata O, Carrascoc C, Sauthoffa G and Kaysser-Pyzalla A R 2010 Design

and characterization of microstructure evolution during creep of 12% Cr heat resistant

steels Mater. Sci. Eng. A 527 3864-3876

[3] Bendick W, Gabrelb J, Hahnc B and Vandenberghe B 2007 New low alloy heat resistant

ferritic steels T/P23 and T/P24 for power plant application Int. J. Pres. Ves. Pip. 84 13-20

[4] Vallant J C, Vandenberghe B, Hahn B, Heuser H and Jochum C 2008 T/P23, 24, 911 and 92:

New grades for advanced coal-fired power plants-properties and experience Int. J. Pres.

Ves. Pip. 85 38-46

[5] Cerjak H, Hofer P and Schaffernak B 1999 The influence of microstructural aspects on the

service behaviour of advanced power plant steels ISIJ Int. 39 874-888

[6] Takeuchi SS, and Argon A 1976 Steady-state creep of single-phase crystalline matter at high

temperature J. Mater. Sci. 11 1542-1566

High-Temperature Creep Tests and Analyses for T23 and T24 Steels

55