Effect of Polarity on Erosion of Off-line Arc in Electric

Friction Couples

L M Song

1,*

, L X Jia

1,2

and R H Zhang

1

1

Department of Materials Science & Engineering, Luoyang Institute of Science and

Technology, Henan Luoyang 471023, China

2

National United Engineering Laboratory for Advanced Bearing Tribology, Henan

University of Science and Technology, Henan Luoyang, 471023, China

Corresponding author and e-mail: L M Song, songlianmei1973@126.com

Abstract. Off-line arc in pantograph-catenary system of high-speed train affects contact and

current transmission. A series of comparative tests on erosion of off-line arc occurring with

break of contact between W probe and copper specimen at different polarities were carried

out on a home-made current-carrying arc tester. Experimental results were distinctly different

at different polarities. Arc erosion was serious when W probe was anode and copper

specimen was cathode. However, arc erosion was alleviated when W probe was cathode and

copper specimen was anode. Experimental results are discussed on basis of arc physical

essence. Experimental results have related with generation mechanisms of charged particles

and arc state and arc force. Proper match between polarity and physical properties of electric

friction couples can alleviate erosion. The study provides theory support for proposal of

electric arc power collection system.

1. Introduction

With the rapid development of global economy, high-speed railway is the most competitive and

advanced mode of transportation. Nowadays, the operating speed of high-speed trains has reached

350km/h and the required electric current and voltage are up to 1000A and 25kV respectively. Such

high traction power is transmitted to the moving trains from the ground by pantograph-catenary

system. Pantograph-catenary system is elastic and prone to vibrate at high speed, thus contact loss

occurs inevitably. Meanwhile, high current and voltage are transmitted by pantograph-catenary

system, so off-line arc occurs undoubtedly. Off-line arc damages contact surface of electric friction

couples and causes severe wear and makes electric power transmit unstably. Arc ever burned out

contact wire and led to interruption of power supply. In Japan and Germany, advanced manufacturing

and assembly technologies were adopted to avoid contact loss, but they failed [1, 2].

Much works have been carried out to understand the friction and wear properties and stability of

electric transmission of electric friction couples. Temperature of contact surface increases when

electric current passes through the contact surface between friction couples, High temperature leads

to a reduction of the bond energy in metal and causes softening of materials [3]. Meanwhile, high

temperature helps form oxidation film on the contact surface which may prevent direct contact

between friction couples, thus leads to a reduction of real contact area [4]. In addition, electrons can

Song, L., Jia, L. and Zhang, R.

Effect of Polarity on Erosion of Off-line Arc in Electric Friction Couples.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 357-363

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

357

pass through thin insulating oxidation films by the quantum tunnel effect [5]. Above reports show

that appropriate temperature on contact surface plays lubrication action and contributes to low

friction and wear and good electric conductivity. However, when arc occurs with break of contact,

surface erosion is aggravated. Thicker oxidation film makes contact resistance and surface

temperature higher [6]. The higher temperature inhibits the cohesion process between oxidation film

and the base material. When oxidation film reaches critical depth, it will break [7, 8]. Because

oxidation film is harder than the substrate, the oxide debris causes severe abrasive wear [9]. In

addition, because thick oxidation film has poor electric conductivity, charged particles will gather in

the layer and form high electric field. Once the layer thickness and electric field reach a certain value,

arc occurs again [10].

Above reports show that off-line arc play an important role in service life and electric

transmission quality of electric friction couples. However less work has been carried out that arc

alone has effect on erosion and electric transmission quality. In this study, a series of tests were

carried out at different polarities on a home-made current-carrying arc tester. Experimental results

were distinctly different at different polarities. Experimental results are discussed on basis of arc

physical essence. Experimental results have related with generation mechanisms of charged particles

and arc state and arc force. Proper match between polarity and physical properties of electric friction

couples can alleviate erosion and improve electric transmission. The study provides theory support

for proposal of electric arc power collection system.

2. Experimental apparatus and experimental procedure

2.1. Principle of experimental apparatus

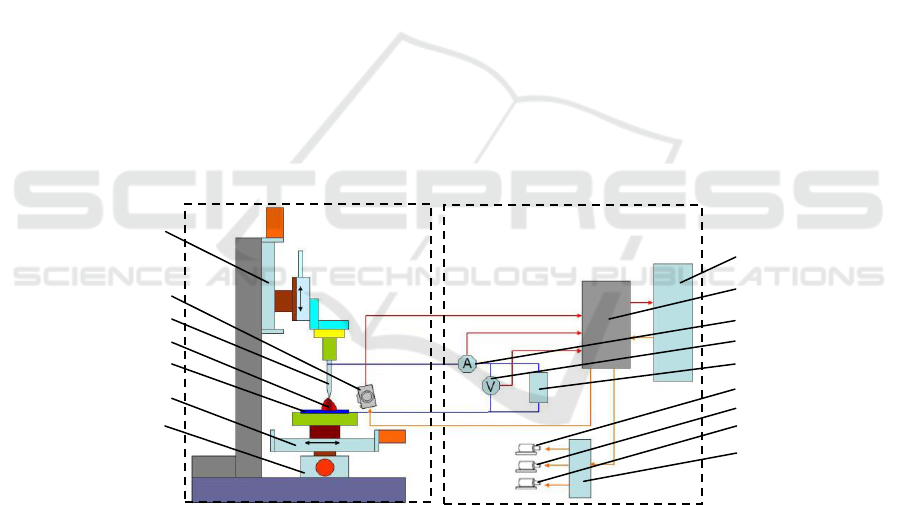

Figure 1. Principle diagram of current-carrying arc tester.

Experiment was carried out on a home-made current-carrying arc tester whose principle is shown in

Figure 1. The tester consists of mechanical and measure-control systems. In the mechanical system,

probe moves up and down at given speed by adjusting rotation rate and orientation of stepping motor

of Z direction. Meanwhile specimen moves back and forth at given speed by adjusting rotation rate

and orientation of stepping motor of X direction. When probe slides with specimen, probe and

specimen and electric source form a closed electric circuit and current is transmitted by the contact

surface between probe and copper. When probe separates from specimen, probe and arc and

specimen and electric source form a closed electric circuit and current is transmitted by arc.

Measurement-control system consists of voltage sensor and current sensor and high-speed camera. In

Arc current

Arc voltage

Arc photograph

Synchronous trigger signal

Measurement and control part

Mechanical part

Computer

Data acquisition

Motion control

X-direction motor

Y-direction motor

Z-direction motor

Electric source

Voltage sensor

Current sensor

Z-direction slipway

Probe

Arc

Specimen

Y-direction slipway

High-speed camera

X-direction slipway

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

358

addition all these data are collected synchronously by data acquisition card and are displayed on the

computer screen after treatment of software.

2.2. Experimental procedure

In the experiment probe was tungsten alloy which was made up of W and ThO

2

and the content of

ThO

2

was 0.7~0.99%. W probe was 2.4mm in diameter and 45mm in length and its end was

processed into cone which was 30 degree in angle. Specimen was pure copper which was 80mm in

length and 40mm in width and 8mm in thickness and copper specimen and W probe would be treated

with #800 metallographic abrasive papers. Electric source adopted JP50100D electric source of direct

current which could supply constant current or voltage. Experimental current was set 20A and

experimental voltage was set 25V, 30V, 35V, 40V, 45V. W probe moved up and down at 1mm/s

along Z direction and copper specimen moved back and forth at 15 mm/s along X direction. All

above parameters would be preseted before experiment.

Arc current and arc voltage were measured by current sensor and voltage sensor respectively. Arc

pictures were shot by high-speed camera. Arc dimension was obtained by measuring pixel numbers

of arc picture with the help of Image-Pro Plus software. Microstructures on the erosion surface of

electric friction couples were available by SEM.

3. Test results

3.1. Arc burning processes at different polarities

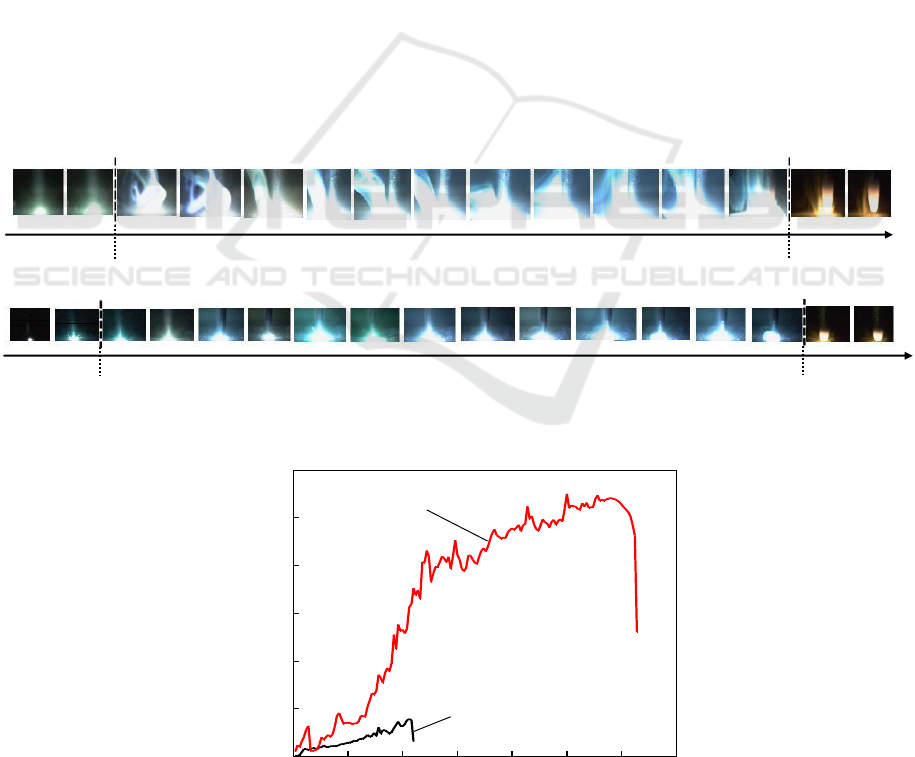

Figure 2. Arc burning processes at different polarities (30V) (a) W Probe: anode, Copper specimen:

cathode; (b) W Probe: cathode, Copper specimen: anode.

0 50 100 150 200 250 300 350

0.0

20.0k

40.0k

60.0k

80.0k

100.0k

120.0k

W probe: Cathode

Copper specimen: Anode

Arc area

A(Pixel number)

Time t(ms)

W probe: Anode

Copper specimen: Cathode

Figure 3. Variation of arc area with time at different polarities (30V).

b

Ignition

Arc burning steadily

Extinction

a

Ignitio

n

Arc burning steadily

Extinction

Effect of Polarity on Erosion of Off-line Arc in Electric Friction Couples

359

Figure 2 shows arc burning processes at different polarities. The common characteristics were firstly

arc grew up rapidly and then burned steadily along with metallic vapour and at last arc extinguished

rapidly. But arc burning processes have distinct differences at different polarities.

When W probe was anode and copper specimen was cathode, arc burned strongly with a great

deal of metallic vapours and arc was bright white. However, arc burned unsteadily and spatter flied

out, as shown in Figure 2 (a). Meanwhile arc area was large, as shown in Figure 3. When W probe

was cathode and copper specimen was anode, arc burned with a little metallic vapour and arc was

green. However, arc burned steadily and spatter flied out occasionally, as shown in Figure 2 (b).

Meanwhile arc area was little, as shown in Figure 3.

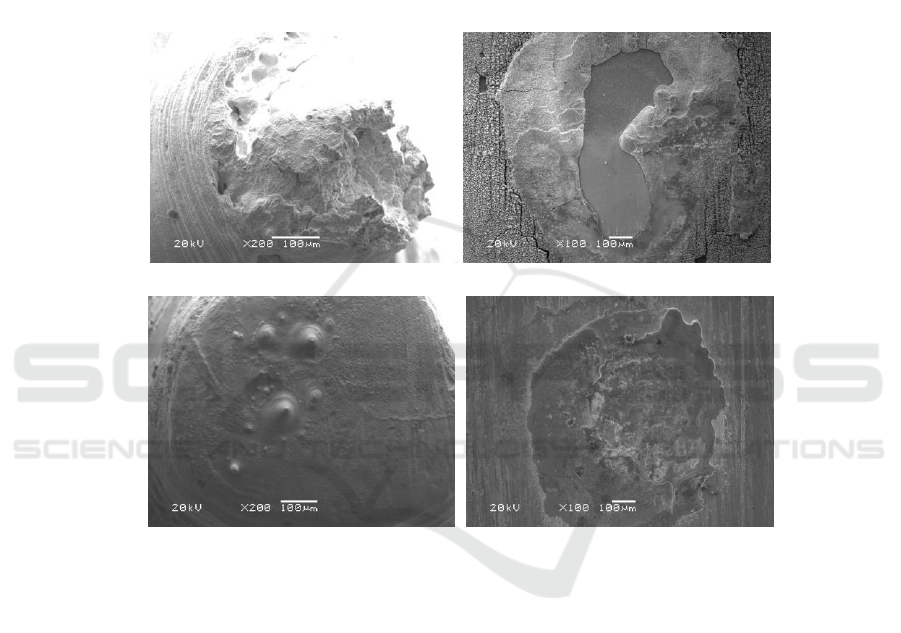

Figure 4. Micrographs of current-carrying arc erosion at different polarities (40V). (a) W probe as

anode, (b) copper specimen as cathode, (c) W probe as cathode, (d) copper specimen as anode.

3.2. Erosion of off-line arc at different polarities

Figure 4 shows SEM micrographs of off-line arc erosion of W probe and copper specimen at

different polarities. When W probe was anode and copper specimen was cathode, W probe surface

was rough and eroded badly and the surface of copper specimen form erosion pit, as shown in Figure

4 (a) (b). However, when W probe was anode and copper specimen was cathode, W probe surface

was smooth and eroded slightly and the surface of copper specimen melted only and no erosion pit

formed, as shown in Figure 4 (c) (d).

The experimental results show arc erosion was serious when W probe was anode and copper

specimen was cathode. While arc erosion was slight when W probe was cathode and copper

specimen was anode.

4. Discussions

4.1. Effect of generation mechanisms of charged particles

Current density passed by W probe is high due to its small diameter and then lots of resistance heat is

produced which makes W probe with high melting point reach high temperature. Copper specimen is

d

c

b

a

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

360

prone to melt under the high temperature of arc due to its low melting point, but copper could not

reach high temperature due to high heat conductivity.

When W probe is anode and copper specimen is cathode, W probe and copper specimen provide

anode ions and electrons respectively. W probe is impacted by electrons and kinetic energy of

electrons turns into thermal energy, and thus W probe evaporates and a great deal of metallic vapour

flows out, as shown in Figure 2 (a). Meanwhile, arc erosion of W probe is serious which is shown in

Figure 4(a). Anode ions are provided by thermal ionization in anode region of W probe. Copper

specimen is impacted by anode ions and thermal energy produces, however it cannot reach high

temperature due to high heat conductivity, and thus copper specimen surface melt alone and no

distinct evaporation happens. Because of low temperature of copper specimen surface and little

metallic vapour, it is impossible to produce enough electrons by thermal emission and ionization.

Because no enough electrons keep balance with anode ions, surplus anode ions gather above copper

specimen and high electric field intensity is formed. Electrons can be produced by electric field

emission.

When W probe is cathode and copper specimen is anode, W probe and copper specimen provide

electrons and anode ions respectively. W probe is impacted by anode ions and thermal energy is

produced. Under the thermal energy and resistance heat, W probe reaches easily high temperature

which helps W probe emit electrons by thermal emission. Meanwhile, electron emission consumes

much energy, and thus W probe surface is cooled. So erosion on the surface of W probe is slight, as

shown in Figure 4(c), and little metallic vapours are flowed out which is shown in Figure 2(b).

Copper specimen is impacted by lots of electrons and is heated, but copper specimen cannot

evaporate strongly due to its high thermal conductivity. No enough anode ions are produced by heat

ionization alone. Because no enough anode ions keep balance with electrons, surplus electrons gather

above copper specimen and high electric field intensity is formed. Anode ions can be produced by

electric field ionization.

4.2. Effect of arc state

Boddy et al. [11] found that arc between switch contacts would undergo two stages. The first stage is

described as metallic vapour state arc which mainly burns in metallic vapour. The second stage is

described as gas state arc which burns in little metallic vapour and surrounding air takes part in arc

burning. When arc transfers from metallic vapour state to gas state, arc voltage would jump.

0 20 40 60 80 100 120 140 160 180 200 220

0

4

8

12

16

20

24

28

32

36

W probe: Cathode; Copper specimen: Anode

W probe: Anode; Copper specimen: Cathode

Metallic Vapor

State

Gas State

Gas State

Arc Voltage

U(V)

Time t(ms)

Metallic Vapor

State

Figure 5. Variation of arc voltage with time at different polarities.

Effect of Polarity on Erosion of Off-line Arc in Electric Friction Couples

361

Figure 5 is variation of arc voltage with time at different polarities. When W probe is anode and

copper specimen is cathode, off-line arc is mainly metallic vapour state. When arc is in metallic

vapour state, charged particles are produced by ionization of metallic vapour. Metallic vapour is

easily ionized due to low ionization voltage, so a great deal of charged particles can keep arc burning

strongly and help current-carrying efficiency increase. However charged particles which are

produced by metallic vapour are heavy and move slowly, thus arc heat concentrates and arc erosion

gets serious. When W probe is cathode and copper specimen is anode, off-line arc quickly turns into

gas state. When arc is in gas state, air takes part in ionization. Charged particles are ionized

difficultly because of high ionization voltage of air, thus arc burns weakly. Charged particles which

are produced by air are light and move quickly, thus arc heat disperses and arc erosion is alleviated.

5. Conclusions

Electric erosion of current-carrying arc was distinctly different at different polarities.

The forming mechanisms of charged particles were different at different polarities. When W

probe was anode and copper specimen was cathode, W probe produces anode ions by

thermal ionization and copper specimen emitted electrons by thermal emission and electric

field emission; When W probe was cathode and copper specimen was anode, W probe emits

electrons by emitted electrons by thermal emission and copper specimen produced anode

ions by electric field emission.

Arc state was different at different polarities. When W probe was anode and copper

specimen was cathode, current-carrying arc was mainly metallic vapor state and thus arc

burned easily but erosion was serious; When W probe was cathode and copper specimen was

anode, current-carrying arc was mainly gas state and thus arc burned difficultly but erosion

was light.

Proper match between polarity and physical properties of electric friction couples can

alleviate erosion and improve electric transmission. The study provides theory support for

proposal of electric arc power collection system.

References

[1] Gao Z B, Wu G N, Lu W, He C H, Zhou L and J 2009 Research review of arc phenomenon

between pantograph and catenary in high-speed electrified railway High Voltage Apparatus

45:104-108

[2] Lei D, Wu G N, Zhang X Y, Wang W G and He C H 2008 Research of a method of inhibition

of electric arc between pantograph and catenary in high-speed electrified railway Electric

Railway 5:1-4

[3] Holm R 1967 Electric Contacts Germany: Springer-Verlag 7

[4] Zaidi H., Chin K J and Frene J 2001 Analysis of surface and subsurface of sliding electrical

contact steel/steel in magnetic Surface and Coatings Technology 148: 241-250

[5] Fisher J C and Giaever I 1961 Tunneling through thin insulating layers Journal of Applied

Physics 32(2): 172-177

[6] Mansori M EI, Paulmier D, Ginsztler J and Horvath M 1999 Lubrication mechanisms of a

soliding contact by simultaneous action of electric current and magnetic field Wear

225~229:1011-1016

[7] Wang Y A, Li J X, Yan Y and Qiao L J 2012 Effect of electrical current on tribological

behavior of copper-impregnated metalized carbon against a Cu-Cr-Zr alloy Tribology

International 50:26-34

[8] Csapo E, Zaidi H and Paulmier D 1996 Friction behavior of a graphite-graphite dynamic

electric contact in the presence of argon Wear 192:151-156

[9] Shunichi K and Koji K 1999 Effect of arc discharge on the wear rate and wear mode transition

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

362

of a copper-impregnated metalized carbon contact strip sliding against a copper disk

Tribology International 32:367-378

[10] Wang Y A, Li J X., Yan Y and Qiao L J 2012 Effect of surface film on sliding friction and

wear of copper-impregnated metalized carbon against a Cu-Cr-Zr alloy Applied Surface

Science 258:2362-2367

[11] Rong M Z 1999 Electrical Contacts Fundamentals Xi’an: Xi’an Jiao Tong University 38-45

Effect of Polarity on Erosion of Off-line Arc in Electric Friction Couples

363