The Synthesis of Multi-heteropoly Acid Containing Titanium

and Its Application on Esterification Reaction

J Y Ren, Q Wang

*

, W H Dai, T Liu, J S Yan and Y Feng

Department of biological medicine and chemical Engineering, Liao Ning Institute of

Science and Technology, Benxi, liaoning, 117004, China

Corresponding author and e-mail: Q Wang , 174783285 @qq.com

Abstract. The novel ternary undecatungstotitanotitanic heteropoly acid (H

4

Ti (H

2

O)

TiW

11

O

39

) was synthesized successfully by the method of ion exchanging-concentration. It

was used as the catalyst for the esterification of maleic anhydride with 2-ethylhexyl alcohol in

liquid phase. The effects of reaction time, ratio of anhydride to alcohol and the amount of

water-carrying agent toluene on synthesizing di-2-ethylhexyl maleate were investigated. The

suitable condition for synthesizing the ester was obtained. The catalyst has outstanding

advantages such as high esterification rate, less catalyst consumption.

1. Introduction

Heteropoly acid is a kind of solid super acid, which has been widely used as a new type of catalyst in

organic synthesis reactions. It has many advantages such as high catalytic activity, low equipment

corrosion, and small pollution. It has many reports on its catalytic esterification reaction [1-2].

Maleic acid di-2-ethylhexyl maleate, also known as two ethylhexyl maleate, is abbreviated as

DOM. It is an important internal plasticizer. It is widely used in paint, coatings, adhesives, fiber

treatment agents and so on. The products have the advantages of good gloss, aging resistance, acid

alkali resistance and so on. In addition, it is also widely used in the fields of petroleum and paper

making, is also an important chemical intermediates [3].

O

O

O

+

CH

2

CH(CH

2

)

3

CH

3

HO

C

2

H

5

CH

CH

C

O

O CH

2

CH(CH

2

)

3

CH

3

C

2

H

5

C

O

OH

H

+

C

8

H

17

OH

CH

CH

C

O

O CH

2

CH(CH

2

)

3

CH

3

C

2

H

5

C

O

O CH

2

CH(CH

2

)

3

CH

3

C

2

H

5

At present, the catalyst used in the industrial production of diethylhexyl maleate is still sulfuric

acid. Although sulfuric acid is used as a catalyst, it is inexpensive and easy to obtain, but it requires

high corrosion resistance of equipment, large amount of waste water, and long process flow.

Operation is troublesome, due to long reaction period, high temperature, many side reactions, and

poor product quality. Therefore, the current research on the synthesis of DOM is mainly focused on

the research of catalysts, Wu uses a composite solid superacid SO

4

2-

/ZrO

2

-TiO

2

as a catalyst

[4], Luo

used solid acid catalyst SO

4

2-

/TiO

2

as catalyst [5], Zou Changjun and others used macroporous strong

acidic styrene cation exchange resin catalyst [6]. However, these methods generally have the

Ren, J., Wang, Q., Dai, W., Liu, T., Yan, J. and Feng, Y.

The Synthesis of Multi-heteropoly Acid Containing Titanium and Its Application on Esterification Reaction.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 621-624

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

621

disadvantages of low catalyst activity, large amount, or pressure operation, and high equipment and

operation requirements.

At present, the catalyst used in the industry is still concentrated sulfuric acid, and the development

of a catalyst that can achieve the catalytic effect of concentrated sulfuric acid and overcome its

shortcomings is an urgent problem to be solved. The novel multi-heteropoly acid

undecatungstotitanotitanic acid composite [H

4

Ti (H

2

O) TiW

11

O

39

] was used for the catalytic

synthesis of DOM. The catalytic performance was more excellent. It had the outstanding advantages

of less catalyst and higher esterification rate.

2. Experimental section

2.1. Instruments and Reagents

Experimental instruments include the Beijing Rayleigh WQF-510A FTIR infrared spectrometer and

the Beijing General Analysis TU-1901 double beam UV-Vis spectrophotometer. All reagents used

were of analytical grade.

2.2. Preparation of heteropoly acids

Heteropoly acid catalyst H

4

Ti (H

2

O) TiW

11

O

39

was synthesized according to the literature.

Take 18.15g Na

2

WO

4

2H

2

O and add 100mL deionized water to dissolve it. The pH value of the

ice acetic acid solution is 6.3, heated to the micro tenging, and the side stirring edge slowly drops the

Ti

4+

solution of 0.33 mol/L (TiCl

4

dissolved in the 0.1 mol/L hydrochloric acid) 15mL, and the pH

value is 5.5. After half an hour of reaction, 0.33mol /L Ti

4+

solution was added to 15mL, and the pH

value was adjusted to 5 with glacial acetic acid. After continuing to react to 1.5h, filtering, adding a

proper amount of ethanol into the filtrate and precipitating a colorless oil, after placing the

refrigerator in the refrigerator, separating the oil, adding some deionized water and adding a proper

amount of ethanol to precipitate the oil, after repeated operation and purification for 3 times,

dissolved in 40mL water, and added a proper amount of hydrogen cation exchange resin. The pH

value of the stirring solution is less than 1, and undecatungstotitanotitanic acid can be prepared.

2.3. Esterification

The maleic anhydride 5.0g, undecatungstotitanotitanic acid catalyst 0.1g, a proper amount of 2-

ethylhexyl alcohol, toluene and zeolite are added to the three bottles of 100mL, and the oil water

separator is added to the oil-water separator. The saturated sodium chloride solution is added to the

oil-water separator and heated to the reflux. The reaction has been reacted for a certain time, and the

toluene is steamed out and cooled to room temperature 15 minutes before the end of the reaction.

After that, an appropriate amount of solution was taken and the acid value was determined by

0.05mol/L sodium hydroxide standard solution.

The acid value was determined according to the national standard method, and the esterification

rate was calculated according to the following formula.

esterificationrate =

Acidityvaluebeforereaction − acidvalueafterreaction

Acidityvaluebeforereaction

× 100%

The ester decompressed distillation is refined, and the catalyst is stored in the reactor. The

esterification catalysis of the catalyst under the next same condition is not treated directly. The

catalytic activity is repeated for five times. The catalytic activity has no obvious difference, the

catalyst can be reused many times.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

622

3. Results and discussion

3.1. Infrared and UV spectra of heteropoly acids

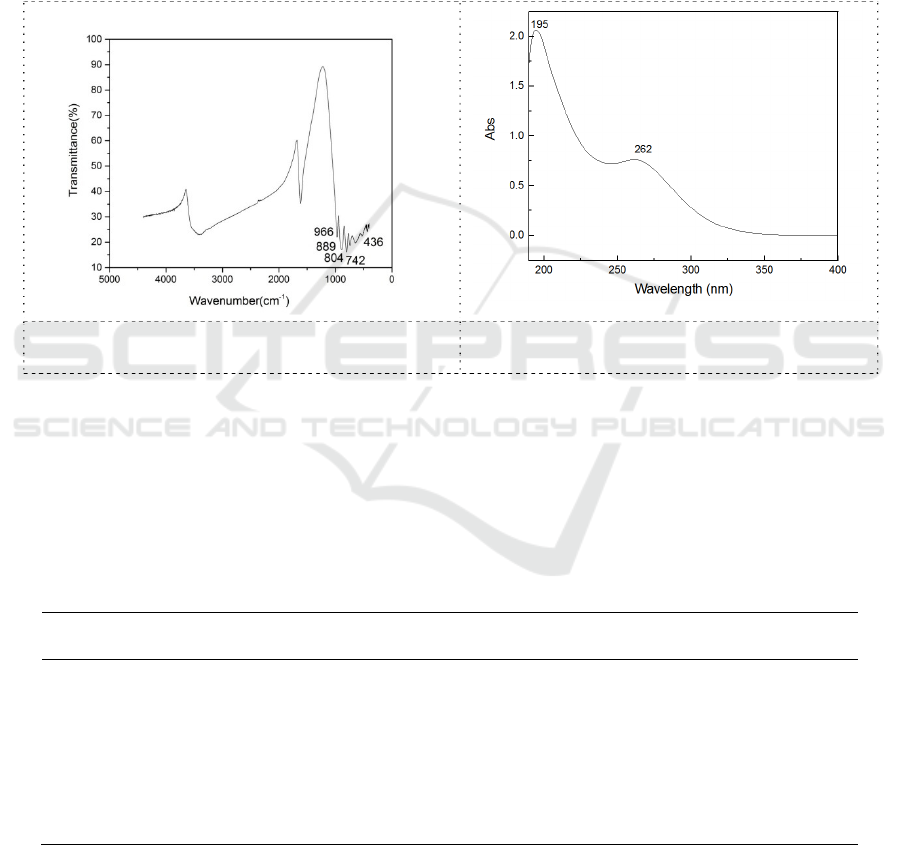

Figure 1 and Figure 2 show there are 5 characteristic peaks in the infrared spectrum of the synthetic

products, which conform to the characteristic vibration of Keggin heteropoly acids, respectively: V

Od 966 cm

-1

as terminal oxygen atoms, V Ob 889cm

-1

as co top oxygen atoms, V Oc 804cm

-1

,

742cm

-1

as the oxygen atoms shared by the common side, and V Oa 436 cm

-1

as the oxygen atom

connected with the titanium atom. In the UV spectrum, there are two absorption bands, which are Od

→ W 195 nm and Ob/Oc → W 262 nm, which conform to the characteristic absorption of Keggin

heteropoly acids and be the transition of tungsten oxygen bonds.

Figure 1. infrared spectrum of heteropoly

acid H

4

Ti (H

2

O) TiW

11

O

39

Figure 2. UV spectra of heteropoly acid

H

4

Ti (H

2

O) TiW

11

O

39

3.2. Selection of esterification conditions

For the molar ratio of maleic anhydride to 2- ethylhexanol, the reaction time and the amount of three

conditions for toluene, see Table 1, the optimum reaction conditions are the molar ratio of maleic

anhydride to 2- ethyl hexanol, the reaction time 4 hours, the dosage of toluene with water agent 10ml,

and the esterification rate of two ethyl hexyl maleate to 99.5%.

Table 1.Data of esterification reaction

NO. reaction time (h)

anhydride alcohol

ratio (mol)

Toluene (mL)

esterification rate

(%)

1 3 3 15 84.3

2 4 3 15 93.8

3 5 3 15 95.7

4 4 2.5 15 86.8

5 4 3.5 15 96.3

6 43594.7

7 4 3 10 99.5

8 4 3 20 88.6

Maleic anhydride (maleic anhydride) is a highly active acylate, which reacts with 2- ethyl hexanol

to produce monoester quickly. One carboxyl group is retained in the mono ester molecule, which can

continue to react with 2- ethylhexyl alcohol to produce diester, but the acylation activity of

carboxylic acid is weak and needs to be carried out in the presence of acid catalyst. Heteropoly acid

The Synthesis of Multi-heteropoly Acid Containing Titanium and Its Application on Esterification Reaction

623

as catalyst has mild reaction conditions, high esterification rate, and can be reused. [10] This is

determined by the characteristics of heteropoly acid catalyst. The esterification reaction of carboxylic

acid is reversible. In order to improve the conversion of reversible reaction, the amount of 2- ethyl

hexanol in reactant can be increased, but excessive excess makes the cost increase. The better method

is to reduce the concentration of the product and add the toluene with water agent, which can make

the reaction water leave the reaction system and get a higher conversion rate.

4. Conclusions

The synthesis of two ethyl hexyl maleate with undecatungstotitanotitanic acid as catalyst was used as

a catalyst for the synthesis of two ethyl hexyl maleate. It was easy to operate, and a good

esterification rate was obtained. The catalytic activity was high and the amount of catalyst was less. It

could be reused continuously. No waste acid was discharged and there was no environmental

pollution. It was of positive significance to the solution of the existing sulfuric acid catalytic process.

Acknowledgments

This work was financially supported by Liaoning Natural Science Foundation Project (20170540475)

and Science and technology research project of Liaoning Provincial Education Department

(201710311) and entrepreneurial training program for college students of Liaoning Institute of

Science and Technology in 2018 fund (201811430071) (201811430073).

References

[1] Erythropel H C, Brown T, Maric M, Nicell J A, Cooper D G and Leask R L. 2015 Designing

greener plasticizers: Effects of alkyl chain length and branching on the biodegradation of

maleate based plasticizers [J]. Chemosphere, 134-139.

[2] Yamak H B, Tamer Y and Yıldırım H. 2016 The effect of maleic acid diesters type on the

stability of vinyl acetate emulsion polymers [J]. Colloids and Surfaces A: Physicochemical

and Engineering Aspects, 497-502.

[3] Butini S, Nikolic K, Kassel S, Brückmann H, Filipic S, Agbaba D, Gemma S, Brogi S,

Brindisi M, Campiani G and Stark H. 2016 Polypharmacology of dopamine receptor

ligands [J]. Progress in Neurobiology, 142-149.

[4] Wu H T, Yu C and Ge S X. 2007 Solid superacid SO

4

2-

/ZrO

2

-TiO

2

catalyzed synthesis of [J].

chemical and bioengineering of maleic acid two (2- ethyl) hexyl ester, 24 (5): 21 ~ 23.

[5] Luo Z C, Wang W T and Ding S G. 2004 Solid acid catalyzed synthesis of maleic acid (2-

ethyl hexyl ester) [J]. Tianjin chemical industry, 18 (5): 11 ~ 12.

[6] Zou C J, Kong Z H and Yang H R. 1995 Catalytic synthesis of maleic acid two di-2-ethylhexyl

maleate [J]. Jilin technology, 3: 26-29.

[7] Cheryl-Low Y L, Lee H V and Abd Hamid S B. 2017 Catalytic upgrading of bio oil model

compound into polyol ester via green alginate catalyzed esterification reaction [J]. Process

Safety and Environmental Protection, 111-120.

[8] Chen L F, Zhang Z C, Lu Y J, Zhang C, Zhang X, Zhang C Q and Roskilly A P. 2017

Experimental study of the gaseous and particulate matter emissions from a gas turbine

combustor burning butyl butyrate and ethanol blends [J]. Applied Energy, 195-206.

[9] Caplar R and Kulisic P. 1973 Proc. Int. Conf. on Nuclear Physics (Munich) vol 1 Amsterdam:

North-Holland/American Elsevier, p 517

[10] Hu G D and Wu Q Y. 1991 Catalytic characteristics of heteropoly acid - pseudo liquid phase

catalysis [J]. Liaoning chemical industry, 4, 14 ~ 19.

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

624