Mechanical Property and Durability Analysis of Crumb

Rubber Modified Concrete

Y B Jiao

1,2

, H C Cai

2

, M S Zhang

2,*

, T Sha

2

, Y Q Feng

2

and H Chen

2

1

Key Laboratory of Urban Security and Disaster Engineering of Ministry of

Education, Beijing University of Technology, Beijing, China

2

College of Transportation, Jilin University, Changchun, China

Corresponding author and e-mail: M S Zhang, zms@jlu.edu.cn

Abstract. With the increasing of waste rubber tires, their disposal leads to great threat to

environment. Crumb rubber produced from waste tires can be used to modify the ordinary

concrete, which can realize the utilization of waste resources. In this study, crumb rubber with

particle size 2-4mm was used to replace the coarse aggregates of ordinary concrete.

Corresponding mechanical and durability properties including compressive strength, splitting

tensile strength, axial compressive strength, elastic modulus, freeze-thaw resistance and

sulfate resistance performances were measured and analyzed. The results reveal that crumb

rubber presents negative effect on mechanical properties and positive effect on durability

performance of concrete.

1. Introduction

In recent years, waste utilization has got wide attentions for sustainable development. Reuse of waste

materials can be conducive to not only environmental protection, but also reducing consumption of

natural resources. Millions of used tires were generated because of the increasing number of vehicles.

The number of end-of-life tires (ELTs) is about 200 million each year in China, which presents an

increasing rate of over 10% [1, 2]. Disposal of these tires has become a serious social problem due to

the difficulty to degrade.

Crumb rubber can be applied to modify concrete, which is an effective way for disposal of waste

tires [3]

.

Si et al. [4] investigated the laboratory performances of self-consolidating concrete modified

by rubber. The results revealed that mechanical properties were reduced because of the addition of

crumb rubber. However, the durability performances were improved. Bisht and Ramana [5]

evaluated the mechanical and durability properties of crumb rubber concrete. It has been observed

that workability, compressive and flexural strength decrease with the increasing of crumb rubber.4%

replacement of fine aggregates for crumb rubber can be used for non-structural elements. Xue et al.

[6] demonstrated the compressive properties of rubber concrete at temperatures of -30 and 20°C. The

results showed that the deformation ability of rubber concrete at -30°C was much better than ordinary

one. Liu et al. [7] investigated the mechanical and durability performances of rubber concrete. The

results revealed that crumb rubber presents negative effects on mechanical properties and positive

effects on durability performance. 20% replacement of fine aggregate and 5% replacement of mixture

present favorable performances.

Jiao, Y., Cai, H., Zhang, M., Sha, T., Feng, Y. and Chen, H.

Mechanical Property and Durability Analysis of Crumb Rubber Modified Concrete.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 291-296

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

291

In this study, crumb rubber with particle size 2-4 mm was used to replace the coarse aggregates in

ordinary concrete. Compressive strength, splitting tensile strength, axial compressive strength and

elastic modulus were used to evaluate the effects of crumb rubber on mechanical performances of

concrete. Freezing-thawing resistance and corrosion resistance were demonstrated to evaluate

corresponding durability performances.

2. Materials and methods

2.1. Materials

Cement used in this study was P. C. 32.5, which is composite Portland cement with compressive

strength 32.5 MPa after 28d standard curing. Its physical properties were measured and listed in

Table 1. Coarse aggregates were limestone, whose properties were listed in Table 2. Fine aggregate

was river sand with finesse modulus of 3.0. The particle size of 2-4 mm for crumb rubber was used

as replacement material, whose apparent density is 1200 kg/m

3

. Crumb rubber was irregularly

polygon, corresponding appearance was shown in Figure 1. Particle size distributions of fine

aggregate and crumb rubber were shown in Figure 2.

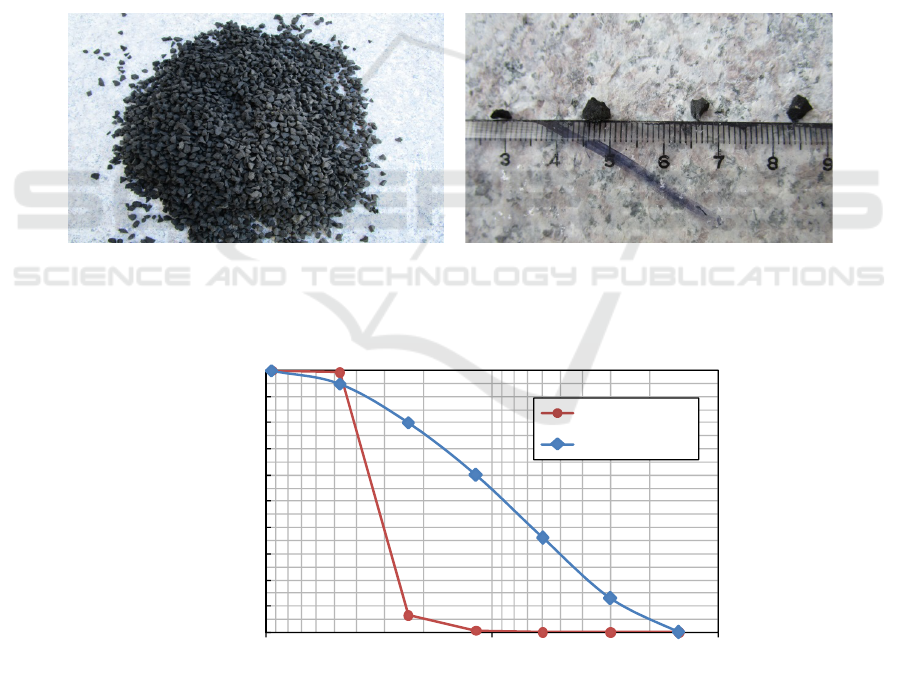

(a) (b)

Figure 1. Crumb rubber (a: appearance, b: particle size).

0

10

20

30

40

50

60

70

80

90

100

0.1110

Passing percentage (%)

Sieve size (mm)

Crumb rubber

Fine aggregate

Figure 2. Particle size distribution of fine aggregate and crumb rubber [7].

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

292

Table 1. Physical properties of cement.

Items Measured values

Technical criterion

[8]

Fluidit

y

(mm) 184 ≥180

Initial settin

g

time (min) 180 ≥45

Final settin

g

time (min) 260 ≤600

Flexural stren

g

th (28d, MPa) 6.7 ≥5.5

Compressive stren

g

th (28d, MPa) 35.9 ≥32.5

Table 2. Physical properties of coarse aggregate.

Items Measured values Technical criterion [8]

Cla

y

content (%) 0.4 ≤1.0

Elon

g

ated particle content (%) 7 ≤15

Specific

g

ravit

y

(

g

/c

m

3

) 2650 ≥2600

Crushin

g

value (%) 8 ≤16

2.2. Mixture Proportion

The mixture proportion for plain concrete (PC) was determined according to specification for mix

proportion design of ordinary concrete (JGJ 55-2011) [9]. Crumb rubber concrete (CRC) was

produced by replacing coarse aggregate in PC by crumb rubber. The replacement principle is to

guarantee an equal volume between crumb rubber and coarse aggregate. The replacement levels

varied from 5% to 20%. The mixture proportions used in this study were listed in Table 3.

Table 3. Mixture proportions for crumb rubber concrete

Rubber

content

(%)

Mix

Wei

g

ht per cubic meters (k

g

)

Water Cement Fine aggregate Coarse aggregate Crumb rubber

0 PC 180 430 593 1197.0 0

5 CRC-1 180 430 593 1135.8 26.6

10 CRC-2 180 430 593 1074.6 53.2

15 CRC-3 180 430 593 1016.1 79.8

20 CRC-4 180 430 593 957.6 106.4

2.3. Characterization methods

Concrete specimens were produced according to JTG E30-2005 [10]. Cube specimens

(150mm×150mm×150mm) were used to evaluate the performances of compressive strength, splitting

tensile strength and durability properties, while prism specimens (150mm×150mm×300mm) were

produced for axial compressive strength and modulus of elasticity. Compressive strength, axial

compressive strength, modulus of elasticity, splitting tensile strength for PC and CRC were measured

after the specimens cured for 28 days according to GB/T 50081-2002 [11]. As for durability

performance including freezing-thawing resistance and sulfate resistance, they were tested after the

specimens cured for 60 days according to GB/T 50082-2009 [12]. Three specimens were used for

each test and corresponding average value was treated as representative one.

Strength loss rate was used to evaluate the freezing-thawing resistance performance of CRC,

which can be calculated by

Mechanical Property and Durability Analysis of Crumb Rubber Modified Concrete

293

100

co cn

c

co

ff

f

f

−

Δ= ×

(1)

where

c

f

Δ is strength loss ratio of concrete after freeze-thaw effects,

co

f

and

cn

f

are compressive

strength before and after 25 times of freeze-thaw cycles.

As for sulfate resistance performance, specimens were firstly immersed into sulfate solution and

then dried at temperature 80°C. Anti-corrosion coefficient of specimens after 15 cycles sulfate

soaking and drying was calculated by

100

cn

f

co

f

K

f

=×

(2)

where

f

K is anti-corrosion coefficient of concrete after sulfate soaking and drying,

co

f

and

cn

f

are

compressive strength before and after 15 times of sulfate attack.

3. Results and discussions

3.1. Mechanical properties

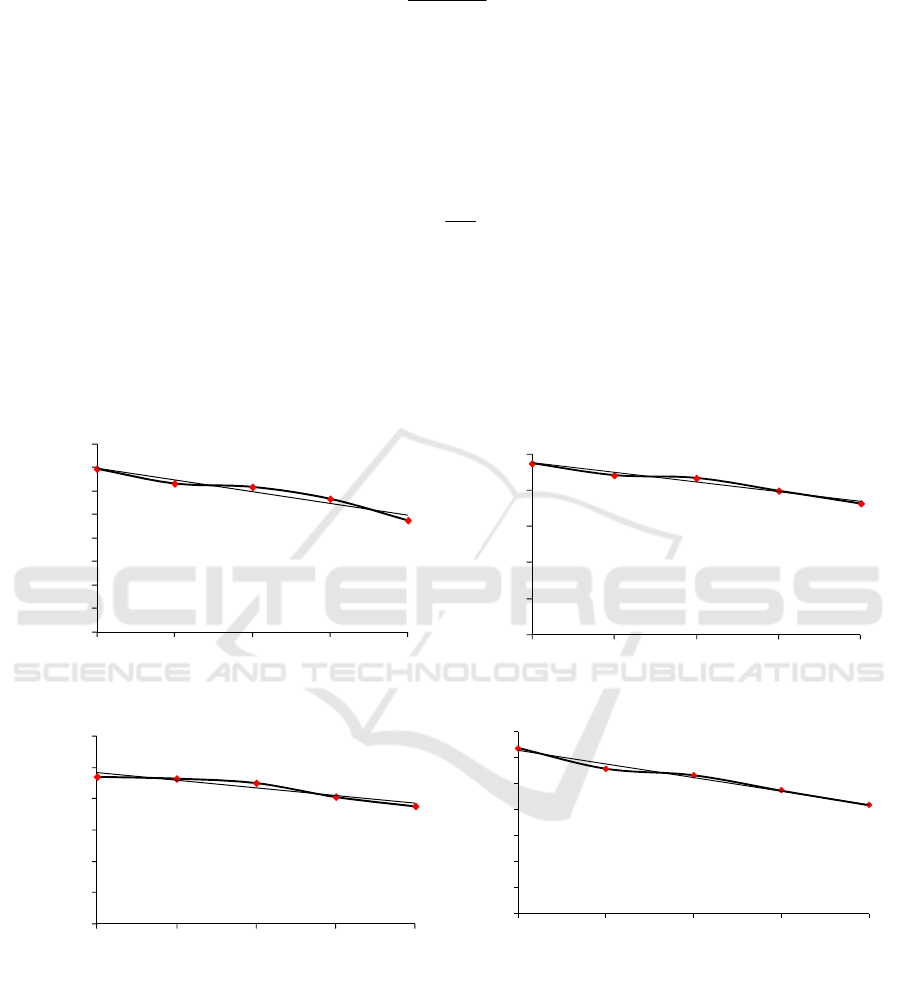

y = -0.5044x + 34.93

R² = 0.9439

0

5

10

15

20

25

30

35

40

0 5 10 15 20

Cubic compressive strength

(MPa)

Rubber content (%)

y = -0.2642x + 23.776

R² = 0.9684

0

5

10

15

20

25

0 5 10 15 20

Axial compressive strength

(MPa)

Rubber content (%)

(a) (b)

y = -0.0246x + 2.412

R² = 0.9174

0

0.5

1

1.5

2

2.5

3

0 5 10 15 20

Splitting tensile strength

(MPa)

Rubber content (%)

y = -0.5188x + 31.318

R² = 0.9818

0

5

10

15

20

25

30

35

0 5 10 15 20

Modulus of elasticity (GPa)

Rubber content (%)

(c) (d)

Figure 3. Relationships between mechanical properties and rubber content (a: cubic compressive

strength, b: axial compressive strength, c: splitting tensile strength, d: modulus of elasticity).

The relationships between cubic compressive strength, axial compressive strength, splitting tensile

strength, modulus of elasticity and crumb rubber content were shown in Figure 3, respectively. As

can be seen from the results, mechanical properties of rubber concrete decrease with the increasing of

rubber content, which have favourable linear relationships. It revealed that replacement of coarse

aggregate for crumb rubber presents negative effects on mechanical properties of concrete. Moreover,

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

294

the downtrends are relatively slow for mechanical properties of concrete, when the rubber content is

less than 10%. The reasons lie in that rubber particles is elastic material, whose compressive strength

is weaker than coarse aggregate. Moreover, adhesive ability between aggregate and cement mortar is

better than that between crumb rubber and cement mortar. Therefore, replacement of coarse

aggregate by crumb rubber lead to the reduction of concrete.

Ratios between splitting tensile strength and cubic compressive strength (λ) were also calculated,

which were shown in Figure 4. The results revealed that λ of PC increases after the addition of crumb

rubber. Replacement of coarse aggregate for crumb rubber can improve the brittleness of concrete.

6.6%

6.8%

7.0%

7.2%

7.4%

7.6%

7.8%

8.0%

0 5 10 15 20

λ

Rubber content (%)

Figure 4. Relationships between λ and rubber content.

3.2. Durability performance

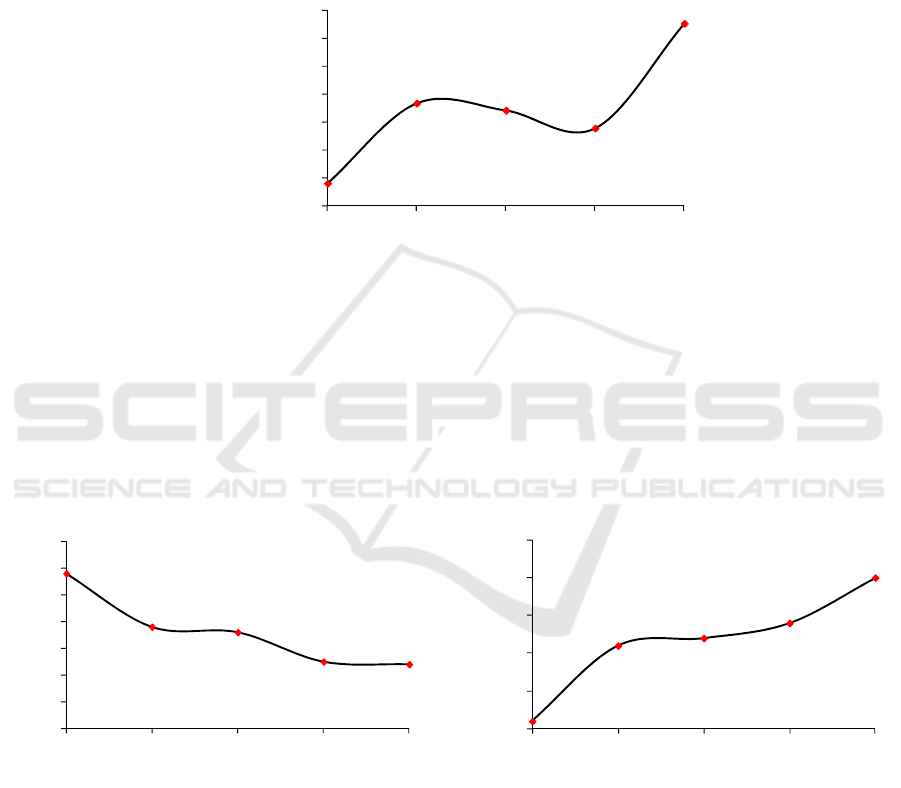

Strength loss rates of PC and CRC after 25 times of freeze-thaw cycle were calculated. Meanwhile,

anti-corrosion coefficients for PC and CRC after 15 times of sulfate attack were also obtained. The

results were shown in Figure 5. The results revealed that compressive strength loss rate of concrete

decreases with the increasing of rubber content, and anti-corrosion coefficient increases with the

increasing of rubber content. Replacement of coarse aggregate for crumb rubber can improve the

freezing-thawing resistance and corrosion resistance abilities. Freeze-thaw resistance improves by

34.5% when the rubber content is 5%.

0

1

2

3

4

5

6

7

0 5 10 15 20

Strength loss rate (%)

Rubber content (%)

0.96

0.965

0.97

0.975

0.98

0.985

0 5 10 15 20

Anti-corrosion coefficient

Rubber content (%)

(a) (b)

Figure 5. Relationships between durability performances and rubber content (a: strength loss rate, b:

anti-corrosion coefficient).

4. Conclusions

In this study, crumb rubber with particle size 2-4mm was used to replace the course aggregate and

realize the modification of concrete. Mechanical and durability performances of crumb rubber

modified concrete were demonstrated. Following conclusions can be obtained:

Mechanical Property and Durability Analysis of Crumb Rubber Modified Concrete

295

(1) Addition of crumb rubber into concrete to replace the course aggregates presents negative

effects on cubic compressive strength, axial compressive strength, splitting tensile strength and

modulus of elasticity.

(2) Ratios between splitting tensile strength and cubic compressive strength show rising trend

with the increasing of rubber content. Replacement of coarse aggregate for crumb rubber can

improve the brittleness of concrete.

(3) Compressive strength loss rate of concrete decreases with the increasing of rubber content, and

anti-corrosion coefficient increases with the increasing of rubber content. Replacement of coarse

aggregate for crumb rubber can improve the freezing-thawing resistance and corrosion resistance

abilities of concrete.

Acknowledgment

The authors express their appreciation for the financial support of National Natural Science

Foundation of China (51408258); High Level Talent Support Program of BJUT (2017); China

Postdoctoral Science Foundation funded project (2014M560237); Science & Technology

Development Program of Jilin Province (2018-1-6, 20180201026SF).

References

[1] Wei H B, He Q Q, Jiao Y B, Chen J F and Hu M X 2016 Evaluation of anti-icing performance

for crumb rubber and diatomite compound modified asphalt mixture

J. Construction &

Building Materials

107:109-116

[2]

Liu H Y, Chen Z J, Wang W, Wang H N and Hao P W 2014 Investigation of the rheological

modification mechanism of crumb rubber modified asphalt (CRMA) containing TOR

additive

J. Construction & Building Materials 67:225-233

[3]

Yung W H, Yung L C and Hua L H 2013 A study of the durability properties of waste tire

rubber applied to self-compacting concrete

J. Construction & Building Materials

41(41):665-672

[4]

Si R Z, Wang J P, Guo S C, Dai Q L and Song H 2018 Evaluation of laboratory performance

of self-consolidating concrete with recycled tire rubber

J. Journal of Cleaner Production

180:823-831

[5]

Bisht K and Ramana P V 2017 Evaluation of mechanical and durability properties of crumb

rubber concrete

J. Construction & Building Materials 155:811-817

[6]

Xue G and Pei Z 2018 Experimental study on axial compressive properties of rubber concrete

at low temperature

J. Journal of Materials in Civil Engineering 30(3)

[7]

Liu H B, Wang X Q, Jiao Y B and Sha T 2016 Experimental Investigation of the Mechanical

and Durability Properties of Crumb Rubber Concrete.

J. Materials 9(3):172

[8]

Ministry of Communications of the People's Republic of China 2014, Technical Guidelines for

Construction of Highway Cement Concrete Pavements

(JTG/T F30-2014)

[9]

2011 Ministry of Housing and Urban-Rural Construction of the People's Republic of China

Specification for mix proportion design of ordinary concrete (JGJ55-2011)

[10]

2005 Ministry of Communications of the People's Republic of China Test Methods of Cement

and Concrete for Highway Engineering

(JTG E30-2005)

[11]

2002 Ministry of Housing and Urban-Rural Construction of the People's Republic of China,

Standard for Test Method of Mechanical Properties on Ordinary Concrete (GB/T 50081-

2002)

[12]

2009 Ministry of Housing and Urban-Rural Construction of the People's Republic of China

Standard for Test Methods of Long-term Performance and Durability of Ordinary Concrete

(GB/T 50082-2009)

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

296