Research on the Application of New Model of Intelligent

Manufacturing in Aluminum Industry

Youfeng Li

1

and Yue Zeng

1

1

the Software Engineering Institut of Jinling Institute of Technology ,Nanjing,Jiangsu ,China,210007

Keywords: Intelligent Manufacturing; New Mode; Architecture.

Abstract: Through the analysis of the problems faced by the aluminum industry in China, the necessity of introducing

a new model of Intelligent Manufacturing in aluminum industry is put forward. Taking M aluminum

industry as an example, this paper expounds the new mode of Intelligent Manufacturing in modern

aluminum industry from several aspects, such as application goals, application difficulties, intelligent

manufacturing system architecture and architecture design ideas.

1 INTRODUCTION

With the development of lightweight transportation,

new generation of electronic information industry,

new energy vehicles, high-end equipment

manufacturing, energy saving, environmental

protection and other strategic emerging industries,

the demand for aluminum market is increasing year

by year. However, the competition of the aluminum

industry is fierce, the high-end products are few,

how to improve the comprehensive competitiveness

of the enterprises, the introduction of the new

intelligent manufacturing model is inevitable. Based

on the equipment and production line automation,

intelligent transformation of the new mode of

intelligent manufacturing, construction of

"unmanned workshop", to promote the

transformation of the mode of production to the

intelligent, flexible, fine; new type mould industry

through the establishment of industrial data analysis,

optimization and "Internet plus" collaborative

manufacturing, to enhance the research and

development, production, management, marketing

and service of the whole process of the level of

intelligence, improve labor productivity, reduce the

cost. Taking M aluminum industry as an example,

this paper expounds the construction of a new

intelligent manufacturing model for aluminum

industry.

2 PROBLEMS OF THE

ALUMINUM INDUSTRY

China's aluminum industry is developing rapidly,

but compared with the world powers, there are still

some gaps in technological innovation, industrial

structure, quality and efficiency, green development

and resource protection.

(1)The ability of technological innovation is

insufficient. Basic common key technology, deep

processing technology and applied technology

research and development are inadequate.

Aluminum products generally have poor quality

stability and high cost, and some high-end aluminum

products still rely on imports.

(2) Structural contradictions are prominent. The

concentration of aluminum industry is low, and the

strength of the enterprise is weak. The production

line of high end processing line is generally not

high, the middle and low end processing products

are homogenized and the market competition is out

of order. At the same time, with the further

standardization and development of the aluminum

processing market, the high-end products market

will gradually change to new energy materials and

functional materials such as aluminum foil for

lithium batteries, automotive aluminum and so on,

and will become a major trend of future

development.

(3) The upstream and downstream constraints are

uncontrollable. The concentration of aluminum

industry is low, and the cooperation between

upstream and downstream is insufficient, and it is

affected by the fluctuation of the upstream and

downstream industries and the operating

environment. The superposition of multivariable in

the process of production leads to the bottleneck of

the precision of the process standard for the whole

process of production.

(4) Industry transformation is difficult. The

aluminum industry has extensive production mode

and low production efficiency. It is labor intensive,

resource consumption is large and product

homogenization is serious, resulting in low

profitability. All of these restrict the development of

China's aluminum deep processing products. At

present, there is a big gap with the international

advanced production level at present. The promotion

and application of new technology, new technology

and new equipment still have a long way to go, and

the transformation of the whole industry is difficult.

In the whole industry inefficient allocation of

resources, lack of technological innovation ability

under such circumstances, China's high precision

aluminum must conform to the new round of

technological revolution and the industrial

revolution opportunities, accelerate the intelligent

manufacturing, networking, big data and other

information technology and manufacturing

integration, increase the machine substitutions and

production control applications such as efforts to

promote production change the way to intelligent,

flexible, fine; carry out the construction of public

service platform and energy control center, R & D

system, information system, operation management

system, integrated enterprise; gradually promote

industrial software, data management, engineering

services, technical standards of resource sharing and

cloud application services, the establishment of the

"new industrial model Internet plus" collaborative

manufacturing, accelerate industrial restructuring

and upgrading.

3 NEW INTELLIGENT

MANUFACTURING MODEL

3.1 New Model Application Target

The application of a new model of the intelligent

manufacturing, accelerate the intelligent plant

construction, set up production plan, process

coordination, equipment control, resource

optimization, quality control and decision support

intelligent integrated control platform to achieve

high precision aluminum production, fine, intelligent

man-machine and optimize the allocation of

resources, accelerate enterprise data sharing,

improve production and management efficiency and

promote the technology innovation continuously,

realize the enterprise management, to strengthen

industrial cooperation.

(1)Speed up data sharing

M aluminum through the introduction of a new

model of intelligent manufacturing, so in terms of

planning, scheduling, production, research and

development, business operation and market

development, to realize people and people, people

and equipment between the highly cooperative and

information group, point to the opposite point of the

real-time transmission, integration, sharing, and

small batch and large-scale production needs full

customization of M aluminum.

(2)Improving enterprise efficiency

M aluminum through the construction of

intelligent control platform, constantly optimize the

lean production mode, real-time control of material

consumption is minimized, reduce the

manufacturing process and the loss of inventory;

optimization of supply chain system, and effective

control of suppliers and customers the cost of space,

achieve both effective coordination, improve

logistics efficiency of materials and products, reduce

inventory cost three each between.

(3)Promoting continuous innovation

M aluminum manufacturing technology,

networking and cloud computing, big data, as the

representative of information technology to

accelerate the integration and innovation, the

construction of intelligent plant, promote the

automatic data acquisition system, simulation and

analysis of large enterprises to make full use of data

in real time or virtual scene, effectively activate the

innovation potential, innovation mode, efficient and

quickly respond to the market, leading the industry,

enhance the market competitiveness of enterprises.

(4) Strengthening industrial coordination

M aluminum to intelligent plant for the direction

of development, carry out the application of a new

model of intelligent manufacturing, through e-

commerce, big data, cloud platform, the response of

downstream users customization, processing and

distribution requirements, established from the early

intervention (EVI) to the full user technical support

and service system to promote win-win, service-

oriented manufacturing manufacturing, business

model innovation, improve value-added service.

3.2 New Model Application Difficulties

When the new model of intelligent manufacturing is

introduced in M aluminum industry, many

difficulties are encountered, which are mainly

embodied in several aspects.

(1)Hard hardware integration

The process of aluminum production involves

the types, quantities and interfaces of the equipment,

the complex process of the section and the great

difference in the process. It is difficult to integrate

and control the equipment of each section and

collect electronic data in an all-round way to form a

line of industrial automation. It is necessary to

cooperate fully and comprehensively with the

relevant people, things, technology and so on. In

addition, the M aluminum part of the equipment is

obsolete and needs to be replaced or modified to

provide conditions for intelligence.

(2)Difficult data acquisition and transmission

The intelligent manufacturing process requires

centralized control of the control system in all

processes to improve the industrial bus. M

aluminum industry needs to improve the intelligence

level of some energy metering instruments to ensure

the stability of data collection. It is necessary to

unify the interface modes of each machine and

equipment. It is necessary to unify the version of

every software system to ensure the coordination

between database and function, so as to ensure

unified management and protection. The internal

communication of the enterprise needs to further

improve the industrial Ethernet and achieve the

stable transmission of the data of the control system.

(3) Difficult software integration

It is difficult to integrate the intelligent

manufacturing management and control system of M

aluminum industry. It is necessary to connect with

the data and process of R & D design system,

formula system, raw material detection management

system, and need to form synergistic control with

supply chain. The need to achieve and the

production process and process standardization

management system docking, ensure the realization

of process in strict accordance with the provisions of

the file, effectively control the deviation of the

specific implementation (such as credit, price etc.),

real time tracking, contrast analysis (such as

ingredients, quality), get the corresponding results,

efficient operation, standardized management

system.

(4) Difficult data coordination

It is difficult to standardize the main data

encoding of M aluminum industry. We need to

improve the convenience of data viewing in

production process, and we need to integrate product

coding from smelting, casting rolling to packaging

process to ensure the uniqueness of product coding.

The scientific data report of M aluminum

industry is difficult. If we want to improve the

utilization rate of system reports, reduce or even

eliminate the manual processing ratio of workshop

reports, and enhance the real-time data, we should

integrate reports and unify the reporting caliber and

calculation standard, so as to make meticulous

management.

It is difficult to standardize the BOM database of

M aluminum industry. Need to use system

management tools, improve the main materials,

alloy configuration, process parameter control,

coordinate with production and business;

information tools need to establish security, establish

the BOM configuration list, according to the

authority of special control, implementation and

material consumption, intelligent workshop, supply

chain collaborative business system and job shop

Control Co.

3.3 Construction of Intelligent

Manufacturing System

(1) General architecture of intelligent manufacturing

system

Based on industry 4, intelligent plant system, key

features and core technologies, M aluminum

enterprise designs and implements a new intelligent

manufacturing mode combined with its own needs.

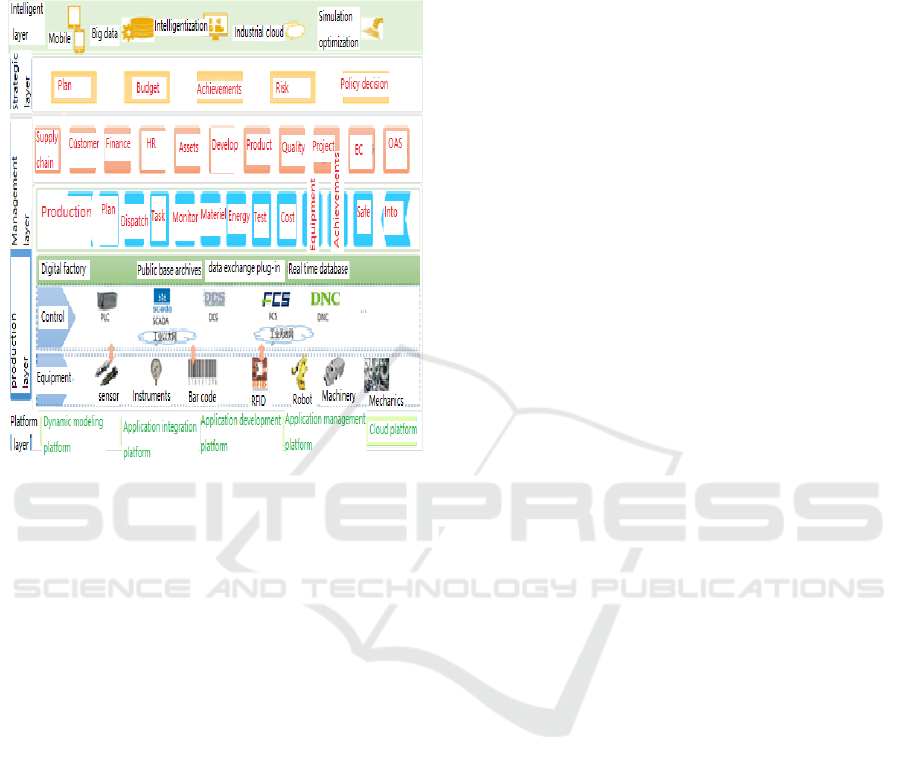

The overall architecture is illustrated in Figure 1.

System design in accordance with the "overall

planning and implementation of distribution"

principle, the production equipment from the

equipment intelligent, intelligent, intelligent

management, research and development of

intelligent and multi dimension data integration and

optimization analysis, based on the "Internet plus"

supply chain and industry chain interconnection,

expansion design and implementation.

The smart factory from the platform layer,

professional production level, operations control,

strategic control layer, intelligent application support

M aluminum intelligent manufacturing system to

achieve synergy, transparent management of

production preparation process, the interconnection

of intelligent equipment, intelligent manufacturing

resource management, research and production of

supply and marketing integration, intelligent

decision support. Analysis and optimization of

dynamic operation, to achieve a full range of

production process management and intelligent

control.

Figure 1: Architecture of M aluminum industry Intelligent

Manufacturing System.

Platform layer: the technology platform based on

SOA and ESB supports the construction of all stages

of the whole intelligent factory. The platform layer

includes dynamic modeling platform, application

integration platform, application development

platform, application management platform, and

cloud technology running platform.

Professional production: through digital factory

platform, the integration of equipment, control

system and production execution system is realized,

and digital factory is established to realize intelligent

control in production process. The digital factory

platform through the plant modeling tools, establish

factory digital model, through equipment integration

and data integration technology to all levels of data

integration between systems, and integrated

automation equipment, establish intelligent plant

data acquisition and monitoring; production

implementation work order planning, scheduling,

production, inspection of the whole process of

closed loop management, acquisition, production

schedule site operation, quality inspection,

production equipment state information, realize the

visualization of the production process and

traceability.

Management and control layer: to achieve

enterprise R & D, supply chain, customer

relationship, finance and other business management

and control, establish e-commerce collaborative

platform, realize supply chain upstream and

downstream synergy, ensure production, logistics,

supply and production synergy.

Intelligent application layer: through continuous

improvement and optimization technology, realize

the operation of dynamic process optimization,

manufacturing and management information

sharing, full transparent, with big data, cloud

computing enterprise intelligent management and

decision making, enhance the enterprise resource

allocation optimization, automatic operation, real-

time optimization, sophisticated and intelligent

production management the level of scientific

decision-making.

(2) The design idea of intelligent manufacturing

system

Planning and design in accordance with

industrial 4 and intelligent manufacturing elements.

From the analysis and optimization of collaborative

development of intelligent, intelligent production,

intelligent storage, intelligent supply chain system,

intelligent management, intelligent customer and

industry data, to develop and implement transparent

preparation for production in the process of

collaborative management, intelligent equipment

interoperability, resource management, intelligent

production research and production supply and

marketing integration, decision support analysis and

optimization of intelligent data, thus, to reach full

production process management and intelligent

control. M aluminum intelligent manufacturing

project implemented in three phases, MES system,

material logistics, supply chain collaborative

commerce implementation of the first phase of the

implementation of the production process,

transparency, visualization and supply chain

cooperation; research and development

management, the implementation of the second

phase of intelligent warehouse, device control,

implementation of developing and manufacturing

integration, intelligent storage management and

process control third equipment; implementation of

automatic scheduling, online optimization,

intelligent analysis of large data, intelligent

applications, big data analysis and optimization of

intelligent manufacturing.

(3)Network architecture of intelligent

manufacturing system

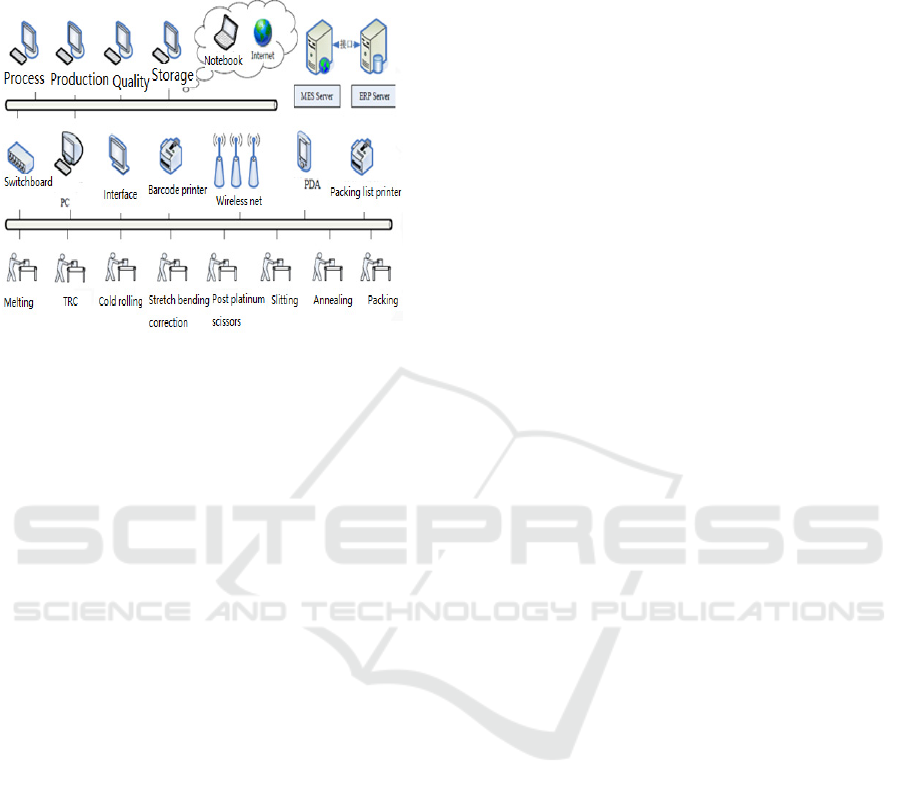

The M aluminum industry system uses B/S and

C/S architecture, which is mainly used in the internal

management of the enterprise. The network includes

two parts of the online LAN and the wireless LAN.

The system network architecture is shown in Figure

2.

Figure 2: Network architecture of M aluminum industry

Intelligent Manufacturing System

3.4 The Intelligent Embodiment of the

New Model

(1) Intelligent research and development

The M aluminum industry intelligent

manufacturing system can carry out new product

research and development according to the new

customer needs. The new product materials BOM,

formula, process route and production guidance are

planned. The new product is formed, from the basic

data of R & D system or PLM MES system to

transfer material definition, BOM, process route for

production, MES system planning and scheduling,

production scheduling based on P-BOM data, at the

same time in the production process of abnormal

feedback to the R & D department. The R & D

department optimizes the product formulation and

design plan, and realizes the synergy and integration

of data and process between R & D and

manufacturing, so as to shorten the product

development cycle and improve the accuracy of

production and delivery.

(2)Intelligent production

M aluminum in intelligent manufacturing

system, MES system implementation of production

plan scheduling and monitoring and scheduling,

from procurement, inventory, production and sales

to the barcode /RFID management of financial

management, the use of bar code acquisition /RFID

melting, casting, rolling, bending straightening,

cutting, slitting, thick foil annealing, cutting process

the production and packaging material input, quality

information, process parameters and production

process data, and workshop condition real-time

monitoring and adjustment, can achieve flexible

production, MES system to realize data acquisition,

error proofing, leakage alarm and process quality

control, materials, personnel, technology and other

courses, traceability. The running state of accurate

perception of enterprises, workshops, equipment,

system; execution plan decision of equipment,

workshop and production lines to make adjustments;

fast and accurate processing, recognition and

processing of real-time state data acquisition;

judgment and choice according to the results of data

analysis according to the rules set automatically

make the final. The plant state perception, precise

execution, real-time analysis, decision-making.

(3)Intelligent logistics

M aluminum intelligent manufacturing system,

the introduction of advanced barcode and wireless

communication technology in the warehouse

management, on arrival inspection and warehouse

storage, transfer, transfer bank transfer, inventory

and other each work link data acquisition

automation, ensure the accuracy and efficiency of

the warehouse management of the operation part of

data input, and can be integrated with ERP system,

ensure the real data and ERP timely and accurate

access to inventory, and maintain a reasonable

control inventory. Through scientific coding, it is

also convenient to manage the batch and shelf life of

the goods. Barcode technology WMS is a way to

achieve modern warehouse management. It is a way

to ensure warehouse operation optimization, make

full use of warehouse space, reduce operation cost,

improve agility and increase business efficiency.

(4)Intelligent management

As the core business system of the enterprise,

intelligent management is also the most basic

information system. To achieve the comprehensive

management of people, money and things, M

Aluminum Group has established a complete ERP

system based on group management and control,

including financial accounting, supply chain, human

resources, production orders, equipment

management and so on.

(5) Intelligent customer collaboration

M aluminum industry is built on the core of

CRM/MRO based customer collaboration, aiming at

building the whole life cycle management of

customers, and building a unified, complete and

cross sectoral global view of customers, so as to

achieve seamless transfer of customer information

from market, sales to customer service team.

Through the customer relationship management

system, every employee who faces customers can

get effective sales information in time and

accurately, get the information needed for high-

quality customer service, improve the core

competitiveness of enterprises, and achieve the goal

of rapid growth. The entire business process of an

enterprise, including judgment, selection, struggle,

development and maintenance, is truly customer

centered.

(6)System integration scheme

M aluminum intelligent manufacturing system,

through integration with ERP, MES, PLM, SCM and

other systems, establishes a unified data center, and

collects real-time data collected from each section

and the control system of the public system on the

smart factory platform. A monitoring platform

covering the whole company's production and

operation is established to achieve the whole process

tracking of sales orders, production process tracking,

production scheduling optimization scheduling and

product quality management traceability. Real time

collection and centralized storage of production data

are realized. To improve the enterprise's resources

allocation optimization, operation automation, real-

time online optimization, production management

refinement and the scientific level of intelligent

decision-making.

(7) Large data analysis and optimization

M aluminum industry intelligent manufacturing

system, integrated production, supply, marketing,

storage and other large industrial data, and to carry

out analysis and optimization.Based on the data

collection, data management, data analysis,

knowledge, wisdom "of the whole process of ideas

and principles, M aluminum intelligent platform,

through the establishment of a unified central data

center, a large set of material procurement, sales,

production, real-time, management, human

resources and financial data. Through the data

mining technology such as OLAP, the data is fully

excavated and analyzed. According to different

management priorities, management levels and

management dimensions, we carry out professional

analysis, performance analysis, benchmarking

analysis and problem analysis for all stages of

business, so as to identify problems, intelligent

decision analysis and promote management.

4 CONCLUSIONS

The M aluminum industry introduces a new model

of intelligent manufacturing. The core of intelligent

equipment, data acquisition, analysis automation,

system integration, "Internet plus" collaborative

manufacturing, to achieve the customer

customization B2M production mode, improve the

technical and economic benefits of enterprises,

improve the social benefits. Through the "intelligent

production equipment", "logistics and transport

material recognition accuracy", "product

development cycle", "production scheduling

accuracy", "production efficiency", "single"

productivity ", the rate of finished products",

"product defect rate", "tons of foil energy

consumption and other indicators in the comparison

system to enhance the rate before and after the

implementation of the actual proof of the superiority

is obvious, the introduction of a new model of M

aluminum, is similar to.

REFERENCES

1. Qinglin Guo, Ming Zhang. Multi agent basedschedulin

goptimization for Intelligent ManufacturingSystem[J].

TheInternationalJournalofAdvancedManufacturingTec

hnology,2009,445-6:.

2. Bo-huLi,Bao-cunHou,Wen-taoYu,Xiao-bingLu,Chun

weiYang.Applications of artificial intelligence inintelli

gent manufacturing :areview[J].FrontiersofInformation

Technology&ElectronicEngineering,2017,181:.

3. Ouyang HuaBing, Shen Bin. Intelligent Manufacturing

SystemBasedonMachiningFeaturesanditsApplication

[J].EnergyProcedia,2011,11:.

4. QinglinGuo,MingZhang.Anovelapproachformultiagen

tbasedIntelligentManufacturingSystem[J].Information

Sciences,2009,17918:.

5. ArmandBaboli,JunOkamoto,MarcosS.G.Tsuzuki,Thia

goC.Martins,PauloE.Miyagi,FabrícioJunqueira.Intellig

entManufacturingSystemConfigurationandOptimizatio

nConsideringMobileRobots,MultiFunctionalMachines

andHumanOperators:NewFacilitiesandChallengeforIn

dustrialEngineering[J].IFACPapersOnLine,2015,483:.

6. QinglinGuo,MingZhang.Anagentorientedapproachtore

solveschedulingoptimizationinintelligentmanufacturin

g[J].RoboticsandComputerIntegratedManufacturing,2

009,261:.

7. LiJinfa,LiBiting.EvaluationMethodofR&DInvestment

ValueofIntelligentManufacturingEnterpriseBasedonGr

owthOption[J].ProcediaEngineering,2017,174:.

8. Yubao Chen. Integrated and Intelligent Manufacturing:

Perspectives and Enablers[J].Engineering,2017,35:.