Study on Electro-thermal and Electromagnetic Properties of

Carbon Fiber Heating Wire in Airport Cement Concrete

Pavement

Y Lai

1, 2, *

, Y Liu

1, 2

, P Wang

1, 2

and D X Ma

1, 2

1

China Airport Construction Group Corporation, Beijing, 100101, China

2

Beijing Super-Creative Technology Co., LTD, Beijing, 100621, China

Corresponding author and e-mail: Y Lai, cacclaiyong@126.com

Abstract. This paper studies the electro-thermal and electromagnetic properties of carbon

fiber heating wire (CFHW) buried in airport cement concrete pavement. The temperature of

CFHW is analyzed when the input power of CFHW is from 10 W/m to 60 W/m. The

magnetic flux density is analyzed when the heat flux is from 100 W/m

2

to 600 W/m

2

. It is

shown that the temperature of 24k CFHW is higher than that of 48k CFHW, and the magnetic

flux density of pavement with 15 cm CFHW spacing is higher than that of 10 cm CFHW

spacing. The 24k CFHW is more suitable for melting snow on airport pavement. The

magnetic flux density can meet the electromagnetic environment requirements for

aeronautical radio navigation stations.

1. Introduction

Snow, ice and slush on airport cement concrete pavement significantly impact aircraft landing,

taxiing and takeoff safety in winter because snow, ice and slush reduce the friction coefficient

between the tire and the surface of airport pavement, which not only hinders the transportation of

people and goods but also threatens people's lives and properties [1]. The traditional method of

pavement snow removal with snow-melting chemicals or machine induces flight delay and needs a

large number of manpower, chemicals and machine, which is labor intensive and time-consuming.

The use of snow-melting chemicals also leads to some adverse effects on the structure, function and

environment [2-4].

It is necessary to conduct timely and high-efficient removal of snow and avoid the adverse effects

of snow-melting chemicals on airport pavement. Some other pavement snow-melting methods have

been researched, such as super-long flexible heat pipes [5], electric heating cables [6], electrically

conductive concrete [7-9], hydronic heating system [10-12] and CFHW [1, 13].

In recent years, Zhao et al. conducted a systematic study on bridge deck and pavement snow-

melting by embedding CFHW in concrete [1, 13]. In different climatic conditions, the results showed

that the method can meet the requirement of bridge deck and pavement snow-melting with different

input powers. However, the snow-melting method with CFHW requires further study on the

application of airport pavement [14]. The CFHW generates electromagnetic fields when it is

electrified. The Electro-thermal and Electromagnetic Properties of CFHW are the important factors

of melting snow on airport pavement. The aeronautical radio navigation stations have some specific

Lai, Y., Liu, Y., Wang, P. and Ma, D.

Study on Electro-Thermal and Electromagnetic Properties of Carbon Fiber Heating Wire in Airport Cement Concrete Pavement.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 319-323

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

319

electromagnetic environment requirements [15]. Therefore, it is proposed that the electro-thermal and

electromagnetic properties of CFHW is studied.

2. Experiment

2.1. Materials

The raw materials include cement, fine aggregate, coarse aggregate, water, water reducer and CFHW.

The mix proportions of concrete are given in table 1. The cement is Ordinary Portland Cement 42.5.

The fine aggregate is natural sand with fineness modulus of 2.7. The coarse aggregate gradation is

the gravel of 5~40 mm. The mixed water is tap water. The ratio of water to cement is 0.42. The sand

ratio is 0.3. The solid content of water reducer is 5.0%. The heating material is 24k and 48k CFHW

with Teflon coat, the resistance of which is 18.89 Ω/m and 8.75 Ω/m, respectively.

Table1. Mix proportions of concrete.

Cement

(kg m

-3

)

Fine aggregate

(kg m

-3

)

Coarse a

gg

re

g

ate (k

g

m

-3

)

Water

(kg m

-3

)

Water reducer

(kg m

-3

)

5-20 m

m

20-40 mm

330 609.4 568.8 853.2 138.6 6.6

2.2. Experiment program

The 24k and 48k CFHW are connected to the AC voltage regulator which is connected with the

power supply. The load power of CFHW is 0~60 W/m by adjusting the output voltage. The CFHW

hang in the air at ambient temperature of 0°C. The temperature sensor is tied up on the CFHW, and

the temperature is measured by the data acquisition device.

The mixture is stirred for 90s according to GB/T 20473-2009. The specimens are prepared in the

mold of 60 cm×60 cm×40 cm. The 24k and 48k CFHW are located 5 cm below the pavement

surface. The CFHW spacing is 10 cm and 15 cm. The cement concrete pavement is cured for 28 days

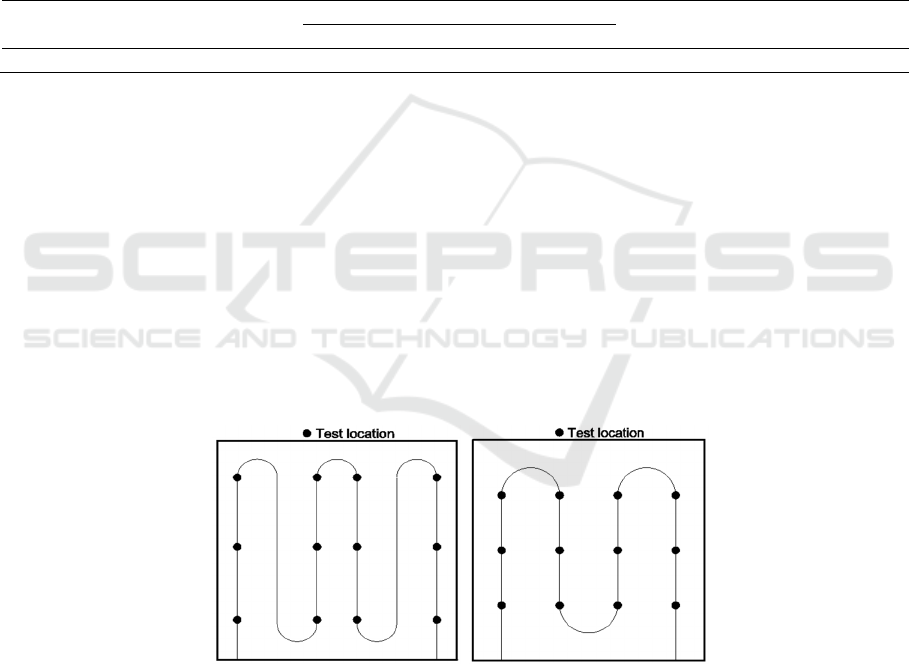

at 20°C and 60%±5% relative humidity. As shown in Figure 1, the test location of magnetic flux

density contains 12 test points. The test location of magnetic flux density that is directly above the

CFHW is 0 m, 0.25 m, 0.5 m, 0.75 m and 1 m on the pavement surface, respectively. The test is

carried out at the ambient temperature of 0 °C.

(a) 10 cm CFHW spacing (b) 15 cm CFHW spacing

Figure 1. Test location of magnetic flux density.

3. Results and discussion

In the experiment, the input power is controlled by an AC voltage regulator. The power of CFHW is

10 W/m, 20 W/m, 30 W/m, 40 W/m, 50 W/m and 60 W/m, respectively. The input heat flux of the

airport cement concrete pavement is 100 W/m

2

, 200 W/m

2

, 300 W/m

2

, 400 W/m

2

, 500 W/m

2

and 600

W/m

2

, respectively.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

320

3.1. Electro-thermal properties

The resistance value of CFHW is invariable after heating, which is considered to be a constant value.

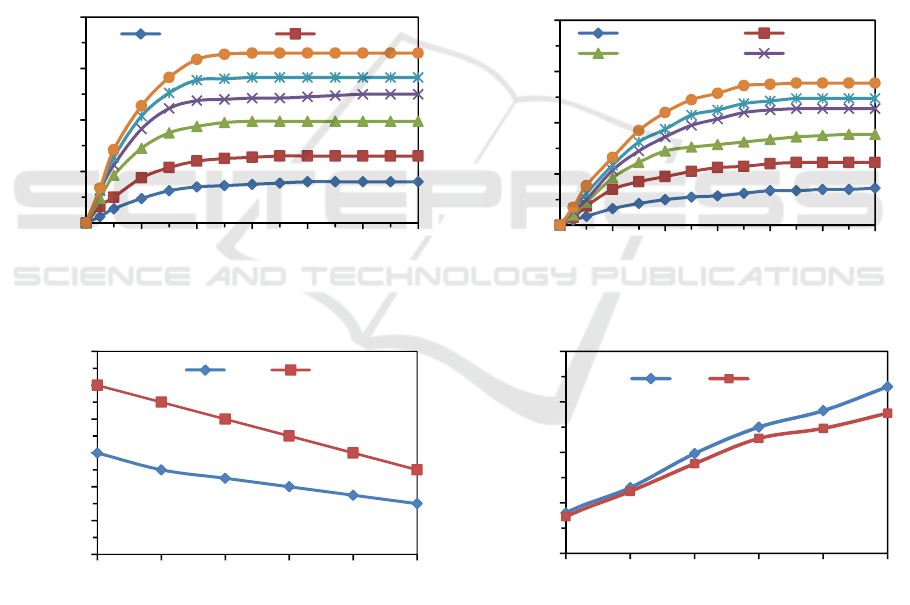

The temperature of 24k and 48k CFHW is measured against heating time as shown in Figure 2. After

the CFHW is electrified, the temperature of CFHW increases rapidly. The greater the power is, the

greater the temperature increases. However, the temperature increase decreases with time and then

gradually becomes stable. As shown in Figure 3, when the power per meter is increased from 10

W/m to 60 W/m, the time that the temperature of 24k CFHW is stable is shortened from 8 minutes to

5 minutes, and the time that the temperature of 48k CFHW is stable is shortened from 12 minutes to

7 minutes. The time difference between the temperature of 24k and 48k CFHW reaches a stable

value is decreased from 4 minutes to 2 minutes.

As shown in Figure 4, when the power per meter increases from 10 W/m to 60 W/m, the constant

temperature of 24k CFHW increases from 32°C to 132°C, the constant temperature of 48k CFHW

increases from 29°C to 111°C. The temperature difference between 24k and 48k CFHW increases

from 3°C to 21°C. The greater the power is, the shorter the temperature of CFHW tends to be

constant, and the higher the temperature is. The CFHW with Teflon coat is intact without damage

after heating, indicating that the high temperature performance of CFHW with Teflon coat is better.

Based on the thermal effect and the price of CFHW, the 24k CFHW is selected as the following test.

(a) 24k CFHW (b) 48k CFHW

Figure 2. The CFHW temperature variation with heating time.

Figure 3. The time variation with power per meter. Figure 4. The CFHW temperature variation

with powe

r

per mete

r

.

3.2. Electromagnetic properties

According to GB 6364-2013, a key requirement of electromagnetic environment is protection rate

that is the minimum ratio between signal electric field intensity at receiving point of normal

operation of navigation receiving equipment and interference electric field intensity of the same

0

40

80

120

160

024681012

Temperature /°C

Time /min

10 W/m 20 W/m

0

40

80

120

160

024681012

Temperature /°C

Time /min

10 W/m 20 W/m

30 W/m 40 W/m

2

4

6

8

10

12

14

10 20 30 40 50 60

Time /min

Power per meter /W•m

-1

24k 48k

0

40

80

120

160

10 20 30 40 50 60

Temperature /°C

Power per meter /W•m

-1

24k 48k

Study on Electro-Thermal and Electromagnetic Properties of Carbon Fiber Heating Wire in Airport Cement Concrete Pavement

321

channel. In the test, the electric field intensity measured at any position of concrete pavement is 0

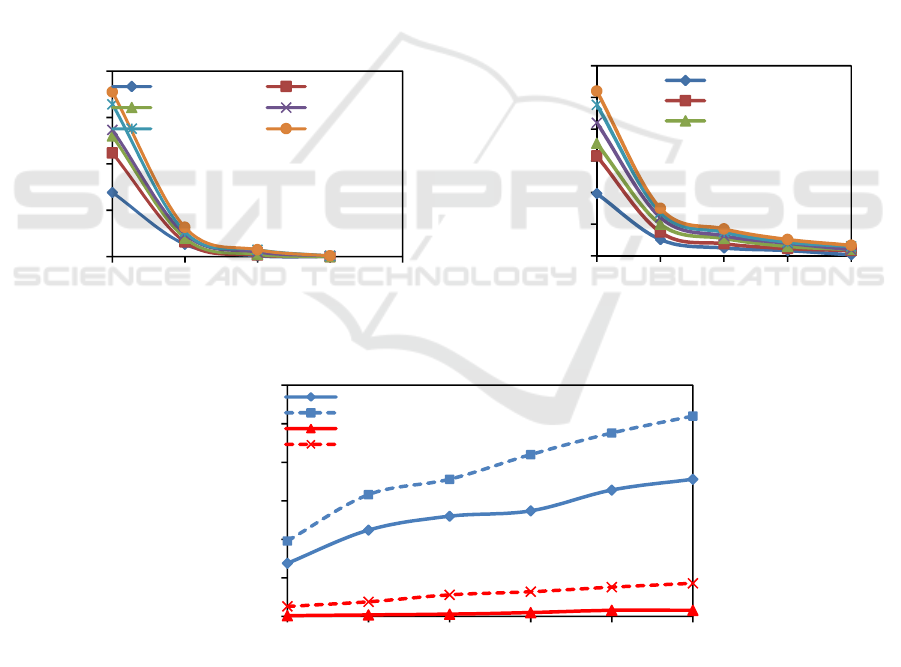

V/m. The magnetic flux density of pavement with 24k CFHW is measured against height as shown in

Figure 5. For the same heat flux, the magnetic flux intensity on concrete pavement rapidly decreases

when the height increases from 0 m to 0.25 m, and then the magnetic flux intensity decreases slowly

with the increase of height. As shown in Figure 5(a), the magnetic flux intensity of pavement with 10

cm CFHW spacing is 0μT when the height is higher than 0.75 m. As shown in Figure 5(b), the

magnetic flux intensity of pavement with 15 cm CFHW spacing is close to 0μT when the height is 1

m.

As shown in Figure 6, the magnetic flux density increases with the increase of the heat flux for

different height and spacing. When the heat flux increases from 100 W/m

2

to 600 W/m

2

, the

magnetic flux density of pavement surface with 10 cm CFHW spacing increases from 0.69μT to

1.78μT, and the magnetic flux density of pavement surface with 15cm CFHW spacing increases from

0.98μT to 2.6μT. At the height of 0.5 m above the pavement, when the heat flux increases from 100

W/m

2

to 600 W/m

2

, the magnetic flux density with 10cm CFHW spacing increases from 0μT to

0.08μT, and the magnetic flux density with 15 cm CFHW spacing increases from 0.13μT to 0.43μT.

The magnetic flux density of pavement with 15 cm CFHW spacing is higher than that of 10 cm

CFHW spacing for the same heat flux. This is because the current of CFHW with 15 cm spacing is

larger than that of 10 cm CFHW spacing. All the test data show that the electromagnetic performance

meets the requirements of the navigation electromagnetic environment.

(a) 10 cm spacing (b) 15 cm spacing

Figure 5. The relationship of magnetic flux density and height.

Figure 6. The relationship of magnetic flux density and heat flux.

4. Summary

The CFHW with Teflon coat has the advantages of fast heating speed, good heat resistance and the

stable resistance value. It is easy to control when the CFHW is electrified. Compared with the 48k

CFHW, the heating rate of the 24k CFHW is faster for the same power, the time to achieve stable

0,0

0,5

1,0

1,5

2,0

0,00 0,25 0,50 0,75 1,00

Magnetic flux density

/μT

Height /m

100 W/m² 200 W/m²

300 W/m² 400 W/m²

500 W/m² 600 W/m²

0,0

0,5

1,0

1,5

2,0

2,5

3,0

0,00 0,25 0,50 0,75 1,00

Magnetic flux density

/μT

Height /m

100 W/m²

200 W/m²

300 W/m²

0,0

0,5

1,0

1,5

2,0

2,5

3,0

100 200 300 400 500 600

Magnetic flux density /μT

Heat flux /W·m

-2

0 m height and 10 cm spacing

0 m height and 15 cm spacing

0.5 m height and 10 cm spacing

0.5 m height and 15 cm spacing

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

322

temperature is shorter and the temperature is higher; the economic benefit and the heating effect of

24k CFHW are better in snow-melting project. The magnetic flux density of pavement with 10 cm

CFHW spacing is less than that of 15 cm CFHW spacing when the heat flux is less than 600 W/m

2

.

The farther the distance is, the smaller the magnetic flux density is. The magnetic flux density is zero

when the height is greater than 1 m. The electromagnetic performance of snow-melting pavement

meets the requirements of navigation electromagnetic environment.

Acknowledgments

This work was financially supported by Science and Technology Project of CAAC (MHRD201225)

and Science and Technology Project of CAAC (20150225).

References

[1] Zhao H M, Wang S G, Wu Z M and Che G J 2010 Concrete slab installed with carbon fiber

heating wire for bridge deck deicing Journal of Transportation Engineering 136 500-509

[2] Wang K J, Nelsen D E and Nixon W A 2006 Damaging effects of deicing chemicals on

concrete materials Cement and Concrete Composites 28 (2) 173-188

[3] Kayama M, Quoreshi A M, Kitaoka S, Kitahashi Y, Sakamoto Y, Maruyama Y, Kitao M and

Koike T 2003 Effects of deicing salt on the vitality and health of two spruce species, Picea

abies Karst., and Picea glehnii Masters planted along roadsides in northern Japan

Environmental Pollution 124 (1) 127-137

[4] Thunqvist E L 2004 Regional increase of mean chloride concentration in water due to the

application of deicing salt The Science of the Total Environment 325 (1-3) 29-37

[5] Wang X Y, Zhu Y, Zhu M Z, Zhu Y Z, Fan H T and Wang Y F 2017 Thermal analysis and

optimization of an ice and snow melting system using geothermy by super-long flexible

heat pipes Applied Thermal Engineering 112 1353–1363.

[6] Henderson D J 1963 Experimental roadway heating project on a bridge approach Highway

Research Record 111 (14) 14-25

[7] Xie P and Beaudoin J J 1995 Electrically conductive concrete and its application in deicing,

Proceedings of the Second CANMET/ACI International Symposium Las Vegas USA pp.

399-417

[8] Tuan C Y 2004 Electrical resistance heating of conductive concrete containing steel fibers and

shavings ACI Materials Journal 101 (1) 65-71

[9] Zhang K, Han B G and Yu X 2011 Nickel particle based electrical resistance heating

cementitious composites Cold regions Science and Technology 69 (12) 64-69

[10] Lee R C, Sackos J T, Nydahl J E and Pell K M 1984 Bridge heating using ground-source heat

pipes Transportation Research Record 962 51-56

[11] Liu X B, Rees S J and Spitler J D 2006 Modeling snow melting on heated pavement surfaces

part I: model development Applied Thermal Engineering 27 (5-6) 1115-1124

[12] MiróR 2012 Airport heated pavement and ground heating systems: An annotated bibliography

Federal Research Division Library of Congress Washington

[13] Zhao H M, Wu Z M, Wang S G, Zheng J J and Che G J 2011 Concrete pavement deicing with

carbon fiber heating wires Cold regions Science and Technology 65 (12) 413-420

[14]

Lai Y, Liu Y and Ma D X 2014 Automatically Melting Snow on Airport Cement Concrete

Pavement with Carbon Fiber Grille Cold Regions Science and Technology 103(6) 57-62

[15] China National Standardization Management Committee 2013 Electromagnetic environment

requirements for aeronautical radio navigation stations National standard of People's

Republic of China 2-17

Study on Electro-Thermal and Electromagnetic Properties of Carbon Fiber Heating Wire in Airport Cement Concrete Pavement

323