Hierarchical Porous Carbon Materials Derived from

Microwave-assisted Heating of Zeolitic Imidazolate

Frameworks for Use as Supercapacitor Electrodes

J Z Zou

1, 2

, S Y Liu

1

, H L Wu

1,*

, Q Luo

1

, L Huang

1,3

, X R Zeng

1,2

, J Ma

1

, Y C

Yao

1

, Q Zhang

4

and B L Peng

1

1

Shenzhen Key Laboratory of Special Functional Materials & Shenzhen Engineering

Laboratory for Advance Technology of ceramics, College of Materials Science and

Engineering, Shenzhen University, Shenzhen, 518060. P.R. China

2

Guangdong JANUS Intelligent Group Corporation Limited, Dongguan, 441900,

P.R. China

3

Key Laboratory of Optoelectronic Devices and Systems of Ministry of Education

and Guangdong Province, College of Optoelectronic Engineering, Shenzhen

University, Shenzhen 518060, P.R. China

4

School of Aerospace, Transport and Manufacturing, Cranfield University, Cranfield,

Bedfordshire, MK43 0AL, UK

Corresponding author and e-mail: H L Wu, whl@szu.edu.cn

Abstract. A series of hierarchically structured nanoporous carbons are prepared via the direct

carbonization of zeolitic imidazolate frameworks (ZIF-8) using a microwave-assisted heating

method for the first time. The results indicate that the microwave carbonization temperature

has a remarkable influence on the surface area and pore structure of the obtained porous

carbons. ZIF-8 provides the carbon and the microporous structure. Significant numbers of

mesopores and macropores emerge in the samples carbonized at high temperatures, indicating

a clear d ifference from carbons prepared using traditional heating methods. The resulting

porous carbons possess surface areas ranging from 384.4 to 947.5 m

2

g

-1

and pore volumes

ranging from 0.17 to 0.49 cm

3

g

-1

. For a carbonization temperature of 1000 °C , the porous

carbon possesses the largest specific capacitance of 207.7 F g

-1

at 0.1 A g

-1

and the highest

retention of 66.5% when the current density increases from 0.1 to 10 A g

-1

, which should be

attributed to the proper hierarchical pore structure and the relatively high graphitization

degree.

1. Introduction

Due to the rapid consumption of fossil fuel resources and associated environmental problems,

research into efficient energy storage systems has attracted considerable interest. Among the various

energy storage devices, compared to traditional batteries, supercapacitors have attracted more and

more attention due to their high power densities, fast charging and discharging characteristics, long

cycle lives, less environmental pollution, etc. These devices have been widely used in digital devices,

electric vehicles, communication technologies and other fields [1-3]. Research has been focused on

Zou, J., Liu, S., Wu, H., Luo, Q., Huang, L., Zeng, X., Ma, J., Yao, Y., Zhang, Q. and Peng, B.

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as Supercapacitor Electrodes.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 571-583

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

571

increasing the energy density of supercapacitors without weakening the high power density and

stable cyclic life. Currently, nanoporous carbon (NPC) materials are identified as one of the most

promising candidates for supercapacitor electrode materials due to their high thermal and chemical

stabilities, large specific surface areas, controllable pore structures, high conductivities, easy

manufacturing in large quantities with relatively low costs, etc [4-6]. In the electrochemical capative

performance, the pore size distributions of the porous carbons play an important role, and a

hierarchical pore structure with well-interlinked small and large pores is regarded to provide new

accesses to improve both the specific capacitances and rate capabilities of porous carbons as

supercapacitor electrodes [7-12]. As a result, many approaches have been studied to prepare highly

porous carbons and adjust their pore structures, including laser ablation [13], chemical vapour

decomposition (CVD) [14], arc discharging [15] and templating [16,17], as well as physical or

chemical activation methods [18]. Among these methods, the template method has become one of the

most studied approaches for the preparation of nanoporous carbons due to its regulated architecture,

relatively narrow pore size distribution, and desirable physicochemical properties [19]. However, the

templating process requires additional pore-forming templates and acid treatment steps to remove the

templates, which result in enhancement of preparation cost and difficulty of utilization for large-scale

production.

To solve these major problems, a class of novel porous materials, crystalline metal-organic

frameworks (MOFs), have attracted an enormous amount amount of attention because they can act as

excellent precursors or sacrificial templates for the preparation of nanoporous carbons (NPCs) due to

their extremely high specific surface areas, favourable thermal stabilities, tailored pore structures and

adjusted channels [20-23]. Importantly, MOFs can act as both the templates and the carbon sources,

thus reducing the producing and purifying steps to obtain the resulting porous carbon.

Currently, it is widely used for the carbonization technique to prepare hierarchically nanoporous

carbons by selecting appropriate carbon sources or precursors. However, this kind preparation

method of nanoporous carbons is still unfavourable because there is always a very slow heating rate

with the conventional heating techniques (tube furnace), which makes the carbonization expensive

and difficult to scale up. Moreover, carbon materials prepared in this way can only generate similar

pore structures to the MOFs precursors, lacking variety if there is no other treatment. Microwave-

assisted heating, which arises from the direct interaction of matter with electromagnetic energy, has

attracted an increasing attention due to its potential advantages over traditional heating techniques

[24]. These advantages include a remarkable decrease in heat-up time, a smaller requirement of

energy, fewer steps involved in the heating process, a more sensitive and efficient operating system,

etc. The final samples obtained from the microwave-assisted heating method will most likely be

more economically competitive than those obtained using conventional methods [25].

In this work, we choose ZIF-8 as a precursor for the preparation of nanoporous carbons using a

microwave-assisted heating method. The approach presented here does not require any addition of

carbon sources or pore-forming templates. Furthermore, the surface area and pore structure are easily

regulated by controlling the microwave carbonization temperature. The resulting ZIF-derived

nanoporous carbons are comprehensively characterized using a varieties of techniques. It is discussed

in detail for the structural evolution of the nanoporous carbons with increasing temperature and their

electrochemical behaviour as electrode materials for supercapacitors.

2. Experimental section

2.1. Preparation of ZIF-8

ZIF-8 powder was synthesized on the basis of the method reported in the literature [26]. All

chemicals were purchased from Aladdin Chemical Co (Shanghai China). First, 2.62 g of zinc nitrate

hexahydrate (Zn (NO

3

)

2

·6H

2

O) was dissolved in 100 mL of methanol to form solution A, and 5.79 g

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

572

of 2-methylimidazole (MmIm) was dissolved in 100 mL of methanol to generate solution B. Then,

two solutions above were mixed up and stirred for 1 h at room temperature. After that, the resulting

milky solution was centrifuged at 10000 rpm for 5 min, and the supernatant was removed. The

precipitates was washed with methanol and centrifuged again. The whole process was repeated twice.

The resulting powder was dried in an oven at 60 ºC overnight.

2.2. Preparation of nanoporous carbon (NPC)

Five nanoporous carbons were prepared from direct carbonization of ZIF-8 using a microwave-

assisted heating method as follows: First, a quartz tube with 0.8 g of dried ZIF-8 powder was inserted

into an alumina crucible filled with SiC powder (a microwave absorber), which has a critical

auxiliary heating effect. Then, the whole alumina crucible was wrapped with asbestos and placed in a

microwave furnace. The furnace was heated up to the required carbonization temperature (600, 700,

800, 900 or 1000 °C) at a very high rate of heating (generally within 5 min) under a nitrogen

atmosphere with a gas pressure of 20 kPa. Then the target temperature was maintained for 3 h,

followed by cooling to room temperature in nitrogen. After treated with an aqueous solution of HCl

(0.1 M) to remove Zn or ZnO residue from the decomposition of ZIF-8 template, the as-prepared

nanoporous carbon materials were denoted as NPC-600, NPC-700, NPC-800, NPC-900, and NPC-

1000 respectively. For comparison, another carbon sample was obtained by direct carbonization of

ZIF-8 using a tube furnace. Firstly, the furnace was filled with nitrogen gas at room temperature.

Then, the furnace was heated up to 1000 °C at a conventional rate of 5 °C/min and held at 1000 °C

for 3 h. After the furnace was cooled to room temperature in nitrogen, the carbon sample was treated

with 0.1 M HCl and labelled as NPC-T-1000.

2.3. Characterization

X-ray diffraction (XRD) patterns were obtained on a Bruker D8 advance powder X-ray

diffractometer using Cu Kα radiation (20 kV, 200 mA, λ=1.54178 Å) with a step size of 0.02° and

step time of 0.5 s. Scanning electron microscopy (SEM) images were examined using a Hitachi SU-

70 scanning electron microscope at an acceleration voltage of 20 kV. Nitrogen adsorption-desorption

curves were recorded using a micrometrics ASAP 2020 instrument at liquid nitrogen temperature (77

K). All samples were degassed at 523 K for 4 h before measurement. The Brunauer-Emmett-Teller

(BET) surface areas were calculated from the nitrogen isotherm curves ranging from the relative

pressure of 0 to 0.3. The total pore volumes were determined from the amount of nitrogen adsorbed

at P/P

0

of ca. 0.99. The pore size distributions (PSDs) were determined using a density functional

theory (DFT) method. The micro- and mesopore volumes were obtained using adsorption isotherms

from a DFT method, and the macropore volumes were determined by subtracting the micro- and

mesopore volumes from the total pore volume. Transmission electron microscope (TEM) images

were obtained using a Joel JEM-2100 at an acceleration voltage of 100 kV. Laser Raman

spectroscopy was performed on a Renishaw inVia Reflex.

2.4. Electrode preparation and electrochemical performance test

All electrochemical performances were examined on a standard three-electrode electrochemical

station,

which was equipped with a counter electrode of Pt, a reference electrode of Hg/HgO, and a working

electrode of ZIF-derived nanoporous carbon in 6 M KOH. The working electrode was prepared by

mixing up ZIF-derived nanoporous carbon (85 wt%), acetylene black (10 wt%) and

polytetrafluoroethylene (5 wt%) with moderate ethanol to form slurry and then coat onto a nickel

foam with a coating area of 1 cm

2

, The foam was dried at 110 °C in vacuum oven overnight, Then, in

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as

Supercapacitor Electrodes

573

order to completely adhere with the electrode material, the foam was pressed under a pressure of 10

MPa. The mass loading of active materials on the prepared working electrode is nearly 5 mg cm

-2

.

All electrochemical experiments were performed at ambient temperature on a CHI660e

electrochemical workstation (Shanghai Chenhua Instruments Co.). Before the measurements, the

working electrodes were soaked in electrolyte for half an hour so that the active materials could be

fully infiltrated by the electrolyte. The primary testing method was cyclic voltammetry (CV) at

different scan rates ranging from 5 to 200 mV s

-1

. Galvanostatic charge/discharge (GC)

measurements were also performed at different current densities raging from 0.1 A g

-1

to 10 A g

-1

in

the potential range of -1.0~0 V. Electrochemical impedance spectra (EIS) were measured over the

frequency ranging from 100 kHz to 0.01 Hz with an alternate current perturbation of 5 mV at open

circuit voltage. The EIS data were analysed using Nyquist plots with the real part (Z') and imaginary

part (Z'') of impedance marked as the X-axis and Y-axis, respectively.

For galvanostatic charge/discharge processes, the specific capacitances were calculated using the

following equation[27]: C

m

=IΔt(mΔV)

-1

. In this equation, C

m

(F g

-1

) is the specific capacitance, I (A)

represents the discharge current, Δt (s) represents the discharge time, m (g) refers to the mass of

active material on the electrode, and ΔV (V) is the voltage change within the discharge time.

3. Results and discussion

3.1. Structure and texture characterization

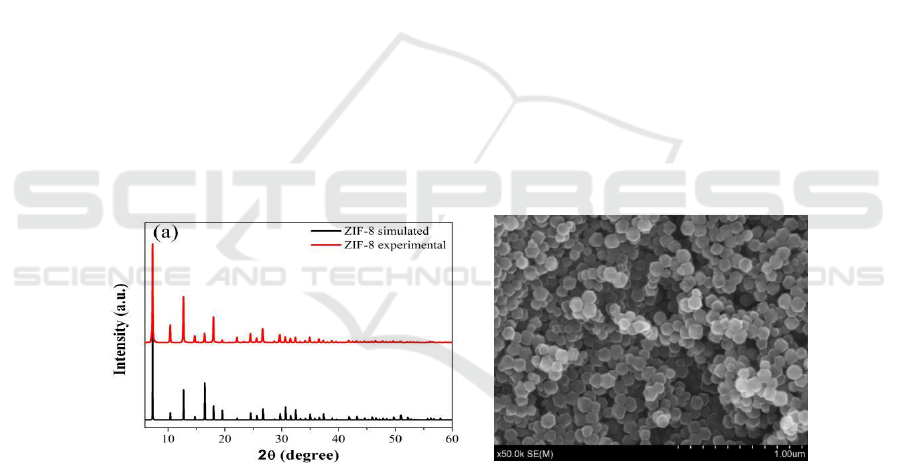

Figure 1 shows the XRD and SEM images of as-synthesized ZIF-8. The XRD pattern of ZIF-8

powder is in great agreement with the simulation, suggesting that the ZIF-8 material has been

synthesized successfully [28]. And the SEM image shows a typical rhombic dodecahedron

morphology of ZIF-8 with a particle size of approximately 100 nm.

Figure 1. (a) XRD pattern and SEM image of ZIF-8.

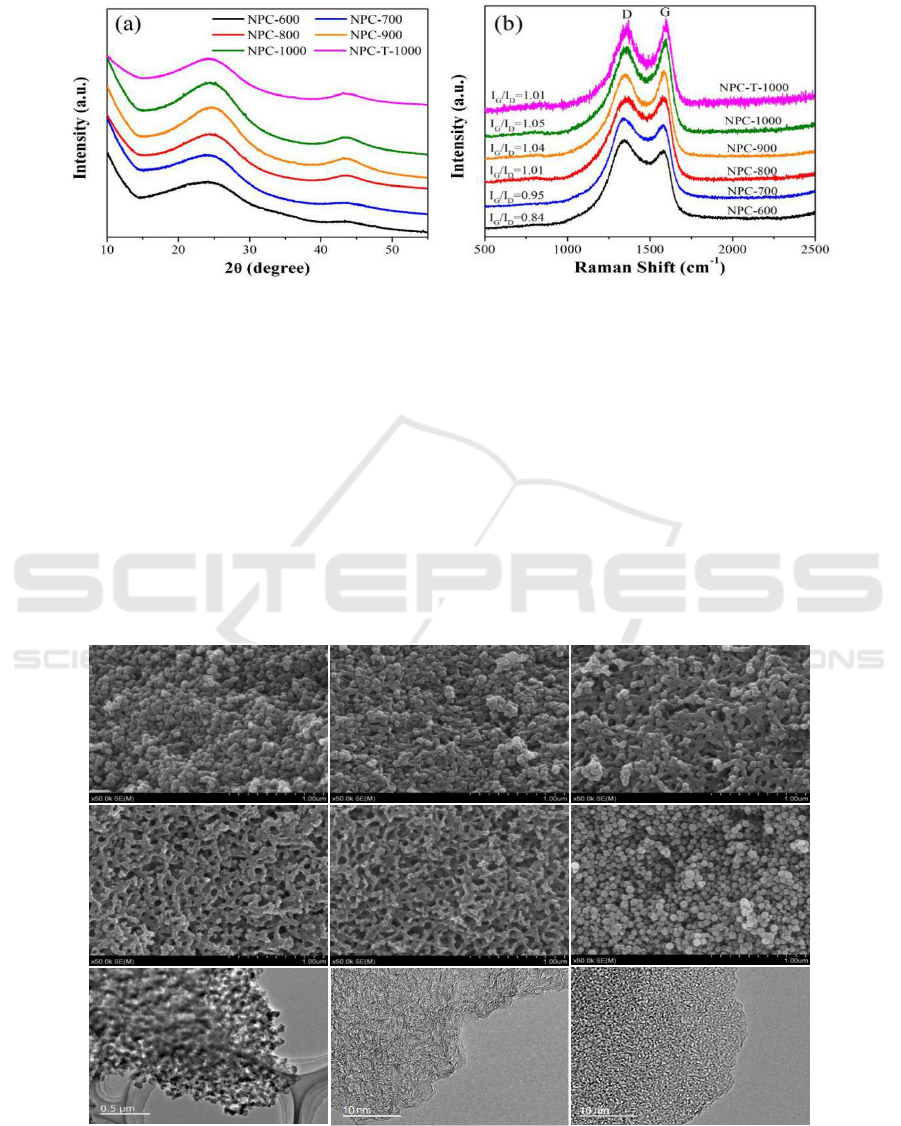

XRD patterns of NPC-600, NPC-700, NPC-800, NPC-900, NPC-1000 and NPC-T-1000 are

shown in Figure 2a. As we can see, after carbonization, all of the resulting porous carbon samples

lose the characteristic XRD peaks of the parental ZIF-8, and display two broad peaks at 2 = 23° and

44°, which are corresponding to the (002) and (101) planes of graphitic carbon. The (002) refers to a

graphite-like peak, and (101) is related to the honeycomb lattice in single-layer graphene [29, 30].

Two broad diffraction peaks of NPC-1000 are the most noticeable among six ZIF-derived

nanoporous carbon samples, indicating that NPC-1000 may hold better electrical conductivity and

crystalline degree.

(b)

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

574

Figure 2. Powder XRD patterns and Raman spectra of six ZIF-derived nanoporous carbons.

To further study the graphitization degree of the six ZIF-derived nanoporous carbons, Raman

spectra are given in Figure 2b. There are two featured broad peaks centered at approximately 1580

cm

-1

and 1360 cm

-1

, which are named the G band (graphite) and D band (disorder) respectively. The

G band presents ideal graphitic sp

2

carbons, and the D band relates to disordered carbons [31, 32].

Generally, the graphitization degree of porous carbons can be estimated by comparing the relative

intensity ratio of the G band to the D band (I

G

/I

D

) [33]. The ZIF-derived nanoporous carbon samples

exhibited a gradual increase in I

G

/I

D

values from 0.84 to 1.05 as the microwave carbonization

temperature increased from 600 to 1000 °C, indicating that these nanoporous carbons possess both

graphitic and disordered structures [34] and a higher carbonization temperature contributes to the

generation of graphitic sp

2

carbons. In addition, NPC-T-1000 achieves a lower I

G

/I

D

value than NPC-

1000, which exhibits that microwaves are conducive to the formation of graphite carbon.

Figure 3. SEM images of six ZIF-derived nanoporous carbons: (a) NPC-600, (b) NPC-700, (c) NPC-

800, (d) NPC-900, (e) NPC-1000, (f) NPC-T-1000 and representative TEM images of NPC-1000 (g,

h) and NPC-T-1000 (i).

(h)

(a)

(c)

(d)

(e

)

(g)

(b)

(f)

(i)

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as

Supercapacitor Electrodes

575

To explore the morphologies and structures of the six as-prepared ZIF-derived nanoporous carbon

materials, both SEM and TEM analyses were performed. As shown in Figure 3, apparent

morphological changes occur in the ZIF-derived nanoporous carbons. NPC-600 turns into spherical

particles with a decreased particle size of approximately 75 nm, which is similar to NPC-T-1000. As

the temperature increased to 800 °C , the sample cannot maintain the typical granular morphology

well and undergoes particle bonding, forming interconnections between particles. In particular, for

NPC-1000, instead of a typical granular morphology, a three-dimensional network morphology

derived from interconnected particles has been adopted, generating obvious mesopores in the range

of 30-40 nm and macropores in the range of 60-100 nm. Obviously, the morphologie and structure of

NPC-1000 is quite distinct from the carbon material prepared by direct carbonization of ZIF-8 using

a tube furnace [34, 35]. This indicates that the heating mode have important influence on the pore

structure of carbon materials and the microwave-assisted heating process can be explained as follows:

it generates a large amount of thermal energy when using microwave-assisted heating method to

carbonize ZIF-8 at a very fast heating rate. Thus, the organic species of ZIF-8 are quickly

decomposed, but the evacuating speed is far slower than the decomposing speed, so some of the

released linkers or atoms return to form bonds with each other, which appear as macroscopic particle

interconnections. As the temperature increased higher, large numbers of meso- and macropores

appear due to the large improvement in the evacuating and decomposing efficiency of ZIF-8.

Representative TEM images for NPC-1000 and NPC-T-1000 are presented in Figure 3 (g, h).

Mesopores and macropores are clearly visible in NPC-1000, and the high-resolution TEM reveals

that the sample possesses many micropores over the entire sample surface with a well-developed

graphitic structure while NPC-T-1000 is nearly amorphous. The relatively high graphitization degree

of NPC-1000 makes it a better electrical conductivity, which play an important role in

electrochemical performance.

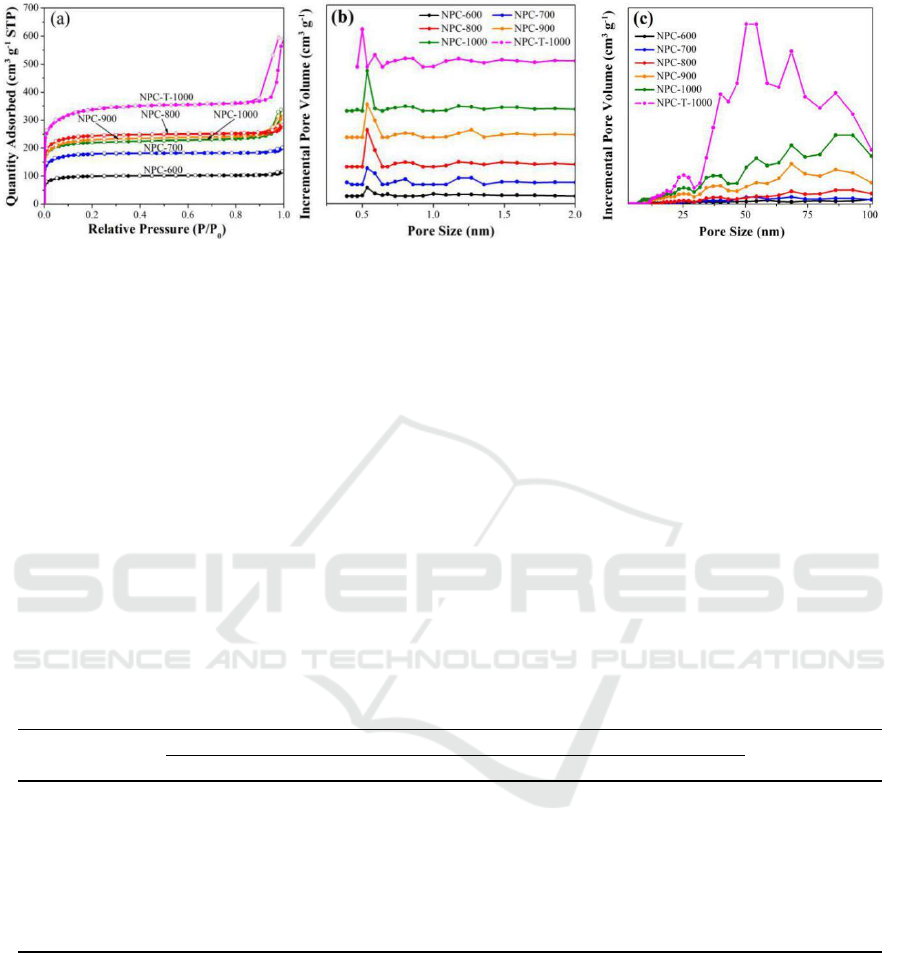

The nitrogen adsorption-desorption isotherms at 77 K (Figure 4a) were used to measure the

specific surface areas and nanopores of the obtained porous carbons. At low relative pressure

(P/P

0

<0.1), all six porous carbons display significant nitrogen adsorption, which is in agreement with

type I adsorption-desorption isotherm, indicating the development of microporosity. The isotherms

for all the porous carbons are extremely similar, and the adsorption-desorption isotherm branches are

almost reversible, indicating that all the carbons are predominantly microporous, which is

corresponding to micropore structures presented in the parental ZIF-8 that acts as both the template

and the carbon precursor [35]. In particular, for NPC-900 and NPC-1000, there appear hysteresis

loops at high relative pressure (P/P

0

>0.8), indicating the existence of partial mesopores or

macropores in the carbons, which is in great agreement with the SEM and TEM results. It should be

noted that NPC-T-1000 give the isotherm with a larger hysteresis loop than that of NPC-1000 over

the relative pressure from 0.8 to 1.0. This is come from the interparticle space among the assembled

small-sized particles rather than porosity in the material itself, which is invalid in electrochemical

behaviour. The textural properties of the carbons are listed in Table 1. The BET surface areas and

total pore volumes of six carbon samples are in the ranges of 384.4-1281.4 m

2

g

-1

and 0.17-0.87 cm

3

g

-1

. Among them, NPC-T-1000 shows the highest surface area of 1281.4 m

2

g

-1

, and the largest total

pore volume of 0.87 cm

3

g

-1

due to the rich intergranular space. In comparison, NPC-1000 possesses

lower values of 852 m

2

g

-1

and 0.49 cm

3

g

-1

respectively. The proportion of micropore surface area

for the carbon materials using micro-assisted heating method is approximately 95%, and the

proportion of mesopore and macropore volume varies from 35% to 41%. The relatively low

micropore contributions for NPC-900 and NPC-1000 can be attributed to the complete

decomposition of ZIF-8 and the formation of particle interconnections at high microwave

carbonization temperature, leading to the formation of mesopores and macropores. NPC-1000 has the

largest proportion of mesopore and macropore volume of 41%, which may make the sample a faster

electron transfer.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

576

Figure 4. N

2

adsorption-desorption isotherms (a) and the corresponding pore size distributions of

the ZIF-derived nanoporous carbons at different temperature, (b) micropore size distribution, (c)

meso- and macropore size distribution.

To obtain more detailed information about the nanoporous structures, the pore size distributions

(PSDs) (Figure 4b, c) were calculated using density functional theory based on the N

2

adsorption data.

Five ZIF-derived nanoporous carbons using microwave-assisted heating exhibit narrow and sharp

micropore size distribution centred at approximately 0.6 nm, while NPC-T-1000 suffers a smaller

micropore size less than 0.5 nm. Small micropores may lead to low efficiency in capacitive

performance, NPC-900 and NPC-1000 also possess macropores larger than 50 nm and mesopores of

20-50 nm. There are some other differences among the materials carbonized at different microwave

carbonization temperatures. The PSD peaks of the samples carbonized at high temperature are higher

than those of the low-temperature carbonized samples, and the micropore size of the carbons is

slightly increased with increasing microwave carbonization temperature, indicating that the

microwave holding temperature has a significant effect not only on the surface area and pore volume

but also on the pore diameter and amount.

Table 1. Surface area, pore volume and capacitance of ZIF-derived nanoporous carbons.

Samples

surface area (m

2

g

-1

)

Pore volume (cm

3

g

-1

)

C

m

f

(F g

-1

)

S

BET

a

S

micro

b

V

t

c

V

micro

d

V

meso/macro

e

NPC-600

384.4

367

0.17

0.11

0.06

109.6

NPC-700

693.1

669.4

0.30

0.23

0.07

149.9

NPC-800

947.5

906

0.42

0.32

0.1

194.3

NPC-900

886.9

832.2

0.47

0.29

0.18

201.1

NPC-1000

852

799.1

0.49

0.29

0.2

207.7

NPC-T-1000

1281.4

1161.9

0.87

0.41

0.46

181.5

a

Brunauer-Emmett-Teller (BET) surface area.

b

Microporous surface area.

c

Total pore volume at P/P

0

=0.99.

d

Micropore volume.

e

Mesopore and macropore volume.

f

Specific capacitance at a current density of 0.1 A g

-1

.

3.2. Electrochemical analysis

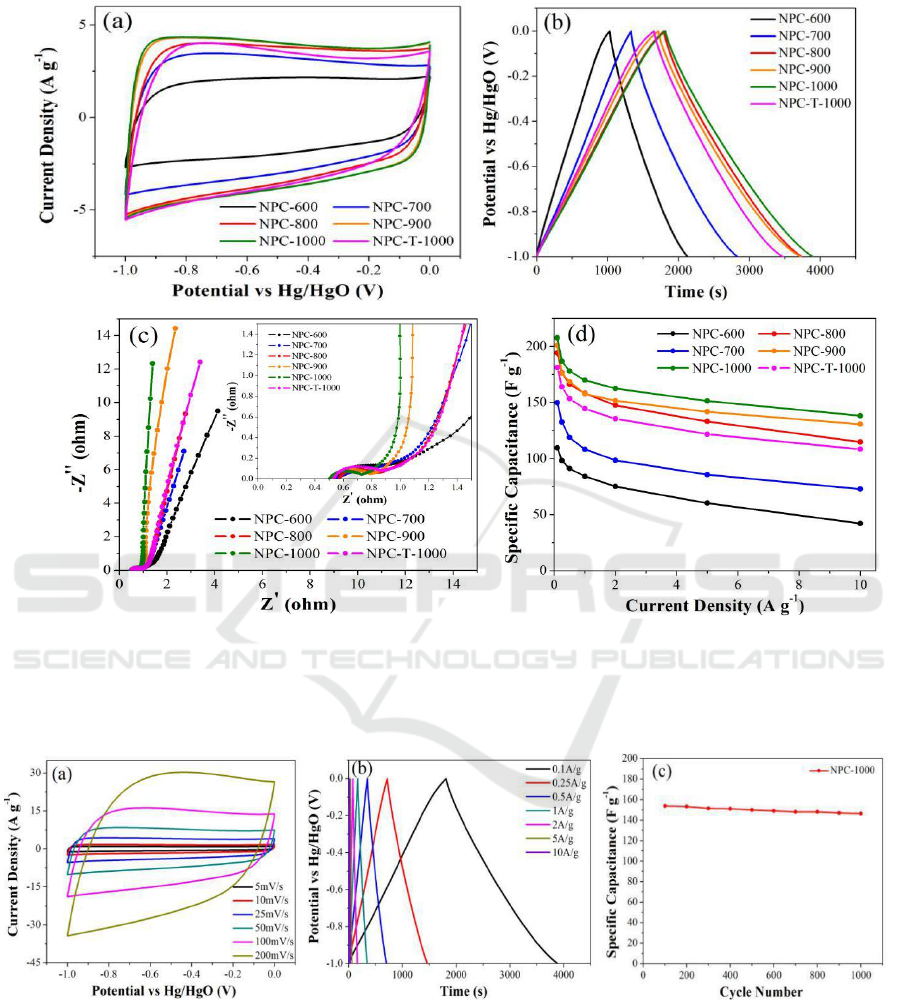

To investigate the capacitive performance of the six ZIF-derived nanoporous carbons, the CV, GC,

and EIS were measured. The CV curves of the ZIF-derived nanoporous carbons at a scan rate of 25

mV s

-1

are illustrated in Figure 5a, the cyclic voltammetry curves for all ZIF-derived nanoporous

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as

Supercapacitor Electrodes

577

carbons exhibit a nearly rectangular shape, which is typical behaviour for supercapacitors [36,37].

Compared to all other carbon samples, NPC-1000 shows the largest CV area and a more rectangular

shape. The GC curves (Figrue 5b) at a current density of 0.1 A g

-1

are symmetric, and NPC-1000

possesses the longest discharge time. The specific capacitances of the six nanoporous carbons are

listed in Table 1, these values were calculated according to the discharge process. Obviously, NPC-

1000 presents the largest capacitance value of 207.7 F g

-1

compared to other porous carbons. This

result presumably arises from both the higher percentage of graphitic carbons and the suitable

hierarchical micro/meso/macropores structure of NPC-1000, which are advantageous for electrical

conductivity and quick diffusion of electrolyte to the electrode [38-40]. It must be noted that although

NPC-T-1000 possesses the largest value of surface area, its capacitance is only 181.5 F g

-1

, which is

even lower than the values of NPC-800 and NPC-900. The phenomenon reveals that capacitance is

not in direct proportion to the specific surface area, there is only part of micropores are in effective

use when the charge is transfered.

Figure 5c shows the electrochemical impedance spectroscopy, providing available details about

the frequency responses of six ZIF-derived nanoporous carbons as supercapacitor electrode materials.

In the high frequency region, the Nyquist plots exhibit depressed semicircles for the carbons (see the

inset of Figrue 5c), which is related to the charge transport resistance between the electrode and

electrolyte [41]. NPC-1000 shows a smallest crossing value of the Z’ axis, which indicates that NPC-

1000 has lower interfacial contact resistance, because NPC-1000 possesses a hierarchical pore

structure, which is favourable for electrolyte ion migration. In the low frequency region, the larger

the curve slope, the better the capacitive behaviour. A vertical curve indicates ideal capacitive

behaviour and a fast transportation of the electrolyte ions in the nanopores of the carbon materials

[42]. A shift of the vertical curve could result from the Warburg resistance for the electrolyte ions.

Obviously, the EIS curve for NPC-1000 shows the largest value of curve slope, i.e., the lowest

Warburg resistance, which demonstrates that NPC-1000 possesses the best electrical properties

among the nanoporous carbons to act as an electrode material. The specific capacitances of six ZIF-

derived nanoporous carbons at different current densities are presented in Figure 5d. Obviously,

NPC-1000 shows the best capacitive performance. Detailedly, NPC-1000 shows the highest

capacitance of 207.7 F g

-1

at 0.1 A g

-1

. Moreover, the capacitance of NPC-1000 still keep 66.5%

when increasing the current density from 0.1 to 10A g

-1

. In comparison, NPC-T-1000 achieves lower

values of 181.5 F g

-1

and 60.1% under the same test conditions. Obviously, NPC-1000 achieves the

largest retention among the six nanoporous carbon samples.

To further study the electrochemical performance of NPC-1000, we performed a series of

capacitive measurements at different current densities and different scan rates (Figure 6). Figure 6a

exhibits the CV curves of NPC-1000 at different scan rates of 5, 10, 25, 50, 100 and 200 mV s

-1

, all

of them are in typical rectangular shape. At 200 mV s

-1

, the CV curve suffers from some slight

distortion, which may result from the limited mass transfer or ion transport [43]. As shown in Figure

6b, the triangle charge/discharge curves of NPC-1000 exhibit almost linear and symmetrical shapes

at different current densities ranging from 0.1 to 10 A g

-1

, indicating that the NPC-1000 electrode

possesses good electrochemical reversibility [44]. The capacitance of NPC-1000 reaches 207.7 F g

-1

at 0.1 A g

-1

. It must be noted that this value is much larger than the ones of ZIF-8-derived nanoporous

carbons using traditional carbonization method, like Z-800 derived from direct carbonization of ZIF-

8 carbonized at 800 °C (130F g

-1

at a scan rate of 50 mV s

-1

) and Z-1000 at 1000 °C (112F g

-1

at a

scan rate of 50 mV s

-1

) [31]. In addition, it was investigated and shown in Figure 6c for long-term

cycle stability of NPC-1000 at a current density of 5 A g

-1

. The capacitance of NPC-1000 keeps

almost unchanged and only 4.7% of capacitance is lost after 1000 cycles, indicating that the material

structures of NPC-1000 are very stable in the charge and discharge process.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

578

Figure 5. Electrochemical properties of ZIF-derived nanoporous carbons. (a) Cyclic voltammetry

curves at 25 mV s

-1

, (b) galvanostatic charge and discharge curves at 0.1 A g

-1

, (c) impedance

spectroscopy, and (d) specific capacitance at different current densities.

Figure 6. Capacitive performance of NPC-1000. (a) Cyclic voltammetry curves at different scan

rates, (b) galvanostatic charge and discharge curves at different current densities, and (c) cycling

stability at 5A g

-1

.

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as

Supercapacitor Electrodes

579

Table 2. MOFs derived nanoporous carbons for supercapacitor.

Samples

BET

(m

2

g

-1

)

Electrolyte

Scan rate

(mV s

-1

)

Current

density

(A g

-1

)

Capacitance

(F g

-1

)

Ref.

NPC-1000

838

6 M KOH

0.1

207.7

this work

Z-700

520

0.5M H

2

SO

4

50

—

23

31

Z-800

720

0.5M H

2

SO

4

50

—

130

31

Z-900

1075

0.5M H

2

SO

4

50

—

128

31

Z-1000

1110

0.5M H

2

SO

4

50

—

112

31

MC

1812

6M KOH/1.5M,

NEt

4

BF

4

acetonitrile

—

0.25

149/113

44

C800

2169

1 M H

2

SO

4

5

—

188

45

C1000

3405

1 M H

2

SO

4

5

—

161

45

C-MOF-5

2119

1 M H

2

SO

4

—

1

150

46

C-MOF-2

1378

1 M H

2

SO

4

—

1

170

46

C-Zn-BTC

1326

1 M H

2

SO

4

—

1

134

46

C-Zn-NDC

920

1 M H

2

SO

4

—

1

114

46

C-Zn-ADA

513

1 M H

2

SO

4

—

1

95

46

C-Zn-PAA

495

1 M H

2

SO

4

—

1

110

46

4. Conclusions

In summary, we have used, for the first time, a microwave-assisted heating technique to efficiently

prepare hierarchical porous carbon materials via the direct carbonization of ZIF-8 without any

additional carbon sources. In this study, the surface areas and pore structures of the resulting carbons

were easily controlled by the microwave carbonization temperature. The obtained ZIF-derived

nanoporous carbons exhibit specific surface areas in the range of 384.4-947.5 m

2

g

-1

and pore

volumes in the range of 0.17-0.49 cm

3

g

-1

. These porous carbon materials are mainly composed of

micropores, but certain amounts of mesopores and macropores emerge due to the interconnection of

nanoparticles when the carbonization temperature is higher than 800 °C, which is quite different from

carbon material prepared using traditional heating techniques. Of all the ZIF-derived nanoporous

carbons examined, NPC-1000 possesses the highest percentage of mesopores and macropores and

achieves the highest capacitance of 207.7 F g

-1

at a current density of 0.1 A g

-1

, due to its higher

percentage of graphitic carbons and proper hierarchical pore structure. Moreover, NPC-1000 also

shows excellent rate capability as a capacitor electrode material. The capacitance retention of NPC-

1000 is 66.5% when the current density changes from 0.1A g

-1

to 10A g

-1

. Therefore, microwave-

assisted heating is a very promising technique for the synthesis of MOF-derived nanoporous carbons.

In particular, it can be used as a reference route for the preparation of hierarchical porous carbon

materials. Future work will focus on improvements to provide improved microwave power control

and allow the carbonization of other MOF precursors.

Acknowledgment

We thank the editor and reviewers for their valuable comments and suggestions and Shenzhen

University for the financial support. This research work was supported by National Natural Science

Foundation of China (Nos. 51202150 and 51272161), Science and Technology R&D Program of

ShenZhen (JCYJ20150324141711663), Program of Introducing Innovative Research Team in

Dongguan (No.2014607109) and Open Foundation of Yanshan University Aviation Key Laboratory

of Science and Technology on Generic Technology of Self-Lubricating Spherical Plain Bearing

(No.HKKJ20140802).

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

580

References

[1] Winter M and Brodd R J 2004 What are batteries, fuel cells, and supercapacitors? Chem Rev.

104(10) 4245-70

[2] Zhao Y, Liu J, Hu Y, Cheng H, Hu C, Jiang C and et al 2013 Highly compression-tolerant

supercapacitor based on polypyrrole-mediated graphene foam electrodes Adv Mater. 25(4)

591-5

[3] Wang D W, Liu S J, Jiao L, Fang G L, Geng G H and Ma J F 2017 Unconventional mesopore

carbon nanomesh prepared through explosion-assisted activation approach: a robust

electrode material for ultrafast organic electrolyte supercapacitors Carbon. 119 30-9

[4] Wang D W, Liu S J, Fang G L, Geng G H and Ma J F 2016 From trash to treasure: direct

transformation of onion husks into three-dimensional interconnected porous carbon

frameworks for high-performance supercapacitors in organic electrolyte Electrochim Acta.,

216 405-11

[5] Borchardt L, Oschatz M and Kaskel S 2014 Tailoring porosity in carbon materials for

supercapacitor applications Mater Horiz. 1(2) 157-68

[6] Wang D W, Liu S J, Jiao L and Fang G L 2017 A smart bottom-up strategy for the fabrication

of porous carbon nanosheets containing rGO for high-rate supercapacitors in organic

electrolyte Electrochim Acta. 252 109-18

[7] Wang H and Gao Q 2009 Synthesis, characterization and energy-related applications of

carbide-derived carbons obtained by the chlorination of boron carbide Carbon. 47(3) 820-8

[8] Wang D W, Li F, Liu M, Lu G Q and Cheng H M 2008 3D aperiodic hierarchical porous

graphitic carbon material for high-rate electrochemical capacitive energy storage Angew

Chem. 47 373-6

[9] Wang D W, Fang G L, Geng G H and Ma J F 2017 Unique porous carbon constructed by

highly interconnected naonowalls for high-performance supercapacitor in organic

electrolyte Mater Lett., 189 50-3

[10] Xia K, Gao Q, Jiang J and Hu J 2008 Hierarchical porous carbons with controlled micropores

and mesopores for supercapacitor electrode materials Carbon. 46, 1718-26.

[11] Largeot C, Portet C, Chmiola J, Taberna P L, Gogosti Y and Simon P 2008 Relation between

the ion size and pore size for an electric double-layer capacitor J Am Chem Soc. 130 2730-1.

[12] Wang D W, Wang Y T, Liu H W, Xu W and Xu L 2018 Unusual carbon nanomesh

constructed by interconnected carbon nanocages for ionic liquid-based supercapacitor with

superior rate capability Chem Eng J. 342 474-83

[13] Thess A, Lee R, Nikolaev P, Dai H, Petit P, Robert J and et al 1996 Crystalline ropes of

metallic carbon nanotubes Science. 273(5274) 483-7

[14] Journet C, Maser W K, Bernier P, Loiseau A, Chapelle M L, Lefrant S and et al 1997 Large-

scale production of single-walled carbon nanotubes by the electric-arc technique Nature.

388(6644) 756-8

[15] Zheng B, Lu C, Gu G, Makarovski A, Finkelstein G and Liu J 2002 Efficient CVD growth of

single-walled carbon nanotubes on surfaces using carbon monoxide precursor Nano Lett.

2(8) 895-8

[16] Yang Q, Xu W, Tomita A and Kyotani T 2005 The template synthesis of double coaxial

carbon nanotubes with nitrogen-doped and boron-doped multiwalls J Am Chem Soc. 127(25)

8956-7

[17] Kim T W, Park I S and Ryoo R 2003 Intramolecular aromatic amination through iron-

mediated nitrene transfer. Angew Chem Int Ed. 42(36) 4360-75

[18] Ahmadpour A and Do D D 1996 The preparation of active carbons from coal by chemical and

physical activation Carbon. 34(4) 471-9

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as

Supercapacitor Electrodes

581

[19] Fuertes A B 2003 Template synthesis of mesoporous carbons with a controlled particle

size J Mater Chem. 13 3085-8

[20] Ma C, Shao X and Cao D 2012 Nitrogen-doped graphene nanosheets as anode materials for

lithium ion batteries J Mater Chem. 22 8911-5

[21] Zhang P, Sun F, Xiang Z, Shen Z, Yun J and Cao D 2014 ZIF-derived in situ nitrogen-doped

porous carbons as efficient metal-free electrocatalysts for oxygen reduction reaction Energy

Environ Sci. 7(1) 442-50

[22] Liu B, Shioyama H, Akita T and Xu Q 2008 Metal-organic framework as a template for

porous carbon synthesis J Am Chem Soc. 130(16) 5390-1

[23] Schoenecker P M, Carson C G, Jasuja H, Flemming C J and Walton K S 2012 Effect of water

adsorption on retention of structure and surface area of metal-organic frameworks Ind Eng

Chem Res. 51(18) 6513-9

[24] National Research Council National Materials Advisory Committee Microwave processing of

materials National Research Council Washington DC National Academy Press 1994

[25] Menéndez J A, Arenillas A, Fidalgo B, Fernández Y, Zubizarreta L, Calvo E G and et al 2010

microwave-assisted heating processes involving carbon materials Fuel Process. Technol. 91

1-8

[26] Maruyama J, Sumino K, Kawaguchi M and Abe I 2004 Influence of activated carbon pore

structure on oxygen reduction at catalyst layers supported on rotating disk electrodes

Carbon. 42(15), 3115-21

[27] Sun L, Tian C, Fu Y, Yang Y, Yin J, Wang L and et al 2014 Nitrogen-Doped Porous Graphitic

Carbon as an Excellent Electrode Material for Advanced Supercapacitors Chem Eur J. 20(2)

564-74

[28] Aleksandra S, Lavinia B, Véronique F, Lionel A, Ghouti M and Raphaël S 2014 Controlling

ZIF-8 nano- and microcrystal formation and reactivity through zinc salt variations

CrystEngComm. 16 4493-500

[29] Fletcher E A 1999 Solarthermal and solar quasi-electrolytic processing and separations: zinc

from zinc oxide as an example Ind Eng Chem Res. 38(6) 2275-82

[30] Yang S J, Kim T, Im J H, Kim Y S, Lee K, Jung H and et al 2012 MOF-derived hierarchically

porous carbon with exceptional porosity and hydrogen storage capacity Chem Mater. 24(3)

464-70

[31] Zhang J T, Yu L and Lou X W 2017 Embedding CoS2 nanoparticles in N-doped carbon

nanotube hollow frameworks for enhanced lithium storage properties Nano Res 10(12)

4298-304

[32] Chen L F, Lu Y, Yu L and Lou X W 2017 Designed formation of hollow particle-based

nitrogen-doped carbon nanofibers for high-performance supercapacitors Energ Environ Sci.

10 1777

[33] Rakhi R B, Chen W, Cha D and Alshareef H 2012 Nanostructured ternary electrodes for

energy-storage applications Adv Energy Mater. 2(3) 381-9

[34] Chaikittisilp W, Hu M, Wang H J, Huang H S, Fujita T, Wu K C W and etal 2012 Nanoporous

carbons through direct carbonization of a zeolitic imida zolate framework for

supercapacitor electrodes Chem. Commun. 48 7259-61

[35] Bai F H, Xia Y D, Chen B L, Su H Q and Zhu Y Q 2014 Preparation and carbon dioxide

uptake capacity of N-doped porous carbon materials derived from direct carbonization of

zeolitic imidazolate framework Carbon. 75 213-26

[36] Wang Q, Yan J, Wang Y, Wei T, Zhang M, Jing X and et al 2014 Threedimensional flower-

like and hierarchical porous carbon materials as high-rate performance electrodes for

supercapacitors Carbon. 67 119-27

[37] Torad N L, Salunkhe R R, Li Y, Hamoudi H, Imura M, Sakka Y and et al 2014 Electric

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

582

double-layer capacitors based on highly graphitized nanoporous carbons derived from ZIF-

67 Chem Eur J. 20 7895-900

[38] Sun L, Tian C, Fu Y, Yang Y, Yin J, Wang L and et al 2014 Nitrogendoped porous graphitic

carbon as an excellent electrode material for advanced supercapacitors Chem Eur J. 20(2)

564-74

[39] Yang S J, Kim T, Lee K, Kim Y S, Yoon J and Park C R 2014 Solvent evaporation mediated

preparation of hierarchically porous metal organic framework-derived carbon with

controllable and accessible large-scale porosity Carbon. 71 294-302

[40] Wu H, Wang X, Jiang L, Wu C, Zhao Q, Liu X and et al 2013 The effects of electrolyte on the

supercapacitive performance of activated calcium carbide-derived carbon J Power Sources

226 202-9

[41] Wu X, Hong X, Luo Z, Hui K S, Chen H, Wu J and et al 2013 The effects of surface

modification on the supercapacitive behaviors of novel mesoporous carbon derived from

rod-like hydroxyapatite template Electrochim Acta. 89 400-6.

[42] Ma C, Shao X and Cao D 2012 Nitrogen-doped graphene nanosheets as anode materials for

lithium ion batteries. J Mater Chem. 22 8911-5.

[43] Li Y, Roy S, Ben T, Xu S and Qiu S 2014 Micropore engineering of carbonized porous

aromatic framework (PAF-1) for supercapacitors application Phys Chem Chem Phys. 16(25)

12909-17

Hierarchical Porous Carbon Materials Derived from Microwave-assisted Heating of Zeolitic Imidazolate Frameworks for Use as

Supercapacitor Electrodes

583