Aqueous Solution of Ammonium Persulfate Assisted

Electrochemical Exfoliation of Graphite into Graphene

D X He, W D Xue and R Zhao

*

Institute of Applied Electrochemistry, School of Materials And Energy,

University of Electronic Science and Technology of China, Chengdu 610054,

PR China

Corresponding author and e-mail: R Zhao, ruizhao@uestc.edu.cn

Abstract. Mass production of high-quality graphene sheets is essential for their further

practical application. Here a facile electrochemical method was carried out to produce bulk of

graphene. Ammonium persulfate (APS) aqueous solution was applied as the electrolyte and

successfully exfoliated the graphite into graphene. The method here shows great promise for

the synthesis of bulk graphene with high quality.

1. Introduction

With the dramatic development of graphene producing and its applications, low-costs, high-quality

and mass production of graphene have been the major challenges and limitations for its further

development. Many excellent graphene preparation strategies have been developed respect to

different requirements and applications. Mechanical exfoliation methods came up with its first

discovery. There is a big step from adhesive tape assisted micromechanical cleavage [1] to sonication

assisted liquid-phase exfoliation [2-3]. They provide feasible means for producing graphene with low

number of defects, but still with an insufficient yield. Chemical vapor deposition (CVD) emerged as

a popular method for the growth of graphene with high quality [4]. However, the costs and

production restricted its further application in industry. With bulk scale production and solution-

processable property,graphene oxide (GO) which produced by the modified Hummer’s method has

been developed as one most available method especially for synthesizing graphene-based composites

materials [5]. But the low quality (most of the graphene are few layers) and environment pollution

problem are still the key limitations.

In recent years, electrochemical exfoliation of graphene or graphene oxide have been explored as

an efficiency strategy to achieve the goal. For example, GO had been achieved with good quality and

high yield via a two-step electrochemical intercalation and oxidation approach using ammonium

sulphate and sulfuric acid as the electrolyte [6]. Furthermore, apply ammonium sulphate [7] or (2, 2,

6, 6-tetramethylpiperidin-1-yl) oxyl (TEMPO) [8] as electrolyte had also been proved to be the ideal

methods to directly produce graphene.

In this study, in the presence of aqueous ammonium persulphate (APS) solution, the

electrochemical exfoliation of graphene was successfully carried out. Few layers graphene was

produced with high quality, low-cost, environment friendly and high efficiency.

658

He, D., Xue, W. and Zhao, R.

Aqueous Solution of Ammonium Persulfate Assisted Electrochemical Exfoliation of Graphite into Graphene.

In Proceedings of the International Workshop on Materials, Chemistry and Engineering (IWMCE 2018), pages 658-662

ISBN: 978-989-758-346-9

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2. Experimental details

Commercial graphite foil (Gee graphite LTD) with a thickness of 0.5 mm was used directly as the

working electrode. The electrochemical process was carried out with a Pt mesh counter electrode and

a DC power supply (BK PRECISION 1688B). A length of about 30 mm of the graphite ribbon was

immersed into aqueous ammonium persulphate (0.1 M, ≥98%, Aldrich) electrolyte and a constant

voltage (10 V) was applied for 5 minutes. The products were washed with water for several times

and dried in the vacuum oven.

The morphology of the powder was characterized by using a transmission electron microscope

(TEM, Philips CM20). The Raman spectra were obtained by using a Raman spectrometer (inVia,

Renishaw) equipped with a λ=532 nm laser. FTIR (Fourier Transform Infra-Red) Spectroscopy was

used to determine the chemical functional groups of the sample. X-ray photoelectron spectroscopy

(XPS) was performed with a Kratos Axis Ultra X-ray photoelectron spectrometer; the curve fitting

was accomplished by CasaXPS software. The samples for atomic force microscope (AFM, JPK

Instruments) and optical microscope (Nikon Eclipse LV100ND microscope) characterization were

prepared by drop casting of the graphene ethanol solution on a Si/SiO

2

wafer.

3. Result and discussion

Electrochemical exfoliation of graphite has been widely used to rapidly producing graphene. Many

organic or inorganic solution have been proved to be good candidates as the electrolyte [7-9]. Here

we firstly applied APS aqueous solution as the electrolyte. The output can be readily increased

through continuous production.

(a)

(b)

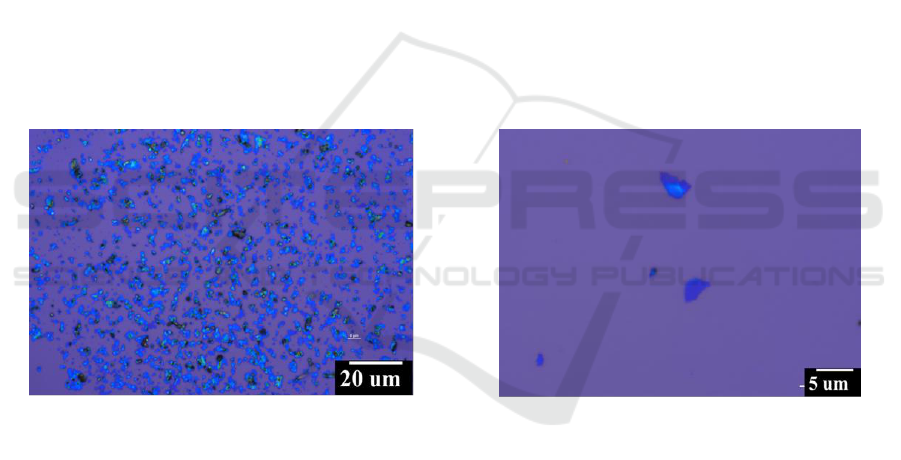

Figure1. (a) and (b) Optical image of the sample under different magnification.

Optical microscope was firstly carried out to roughly evaluate the quality of the products.[10] The

optical contrast differences between the substrates and the 2D nanosheets with different layer

numbers can be readily and reliably observed. As shown in Figure 1a, hundreds nanosheets are

observed in the optical image and more than 95 % showed purple in contrast with the substrate,

indicating that these flakes were few layers graphene. Furthermore, comparing with the related

references [11], the optical contrasts of high-magnification optical microscope image in Figure 1b

showed that most of them are under 6 layers, indicating the high quality of the products. Besides, the

black sheets within the field should be the graphite.

Aqueous Solution of Ammonium Persulfate Assisted Electrochemical Exfoliation of Graphite into Graphene

659

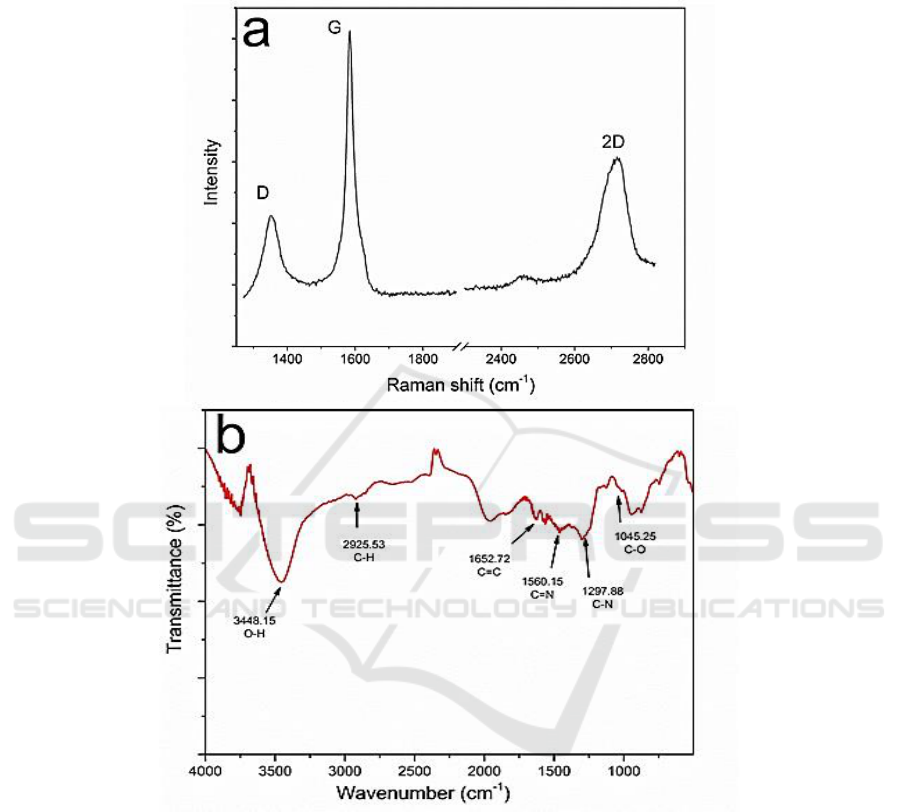

Figure2. (a) Raman spectra characterization of the graphene. (b) FTIR characterization of the

graphene.

Raman spectra and FTIR spectra characterizations were carried out later to obtain more

information about its fundamental structures. As shown in Figure 2a, the two typical peaks at around

1354 cm

−1

and 1585 cm

−1

refer to the disorder-induced D band and crystalline graphitic G band,

respectively. Briefly, the 2D peak at 2716 cm

−1

is the D-peak overtone, the intensity ratio of I

2D

/I

G

is

about 0.5 and indicating the few layers structure of the graphene. That also matches well with the

conclusion we obtained from the optical images in Figure 1.

Furthermore, the fast exfoliation process promoted it with low defects which mainly came from

the functional groups (Figure 2b). More details obtained from the XPS indicated that the C/O ratio is

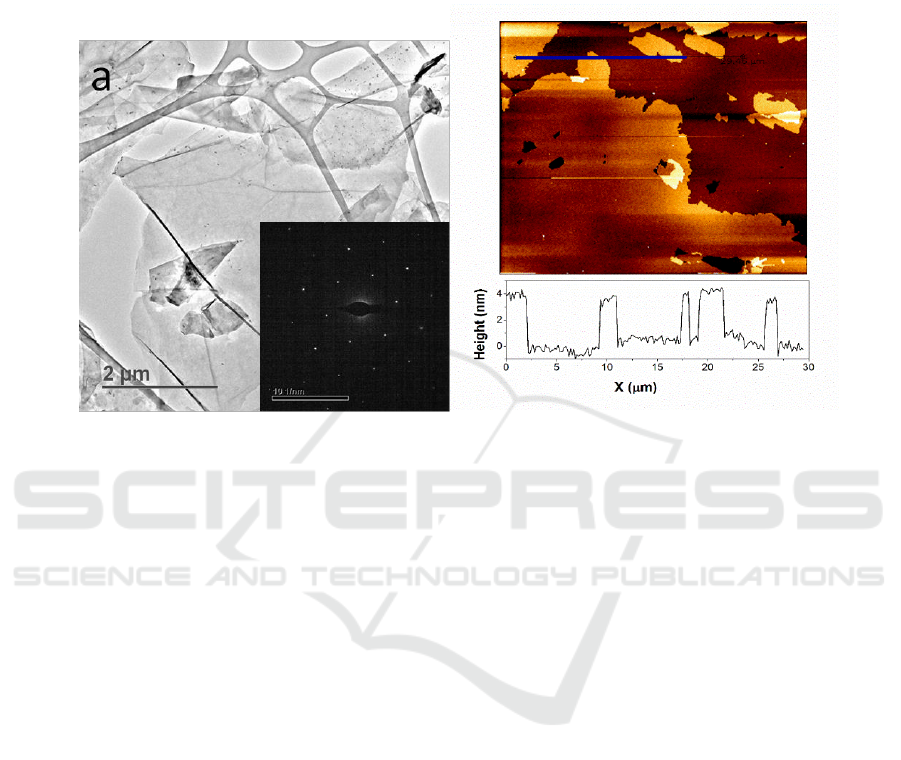

as high as 17.4 and better than most of the related works [12]. TEM was applied to further analyze

the characteristics of the graphene sheets. As shown in Figure 3a, the thin layers were uniformly

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

660

distributed on the substrate. The inset selected-area electron diffraction (SAED) of the thin layer

shows the typical 6-fold symmetry of grapheme [6]. The thickness of the layer can be further

confirmed with AFM analysis. As shown in Figure 3b, the thin flakes were uniformly distributed and

a thickness value of about 3 nm was observed.

Figure 3.(a) typical TEM image of the graphene layer (inset is the corresponding SAED); (b) AFM

image of the graphene layer.

The mechanism of the electrochemical exfoliation process has been recognized as: (i) the bias

voltage results in the electrolysis of water and the radicals oxidize the edge or grain boundaries of the

graphite (

); (ii) the hydrolysis of APS occurs in the water (

,

,

), and the sulfate ions

(SO

4

2-

) and water intercalate in between the graphite layers; With a continuous exfoliation process,

these two steps synergetic work on exfoliating the layers.[9] Finally, bulk of graphene was obtained.

4. Conclusions

Herein, APS aqueous solution was used for the first time as the electrolyte to synthesize graphene.

The graphene was produced with low cost, environment-friendly and high quality. Most of the flakes

are blow 4 nm thick and with low ratio of defects. The result presented herein provided an alternative

method for producing graphene powder with large-scale.

References

[1] Novoselov A A F K S, Geim A K, Morozov S V, Jiang D, Zhang Y and Dubonos S V 2004

Science (80-. ) 306 666

[2] Lotya M, Hernandez Y, King P J, Smith R J, Nicolosi V, Karlsson L S, Blighe F M, De S, W

Zhiming, McGovern I. T, Duesberg G S and Coleman J N 2009 J Am Chem. Soc. 131 3611

[3] Nuvoli D, Valentini L, Alzari V, Scognamillo S, Bon S B, Piccinini M, Illescas J and Mariani

A 2011 J. Mater. Chem. 21 3428

[4] Li X, Cai W, An J, Kim S, Nah J, Yang D, Piner R, Velamakanni A, Jung I, Tutuc E, Banerjee

S K, Colombo L and Ruoff R S 2009 Science (80-. ) 324 1312

[5] Botas C, Álvarez P, Blanco P, Granda M, Blanco C, SantamarRía, Romasanta L J, Verdejo R,

López-Manchado M A and Menéndez R 2013 Carbon N. Y. 65 156

Aqueous Solution of Ammonium Persulfate Assisted Electrochemical Exfoliation of Graphite into Graphene

661

[6] Cao J, He P, Mohammed M A, Zhao X, Young R J, Derby B, Kinloch I A, Dryfe R A W 2017

J. Am. Chem. Soc., jacs. 7b08515

[7] Parvez K, Wu Z S, Li R, Liu X, Graf R, Feng X, Mullen K 2014 J. Am. Chem. Soc. 136, 6083

[8] Yang S, Brüller S, Wu Z S, Liu Z, Parvez K, Dong R, Richard F, Samorì P, Feng X, Müllen K

2015 J. Am. Chem. Soc. 137 13927

[9] Parvez K, Yang S, Feng X, Müllen K, Synth. Met.2015, 210 123

[10] Ni Z H, Wang H M, Kasim J, Fan H M, Yu T, Wu Y H, Feng Y P and Shen Z X 2007 Nano

Lett. 7 2758

[11] Li H, Wu J, Huang X, Lu G, Yang J, Lu X, Xiong Q and Zhang H 2013 ACS Nano.7 10344

[12] Pei S and Cheng H M 2012 Carbon N. Y. 50 3210

IWMCE 2018 - International Workshop on Materials, Chemistry and Engineering

662