Performance Prediction Analysis of Hydraulic Pump Based on

Improved BP Neural Network

Dongyang Zhang

1

, Shaohui Su

2

, Yiting Wang

3

, Chang Chen

4

, Shengran Meng

5

and Guojin Chen

6

1,2,3,4,5,6

College of mechanical engineering,Hangzhou Dianzi University,No. 2 street,Hangzhou,China

Keywords: BP neural network, Algorithm optimization, Performance prediction, Hydraulic pump.

Abstract: Aiming at the disadvantages of standard BP neural network about slow convergence rate and getting into

local minimum value easily, the momentum factor and conjugate gradient method are introduced to

optimize the BP neural network, and the convergence speed and prediction accuracy are improved. The

improved BP neural network is applied to the performance prediction of hydraulic pump with different

characteristic hydraulic oil, and the forecast result is compared with the standard BP algorithm prediction

value and the actual value. The results show that the improved BP algorithm has better prediction results on

the performance prediction of hydraulic pump, which not only improves the calculation speed, but also

improves the prediction precision greatly, and also has a good application prospectin the intelligent

manufacturing industry.

1 INTRODUTION

Hydraulic oil as a kind of liquid working medium,

which is used to transfer the energy in hydraulic

pump transmission and control system. The

hydraulic oil has seven kinds of remarkable

characteristics: lubrication, cooling, rust-proof,

sealing, cleaning, shock absorption. Whether the

hydraulic system can be reliable and effective,

depends largely on the performance of hydraulic oil,

so choosing the suitable hydraulic oil is the key to

improve the performance of the hydraulic pump. In

the production process, the choice of hydraulic oil is

usually dependent on experience, through repeated

experiments to select more suitable hydraulic oil, but

the use of this method will lead to a series of

problems, including the long research cycle and high

cost.

Artificial neural Network (ANN) is a

computational model simulating human

physiological mechanism, which provides an

alternative means for identifying complex and highly

nonlinear problems. BP Neural Network is one of the

most widely used algorithms in artificial neural

networks, and its structure is simple and easy to

understand. Li Ping, Shi Lei used BP neural network

to predict the performance of magnesium alloys

under different deformation parameters and obtained

good results. In the reference, the flow stress of high

speed steels during thermal deformation is predicted

by using BP neural network with 3-9-10-1 structure

based on the parameters of strain rate, temperature

and strain.

However, the BP neural network is similar to a

black box, and the weights of each network affect

each output result. Every time's random assignment

of weights will result in different prediction results,

resulting in the network is not reliable, and cycle

training leads to low learning efficiency, long

learning cycle. Once the algorithm into the local

minimum value, the whole learning convergence

process will be oscillated, it is difficult to get

accurate predictions. Aiming at the defects of

standard BP neural network, this paper first uses

standard BP neural network to predict and analyze

the performance of hydraulic pump with different

properties of hydraulic oil, and obtains the predicted

value which is close to the experimental result. Then

when the convergence speed of BP algorithm

reaches a slow stage, an important unconstrained

optimization method-Conjugate gradient method

(CG) is used to improve the standard BP

algorithm(SBPA). The improved BP algorithm(IBPA)

is used to predict the performance of hydraulic pump,

and the prediction result with higher precision and

smaller error is obtained. This method provides a

new way to consider the product performance and

improve the product benefit in the design stage.

2 MAIN INFLUENCING

FACTORS OF HYDRAULIC

PUMP PERFORMANCE

According to the working environment, working

conditions and hydraulic system of the oil

pump,when selecting hydraulic oil for hydraulic

pump, the following factors should be considered

emphatically:

① Suitable viscosity:Hydraulic pump is the

most sensitive component of hydraulic oil viscosity

reaction in hydraulic system. Under the same

working pressure, the higher the viscosity of

hydraulic oil, the greater the running resistance of

hydraulic moving parts, which causes the hydraulic

pump temperature rising, the self-priming ability

decreasing, the pipeline pressure and power loss

increasing. If the oil viscosity is too low, this will

increase the volume loss of hydraulic pump and the

sliding parts of the oil film thinning, then support

capacity decline.

② Good air release characteristics:The

hydraulic oil always contains a certain amount of air.

When the pressure of the hydraulic oil is below a

certain value, the air dissolved in the hydraulic oil

will be separated to form a bubble. A large number

of bubbles with the oil cycle, not only will reduce

the pressure of the system, but also produces a local

hydraulic impact, emitting noise and vibration. In

addition, the air bubble also increased the contact

area between oil and atmosphere, accelerating the

oxidation of hydraulic oil. Therefore, the hydraulic

oil is required to have good air release

characteristics.

③ Adaptation characteristics of sealing

materials:Because of the poor adaptability of the

hydraulic oil and sealing material, the sealing

material will swell, soften or harden to lose the

sealing ability, so it is required that the hydraulic oil

and sealing material should be adaptable to each

other.

Therefore, this paper will take the hydraulic oil

viscosity, air release characteristics, the adaptability

of sealing materials as variables to predict the

hydraulic pump no-load Force, noise, service life

and other performance effects.

3 BP NEURAL NETWORK

ALGORITHM

3.1 Standard BP Neural Network

The learning and training process of standard BP

Neural network is divided into two parts, including

the forward propagation of signal and the reverse

propagation of error. When the signal is transmitted

forward, the parameters are input from the input

layer, then processed through the hidden layer, and

finally uploaded to the output layer. When the output

result is larger than the desired result, the error is

transmitted backwards until the error is smaller than

the maximum allowable error or the number of

training times reaches the starting preset. The reverse

propagation of error is actually the process of

modifying and adjusting the weight value, and the

weight adjustment formula is as follows:

( )

( )

E

Δ

wn

η

wn

=−

(1)

In the formula, n is the iteration number, the η is

the learning rateandthe weight adjustment between

the nodes,

( )

E

wn

is the gradient of the error, the

minus sign represents the descent of the gradient.

3.2 Improved BP Neural Network

3.2.1 Introduction of Momentum Factor

Since the standard BP algorithm adjusts the weights,

it only adjusts according to the gradient direction of

the n-th iteration error, but the gradient direction of

the (n-1)-thiteration error is not considered, thus the

training process is concussed and the convergence is

slow. In order to increase the training speed of the

network, momentum items can be added to the

weight adjustment formula. The weight adjustment

formula at this time is:

( )

( )

( )

-1

E

Δ

wn

η αΔ

wn

wn

= − +

(2)

It can be seen that the increased momentum item

is added from the previous weight adjustment

amount to this weight adjustment amount.

α

is a

momentum factor, generally,

( )

01

α

,

.Momentum

terms reflect the accumulation of experience in

weight adjustment during the learning process and

play a dampening role in the current weight

adjustment.

3.2.2 Introduction of Conjugate Gradient

Method

Due to the excessive number of learning and training

times of the standard BP neural network, the error of

the result is large, and the traditional gradient

descent method is easy to cause the disadvantage of

slow convergence speed and easy to fall into the

local minimum of error surface. Therefore, the

conjugate gradient algorithm is introduced into the

BP neural network with momentum added. The basic

idea is to use the gradient of known nodes to

construct a set of conjugate directions and search for

the extremum of the objective function accordingly.

Combining the BP algorithm with the conjugate

gradient method, the training process is divided into

two stages. In the beginning stage, the BP algorithm

is used, when the convergence rate is slow, and the

conjugate gradient method is used to give full play to

the advantages of the two parties.

The process of the conjugate gradient method

introduced is as follows:

( )

dn

is used to represent the gradient direction,

and the minimum value can be obtained by

searching:

( )

( )

( ) ( )

( )

mi n 1 (3)

n

E w n E w n d n

+ = +

The objective function is

( )

mi n Ew

,

wR

, and

n

is the search step, and the expression is shown

in formula (4).

( ) ( )

( ) ( )

T

n

T

n d n

g

n Ad n

d

=

(4)

The A in the upper form is expressed as the

positive definite Hessian matrix of the error function,

and

( )

gn

is expressed as the gradient direction of

the error function. The gradual search by formula (2)

can be obtained:

( ) ( ) ( )

1

n

w n w n d n

+ = +

(5)

( ) ( ) ( )

( ) ( )

1

00

n

d n g n d n

dg

= − + −

=−

(6)

( ) ( )

( )

00g E w=

(7)

n

is expressed as the direction factor of the

error function. The expression is:

( ) ( )

( ) ( )

11

T

n

T

g n g n

g n g n

=−

−−

(8)

When it starts to iterate,

( ) ( )

00dg=−

.

Therefore, the basic idea of the conjugate gradient

can be expressed as a linear combination of the

iterative direction of the N times and the (N-1) times,

and the

( )

dn

and

( )

1dn−

are a pair of

conjugate vectors.

During training, in order to avoid over fitting

phenomenon, the root mean square error (RME) of

the sample is always calculated periodically.

()

When the root mean square error begins to rise, it

is proved that the over fitting phenomenon appears,

and the neural network obtained by the stop training

at this time has a reasonable reliability for future

prediction.

3.3 Validation of The Effectiveness of

Improved BP Algorithm

In order to study the effect of the improved BP

neural network, the nonlinear function formula (10)

is used to carry out the experiment, and the results

can be compared and analyzed.

( ) ( )

23

2si n 2 cosy x x x= + +

(10)

In the BP neural network, the accuracy of the

error is set to 0.0001, and the Sigmoid function is

used as the activation function. A BP neural network

with a hidden layer is selected for learning and

training, and the output layer has a neural unit,That

is, l=1, the number of nodes in the input layer is set

to 5, that is, n=5; according to formula (11), the

calculation can be obtained:

7

β

=

, the number of

nodes with hidden layer can be calculated to be 9,

that is, m=9.

m n l

β

= + +

(11)

m represents the number of hidden layer nodes, n

indicates the number of input layer nodes, and l

represents the number of nodes in the output layer,

β

is constant and

1,10

.

According to the above selection, the BP neural

network structure of the experiment is 5-9-1, and the

number of hidden layer nodes is 9. The result of the

improved BP neural network is shown in Table 1.

Table 1:Convergence rate of improved BP algorithm.

No.

Time(s)

Number of

iterations

1

19.34

4681

2

24.51

4963

3

21.67

4826

4

24.03

4901

5

19.41

4689

6

20.89

4736

7

24.18

4930

8

18.37

4597

9

22.15

4885

10

21.14

4782

Average value

21.569

4802.3

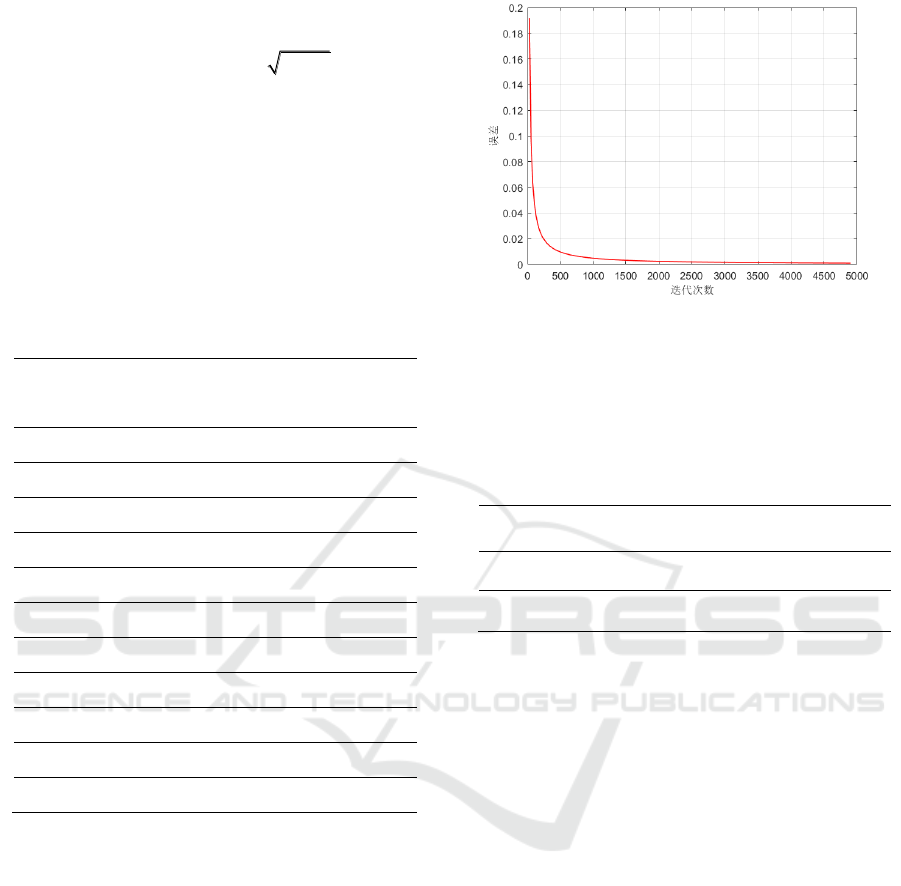

Using the improved BP algorithm to train, the

average convergence time is 21.57s and the average

number of iterations is around 4800. The error curve

is recorded as shown below. Figure 1 shows that as

the number of iterations increases, the error

decreases. When the number of iterations reaches

4800 or more, the accuracy can reach 0.0001. During

the iteration process, the error curve remains smooth

and no jitter occurs. The entire learning process is

fast and smooth.

Figure 1: Improved BP neural network algorithm error.

Compare the average time and number of

iterations of the improved BP algorithm with the

standard BP algorithm. The results are shown in

Table 2:

Table 2:Comparison result.

Items

Average

time(s)

Iterations

Error

accuracy

SBPA

52.86

14558.0

0.0009

IBPA

21.57

4802.3

0.0001

According to Table 2, it can be concluded that the

main reason for the slow error convergence rate of

the standard BP algorithm is the defect of the

algorithm itself; however, the improved BP

algorithm can be used to complete the training in a

shorter time and the error accuracy is less than

0.0001. This not only reduces the training time to a

great extent, but also improves the accuracy of the

prediction results.

4 APPLICATION OF IMPROVED

BP ALGORITHM IN

PERFORMANCE PREDICTION

OF HYDRAULIC PUMPS

4.1 Neural Network Model

Construction

① Determine the object of the experiment: in this

paper, YYB1-AA6/14B-Y2 type hydraulic pump is

selected as the research object, and orthogonal test is

used to study and analyze the influencing factors.

According to the relevant theoretical knowledge and

previous experience, the effects of the viscosity of

hydraulic oil, the air release of hydraulic oil and the

adaptability of hydraulic oil and sealing materials on

the no-load force, noise and service life of the

hydraulic pump are considered. In the experiment,

the selected factors are shown in Table 3.

Table 3:Influencing factors.

No.

viscosity

(cst)

air release

(min)

adaptability to

sealing

materials

1

34.7

(class 32)

<5

better

2

46.5

(class 46)

5~10

good

3

63.4

(class 68)

>10

substandard

In orthogonal experiments, in order to reduce the

numberof the selected samples and workload, we

choose the least orthogonal table. The orthogonal

array of hydraulic pump is selected through

influencing factors (shown in Table 4 below). The

number of test samples is 9, that is, the number of

tests is 9 times. Compared with all tests (3

3

=27

times), 18 times of repeated trials can be effectively

reduced. This greatly reduces the time and workload

of the test.

Table 4:Orthogonal test table for hydraulic pump.

No.

A

(Viscosity)

B

(Air release)

C

(Adaptabilit

y)

1

1

1

1

2

1

2

2

3

1

3

3

4

2

1

2

5

2

2

3

6

2

3

1

7

3

1

3

8

3

2

1

9

3

3

2

② Determine the learning rate and

momentum factor: In the training of BP neural

network, the selection of learning rate has an

important influence on the effect of training.

Excessively increasing the learning rate will

fluctuate the error function. If the learning rate is too

small, it will lead to slow convergence. After

repeated experiments, the learning rate in this paper

is 0.035. The momentum factor can effectively avoid

the error surface falling into the minimum value,

reducing the trend of oscillation and improving the

training speed. Its value is 0.65.

③ Determine the number of hidden layer

nodes: The viscosity of the hydraulic oil, the air

release characteristics and the adaptability of the

hydraulic oil and sealing materials are used as the

input level of the input layer, that is, n=3; the output

of the output layer are the no-load force, noise and

service life of the hydraulic pump, that is, l=3.

According to the formula (11), after repeated tests,

the number of nodes in the hidden layer is calculated

to be m=8, so the prediction model of BP neural

network is 3-8-3.

4.2 Comparison and Analysis of The

Results of Training and Learning

4.2.1 The Result of Training

Using Numpy and Matplotlib two library functions

in Python to achieve the prediction of the two

algorithms. The final results obtained by orthogonal

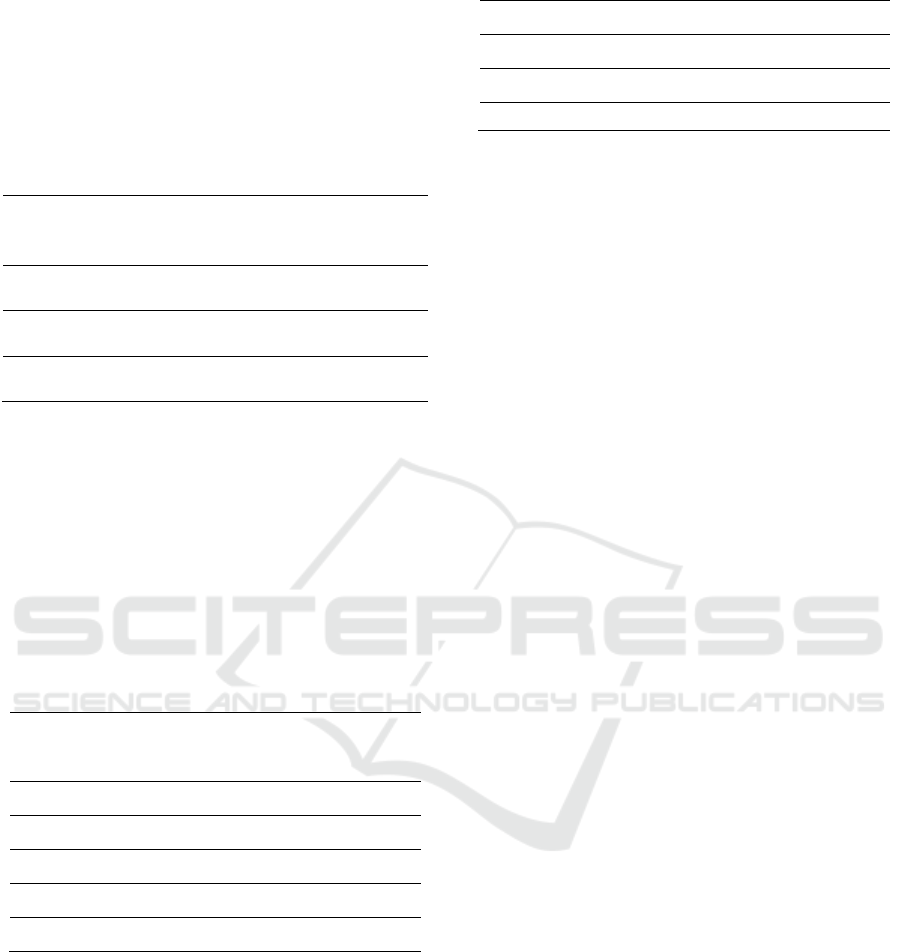

tests are shown in Table 5 below.

Table 5:Training results of standard BP algorithm and improved BP algorithm.

4.2.2 Analysis Results

The training results shown in Table 5 can be shown

in Figures 2, 3, and 4:

Figure 2 :Actual value and training value of the unloaded

force.

According to table 4, it can be seen that when the

viscosity of hydraulic oil is the same, the no-load

force of the hydraulic pump is on the same

horizontal line. When the viscosity of the hydraulic

oil increases, the unloaded force of the hydraulic

pump increases significantly. Thus, it can be seen

that the effect of the unloaded force of the hydraulic

pump on the viscosity of the hydraulic oil is greater

than that of other factors. In addition, the prediction

results obtained by the improved BP algorithm are

closer to the actual values.

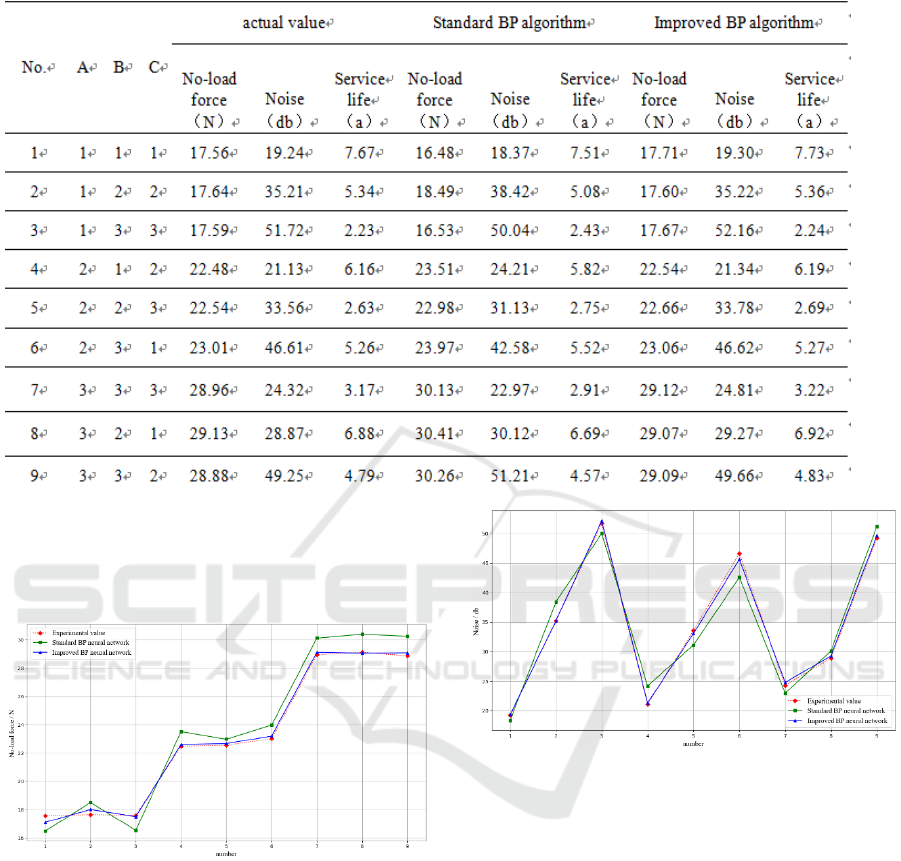

Figure 3:Actual value and training value of noise.

The peaks of curves in Figure. 3 appear in third,

sixth, ninth sets of tests. It is shown from table 4 that

the poor air release performance of hydraulic fluids

is the common ground of these three sets of tests.

The trough of the curve appeared in the first, fourth,

seventh group of experiments. The good release of

the hydraulic oil was the common point of the three

groups. It can be concluded that the noise of

hydraulic pump is greatly influenced by the air

release of hydraulic oil, which is also consistent with

the cavitation phenomenon introduced in the

introduction. In addition, the prediction results

obtained by the improved BP algorithm are closer to

the actual values.

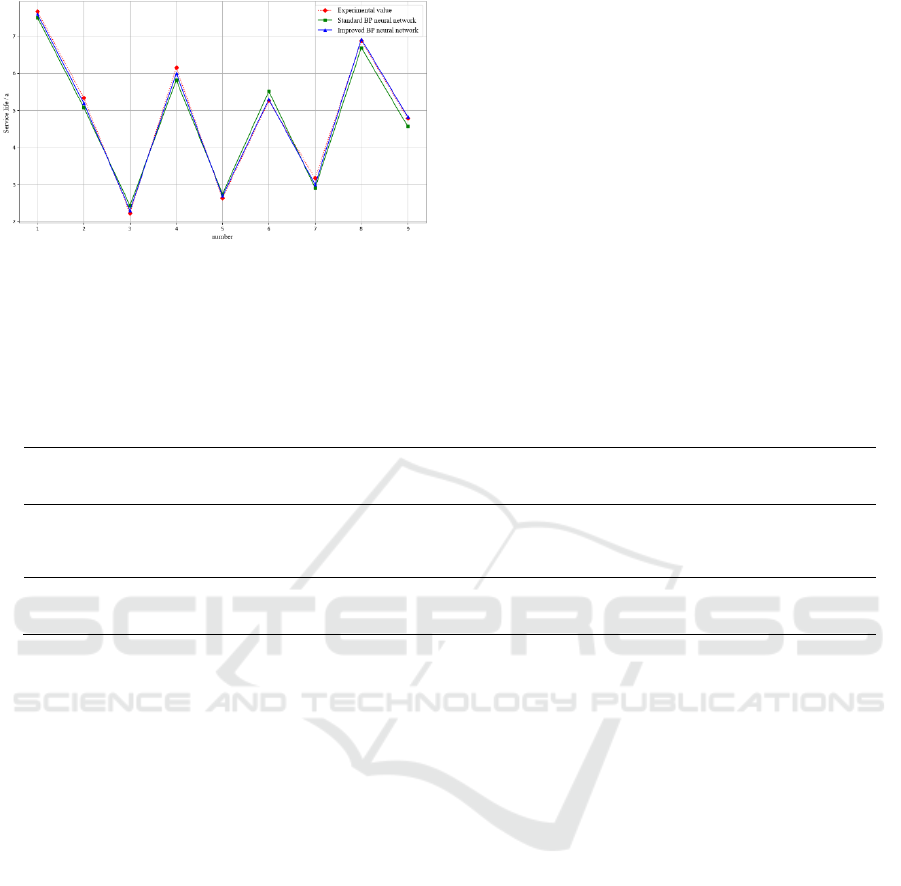

Figure4: Actual value and training value.of service life.

The wave peaks in Figure 4 appear in groups 1, 4,

6 and 8. The hydraulic oil used in the four groups

can be well adapted to the sealing material, so the

service life of the products is relatively long. On the

contrary, the hydraulic oil and seal materials used in

other tests can not be well adapted, which causes the

wear and tear of products and the service life greatly

reduced. This is also in line with our daily

experience. In addition, the prediction results

obtained by the improved BP algorithm are closer to

the actual values.

In summary, the prediction results obtained by

the standard BP algorithm are obviously deviated

from the actual value; the predicted value of the

improved BP neural network is basically consistent

with the actual value, and the relative error is smaller

(as shown in Table 6), the learning rate and the

convergence speed are all improved, which can meet

the requirement of prediction precision.

Table6:Relative error of BP algorithm before and after improvement.

Items

Standard BP algorithm

Improved BP algorithm

Relative error

No-load force

(N)

Noise

(db)

Servie

life(a)

No-load force

(N)

Noise

(db)

Servie

life(a)

Average value

0.53%

0.44%

0.51%

0.08%

0.09%

0.09%

5 CONCLUSIONS

1) In this paper, the BP neural network is improved

by introducing momentum factor and conjugate

gradient method, the nonlinear mapping model

between hydraulic oil characteristics and hydraulic

pump performance is established. The model has

shorter prediction time and higher prediction

precision, which effectively solve the shortcomings

of the standard BP algorithm in the slow

convergence speed and easy to fall into the local

minimum.Through the comparison between the

standard BP algorithm and the improved BP

algorithm for the prediction of the performance of

the hydraulic pump, it is concluded that the

improved BP neural network algorithm is effective

and feasible.

2) Based on the product performance prediction

model constructed, the performance of the products

can be predicted during the design period; this

method can instruct the developers to design the

hydraulic pump and choose the required hydraulic

oil quickly and reasonably. At the same time, the

proposed BP neural network provides a new way of

thinking and new means for the performance

prediction of industrial products affected by complex

parameters, which greatly shortens the development

cycle and reduces the research and development cost.

It has high theoretical significance and engineering

application value in the fast intelligent

manufacturing industry.

ACKNOWLEDGEMENTS

Thank the National Natural Science Foundation of

China (Grant No. 51475129,51675148, 51405117)

for its strong support for this paper.In the writing of

this paper, I got the careful guidance of my tutor, Mr.

SuShaohui. At the same time, thanks to the research

platform provided by Anji Intelligent Manufacturing

Research Institute.

REFERENCES

1. Wang Zu’an,1998.The working principle of hydraulic

system and the classification of hydraulic oil. Oil

Technology.

2. Han Liqun,2006. Artificial Neural Network

Tutorial.Beijing:Beijing University of Posts and

Telecommunications Press.

3. Wang Lei,WangRuliang,Qu Hongfeng,2016. BP

Neural Network Algorithm Improvement and

Application. Software Guide,38-40.

DOI:10.11907/rjdk.161429.

4. Li Ping,Shi Lei,2017. Research on prediction of

mechanical properties of AZ31 magnesium alloy based

on BP neural network. Foundry

Engieering,38(11):2721-2723.

5. JiantaoLiu,HongbingChang,T.YHsu,Xueyu Ruan,2000.

Prediction of the Flow Stress of High-Speed Steel

During Hot Deformation Using a BP Artificial Neural

Network. Journal of Materials Processing Tech,103(2)

6. Regelja, M., Regelja, Lončarić,S.,2005. Development

of an inorganic cations retention model in ion

chromatography by means of artificial neural

networks with different two-phase training algorithms.

Journal of Chromatography A, 1085(1):74.

7. Ba. A. J. S.,1997. Second-Order Methods for Neural

Networks.Kybernetes, 27(2):201 - 203.

8. Chen Qiang,2008. Viscosity, viscosity index and

selection of hydraulic oil.Construction Machinery

Technology and Management,123-127.

9. Bao Xiaobing,2008. Selection and maintenance of

hydraulic oi. Hydraulic pneumatic and seal,4-6.

10. Ai Xiaosong,2008. Intelligent control system of

concrete mixing station.Hunan: Central South

University.

11. Li Jie,2015. Research on bearing fault diagnosis

technology based on neural network. University of

electronics technology.

12. Mehmet Engin,SerdarDemirag,Erkan Zeki Engin, et

al,2007.The classification of human tremor signals

using artificial neural network.Expert Systems with

Application,754-761.

13. Ji Li,WangXiaodong,YangXushu,LiuShushen,Wang

Liansheng,2007. Improved BP algorithm artificial

neural network for QSAR research of environmental

estrogen using genetic algorithm combined with

conjugate gradient method. Chinese Science

Bulletin,2116-2121.

14. Ye Bing,Lei Yan,2004. Analysis of selection method of

hidden layer number and node number in BP neural

network. Journal of shangqiu vocational and technical

college,52-53+60.