Effect of Enzyme on Harmful Components Reduction in

Reconstituted Tobacco

T H Huang

1

, Q S Shi

2,3

, K Wei

1

, J P Gui

2,3

and L S Zheng

2,3, *

1

China Tobacco Guangxi Industrial Co. LTD., Guangxi, 530001, China

2

School of Biological Science and Medical Engineering, Beihang University, Key

Laboratory for Biomechanics and Mechanobiology of Ministry of Education, Beijing,

100083, China

3

Beijing Advanced Innovation Centre for Biomedical Engineering, Beihang

University, Beijing, 100083, China

Corresponding author and e-mail: L S Zheng, lishazheng@buaa.edu.cn

Abstract. To explore the influence of the composite enzymes on harmful components in

reconstituted tobacco, we developed compound enzymes which included power of cellulose

(23-41%, 100,000U/g), xylanase (10-23%, 100,000U/g), complex protease (41-57%,

100,000U/g), pectinase (5-6%, 100,000U/g) and amylase (1.5-3.8%, 10,000U/g). The

compound enzymes were added to the reconstituted tobacco (0.4% enzymes, incubated for 1

h at 45 ± 5°C). We evaluated the quality of the reconstituted tobacco using physical and

chemical indices. The results show that protein and pectin contents were effectively reduced,

with improved taste of the cigarette smoke, and harmful ingredients were reduced, such as

ammonia and hydrogen cyanide, in the mainstream smoke of the composite enzyme treatment

group compared with the untreated control group. This approach will reduce the danger of

mainstream smoke in reconstituted tobacco.

1. Introduction

Papermaking process reconstituted tobacco (RTL) is a type of tobacco product that utilizes

papermaking technology to produce a tobacco product. RTL uses tobacco stems and fines as the

major raw material. The main process of producing RTL includes placing the reconstituted tobacco

raw material in water, immersing and extracting the soluble material, and separating the insoluble

material. Secondly, a sheet is produced from a fiber base of insoluble material using a paper machine.

The insoluble substances are made into substrates, such as base paper, using a similar paper-making

method. Then, concentrated soluble substances are added with other additives to the substrate, which

becomes RTL after drying. A certain amount of recycled tobacco is added to the cigarette as a filling

material, which saves tobacco, reduces the cost of the cigarettes, and adjusts and improves the

physical properties and chemical composition of the cigarette [1-4]. However, biological

macromolecules, such as proteins, starch, and pectin, may affect the quality and effect of recycled

tobacco. Both domestic and overseas researchers have used bio-enzymes to transform and degrade

cellulose, lignin, pectin, proteins, starch, and other bio-macromolecules that influence the quality of

reconstituted tobacco to reduce the content of these macromolecules, which reduces the impurities

Huang, T., Shi, Q., Wei, K., Gui, J. and Zheng, L.

Effect of Enzyme on Harmful Components Reduction in Reconstituted Tobacco.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 351-356

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

351

and irritation and improves the quality of the RTL [5-8]. In this study, we used protease, cellulase,

pectinase, and other biological enzyme preparations to treat reconstituted tobacco leaf extract to

study the effect of the enzyme preparation on the regeneration of tobacco leaves and flue gas,

particularly the release of harmful components in tobacco leaves.

2. Materials and methods

2.1. Materials

Tobacco stems and tobacco powder was supplied by Guangxi Zhongyan Industrial Co., Ltd. The

compound enzyme was developed by Beihang University. Other reagents are analytically pure.

2.2. Method

Preparation of the reconstituted tobacco extract. Tobacco stems: tobacco powder (4: 6) samples was

weighed after being broken by a micro-plant crusher (FZ102 Miniature plant crusher, Taisite, China)

and was formed into a 1:10 solid-liquid ratio at 65 ± 5°C (HH-4 Constant temperature water bath,

Hannuo, China). After stirring for 40 min, the supernatant and residue were collected and the residue

was extracted three times. The supernatant was concentrated by a vacuum rotary evaporator and

concentrated to give the extract.

Extraction with the enzyme preparation. A compound enzyme preparation was added to the

extract at a rate of 0.4% of the total mass of the raw material (the end of the tobacco powder+

tobacco stems), and the mixture was prepared as blank samples and tested. The reaction was carried

out at 45 ± 5°C (TRH-300-GD Humidity Chamber, Thermoline, Australia) for 1 h and heated at

100°C for 10 min. After inactivating the compound enzyme, the extract was concentrated to the

original 1:9 volume at a density of 1.03–1.04 g/ml and made into a coating solution.

Preparation of cigarettes. Compound enzyme 5 was produced and prepared at Beihang University

and used to produce reconstituted tobacco at the proportion of 0.4%; tobacco stems, fines and other

material are used for extracting, concentrating, mixing, papermaking, coatings, drying, perfuming,

and other processes on the production lines of Guangdong Golden Leaf Technology Development

Co., Ltd. They were coated on the same substrate with a coating solution and the compound

enzyme-treated coating solution, respectively. The coating rate was set to 40 ± 2%. After drying at

105°C (FED240 Electric thermostatic drying oven, Binder, Germany), the flake reconstituted tobacco

was prepared. We used slices for the tobacco primary processing, rolling, and linking assembly units

to reforge the tobacco leaf materials, and packaged the reforged tobacco on the production lines of

Guangxi Zhongyan Co., Ltd.

Test methods. The extract was analyzed using physical and chemical indices. The protein content

was determined in accordance with National Food Safety Standards of China GB 5009.5-2010

“Determination of Protein in Foods”. The Kjeldahl digestion in analytical chemistry is a method for

the quantitative determination of nitrogen contained in organic substances plus the nitrogen in tuck

ammonia and ammonium (NH3/NH4+) [9]. Pectin content was determined in accordance with the

“Raw Fiber Material-Determination of Pectin Content (GB/T 10742-2008)”. A method is described

for the determination of pectin content in tobacco pectin by carbazole colorimetric method,

experiment conditions were investigated in detail and the optimum conditions were found as follows:

sulphuric acid 6.0mL, hydrolytic temperature 70°C , hydrolytic time 20min, 0.15% carbazole absolute

ethanol's solution 0.5mL, color reactions were carried out under room temperature, reaction time

30min, The method has been applied successfully to actual samples [10]. Total cellulose was

determined in accordance with “Fibrous Raw Material-Determination of Total cellulose (GB/T

2677.10-1995)”. The Van Soest is a method for the quantitative determination of Total cellulose in

tobacco [11].

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

352

Tobacco smoke analysis: Nicotine, carbon monoxide, water, tar, total particulate matter,

crotonaldehyde, phenol, hydrogen cyanide, ammonia, benzo(a)pyrenes, N-nitrosamines, and other

substances were determined in the total particulate matter of cigarette smoke using the national

tobacco industry standard or relevant national standard methods.

Sensory quality analysis: The taste sense was evaluated by aroma, irritation, coordination,

impurities, and aftertaste of the cigarettes in accordance with the National Industry Standard

YC/T138 “Tobacco and Tobacco Products-the Sensory Evaluation Methods”.

3. Results and discussion

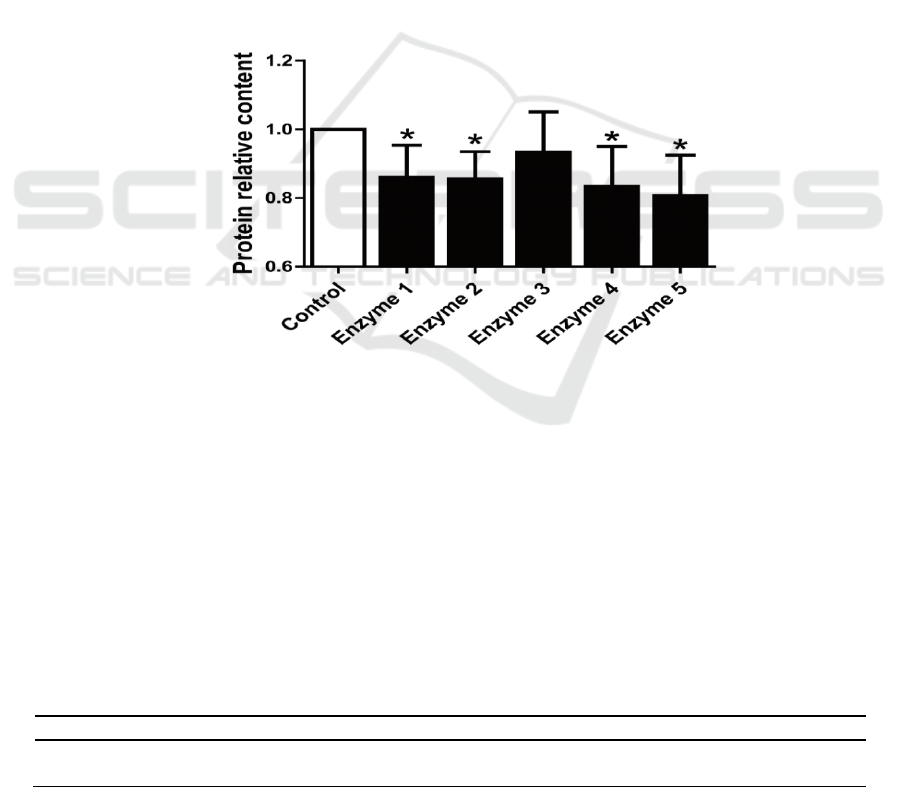

3.1. Effects of the compound enzyme on protein content in the extract

The protein content in the reconstituted tobacco extracts all decreased after being treated by

compound enzyme (Figure 1). Compound enzyme 5 provided the greatest decrease of about 20%.

Compound enzyme 4 reduced protein content in the extract by about 17%. The effects of compound

enzyme 1 and compound enzyme 2 were similar at about 15%. The effect of compound enzyme 3

was the poorest at only 7%. The effects of compound enzymes 3 did not reach statistical significance.

Considering the cost of the enzyme preparation and other factors, compound enzyme 2 and 5 were

selected for follow-up experiments because of their stable results.

Figure 1. Changes in protein content of the extraction solution based on the composite enzyme

treatment.

3.2. Effects of the compound enzymes on pectin and cellulose contents in the extract

Pectin and total cellulose contents in the extract changed after treatment with the compound enzymes

(Table 1). Pectin and cellulose contents did not change after treatment with compound enzyme 2,

indicating that compound enzyme 2 had good degradation efficiency for protein but was not ideal for

pectin or cellulose. Compound enzyme 5 also had good degradation efficiency on pectin by about

12%, but the efficiency of cellulose was not ideal. The reaction conditions for cellulose degradation

require further exploration. The conditions and process needs optimization.

Table 1. Content of pectin and ensemble cellulose in extracting solution by composite enzyme

treatment (%).

Control group

Enzyme group 2

Enzyme group 5

pectin

0.384

0.386

0.338

Total cellulose

0.04

0.043

0.064

Effect of Enzyme on Harmful Components Reduction in Reconstituted Tobacco

353

3.3. Effects of the compound enzymes on the sensory evaluation

We used cigarettes with reconstituted tobacco leaves made from the compound enzyme-treated

extract for the sensory evaluation analysis (Table 2). According to the results, cigarettes in enzyme

groups 2 and 5 improved taste quality, mainly sweetness and impurities, compared with the untreated

control group. Enzyme group 5 had fewer impurities, more abundant fragrance, and shorter residue

time as an aftertaste than the control group and the enzyme 2 group. The analysis showed that

enzyme group 5 was superior to enzyme group 2 and the control group.

Table 2. Results of cigarette smoking sensory quality assessment.

Sample

Sensory quality assessment result

Control group

Woody impurity gas; aftertaste with granular sensation.

Enzyme group 2

Gentle gas; clear sweet aroma; good abundance; slight woody smell;

aftertaste with slight granular sensation.

Enzyme group 5

Smooth gas; great abundance; but less volume of aroma; more sweet feeling;

slight impurity; slight irritation.

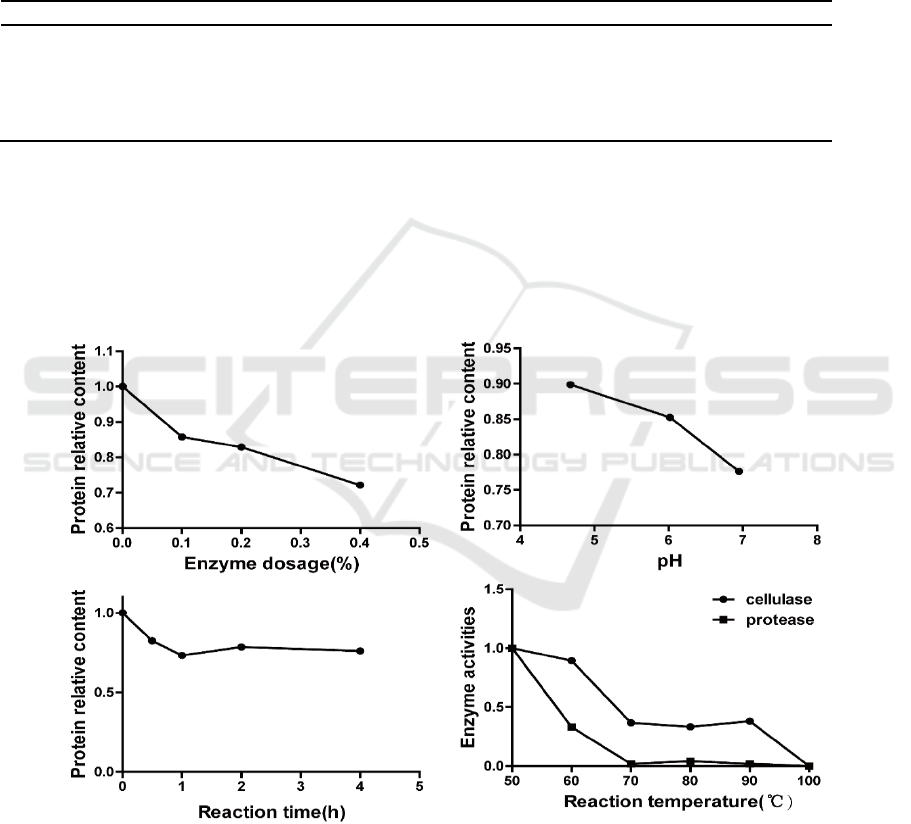

3.4. Optimization of conditions for the compound enzyme treatment

The effects of enzyme dosage, pH, reaction time, and reaction temperature were investigated. The

results are shown in Figure 2.

The amount of enzyme used in the extract had a significant effect on degradation of protein. After

considering the degradation of protein and the price of the compound enzyme, the mass fraction of

0.4% was chosen as the optimal amount of compound enzyme to use.

Figure 2. Effects of enzyme dosage, pH, reaction time, and temperature on protein degradation.

The pH value of the leaf extract had an important effect on the degradation of protein by the

compound enzyme (Figure 2). When the pH value was close to neutral, the effect of the enzyme

preparation was more obvious, indicating that the compound enzyme preparation (at least the

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

354

protease component) pH was close to pH 7, so pH 7 was selected as the pH for the complex enzyme

reaction system.

The protein content in the tobacco leaf extract required a certain reaction time. Protein content

decreased rapidly within 1 h. Protein content did not change with a reaction time more than 1 h.

Although protein content of the reaction was lower than that of the reaction at 30 h, the protein

content was less than that of the reaction at 1 h, so a reaction time of 1 h was chosen, taking into

account practical factors, such as production efficiency.

After the reaction, the enzyme preparation must be completely inactivated, or the flavor of

cigarettes in storage will continue to change. Temperature is essential for the inactivating enzyme

preparations. The changes in protease and cellulase activities in the complex enzyme were studied at

different temperatures.

The results showed that protease activity was almost nil at 70°C, while cellulase was relatively

inactive, and the activity decreased to a low level (0.4) at 70°C and was maintained at a lower state

until 100°C when activity was reduced to nil, so the choice of inactivation temperature was 100°C.

3.5. Effect of enzyme treatment on the extract reconstituted tobacco mainstream smoke

According to the detection method described in section 1.2.4, the results of the three indices in the

main flue gas of the flue-cured tobacco (Table 3) show that a similar amount of tar, nicotine, and

carbon monoxide were released in the enzyme treatment group compared with the control group.

Table 3. Three indicators of mainstream smoke in reconstituted tobacco.

sample

TPM

(mg/a

cigarette)

Nicotine

(mg/a

cigarette)

Moisture

(mg/a

cigarette)

Tar

(mg/a

cigarette

)

CO

(mg/a

cigarette)

Number of suction

ports(mouth/a

cigarette )

Control group

8.40

0.53

1.15

6.7

15.4

5.2

Enzyme

group 5

8.12

0.48

1.21

6.4

15.4

4.9

We further investigate the harmful components of mainstream smoke in reconstituted tobacco.

The results show that the release of hydrogen cyanide (HCN) in the flue gas of the test group was

lower than that of the control sample (P < 0.05) (Table 4). The results show that HCN decreased by

10.5%, ammonia decreased by 21.3%, and the hazard index of tobacco leaf was reduced by 0.2.

Table 4. Harmful components of mainstream smoke in reconstituted tobacco.

Sample

CO

(mg/a

cigarette)

HCN

(ug/a

cigarette)

NNK

(ng/a

cigarette)

NH

3

(ug/a

cigarette)

B[a]P

(ng/a

cigarette)

Phenol

(ug/a

cigarette)

Crotonald-ehyde

(ug/a cigarette)

Hazard

Index

Control group

13.9

85.5

10.8

4.7

6.1

2.7

17.4

8.2

Enzyme group 5

14.5

76.5

11.2

3.7

5.7

2.7

17.0

8.0

HazardIndex=(CO/14.2+HCN/146.3+NNK/5.5+NH3/8.1+B[a]P/10.9+phenol/17.4+Crotonaldehyde/18.6)*10/7.

4. Conclusions

Yang found that the optimum compound enzymes was composed of 0.5g/kg neutral proteinase,

0.1g/kg papaya proteinase and 0.5g/kg pineapple proteinase based on the weight of treated tobacco

leaves. By treating with the compound proteinase, the protein of tobacco was decreased by 13%

[12].Yao found that the neutral proteinase was the most effective enzyme for reducing the protein in

Effect of Enzyme on Harmful Components Reduction in Reconstituted Tobacco

355

tobacco. 120U/g neutral proteinase decreased protein to 12% [13]. Cellulase and pectinase compound

enzymes could degraded the cell wall material into sugars. It could degrade the cell wall material by

5% - 10% [14]. Deng used pectinase storing at 50°C for 12 hours. The results showed that the pectin

was reduced by 18.15% [15].Compared with our results, protein decreased to maximal 20% and

pectin decreased by 12%. It is better than the previous results.

The compound enzyme in this study reduced the release of harmful components in reconstituted

tobacco leaves. Compound enzyme 5 was added, and the extract was reconstituted. The protein

content of the extract was reduced by 20% and pectin content was reduced by 12%. Harmful

components, such as HCN gas, were reduced by 10.5%, ammonia was reduced by 21.3%, and the

hazard index decreased by 0.2 compared with the control cigarette. In conclusion, treating the extract

with a compound enzyme reduced protein and pectin contents as well as the release of harmful

components in reconstituted tobacco leaves, which is beneficial for improving the quality of

reconstituted tobacco.

Acknowledgment

This work was supported by National Natural Science Foundation of China [grant numbers

11572030], National Key R&D Program of China [2017YFC0108505].

References

[1] Chen Z G, Cai B, Wang J X, Ye M Q and Xiong B 2002 Tobacco Science & Technology 2

4-10

[2] Sun X Y, Sun B, Li D L and Zhang Z H 2011 Biomass Chemical Engineering 45 49-56

[3] Bai T, Yi A R, Tang J G, Zhu L H and Meng Z Y 2013 J of Anhui Agricultural Sciences 41

11512-11515

[4] Potts R J, Bombick B R, Meckley D R, Ayres P H and Pence D H 2010 Experimental and

Toxicologic Pathology 62 117-126

[5] Mao Y, Liu Z C, Yao Y J, Wang F L, Wang L and Xie Y M 2011 Tobacco Science

&Technolog 6 48-51

[6] Duan M, Li X, Li Z Y, Che J, Wang C, Hu W Y, Zhou J and Liu W J 2009 Chinese Tobacco

Science 30 69-72

[7] Huang T H, Gui J P, and Zheng L S 2015 J of Northeast Agricultural University 10 102-108

[8] Zheng X G, Zhao C Z, Wei X L, Wang Y X, Li J F, Han X C and Wang A C 2010 Shandong

Food Ferment 1 11-13

[9] Ding J D, Zhang X H, Yao X C, Huang W Y and Lin C W 2010 Food Research &

Development 11 138-140

[10] Shi W, Sun Y and Xu Z B 2013 Grain Science & Technology & Economy 5 31-32

[11] Gao X, Chen K L, Zhang H, Peng L C and Liu Q X 2014 Bioresources 3 4094-4107

[12] Yang Z C, Liu X Z, Ye J B, Xi J Q, Shen H T, Xu H, Peng Y F, Hao H, Wang G F and Yang

Y F 2016 Journal of Henan Agricultural University 5 683-687

[13] Yao G M 2000 Tobacco Science & Technology 9 6-8

[14] Yan K Y and Liu F Z 2011 Biotechnology 4 19-22

[15] Deng G B, Li X M, Li C B, Zhou J and Zhang Z 2003 Tobacco Science & Technology 11

17-18

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

356