Experimental Study on Bonding Performance of Basaltic Fiber

Reinforced Polymer and Inorganic Polymer Concrete

Xin Li

1,a

, HaiQin Xu

1,*,b

, YongHao Qian

1,c

, Tao Wang

1,d

, DanDan Xiao

1,e

and XiaoChun Fan

1,e

1

School of Civil Engineering and Architevture,WuHan Technology of University, LuoShi Road 122, WuHan, China

e

1774353675@qq.com,ffxcfree@126.com,

*Corresponding author

:

TEL +86 13638644921

Keywords: Inorganic polymer concrete, basalt fibre reinforced polymer, bond performance, pull-out test.

Abstract: Inorganic polymer concrete (IPC) and basalt fibre reinforced polymer(BFRP) has good durability. This

paper presents a bond durability test for BFRPbar to the IPC. The test in this article chose BFRP bars in

diameter of 10mm, 12mm and 16mm, with two kinds of IPC in different strength, through experiment, the

bond property between the IPC and BFRP bars is studied systematically. In this paper, the bond-slip curves

of the IPC-BFRP are obtained by the tensile test between them, which proves that they have good bonding

property and provide reference for the application of the IPC-BFRP structure in the engineering.

1 INTRODUCTION

The bond strength between the steel and concrete

plays a key role in their cooperative work [1]. In

response to the requirements of the green building

that the country advocates, the research community

and construction industry have expanded their

horizons to new building materials[2]. In this paper,

the bonding performance between the new concrete-

IPC and the composite bar- BFRP is studied. The

raw material composition of IPC derived from solid

industrial waste is environmentally friendly building

materials. The BFRP raw materials are derived from

natural basalt ore which are not easy to rust. It is a

natural Inorganic non-metallic material. The

structural system composed of the two new materials

can solve the problems of environmental pollution of

reinforced concrete materials and the reduction of

structural mechanical properties caused by steel

corrosion [3].

There are many factors that affect the bond

strength between BFRP and IPC, similar to

reinforced concrete components, mainly by the

following [4-9]: (1) Strength grade of IPC; (2) The

position of BFRP in concrete; (3) When there are

multiple BFRP in a member and they are in a row,

the net distance between the BFRP has an important

influence on the bond strength. The smaller net

distance, the lower bond strength will be. (4)

Thickness of protective layer of IPC; (5) Surface

form and diameter of BFRP; (6) Bond length

between IPC and BFRP, etc. At present, there is still

a lack of in-depth research on the bonding properties

between IPC and BFRP. This article mainly explores

the effect of two different mix ratios of IPC and

BFRP on the Bonding performance. Through the

center pull-out test, the ultimate bond strength of the

test piece and bond stress-slip curve are obtained[5],

to explore the bonding properties between the two.

2 EXPERIMENTAL WORK

2.1 Materials Properties

2.1.1 Inorganic Polymer Concrete

The compressive strengths of Inorganic Polymer

Concrete were determined by using 150mm cube

specimens through Compression test. The concrete

mix design is shown in Table 1. Concrete cube and

pull-out specimens were removed from the moulds

after 24h.And after being cured with water for 28

days, all the specimens and cubes were ready.The28-

day compression strengths of IPC20 was 20.5MPa,

and the 28-day compression strengths of IPC30

was31.3MPa.

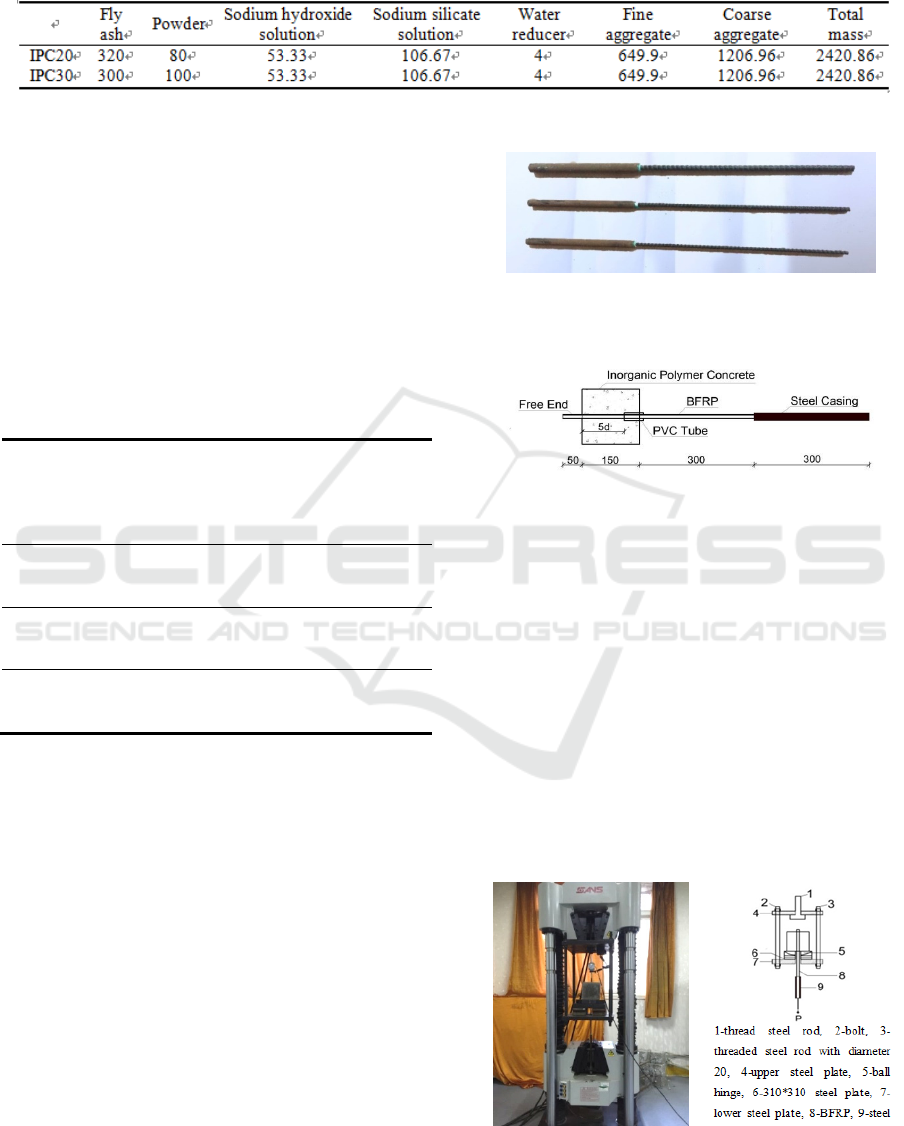

Table 1the mix design of IPC(kg/m3)

Note:In Table 1,the concentration of Sodium hydroxide

solution is 10mol/L,and in Sodium silicate

solution,SiO2/Na2O=2.

2.1.2 BFRP Reinforcing Bars

Three types of BFRP bars with a diameter of 10mm

、12mm and 16mmused in this paper were made by

Jiangsu Green Materials Valley New Material T&D

Co., Ltd (GMV). The tested properties of BFRP is

summarized in Table 2.

Table 2 Physical and mechanical properties of BFRP

reinforcing bars

Bar

Type

Diam

eter/

m

Maxim

um

pulling

force/k

N

Ultimate

tensile

strength/

MPa

Average

tensile

Strength/

MPa

79.16 1302

BFRP10 10 77.99 1283 1274

75.16 1236

109.09 1246

BFRP12 12 105.83 1209 1225

106.88 1221

196.11 1260

BFRP16 16 188.94 1214 1234

191.26 1229

2.2 Test Specimens

In accordance with GB50152-9218 Standard

methods for testing of concrete structures, 18 pull-

out specimens were produced[7]. As shown in Fig 1,

BFRP reinforcing bars with a diameter of 10mm、

12mm、16mm. And two kind of Inorganic Polymer

Concrete were used to test bond strength. The total

length of the BFRP reinforcing bars is 800mm, and

bond length is five times of diameter(5*10mm、

5*12mm 、 5*16mm).The length of free end is

50mm[2].Plastic tubes were adopted to make up un-

bond area. Considering about the poor shear strength

of BFRP bars, steel casing of 300mm length and

resin glue were used to fix the loading end of bars to

prevent the too much power given[10-13].Schematic

diagram of the pull-out specimens are shown in

Fig.2.

Figure1: BFRP reinforcing bars (already fixed)

Figure2:Schematic diagram of the pull-out specimens

2.3 Test Setup and Test Method

The tests were carried out with Electro-

hydraulic servo universal testing machine (

1000KN/SHT4106-G ) in Wuhan University of

Technology, Materials Research and Test Centre at a

rate of 1 mm/min. The pull-out specimen was put in

pull-out shelve. Loading statistics were recorded by

Electro-hydraulic servo universal testing machine,

and the displacement on the free end of the BFRP

transducer. The details of pull-out shelve are shown

in bar was measured with a displacement Fig.4.The

pull-out test setup and instrumentation are shown in

Fig.3.

Figure 3:The test equipment. Figure 4: The pull-outshelve.

3 RESULTS AND DISCUSSION

3.1 Mode of Failure

3.1.1 Pull-out Damage

The BFRP were pulled out and damaged in the

specimens numbered B10C20, B10C30 and

B12C30. During the loading process, due to the

chemical bonding force, mechanical anchorage force

of BFRP and the elastic deformation of bars, the

displacement of free end fell behind the loading end.

As the loading continues, the displacement of free

end and the loading end were found to be developing

gradually. When the pull-out force reached its peak,

the pull-out force began to decrease. At this time, the

slip of free end and the load-end developed at about

the same time, but the displacement of free end still

fell behind the load-side’s displacement. Finally, the

displacement of the free-end and the displacement of

the loading end were synchronized, and the chemical

bonding between BFRP and IPC could be declared

invalid.

By observing the extracted bars, it was found

that the cross ribs of BFRP were seriously worn out.

The BFRP of 10 mm diameter were slightly worn

and relatively well-preserved. And there were a

small amount of inorganic polymer concrete chips

between the cross ribs. The pull-out force would be

larger when use BFRP of 12mm diameter, even

leading to the shear failure of the entire cross ribs

and stacking more IPC debris between the cross ribs.

The specific situation is shown in Figure 5.

Figure 5: pull out damage

3.1.2 Splitting Damage

In this test, concrete specimen splitting failure

occurred on the drawing specimens numbered

B12C20, B16C20, and B16C30. During the test

process, as the pulling force increased, the cross ribs

were wear away, the residual ribs piled up to the free

ends, and the hoop stress of IPC was increasing. The

concrete cracked when the concrete's tensile strength

was insufficient to resist the hoop stress. When a

splitting failure occurred, the load dropped sharply

Figure 6: Concrete splitting failures

and the chemical bonding between BFRP and IPC

failed. The specific cracking of each specimen is

shown in Figure 6.

3.2 Bond Strength

This test assumes that the bond stress is distributed

equably along the depth of BFRP, and the bonding

stress between the IPC and BFRP can be calculated

by Equation (1) [10]:

/ (1)

In the formula,τis the average bond stress;Fis

the loading force of the testing machine;d is the

basalt bar diameter;l

is the effective bond length.

Table 3 Bond test results after pull-out testing.

Note: 20, 30 represents the design strength of the

IPC, B represents basalt bars, 10, 12 and 16

represent the diameters of the BFRP, and the

specimens with the number B12C20 have one and

the other two specimens of the same group with the

failure modes and bonding. There is a significant

difference in strength and it is determined that the

data is invalid and discarded.

By analyzing the data in the table:

(1)Under the premise that the bond length was five

times the diameter of the reinforced material, the

pullout of the reinforcing material was easy to occur

when the IPC with the strength of 20MPa and BFRP

with the diameter of 10mm work together. When

BFRP with the diameter were 12mm and 16mm,the

concrete splitting failures were easy to occur. When

IPC with the strength of 30 MPa worked together

with basalt reinforcements with diameters of 10 mm

and 12 mm, specimens tended to be pulled out and

broke out. When combined with basalt

reinforcement with the diameter of 16 mm, the

concrete splitting failures were easier to occur.

(2) Comparing the test data of the bond

strengths of B10C20, B12C20and B16C20, the

average bond strength between IPC and 10 mm

BFRP was 14.48 MPa. When diameters of BFRP

increased to 12 mm, the bond strength increased

3.73%, and when the diameter of BFRP increased

to 16 mm, the bond strength decreases by

30.52%.Comparing the test data of the bond

strengths of B10C30, B12C30and B16C30, the

average bond strength between IPC and 10 mm

BFRPwas13.07 MPa. When diameter of BFRP

increased to 12 mm, the bond strength decreased by

14.23%, and when BFRP increased to 16 mm, the

bond strength decreased by 18.06%.

(3)Comparing the test data of the bond strength of

B10C20 and B10C30, the average bond strength of

20MPa IPC and 10mm BFRP was 14.48Mpa.The

bond strength decreases by 9.74%, when the

strength of IPC was increased to 30MPa. The

average bond strength of 20MPa IPC and 12mm

BFRP was 15.02Mpa.When the strength of IPC is

increased to 30MPa, the bond strength is reduced

by 25.37%.And the average bond strength of

20MPa IPC and 16mm BFRPwas10.06Mpa.When

the strength of IPC was increased to 30MPa, the

bond strength is increased by 6.46%.

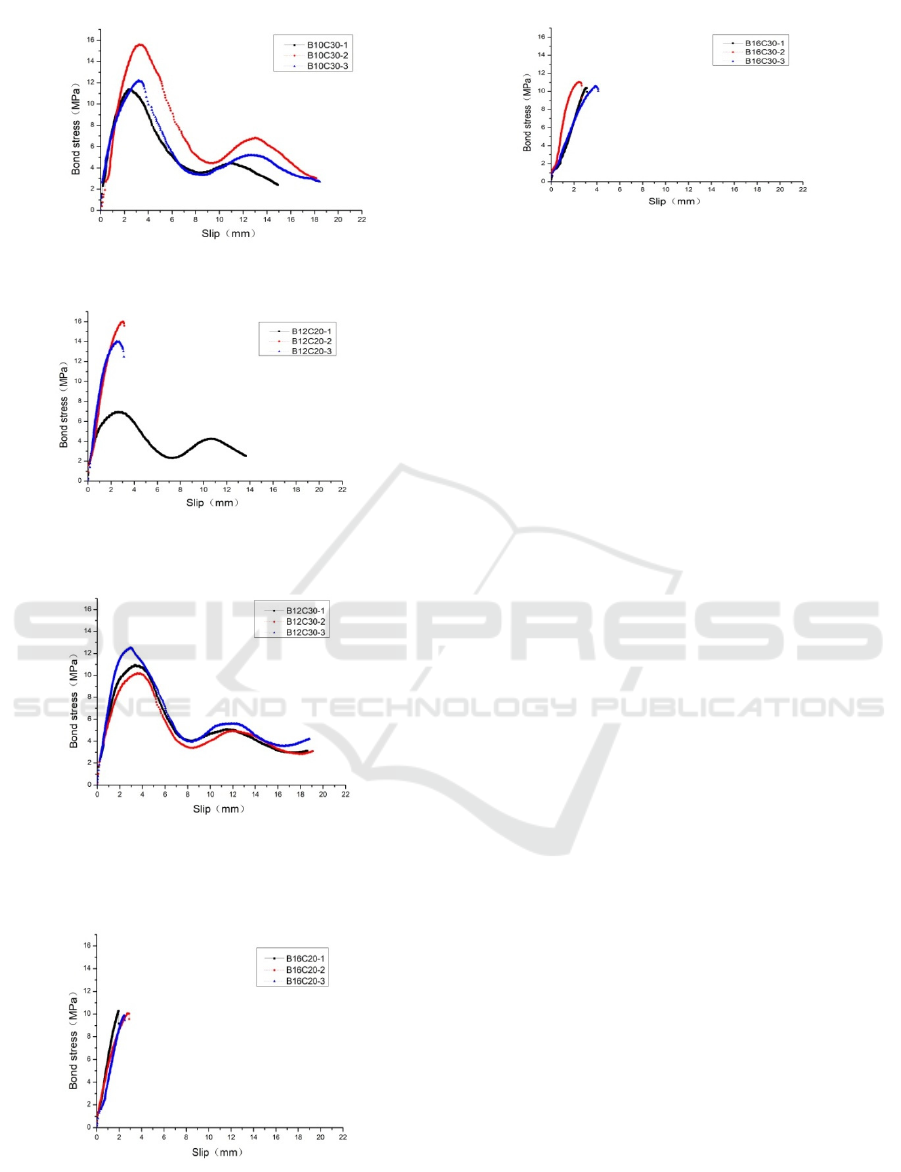

3.3 Bond Stress-Slip Responses

The BFRP would be stretched during the loading

process, making the sliding of the loading end

inaccurate, so the test adopted a displacement meter

to test the free end displacement, and the

displacement data collected at the free end was used

as the slip value. From the obtained load data, the

bond stress was calculated by formula (1), so we can

draw a more realistic bond stress-slip curve.

(a)B10C20

(b)B10C30

(c)B12C20

(d)B12C30

(e)B16C20

(f)B16C30

Figure 6: Bond stress-slip curves

By analyzing the bond stress-free end slip curve,

wefound:

(1) For the pull-out test specimens with BFRP pulled

out from B10C20, B10C30and B12C30, the bond

slip curve exhibited a cyclic decay pattern. As the

cross ribs of the BFRP were successively damaged

when they were pulled out, the load-displacement

curve presented alternate peaks and valleys, and

showed a gradually decreasing trend. The process of

BFRP and IPC bond-slip: At the initial stage of

loading, the bond between BFRP and IPC was

mainly provided by chemical bonding force. The

duration of this process was short, because the

chemical adhesion force was small. Afterwards,

there was a slight displacement at the free end, and

the chemical bonding force disappears. Then the

pull-out force was provided by the friction force and

the mechanical bite force. And on the slip curve, the

pull-out force and the slip were all increasing,

presenting the certain nonlinearity. As the load and

slip continued to increase, the pull-out force slowly

rose, the displacement increased sharply and the

curve became more nonlinear. The pull-out force

reached the peak and then gradually decreased,

because the ribs of BFRP were worn out. The cross

ribs were destroyed one after the other, because the

cross ribs of BFRP had a certain distance. The peaks

and valleys appeared on the curve in order, and they

appeared cyclically decaying.

(2) For specimens with concrete splitting failure

of B12C20, B16C20 and B16C30, when the pull-out

force gradually increased to reach the first peak, the

concrete was split and broken due to the tensile

strength of the concrete that could not resist the

tensile force. Unlike the specimens with basalt bars

were pulled out, the pull-out force rapidly dropped

after the pull-out force reached the first peak.

Concrete creaked due to insufficient tensile strength

to resist tensile stress in the hoop force. On the

curve, the bond stress quickly disappeared after

reaching the first peak and the test stops.

4 CONCLUSIONS

In this paper, based on 18 pull-out test specimens,

the bonding properties between BFRP and IPC are

experimentally studied. The main conclusions are as

follows:

(1) There are two main failure modes for the BFRP-

IPC pull-out test: BFRP are pulled out and IPC is

split and destroyed .

.

(2) When 20Mpa of IPC works together with BFRP

with the diameter of 12mm or more, it is prone to

occurconcrete splitting damage. When 30MPa of

IPC works together with BFRP with the diameter of

16mm or more, it is prone to occurconcrete splitting

damage.

(3) IPC and BFRP have good bonding properties,

and their bond strengths are between 9.85 MPa and

16.02 MPa.

REFERENCES

1. Yuan Xiaohui, Lu Zhean, Fan Xiaochun. Inorganic

Polymer Concrete-steel Bar Pullout Test Study [J].

Journal of Wuhan University of Technology, 2013,

35(6):117-122.

2. Jin Yun-dong.Research on short-and long-term

mechanical propertiers of BFRP bar reinforced marine

sand concrete beams [D]. Nanjing: Southeast

University, 2016.

3. Li Zhongxi. BasaltReinforced Concrete[J].Engineering

Quality, 2010(2): 76-78.

4. Niu Jiangang, HaoJi, Sun Li-bin, etc al. Research on

Bond-anchorage Behavior between Deformed Bars

and HPP Fiber Reinforced Lightweight Aggregate

Concrete. Engineering Mechanics, 2017,34(2):42-49.

5. Yan Ying-xin. Research on Bonding Properties of

Reinforced Steel, FRP Reinforced, Bamboo

Reinforced and Concrete [J]. Jiangxi Building

Materials, 2016,(7):2-4.

6. Wang Yi-lin. Research on Some Issues of Bond

Performance Between Steel bar and Concrete [D].

Wuhan: Huazhong University of Science &

Technology, 2005.

7. Lu Xilin, Zhou Changdong, Jin Ye. Test study on

bond behavior between GFRP bar and concrete in high

temperature [J]. Joumal of Building Structures, 2017,

28(5):42-49.

8. GB 50010-2010, Code for design of concrete

structures [S]. Beijing: China Architecture & Building

Press, 1999.

9. Chen Jian. The Experimental Research on Bond-Slip

Performance of GFRP Bars Embedded in Fiber

Reinforced Concrete [D]. Dalian: Dalian University of

Technology, 2007.

10. Sun Zeyang, Wu Gang, Wu Zhisheng, etc al.

Experimental Study on the Bond Behavior between

Steel Fiber Composite Bar (SFCB)and Concrete [J].

Earthquake Resistant Engineering and Retrofitting,

2009,31(1):21-27.

11. Wei Jun, Wang Yilin, LuoXiaohui. Curve fitting

method of bond stress distribution in steel bar pull-out

test [J]. Journal of Railway Science and Engineering,

2005,2(2):22-24.

12. Hassan M, Benmokrane B, ElSafty A, etcall.Bond

durability of basalt-fiber-reinforced-polymer(BFRP)

bars embedded in concrete in aggressive environments

[J]. Composites Part B, 2016(106):262-272.

13. Wang HZ, Belarbi A. Flexural durability of FRP bars

embeddedin fiber-reinforced-concrete [J].

Construction and Building Materials, 2013(44):541-

550.