The Influence of Wind Speed on Melting Ice on Concrete

Pavement with Carbon Fiber Heating Wire

Y Lai

1, 2, *

, Y Liu

1, 2

, D X Ma

1, 2

, P Wang

1, 2

and X Su

1, 2

1

China Airport Construction Group Corporation, Beijing, 100101, China

2

Beijing Super-Creative Technology Co., LTD, Beijing, 100621, China

Corresponding author and e-mail: Y Lai, cacclaiyong@126.com

Abstract. In this paper, the method of melting ice with carbon fiber heating wire (CFHW)

buried in concrete pavement is presented to increase the friction coefficient. The melting ice

effect, pavement temperature and temperature difference are analyzed. It is shown that, with

an input power of 400 W/m

2

and the average air temperature of -5°C , the time of melting 6.5

mm ice on concrete pavement is 5.5 hours when the wind speed is 0.4 m/s, and the time of

melting 6.5 mm ice on concrete pavement is 10 hours when the wind speed is 4.0 m/s. The

wind speed is an important factor affecting the concrete pavement temperature, longitudinal

temperature difference and melting ice effect. It can improve the efficiency of melting ice by

reducing wind speed. However, the wind speed has little effect on the lateral temperature

difference of the same depth. The research work has important guiding significance for

melting ice project.

1. Introduction

Ice on concrete pavement significantly impacts aircraft landing and vehicle running in winter because

ice reduces the friction coefficient between the tire and the pavement surface. The traditional method

of pavement snow removal with snow-melting chemicals or machine induces traffic delay and needs

a large number of manpower, chemicals and machine, which is labor intensive and time-consuming.

It is necessary to conduct timely and high-efficient removal of snow and avoid the adverse effects of

snow-melting chemicals on concrete pavement. Some other pavement snow-melting methods have

been researched, such as hydronic heating system [1-4], electrically conductive concrete [5-7] and

CFHW [8-10]. The current research of melting snow mainly focuses on CFHW. Zhao et al.

conducted studied pavement and bridge deck deicing with CFHW [9, 10]. In different climatic

conditions, the results showed that the method can meet the requirement of melting ice on bridge

deck and pavement with different input power. The wind speed is an important factor of melting ice

effect. However, the influence of wind speed on melting ice on concrete pavement is less studied.

Therefore, the method of melting ice with CFHW requires further study on the application of

pavement. It needs a systematic study on the influence of wind speed on melting ice on concrete

pavement.

Lai, Y., Liu, Y., Ma, D., Wang, P. and Su, X.

The Influence of Wind Speed on Melting Ice on Concrete Pavement with Carbon Fiber Heating Wire.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 313-318

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

313

2. Experiment

2.1. Materials

The raw materials include cement, fine aggregate, coarse aggregate, water and CFHW. The mix

proportions of concrete are given in table 1. The cement is Ordinary Portland Cement 42.5. The fine

aggregate is natural sand with fineness modulus of 2.85. The mixed water is tap water. The ratio of

water to cement is 0.42. The heating material is 24k CFHW.

Table1.Mix proportions of concrete.

Cement

(kg m

-3

)

Fine aggregate

(kg m

-3

)

Coarse aggregate (kg m

-3

)

Water

(kg m

-3

)

Water reducer

(kg m

-3

)

5-20 mm

20-40 mm

325

579.9

567.9

851.8

136.5

6.5

2.2. Experiment program

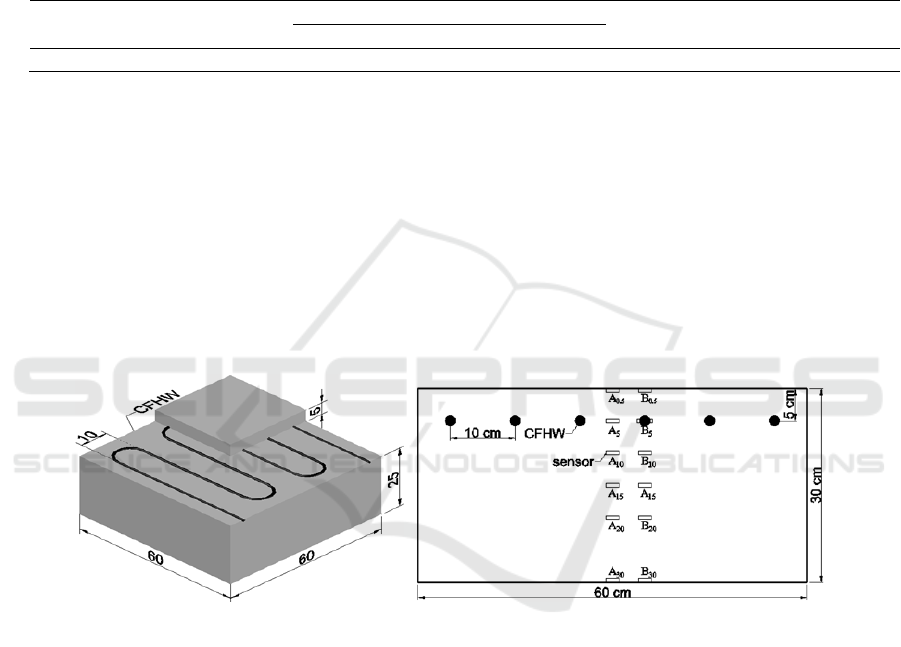

The specimen is prepared in the mold of 60 cm×60 cm×30 cm. The mold is made of 5 cm thickness

polystyrene insulation board. Except for the upper surface of pavement, the remaining five surfaces

have polystyrene boards for thermal insulation. As shown in figure 1, the 24k CFHW is located 5 cm

below the pavement surface, which is bundled in steel mesh like snake. The CFHW spacing is 10 cm.

The concrete pavement is cured for 28 days in natural environment. As shown in figure 2, the depth

of two row temperature sensors vertically embedded in pavement is 0.5 cm, 5 cm, 10 cm, 15 cm, 20

cm and 30 cm, respectively. The A row temperature sensors are located in the middle of CFHW, and

the B row temperature sensors are located directly above and below CFHW. The freezer is used to

simulate outdoor weather in winter, the size of which is 2 m×2 m ×2 m.

Figure 1. Concrete pavement model.

Figure 2.Temperature sensor layout scheme for

pavement.

3. Results and discussion

The air temperature is -5±0.5°C in the freezer, and the average air temperature is -5°C . The relative

humidity is 85%. The solar radiation intensity is 0 W/m

2

. The wind speed is 0.4 m/s and 4.0 m/s,

respectively. The pavement is placed to constant temperature in the freezer before test, and then the 6

mm precipitation water is frozen into the ice on the pavement surface. The thickness of the ice is

6.5mm. In the experiment, the heat flux is 400 W/m

2

.

3.1. Melting ice and pavement temperature

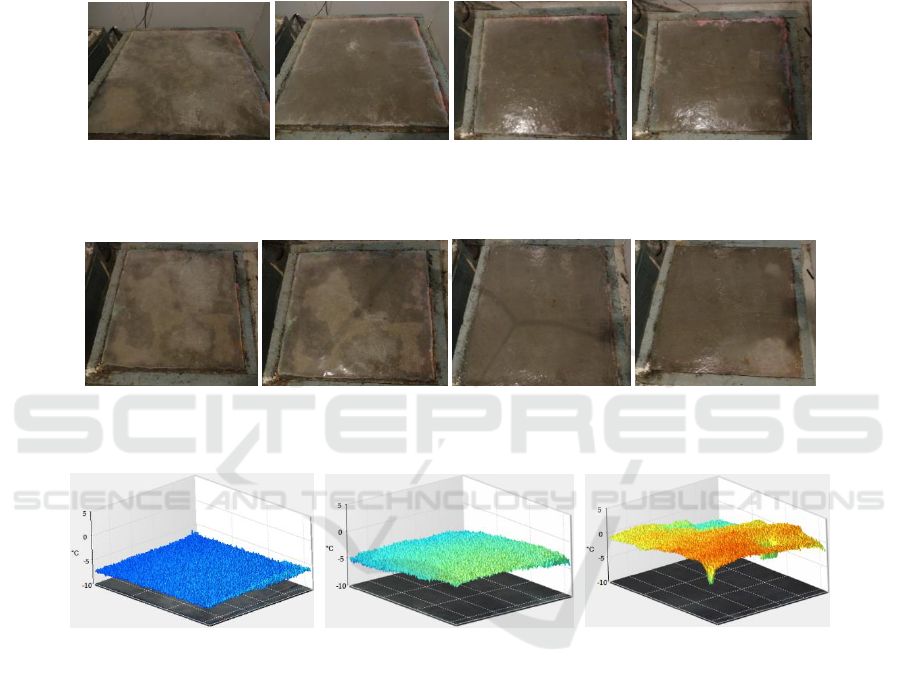

The process of melting ice on the concrete pavement is shown in figure 3 and figure 4. With the

heating system running, the pavement temperature gradually increased. When the wind speed is 0.4

m/s, the bottom of the ice begins to melt at 1.67 hours; the average thickness of the ice drops to 2 mm

at 4 hours; the ice on the pavement surface melts completely at 5.5 hours. When the wind speed is 4.0

m/s, the bottom of the ice begins to melt at 3 hours; the average thickness of the ice drops to 1 mm at

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

314

8 hours; the ice melts completely at 10 hours because of the continuous heating of system. The

heating time is 5.5 hours and 10 hours when the wind speed is 0.4 m/s and 4.0 m/s, respectively.

Compared with 0.4 m/s wind speed, the time of melting 6 mm precipitation ice will extend 4.5 hours

when the wind speed is 4.0 m/s. The essence of wind speed change is to change the convective heat

transfer coefficient of the ice layer surface. With the increase of wind speed, the convective heat

transfer coefficient increases, and the convective heat loss of the ice surface increases. Therefore, the

rate of melting ice decreases with the increase of wind speed, which increases the time of melting ice.

(a) Initial time (b) 1.67 hours (c) 4 hours (d) 5.5 hours

Figure 3.Melting ice on concrete pavement (0.4m/s).

(a) Initial time (b) 3 hours (c) 8 hours (d) 10 hours

Figure 4.Melting ice on concrete pavement (4.0 m/s).

(a) Initial time (b) 1.67 hours (c) 5.5 hours

Figure 5.3D-IR temperture when the wind speed is 0.4 m/s.

The three-dimensional infrared ray (3D-IR) temperature is obtained from the surface of ice or

concrete pavement. The 3D-IR temperature is the measured temperature of the ice surface before the

ice is completely melted. As shown in figure 5, when the wind speed is 0.4 m/s, the 3D-IR

temperature of the ice surface is from -8.1°C to -5.3°C at initial time, and the average temperature is -

6.8°C. The 3D-IR temperature of the ice surface is from -5.9°C to -1.6°C at 1.67 hours, and the

average temperature is -3.4°C. The 3D-IR temperature of the pavement surface is from -1.9°C to

2.4°C at 5.5 hours, and the average temperature is 0.3°C .

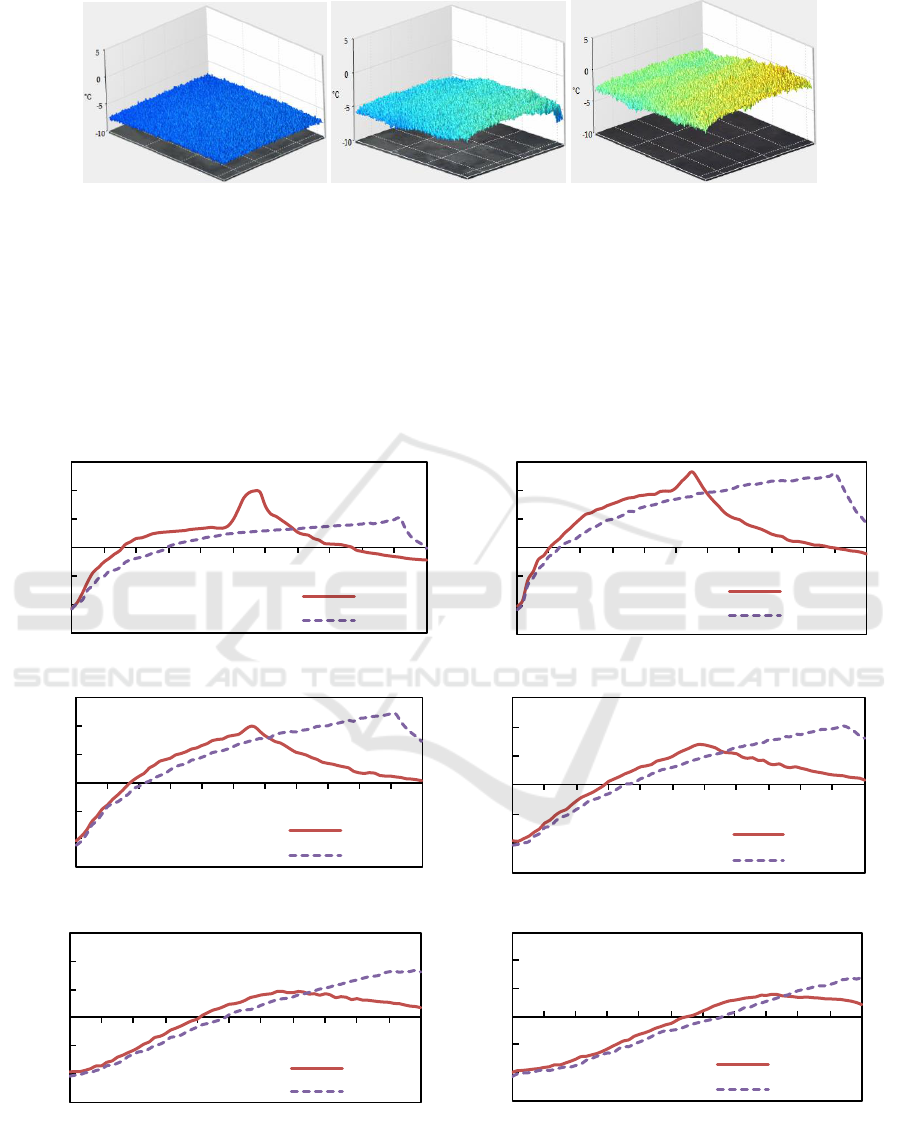

As shown in figure 6, when the wind speed is 4.0 m/s, the 3D-IR temperature of the ice surface is

from -8.1°C to -6.3°C at initial time, and the average temperature is -7.1°C. The 3D-IR temperature

of the ice surface is from -6.7°C to -2.0°C at 3 hours, and the average temperature is -4.5°C. The 3D-

IR temperature of the pavement surface is from -1.8°C to 0.5°C at 10 hours, and the average

temperature is -0.1°C.

The Influence of Wind Speed on Melting Ice on Concrete Pavement with Carbon Fiber Heating Wire

315

(a) Initial time (b) 3 hours (c) 10 hours

Figure 6.3D-IR temperture when the wind speed is 4.0 m/s.

The relationship between the temperature and time at different depths of concrete pavement is

shown in figure 7. As shown in figure 7(a), when the wind speed is 0.4 m/s, the A

0.5

point

temperature of the pavement rises from -4.27°C to 0°C after 1.67 hours heating, and the A

0.5

point

temperature of the pavement is 3.84°C at 5.5 hours. The A

0.5

point temperature drops to 0°C in 3

hours after stopping heating. When the wind speed is 4.0 m/s, the A

0.5

point temperature rises from -

4.30°C to 0°C after 3 hours heating, and the A

0.5

point temperature is 1.95°C at 10 hours. The A

0.5

point temperature decreases to 0°C in 1 hour after the heating stopped.

(a) 0.5 cm depth (b)5 cm depth

(c) 10 cm depth (d) 15 cm depth

(e) 20 cm depth (f) 30 cm depth

Figure 7.Pavement temperture variation with time.

-6

-4

-2

0

2

4

6

0 1 2 3 4 5 6 7 8 9 10 11

Temperature /℃

Time /h

0.4 m/s

4.0 m/s

-6

-4

-2

0

2

4

6

0 1 2 3 4 5 6 7 8 9 10 11

Temperature /℃

Time /h

0.4 m/s

4.0 m/s

-6

-4

-2

0

2

4

6

0 1 2 3 4 5 6 7 8 9 10 11

Temperature /℃

Time /h

0.4 m/s

4.0 m/s

-6

-4

-2

0

2

4

6

0 1 2 3 4 5 6 7 8 9 10 11

Temperature /℃

Time /h

0.4 m/s

4.0 m/s

-6

-4

-2

0

2

4

6

0 1 2 3 4 5 6 7 8 9 10 11

Temperature /℃

Time /h

0.4 m/s

4.0 m/s

-6

-4

-2

0

2

4

6

0 1 2 3 4 5 6 7 8 9 10 11

Temperature /℃

Time /h

0.4 m/s

4.0 m/s

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

316

As shown in figure 7(b)~(f) and figure 8, the temperature of pavement below the embedded

CFHW increases with the increase of the heating time in melting ice process, and the temperature

increase decreases gradually with the increase of the depth. Therefore, with the increase of the

pavement depth, the time of rising to 0°C increases, but the maximum temperature decreases.

Compared with 0.4 m/s wind speed, the rise of the pavement temperature is more slowly when the

wind speed is 4.0 m/s, and the time that the pavement temperature reaches 0°C is longer.

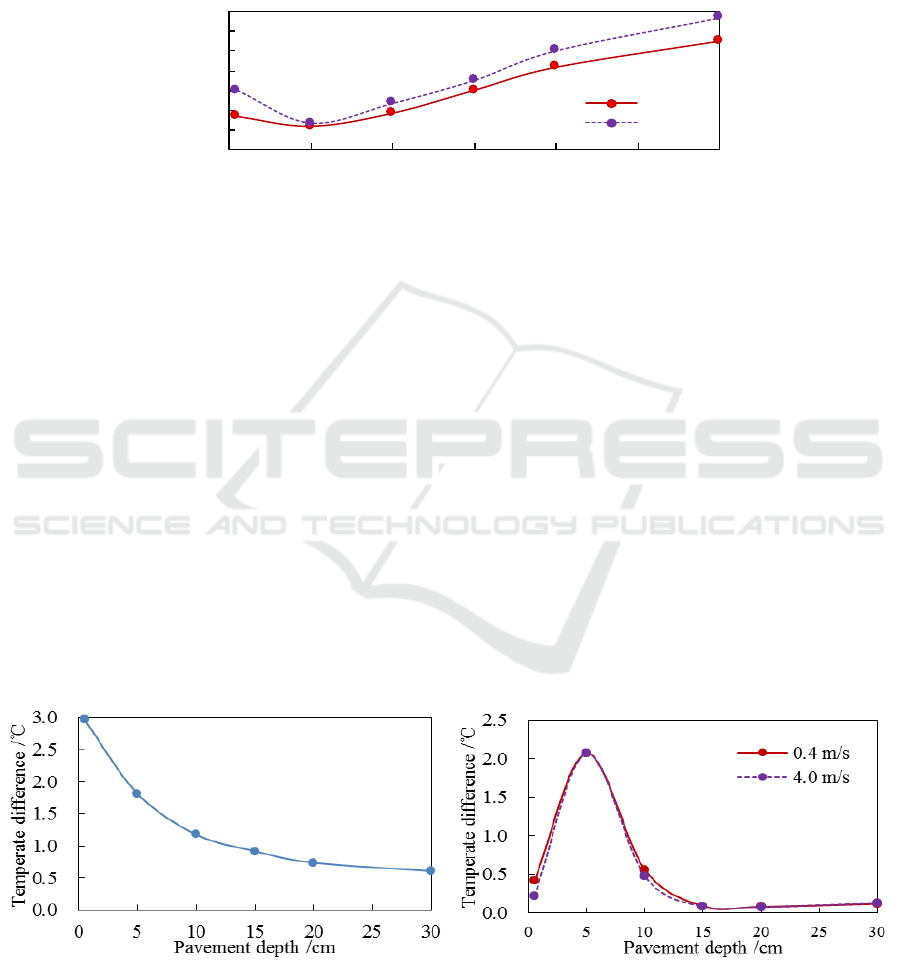

Figure 8.Time variation about different pavement depths up to 0°C .

3.2. Longitudinal and lateral temperature differences of the pavement

The longitudinal temperature difference along the depth of pavement at 5.5 hours is as shown in

figure 9. The longitudinal temperature difference is the difference of the pavement temperature at 0.4

m/s and 4.0 m/s wind speed, which is measured by A row temperature sensors. When the depth of

pavement increases from 0.5 cm to 30 cm, the longitudinal temperature difference will decrease from

2.97°C to 0.61°C . The longitudinal temperature difference decreases with the increase of the depth,

but the decreased rate of the longitudinal temperature difference decreases gradually.

The lateral temperature difference along the depth of pavement during heating is shown in figure

10. The lateral temperature difference is the average value of the horizontal pavement temperature

difference at the same depth in the process of melting ice. The location of the maximum lateral

temperature difference is the depth of 5 cm. The lateral temperature difference decreases when the

distance from CFHW increases. However, when the depth is more than 15 cm, the lateral temperature

difference tends to be stable, and the lateral temperature difference is less than 0.12°C . Compared

with 0.4 m/s wind speed, the lateral temperature difference of the pavement is slightly higher than

that of 4 m/s wind speed when the pavement depth is from 0.5 cm to 30 cm. This is because the wind

speed increases the convective heat transfer. The higher the wind speed, the better the thermal

uniformity of the horizontal pavement at the same depth, but the effect is very small.

Figure 9. The longitudinal temperature

difference along the depth of pavement at 5.5

hours

Figure 10. The lateral temperature difference

along the depth of pavement during heating

0

1

2

3

4

5

6

7

0 5 10 15 20 25 30

Time /h

Pavement depth /cm

0.4 m/s

4.0 m/s

The Influence of Wind Speed on Melting Ice on Concrete Pavement with Carbon Fiber Heating Wire

317

4. Summary

The method of melting ice with CFHW embedded in concrete pavement is effective. It is shown that,

with an input power of 400 W/m

2

and -5°C air temperature, the time of melting 6.5mm ice on

concrete pavement is 5.5 hours when the wind speed is 0.4 m/s. Compared with 0.4 m/s wind speed,

the time of melting ice is 4.5 hours longer than that of 4.0 m/s wind speed. The average 3D-IR

temperature of the pavement surface is close to 0°C for both 0.4 m/s and 4.0 m/s wind speeds when

the ice is melted completely. Compared with 0.4 m/s wind speed, the rise of pavement temperature is

more slowly when the wind speed is 4.0 m/s, and the time of the pavement temperature up to 0°C is

longer. The longitudinal temperature difference decreases with the increase of the depth, but the

decreased rate of the longitudinal temperature difference decreases gradually. Compared with 0.4 m/s

wind speed, the lateral temperature difference of pavement is slightly higher than that of 4.0 m/s

wind speed. The effective distance of the carbon fiber line affecting the lateral temperature

uniformity of the pavement is 10 cm. The wind speed is a very important factor affecting melting ice.

Field wind speed must be taken into account in the design of actual melting ice project.

Acknowledgments

This work was financially supported by Science and Technology Project of CAAC (MHRD201225),

Science and Technology Project of CAAC (MHRD20140107) and Science and Technology Project

of CAAC (20150225).

References

[1] Lee R C, Sackos J T, Nydahl J E and Pell K M, 1984 Bridge heating using ground-source heat

pipes, Transportation Research Record 962 51-56.

[2] Liu X B and Spitler J D, 2004 A simulation tool for the design of the hydronic bridge snow

melting system, Proceedings of the 12th International Road Weather Conference, Bingen

(on Rhine), Germany, June 16-18.

[3] Liu X B, Rees S J and Spitler J D, 2006 Modeling snow melting on heated pavement surfaces

part I: model development, Applied Thermal Engineering, 27 1115-1124.

[4] Xu H N and Tan Y Q, 2015 Modeling and operation strategy of pavement snow melting

systems utilizing low-temperature heating fluids, Energy, 80 666-676.

[5] Tuan C Y and Yehia S, 2004 Evaluation of electrically conductive concrete containing carbon

products for deicing, ACI Materials Journal 101 287-293.

[6] Hou Z F, Li Z Q, Guang K J, 2002 The joule heating analysis of electrically conductive

concrete for roadway deicing system, Seventh International Symposium on Structural

Engineering for Young Exports, Tianjin, China. 977-1001.

[7] Xie P and Beaudoin J J, 1995 Electrically conductive concrete and its application in deicing,

Proceedings of the Second CANMET/ACI International Symposium, Las Vegas, USA, 399-

417.

[8] Lai Y, Liu Y, Ma D X, 2014 Automatically melting snow on airport cement concrete

pavement with carbon fiber grille, Cold Regions Science and Technology 103 57-62.

[9] Zhao H M, Wang S G, Wu Z M and Che G J, 2010 Concrete slab installed with carbon fiber

heating wire for bridge deck deicing, Journal of Transportation Engineering 136 500-509.

[10] Zhao H M, Wu Z M, Wang S G, Zheng J J and Che G J, 2011 Concrete pavement deicing with

carbon fiber heating wires, Cold regions Science and Technology 65 413-420.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

318