Frost-resistance Durability of High Performance Concrete

Prepared with Repeatedly Recycled Concrete Aggregates

J Y Wu

1, 2

, Y S Zhang

1, *

, D Wei

2

, J Geng

2

and P H Zhu

2

1

Jiangsu Key Laboratory of Construction Materials, School of Material Science and

Engineering, Southeast University, Nanjing 211189, China

2

Department of Civil Engineering, Changzhou University, Changzhou 213164, China

Corresponding author and e-mail: Y S Zhang, zhangys279@163.com

Abstract. In this paper, frost-resistance durability of high performance concrete (HPC)

prepared with repeatedly recyc led concrete aggregates was experimentally investigated by

measuring mass, relative dynamic modulus of elasticity and compressive strength before and

after freezing and thawing cycles. Three types of HPC were made with the 2

nd

generation

recycled concrete aggregate (RCA) and natural aggregate concrete (NAC) were also casted as

control concrete, with target value of comp ressive strength 40 MPa. The results demonstrate

that apparent density of the 2

nd

generation RCA was above 2350 kg/m

3

and water absorption

was 8.7%. Scaling of the 2

nd

generation RAC (RRAC) was observed after 150 freezing and

thawing cycles. The loss ratio of co mpressive strength of RRA C was below 20% when

subjected to 300 freezing and thawing cycles. Th is study confirms the feasibility of preparing

HPC with repeatedly recycled concrete aggregates based on frost durability and encourages

facilitating the application of construction and demolition waste.

1. Introduction

Recycled concrete aggregate (RCA) has received much attention in recent years due to its

comparable properties to natural aggregate (NA), which allows the replacement of NA with RCA in

concrete production and provides a sustainable development way for the concrete industry [1-2].

RCA is obtained by crushing the wasted concrete and then washed and classified. Many research

findings about the properties of RCA and its effect on recycled aggregate concrete (RAC) have been

documented [3-5]. It is generally accepted that both mechanical properties and durability of high

performance concrete (HPC) made with RCA can be qualified for structural requirement [6].

However, although the effect of RCA and supplementary cementitious materials on the properties of

RAC has been systematically studied over the past decades [7-8], little attention has been paid to

cyclic utilization of RCA in preparing HPC for structural use.

The present paper investigates the frost-resistance durability of high performance concrete made

with repeatedly recycled concrete aggregate. Three types of RCA from different sources were used to

prepare RAC which were crushed after 28 days curing to get the 2

nd

generation RCA. Then, concrete

made with the 2

nd

generation RCA was prepared, termed RRAC or the 2

nd

generation RAC. Mass and

Wu, J., Zhang, Y., Wei, D., Geng, J. and Zhu, P.

Frost-Resistance Durability of High Performance Concrete Prepared with Repeatedly Recycled Concrete Aggregates.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 261-267

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

261

relative dynamic elasticity modulus of samples were tested every 50 freezing and thawing cycles

while the compressive strength was tested every 100 cycles till the samples are severely damaged.

Findings from this study further confirm the feasibility of preparing HPC with repeatedly recycled

concrete aggregate and promote the application of construction and demolition waste.

2. Materials and Method

2.1. Materials

The cement used in this study was Ordinary Portland cement, P.O.42.5, which is commercially

available in China. The fine aggregate used in this study was natural river sand (NS) with a fineness

modulus of 2.3. Three types of recycled coarse aggregate (RCA) were used to prepare recycled

aggregate concrete (RAC) in this study. The size of RCAs and natural aggregates (NA) is from

4.75mm to 20mm. Two types of RCA were obtained from different recycling plants and marked

RCA1, RCA2, respectively. The other type, RCA3, was obtained from the crushed concrete which

was prepared in the laboratory and cured in standard curing room where the temperature was kept at

20°C and the relative humidity was more than 95%. Physical properties of coarse aggregates can be

seen in Table 1. All these RCAs were identified as Class II according to GB/T 25177-2010 [9]. Three

types of new concrete with a target compressive strength of 40 MPa were prepared with natural sand

and RCA. The new concrete was crushed to produce RCAs after 28 days curing. For convenience,

the newly obtained RCAs could be marked RCA1-2, RCA2-2, RCA3-2, respectively. For instance,

RCA1-2 represents that the RCA was produced by crushing RAC11 made with RCA1.

Table 1. Physical properties of aggregate

Aggregate type

Apparent density

(kg/m

3

)

24h water absorption ratio

(%)

Crush index

(%)

NA

2703

0.2

5.31

RCA1

2610

4.9

10.54

RCA2

2550

5.2

13.69

RCA3

2480

8.2

19.36

2.2. Mix proportion

Four types of concrete mixtures were casted in laboratory, including natural aggregate concrete

(NAC) as control concrete. Recycled aggregate concrete (RAC) was prepared with 100%

replacement level of NA by RCA.

The concrete mixtures formulation was shown in Table 2. Two-stage mixing approach (TSMA)

was used as described by Vivian WY Tam [10]. For convenience, the 2

nd

generation RACs could be

marked RRCA11, RRAC12, RRAC13, respectively. For instance, RRAC13 represents that the RAC

was made with RCA3-2 by crushing the concrete RAC13.

Table 2. Mix proportion of concretes studied in this investigation

Mixture

Cement

Silica fume

Fly ash

Slag

Aggregate

Sand

Water

a

JK-PCA

b

AOS

c

NAC

292

21

76

40

1081

663

150

6

1.3

RRAC11

292

21

76

40

974

647

214

6

1.3

RRAC12

292

21

76

40

1045

688

207

6

1.3

RRAC13

292

21

76

40

929

753

207

6

1.3

a

Free water and additional water are added together.

b

One type of water reducer.

c

One type of air entraining agent.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

262

2.3. Specimens casting and curing

For each concrete mixture, 100mm cubes and 100×100×400mm prisms were cast. The cubes were

used to determine the compressive strength and the prisms were used to measure the weight and

relative dynamic elastic modulus.

All the specimens were cast in steel molds and compacted using a vibrating table. And the

specimens were cured in the standard curing room where the temperature was 20°C and relative

humidity was above 95%.

2.4. Test method

Water absorption ratio, apparent density and crush index of RCA were measured according to

GB50081-2002 [11]. Testing of the freezing and thawing resistance was started at the age of 28 days

according to GB50082-2009 [12]. Three prismatic specimens 100×100 ×400mm for each type were

carried out in the freezing and thawing chamber. Weight and relative dynamic modulus of elasticity

of RAC specimens were measured every 50 cycles; the compressive strength of specimens was tested

every 100 cycles. Loss ratio of compressive strength can be defined in following formula: D

f

=f

cn

/f

c0

.

Where f

co

represents the initial compressive strength and f

cn

means the compressive strength after n

freeze and thaw cycles. It must be pointed out that the loss of compressive strength was considered as

an effective measurement for evaluating the damage degree of RAC exposed to freezing and thawing

environment.

3. Results and discussion

3.1. Physical properties of the 2

nd

generation RCA

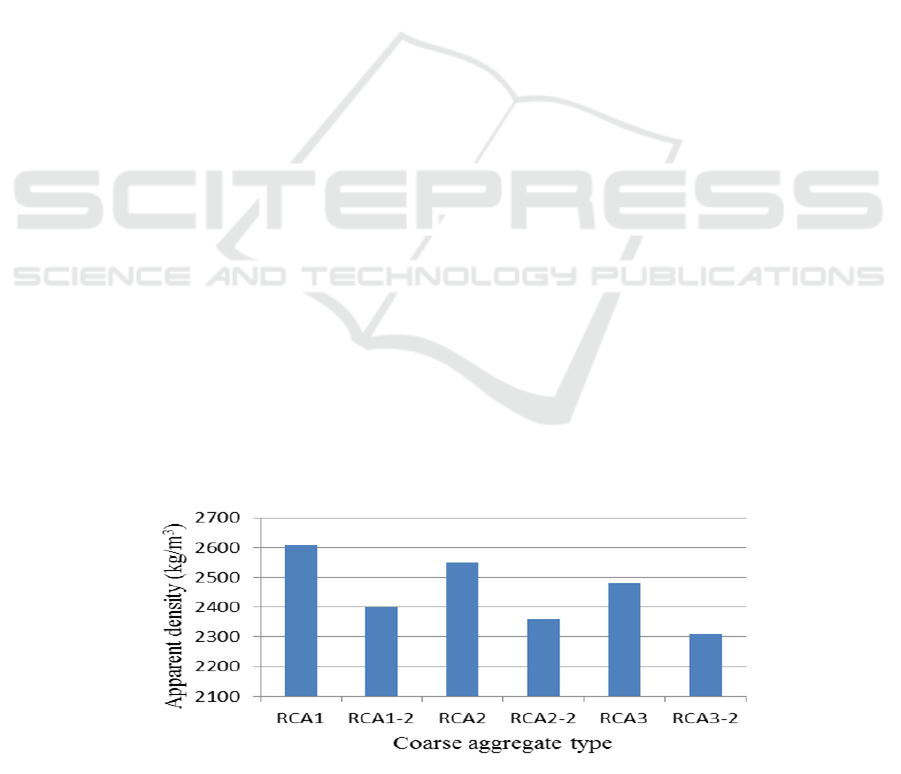

To assess the feasibility of preparing high performance concrete with repeatedly recycled concrete

aggregate, the physical properties of the 2

nd

generation RCA were measured according to Chinese

standard [11]. Figure 1 shows the comparison of apparent density of different types of coarse

aggregate. It can be seen that the apparent density of the 2

nd

generation RCA is smaller than that of

corresponding RCA; for instance, the apparent density of RCA2-2 is only 2400 kg/m

3

, less than that

of RCA2, 2610 kg/m

3

. The average apparent density of RRCA is about 2357 kg/m

3

while that of

RCA is around 2547 kg/m

3

. In addition, the average water absorption ratio of RRCA is around 8.7%

while that of RCA is about 6.1%, and the difference value is approximately 2.6%. However,

according to GB/T 25177-2010

[9], the 2nd generation RCA used in this study can be classified as

type II because the apparent density of them is above 2350 kg/m

3

. The result demonstrates that

RRCA can be qualified as coarse aggregate for structural concrete.

Figure 1.Comparison of apparent density of different types of coarse aggregate

Frost-Resistance Durability of High Performance Concrete Prepared with Repeatedly Recycled Concrete Aggregates

263

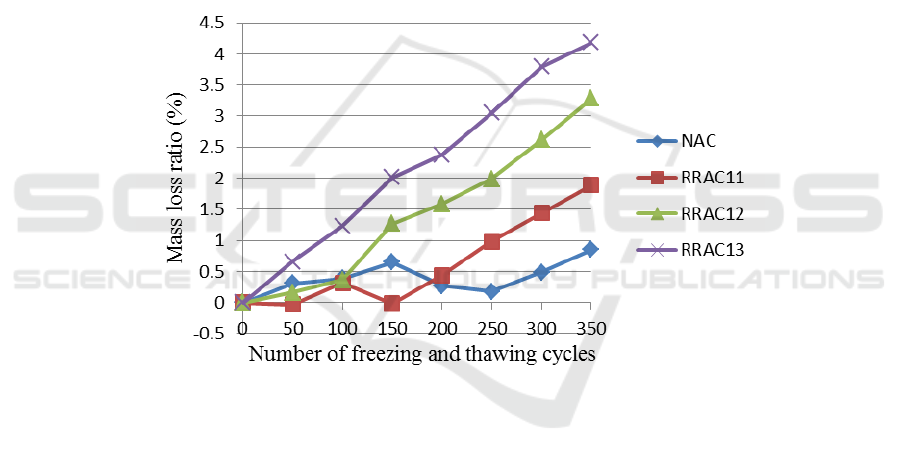

3.2. Mass loss ratio

The mass of samples was carefully measured after removing the water on the surface of sample by

using duster cloth in saturated surface dry; the test was conducted every 50 freeze-thaw cycles. From

figure 2, it can be seen that the mass of sample becomes lighter when the number of freeze-thaw

cycles increases. This is due to the fact that surface scaling of samples was occurred during the

process of freezing and thawing cycle. Scaling was observed on RRAC1 after 150 freezing and

thawing cycles while RRAC2 and RRAC3 were found to be scaling after 150 freezing and thawing

cycles. The mass loss of RRAC3 was the biggest among the four concrete types and the mass loss

ratio was up to 2.57% which is 2 times as much as that of RRAC1. However, the mass loss ratio of

NAC was around 0.5% after 300 freezing and thawing cycles. The results demonstrate that the 2

nd

generation RAC was susceptible to frost damage. The explanation of the results lies in that water

absorption of the 2

nd

generation RCA was much higher than natural aggregate, leading to higher ice

pressure during freezing process; the ice pressure could easily cause damage to concrete surface and

then produce scaling [13].

Figure 2.Mass loss ratio of concrete samples suffered freezing and thawing cycles

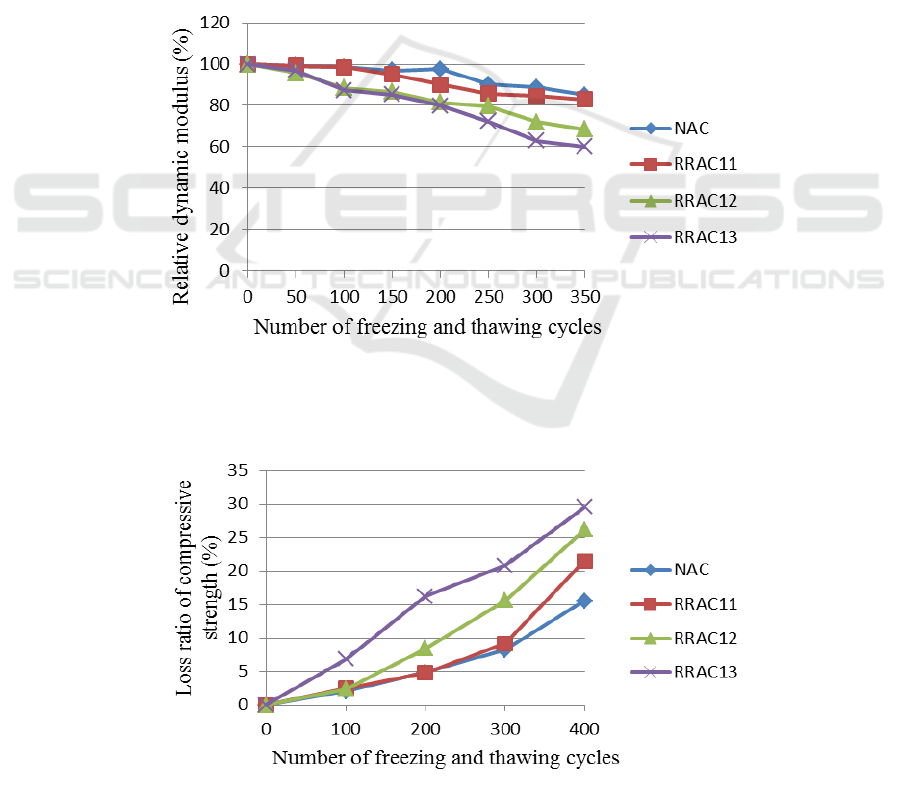

3.3. Relative dynamic modulus of elasticity

In order to investigate the internal damage of samples caused by freezing and thawing cycle, relative

dynamic modulus of elasticity was tested every 50 cycles. Figure 3 illustrates that the relative

dynamic modulus of the 2

nd

generation RAC decreased with freeze-thaw cycles increasing, which is

similar to that of NAC. It is interesting to find that the relative dynamic modulus of elasticity of

RRAC11 is almost the same to that of NAC, which implies that the internal damage of RRAC11 and

NAC samples is nearly identical when suffered freeze and thaw test. However, the relative dynamic

modulus of RRAC12 and RRAC13 decreased faster than that of NAC. Especially for RRAC13, the

relative dynamic modulus was only 60.2% when 350 freeze and thaw cycles are reached, which

signifies that RRAC13 is more easily damaged than the other three concretes. Nevertheless,

according to GB 50082-2009

[12], all three RRACs can subject to 300 freeze-thaw cycles and

performed well in freeze-thaw test, which further confirms the feasibility of using RRCA as coarse

aggregate for structural-grade concrete.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

264

3.4. Loss ratio of compressive strength

The compressive strength of concrete samples was tested before and after freezing-thawing cycles to

evaluate the damage degree of concrete. The initial compressive strength of NAC, RRAC1, RRAC2,

and RRAC3 is 42.5MPa, 41.7MPa, 41.2MPa, 39.3MPa respectively. Figure 4 shows that the

compressive strength of the 2

nd

generation RAC decreased with increasing freeze-thaw cycles [14],

which is similar to that of NAC. Before 300 freeze-thaw cycles are reached, the loss ratio of

compressive strength of RRAC11 is almost the same to that of NAC. However, there is a negligible

difference between RRAC11 and NAC with respect to the loss ratio of compressive strength after

400 freeze and thaw cycles. Generally, the frost durability of the 2

nd

generation RAC is inferior to

that of NAC. This may be attributed to the higher water absorption of RAC. Furthermore, the loss

ratio of compressive strength of the 2

nd

generation RAC exceeds 20%; and it is thought that the

samples were severely damaged [15]. Nevertheless, the loss ratio of compressive strength of all three

RRACs is below 20% when subjected to 300 freeze-thaw cycles, which means the RRACs

performed well in freezing and thawing test.

Figure 3.Relative dynamic modulus of concrete samples suffered freezing and thawing cycles

Figure 4.Loss of compressive strength of samples suffered freezing and thawing cycles

Frost-Resistance Durability of High Performance Concrete Prepared with Repeatedly Recycled Concrete Aggregates

265

4. Conclusions

From the experimental results and discussion above, the main conclusions can be drawn as follows:

On average, apparent density of RRCA is 2357 kg/m3 and water absorption of RRCA is 8.7%.

According to Chinese standard GB/T 25177-2010, it is feasible to use RRCA as coarse aggregate for

structural concrete.

Scaling of the 2nd generation RAC was observed after 150 freezing and thawing cycles. The mass

loss ratio of the 2nd generation RAC is from 1.89% to 4.18% after 350 freezing and thawing cycles.

However, it is within the criterion, that is, 5%.

The relative dynamic modulus of elasticity of RRAC11 is almost the same to that of NAC while

RRAC12 and RRAC13 decreased faster. However, both NAC and RRAC can subject to 300 freeze-

thaw cycles with the relative dynamic modulus of elasticity above 60%, which means that RRACs

are durable in cold weather. Therefore, all three RRACs perform well in freezing and thawing test

regarding to relative dynamic modulus of elasticity.

Compressive strength of the 2nd generation RAC decreases with the number of freeze-thaw

cycles increasing. The loss ratio of compressive strength of RRACs is below 20% when subjected to

300 freezing and thawing cycles. Hence, all three RRACs had a good performance in freezing and

thawing test. The findings in this study confirm the feasibility of using RRCA as coarse aggregate for

structural application.

Acknowledgments

The authors would express great thanks for the financial support from the Natural Science

Foundation of China (Project No.51278073, No.51678081). Jiangsu Wujin Lvhe Building Material

Company and Yangzhou Huisheng Recycling Plant were also appreciated for providing the recycled

concrete aggregates.

References

[1] Xiao J Z, Li W G and Poon C S 2012 Recent studies on mechanical properties of recycled

aggregate concrete in China—A review [J]. Science China Technological Sciences 55(6)

1463-1480

[2] Mcneil K and Kang T H K 2013 Recycled Concrete Aggregates: A Review [J]. International

Journal of Concrete Structures and Materials 7(1) 61-69

[3] Tabsh S W 2009 A S Abdelfatah. Influence of recycled concrete aggregates on strength

properties of concrete [J]. Construction and Building Materials 23 1163–1167

[4] Bogas J A, Brito J DE and Ramos D 2016 Freeze–thaw resistance of concrete produced with

fine recycled concrete aggregates [J]. Journal of Cleaner Production 115 294-306

[5] Kou S C and Poon C S 2012 Enhancing the durability properties of concrete prepared with

coarse recycled aggregate [J]. Construction and Building Materials 35 69-76

[6] Manzi S, Mazzotti C and Bignozzi M C 2013 Short and long-term behavior of structural

concrete with recycled concrete aggregate [J]. Cement and Concrete Composites 37 312-

318

[7] Omary S, Ghorbel E and Wardeh G 2016 Relationships between recycled concrete aggregates

characteristics and recycled aggregates concretes properties [J]. Construction and Building

Materials 108 163-74

[8] Richardson A, Coventry K and Bacon J 2011 Freeze/thaw durability of concrete with recycled

demolition aggregate compared to virgin aggregate concrete [J]. Journal of Cleaner

Production 19 272-277

[9] China building industry press 2010 Recycled Coarse Aggregate for Concrete [S]. GB/T 25177-

2010

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

266

[10] Tam V W Y, Tam C M and Wang Y 2007 Optimization on Proportion for Recycled Aggregate

in Concrete Using Two-stage Mixing Approach [J]. Construction and Building Materials

21(10) 1928-1939

[11] China building industry press. 2002 Standard for test method of mechanical properties on

ordinary concrete [S]. GB/T 50081-2002

[12] China building industry press 2009 Standard for test method of long-term performance and

durability of ordinary concrete [S]. GB/T 50082-2009

[13] Gokce A, Nagataki S, Saeki T, et al. 2011 Identification of frost-susceptible recycled concrete

aggregates for durability of concrete [J]. Construction and Building Materials 25(5) 2426-

31

[14] Jacobsen S 2005 Calculating liquid transport into high-performance concrete during wet

freeze/thaw [J]. Cement and Concrete Research 35(2) 213-219

[15] Andrzej A and Alina K 2002 Influence of recycled aggregates on mechanical properties of

HS/HPC [J]. Cement and Concrete Composites 24 269-279

Frost-Resistance Durability of High Performance Concrete Prepared with Repeatedly Recycled Concrete Aggregates

267