Experimental Study on Properties of Modified Asphalt Mortar with

Different Flame Retardants

Na Li

1

,

2

and Xi juan Xu

2

1

School of Highway, Chang'an University, Xi'an 710064, China

;

2

Xi'an Highway Research Institute, Xi'an 710065, Shaanxi, China

Keywords: Flame retardant modified asphalt,Rheological properties, Flame retardant.

Abstract: Different inorganic flame retardants or organc flame retardants are added to the matrix asphalt, and the

flame retardant modified asphalt is formed through a certain technical process. The experimental study on

the rheological properties of the flame-retardant modified asphalt mortar shows that the addition of the

flame retardant makes the softening point of the asphalt mortar increase, the penetration degree decreases,

the ductility decreases, the viscosity of the asphalt mortar also increased correspondingly, and the viscosity

of the flame-retardant asphalt mortar containing decabromodiphenyl ether was proportional to the added

amount within a certain range. The short-term aging has a certain degree of influence on the penetration and

softening point of the flame-retardant asphalt mortars of each component, but from the analysis of the

results of the residual penetration, it can be concluded that the components of the flame-retardant asphalt

mortar can meet the requirements of anti-aging performance.

1 INTRODUCTION

In recent years, with the appearance of excellent

properties of asphalt pavement, the flame-retardant

modified asphalt has received more attention. From

the research progress of China's flame-retardant

asphalt, the research methods of flame-retardant

bitumen are mostly based on the flame-retardant

basic research of polymer materials, and the

mechanism research and application research are

similar, but they are different in examining the

combustion characteristics of asphalt.

2 TEST SCHEME

In this paper, different flame retardant materials

were selected and mixed into asphalt to prepare

flame-retardant modified asphalt, and its related

properties were tested, analyzed and evaluated.

2.1 The Technical Nature of Raw

Materials

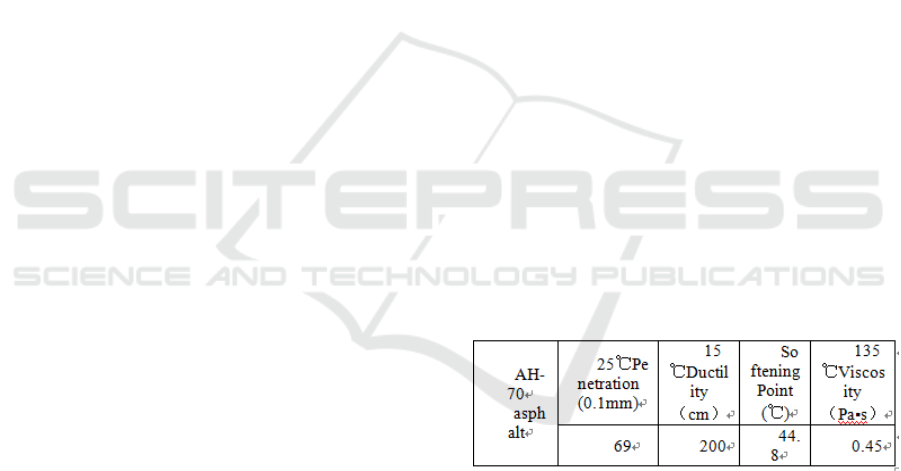

Select Caltex AH-70 asphalt, the main technical

performance as shown in Table 1.

The materials used as flame retardant are shown

in Table 2.

Table 1 The main performance of asphalt mortar.

2.2 Experiment Method

The asphalt is heated to 170±5°C to make it flow

dynamic. After that, a certain amount of flame

retardant of each component is added into the

asphalt mortar, and then sheared with a high-speed

shearing instrument for 30-45 minutes so that the

flame retardant particles can be fully dispersed in

asphalt mortar, which is prepared by flame retardant

modified asphalt mortar. After that, according to

JTG E20-2011, related asphalt mortar performance

indicators were tested, including softening point,

penetration, ductility and viscosity. The TFOT test

of each component flame retardant asphalt mortar

was carried out to simulate the aging process of

asphalt in the construction process of the hot mix

asphalt, and the residual penetration ratio, mass loss,

softening point increment and aging index of each

component were tested after aging.

Table 2 Related properties of the required test materials.

Flame

retardants

dens

ity

(

/cm

3

)

Maxi

mum

particle

size

(

µm

)

P

H

value

Lo

ss of

ignitio

n

(

%

)

melt

ing point

(

℃)

Aluminum

hydroxide

(

ATH

)

2.42 10

<

8.5

——

Zinc

borate

(

ZB

)

2.67 5

—

15.

5

—

Antimony

trioxide

— 1.6

—

— 656

decabromo

diphenyl ether

(

DBDPE

)

3.25 5

—

—

300

~

310

3 ANALYSIS OF TEST RESULTS

3.1 Effect of Addition of Flame

Retardants in Each Component on

Softening Point of Asphalt Mortar

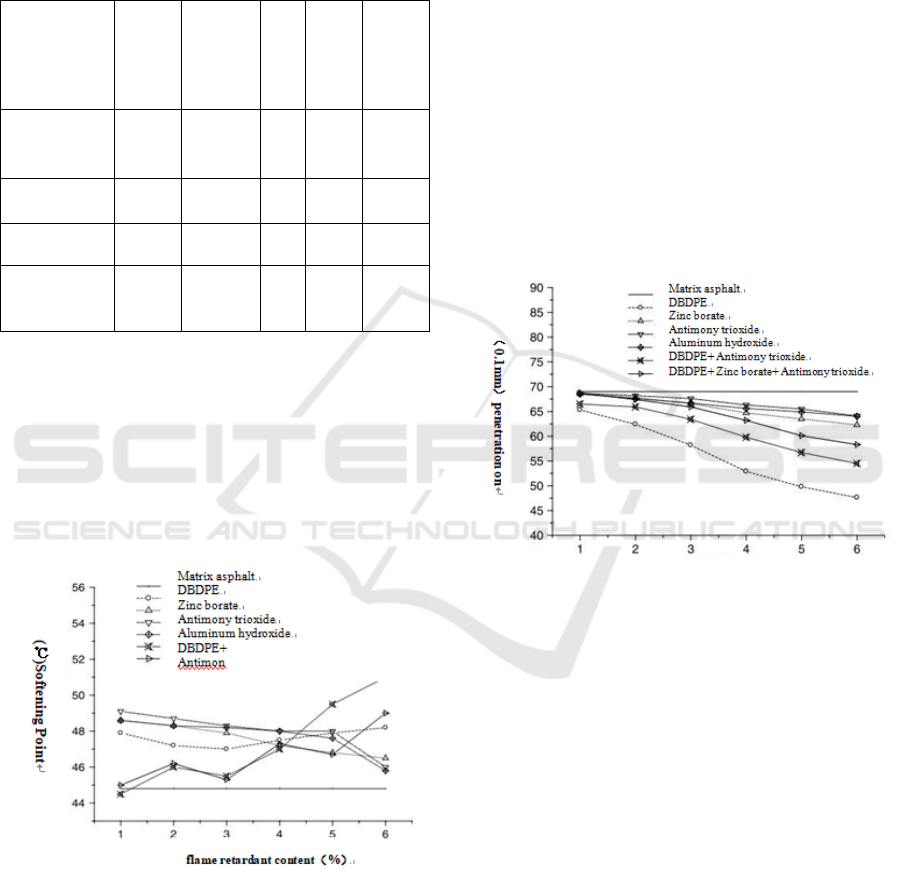

Figure 1 Effect of flame retardant content on softening

point.

As shown in Figure 1, with the increase of the

amount of flame retardant, the softening point of

asphalt mortar has changed greatly, which indicates

that the high temperature performance of asphalt has

been improved by adding flame retardants. When

the content of DBDPE + antimony trioxide reaches

6, the modified asphalt mortar shows a high

softening point compared with the matrix asphalt

and other flame retardant asphalt mortar. For other

flame retardants, ZB, antimony trioxide, and

alumina all have the same effect on the softening

point of the asphalt mortar, which increases with the

increase in the content of flame retardant. However,

However, the softening point of DBDPE modified

bituminous mortar tends to relax, and the increase its

contents but softening point does not increase

significantly. The test results show that the effect of

DBDPE on

the softening point of bituminous mortar

is different from that of antimony trioxide and ZB.

3.2 Effect of Addition of Flame

Retardants in Each Component on

Softening Point of Asphalt Mortar

Figure 2 Effect of flame retardant content on penetration.

As shown in figure 2 , with the increase of the

content of the flame retardant, the penetration of the

flame-retardant asphalt mortar shows a significant

decrease. As the flame retardant powder absorbs the

oil in the bitumen, the bitumen cement hardens and

the penetration is greatly reduced. The comparative

test results show that the effect of DBPE on

penetration is much greater than that of other single

flame retardants. When the DBDPE content is

between 1 and 6%, the penetration value is reduced

from 65.1mm to 47.6mm.For other single-modified

asphalt binders, the reduction tendency of

penetration is relatively flat, and the variation of

penetration is less than 10 mm within the same

flame retardant content range. For the single-

component antimony trioxide, the penetration degree

of the composite modified flame-retardant bitumen

is significantly reduced compared with that of the

modified antimony trioxide only by adding DBDPE.

However, the composite flame-retardant modified

asphalt containing DBDPE has a certain relationship

with the number of components and the degree of

penetration, which again shows that DBDPE has a

great influence on the penetration.

3.3 Effect of Addition of Flame

Retardants in Each Component on

Ductility of Asphalt Mortar

From figure 3, it can be seen that the low

temperature ductility of the modified flame-retardant

asphalt gradually decreases with the increase of the

content of the flame retardant. The reduction effect

exhibited by aluminum hydroxide is more

pronounced than other groups of flame retardants.

One-component inorganic flame retardants have a

great influence on the ductility, but the effect on the

ductility tends to be stable with the increase of the

content of the flame retardant. When the content of

the flame retardant is less than 3%, the ductility is

reduced significantly due to the addition of the

inorganic flame retardant, and when the content

exceeds 3%, the effect of lowering the ductility

tends to be slow.

Figure 3 Effect of flame retardant content on ductility.

3.4 Effect of Addition of Flame

Retardants in Each Component on

Viscosity of Asphalt Mortar

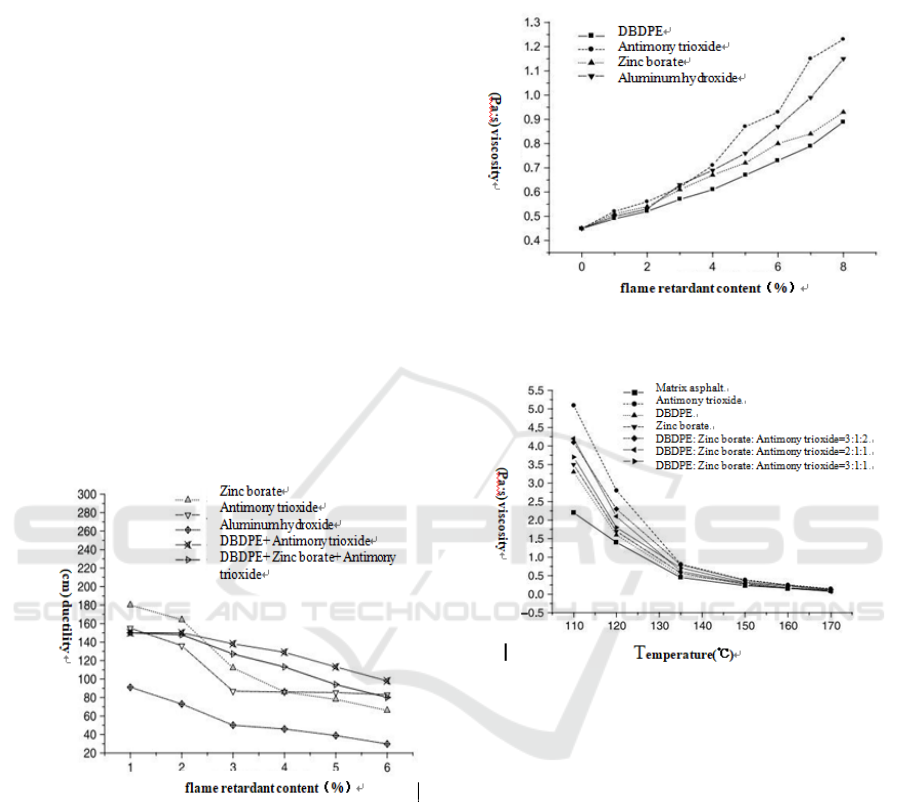

Figure 4 shows that the increase in aspalt viscosity is

not directly proportional to the flame retardant

content. Of all the flame retardants, DBDPE has the

least influence on the asphalt viscosity, while the

antimony trioxide has the greatest effect on the

asphalt viscosity. When the flame retardant content

exceeds 2%, the viscosity of the asphalt martor

mutates, due to the fact that some molecules in the

flame retardant absorb light oil in the asphalt. The

viscosity of DBDPE modified asphalt is basically in

direct proportion to its content, which indicates that

some molecular interactions.

Figure 4 Effect of flame retardant content on viscosity at

135°C.

Figure 5 Effect of temperature on the viscosity of the

flame retardant asphalt mortar at 135 °C .

As shown in figure 5, the viscosity of the flame

retardant modified pitch is higher than that of the

base pitch. Before 135 °C, the impact of various

flame retardants on asphalt viscosity varies greatly.

At 110°C, the flame-retardant asphalt containing 6%

antimony trioxide has a viscosity that is twice that of

the base asphalt, which is about twice that at 120°C.

The viscosity of the flame-retardant modified

bitumen of antimony trioxide and DBDPE is 0.81Pa

• s and 0.5Pa•s, which indicates that the viscosity at

135°C can meet the construction requirements.

3.5 Effect of TFOT on Flame Retardant

Asphalt Mortar

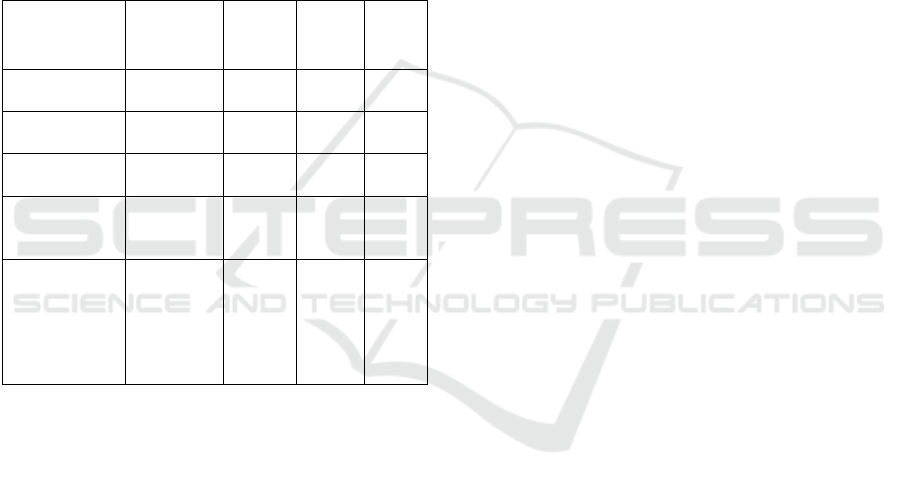

From Table 3, it can be seen that the mass loss of the

flame-retardant modified bituminous mortar TFOT

varies from 0.02% to 0.2% compared to the unaged

bituminous binder. The flame-retardant bitumen

containing 5% DBDPE has the lowest mass loss, but

the flame-retardant bitumen containing 2.5%

antimony trioxide has the largest mass loss among

all the flame-retardant modified asphalt. The

residual penetration ratio of all flame-retardant

modified asphalt mortars is more than 80%, which

means that when the flame retardant is added in the

asphalt mortar, the anti-aging properties of the

asphalt mortar can be improved. From the point of

view of the change of the softening point, it is shown

that the short-term aging has different effects on the

results of the softening point of the asphalt mortar.

Table 3 Effect of short-term aging on flame retardant

modified asphalt mortar.

Flame

retardant

content

Loss

of quality

(%)

P

RP(

%)

Δ

T(

℃)

A

I

5%DBD

PE

0.022

83

.1

4.

8

0

.0075

2.5%

Zinc borate

0.107

86

.1

4.

7

0

.0179

2.5%Anti

mony trioxide

0.188

85

.9

4.

7

0

.0086

5%Alumi

num

h

y

droxide

0.116

81

.7

4.

5

0

.0057

6%DBD

PE: Zinc

borate:

Antimony

trioxide=3:1:

1

0.034

83

.9

4.

9

0

.0118

4 CONCLUSIONS

(1) The addition of flame retardants in each

component increases the softening point to varying

degrees, and the effect of decabromodiphenyl ether

tends to ease with increasing flame retardant content

;Both penetration and matrix asphalt are reduced,

and the influence degree of each component is

different. The effect of single component of

decabromodiphenyl ether is the most significant, the

effect of the mixed flame retardant containing

decabromodiphenyl ether on the penetration is

relatively significant compared with other flame

retardants. The degree of ductility of asphalt mortar

has also been reduced to varying degrees. The

addition of inorganic flame retardants makes this

change relatively significant. When the amount

added exceeds 3%, the effect of this reduction tends

to be moderated.

(2) The addition of flame retardant will also

increase the viscosity of the asphalt mortar. The

decabromodiphenyl ether flame etardant asphalt

mortar viscosity is basically proportional to the

amount of flame retardant added. The effect of

temperature on the viscosity of each flame-retardant

asphalt mortar shows that the 135°C viscosity of the

flame-retardant asphalt mortar can meet the

construction requirements.

(3) The effect of short-term aging on the asphalt

mortar of each component is different.

Decabromodiphenyl ether has the lowes mass loss

after aging and the largest mass loss of antimony

trioxide. From the analysis of the results of the

residual penetration, the flame-retardant asphalt

mortars of various components have good anti-aging

properties.

REFERENCES

1. Bertalan G, Marosi G, Anna P, Ravadits I, Csontos I,

Toth A. Solid State Ionics 2001;141:211.

2. Jakab E, Uddin MA, Bhaskar T, Sakata Y. J Anal

Appl Pyrol 2003;68:83.

3. Ravadits I, To `th A, Marosi G, Ma ´rton A. Polym

Degrad Stabil 2001;74:419

4. "Oxidation index test of rubber combustion properties"

GB 10707-1989

5. Li Zw, Chen Hq et al. Study on the flame retardant

modification technology and flame retardant

mechanism.

6. "Textile burning performance test oxygen index

method" GB/T 5454-1997

7. Jiang Yq,Yang Rj. Effect of Metal Oxides on Flame

Retardant Properties of Polycarbonate Flame

Retardant Systems[J].Plastics,2010,39(4):34-36

8. Tan Yq, Lan Bw, Ji L, et al. Research Methods for

Modification of Flame Retardants Used in Tunnel

Pavements[J]. Journal of Chongqing Jiaotong

University:Natural Science Edition,2009,28(4):711-

714

9. Ou Yx, Li Jj. Flame Retardant Manufacturing,

Performance and Application [M]. Beijing: Ordnance

Industry Press, 2006:35-84.