High Speed online Detection of Fabric Density Based on

Multi-resolution Wavelet Basis

Ya’nan Zhao

1

,Liming Wu

1

and Qi Chen

1

1School of Electromechanical Engineering, Guangdong University of Technology, Guangzhou, China

Keywords: Fabric detection, Wavelet basis, Warp and weft density.

Abstract: The textile industry is a pillar industry in China. Domestic demand and foreign exports are huge. With the

improvement of living standards, the public demanded that textiles be both aesthetical and comfortable.

New indexes should be added to the processing of fabrics, which increase the difficulty to detect. Density

detection is an important part of fabric quality inspection. However, the current detection methods still rely

heavily on labour, with high error and low detection efficiency. Wavelet basis combines machine vision are

introduced to achieve high speed automatic detection. Firstly, the images are preprocessed, and several

wavelet basis reconstruction effects are compared. The wavelet transform is used to extract the feature

information in both latitude and longitude directions, and binarization and smoothing processing are

performed for better calculation of density information. Finally, the density of fabric is obtained. The results

show that the method can detect the density of the fabric quickly, and the speed and efficiency are high.

1 INTRODUCTION

Density inspection is an essential task in the fabric.

Many experts have studied this issue. A foreign

scholar combined the optical field with fabric

organization for the first time and studied the

structure of fabrics by diffraction images, and

calculated the interval through the highlights of the

photo (Akiyama R, 1986).The two-dimensional

spectrum of the fabric was obtained through the Fast

Fourier Transform (FFT), and the feature was

extracted through the frequency analysis of the

fabric images to obtain the density of the fabric (Xu

B, 1996). Taiwan scholar calculated the gray level

co-occurrence matrix according to the different

intervals and angles of pixels, and obtained the

eigenvalues. Then the fabric density of circular

arrangement can be calculated (Huang C, 2000).

Domestic scholars added adaptive filtering to the

fabric image to obtain a picture containing only the

longitudinal and latitudinal texture information. (He

Feng,2007). According to this research, a detection

method was proposed which combining wavelet

image decomposition and Radon transform for the

image texture of the inclined image. The method can

classify fabrics and measure density (Shen

Jianqiang, 2007). For the fabrics with different

texture patterns on both sides, a two-sided fusion

technique was proposed. A double-sided imaging

system is applied to obtain images containing front

and back information of fabrics, and affine and

wavelet transform are used to fuse two-sided fabric

images. A fast Fourier transform is performed to

measure the warp and weft yarn densities of the

fabric in the frequency domain (Zhang R, 2016). In

this paper, the high speed online detection of fabric

density based on multi-resolution wavelet basis is

proposed. It can not only save time, reduce labor,

but also improve efficiency while ensuring accuracy.

2 PRINCIPLE OF DWT

Wavelet transform is a time-frequency analysis

method, which has multi-resolution characteristics

and can provide a time-frequency window with

frequency. The discrete wavelet transform(DWT) of

the size image is defined as follows:

11

0

00

1

0

MN

(,m,n)

xy

W ( ,m,n ) f ( x,y ) ( x,y )

MN

ϕ

ϕ

−−

==

=

∑∑

(1)

11

00

1

MN

ii

( j ,m,n )

xy

W(j,m,n) f(x,y) (x,y)

MN

ϕ

ϕ

−−

==

=

∑∑

(2)

{

}

iH,V,D=

where

W(j,m,n)

ϕ

and

i

W(j,m,n)

ϕ

are low and high

frequency approximation coefficients of images

respectively.

i

(j,m,n)

(x,y)

ϕ

is scaling and translation

transformation of wavelet functions in horizontal,

vertical and diagonal directions.

When the 2D wavelet transform is applied to

image processing, it can be decomposed into two

steps: horizontal wavelet transform and vertical

wavelet transform. The wavelet and scale functions

are applied to the rows and columns of the image

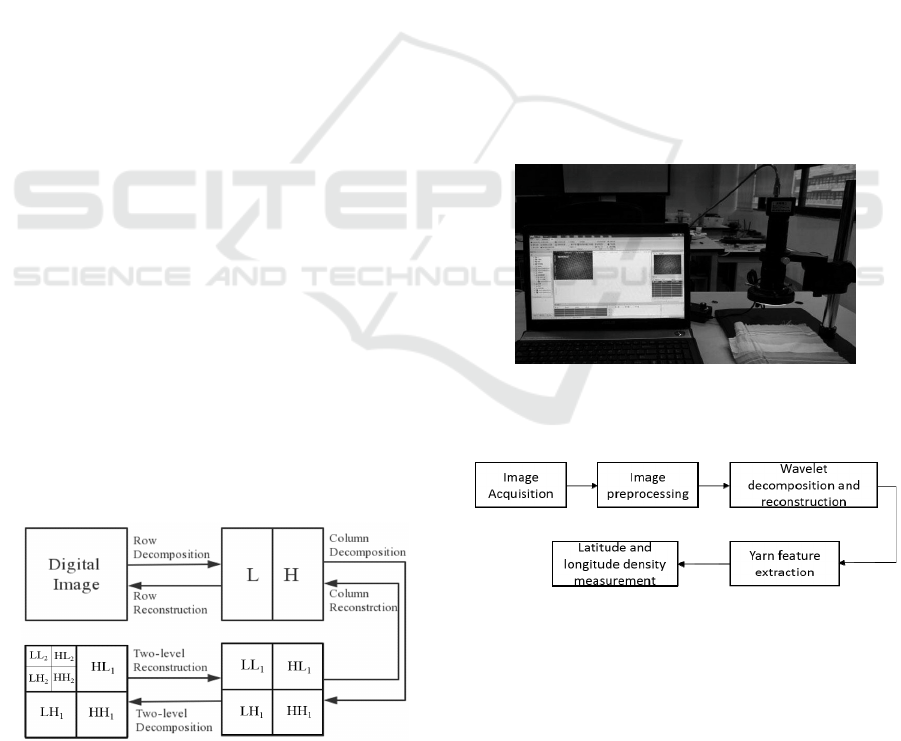

respectively. The figure 1 shows the two-

dimensional discrete wavelet decomposition and

reconstruction process of the image. The

decomposition process can be described as follows:

Firstly, one-dimensional DWT is performed on each

row of the image to obtain the low-frequency

component L and high-frequency component H of

the original image in the horizontal direction. And

then one-dimensional DWT is carried out on each

column of the transformed data to obtain the four

parts of the original image: Low-frequency

components LL in the horizontal and vertical

directions, Low-frequency in the horizontal direction

and High-frequency in the vertical direction LH,

High-frequency in the horizontal direction, and

Low-frequency in the vertical direction HL, and

High-frequency components HH in both horizontal

and vertical directions. The reconstruction process

can be described as follows: Firstly, IDWT is

performed on each column of the transform result.

Then one-dimensional IDWT is performed on each

row of the transform data, and a reconstructed image

can be obtained. It can be seen from the above that

the wavelet decomposition of an image is a process

of separating a signal in accordance with low-

frequency and directed high-frequency. Further

decomposition of the acquired LL component can be

performed according to the requirements in the

Figure 1: Two-dimensional discrete wavelet

decomposition and reconstruction process of the image.

decomposition process until the requirement is

satisfied.

The warp and weft yarns in the fabric are

perpendicular to each other according to certain

rules. The texture information of the warp and weft

can be obtained after the fabric image is

decomposed. Since the information is distributed in

the high frequency regions, the vertical high

frequency subimage and horizontal high frequency

subimage after wavelet decomposition can be used

to analyze the fabric density.

3 IMAGE PROCESSING

3.1 Image Acquisition

As shown in the figure 2, an area array CCD

industrial camera is used for image acquisition, with

an optical zoom lens and a ring light source to

facilitate the adjustment of the detection system. For

better measurement, the collected objects are clean,

neat and clear texture. The collected image samples

are shown in figure 2.

Figure 2: Collected image samples.

The workflow chart is as figure 3:

Figure 3: Workflow chart.

3.2 Image Pre-processing

In the process of image acquisition, the imaging

quality is affected by many factors, such as uneven

illumination, distortion of the optical system, and

noise pollution. It is difficult to meet the detection

requirements. After obtaining the target image, the

acquired image sample needs to be pre-processed to

improve the image quality (Ji Shi, 2012). The pre-

processing process includes the following steps: (1)

Transform the color space. The color of the image

affects the image quality and needs to be converted

into a grayscale image; (2) Histogram equalization

process .It can enhance the contrast of the original

image and makes it evenly distributed; (3) Noise

removal. It can suppress background; noise and

preserve image details as much as possible. Median

filter is used for noise reduction; (4) Local

enhancement, which can increase the contrast of the

image; (5) Image correction. The Canny edge

detector is used to extract the edge information of

the fabric warp and weft yarn, and then Hough

transform is used to detect the angle of the fabric

image to correct it (Kaicheng Fu, 2016).The

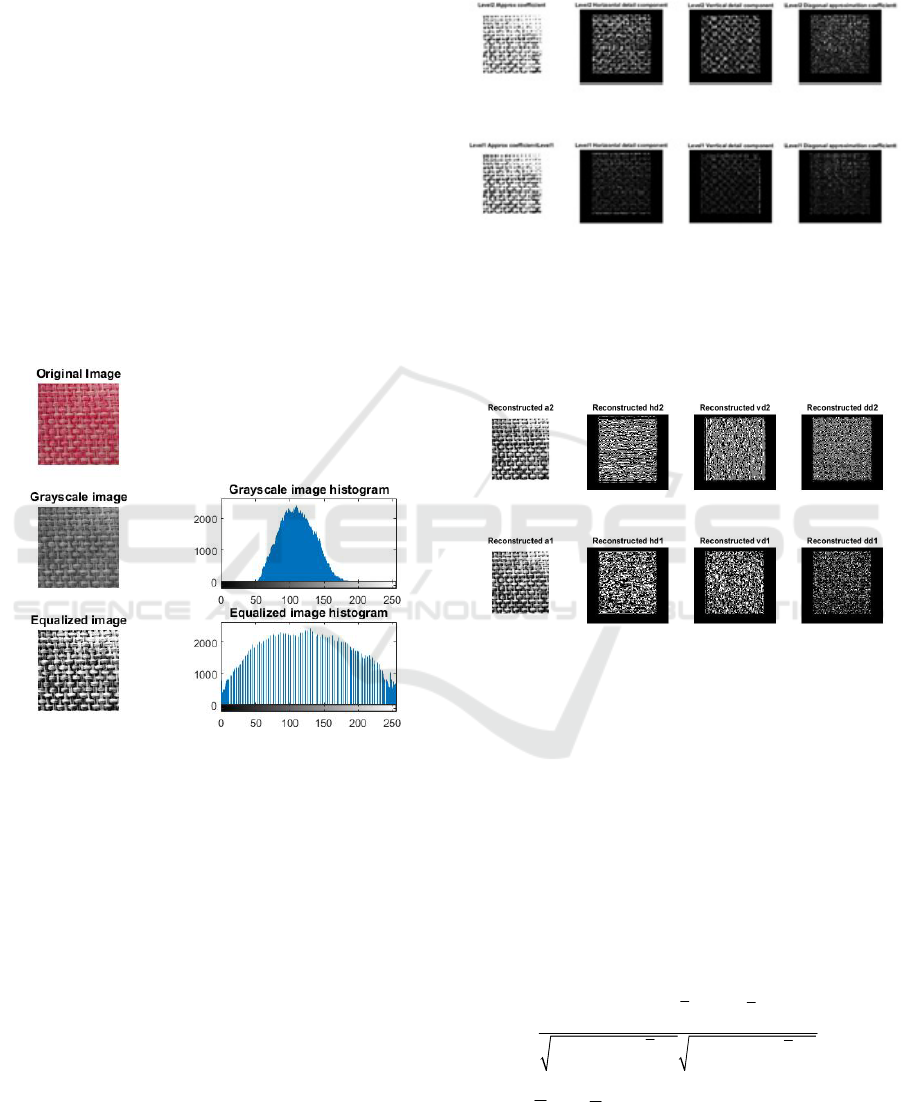

equalized image is shown as figure 4.

Figure 4: Equalized image.

3.3 Feature Extraction of Latitude and

Longitude

Multi-level wavelet decomposition of fabric images

is required in order to obtain clearer images of warp

and weft yarns. The Mallat wavelet basis function is

applied to multidimensional wavelet decomposition

of fabric images. It is found that the four-layer

wavelet decomposition has the best effect. The two-

dimensional decomposition effect is shown in figure

5. After wavelet decomposition, the approximate

component, horizontal component, vertical

component and diagonal component of the fabric

image are obtained, and the horizontal component

and vertical component are selected for wavelet

reconstruction. As shown in Figure 6, the first half is

the result of first order wavelet decomposition, and

the second half is the result of two level wavelet

decomposition.

Figure 5: Two-dimensional wavelet decomposition of

fabric images.

The warp and weft yarn information in the fabric

image is best retained in the high-frequency

horizontal and vertical reconstruction map of a

certain layer.

Figure 6: Two-dimensional wavelet reconstructed of fabric

images.

The number of layers selected during

reconstruction affects the correctness of the final

result directly. When determining the level of

reconstruction, the correlation coefficient method

can be used to determine the optimal level of

reconstruction. After multi-level decomposition of

the image, the correlation coefficients between the

horizontal and vertical reconstruction map of the

layer and the original image are calculated. The

highest correlation coefficient is used as the

coefficient of reconstruction. The correlation

coefficient between A and B as equation (3).

22

mn mn

mn

mn mn

mn mn

(A A)(B B)

t

( (AA))( (BB))

−−

=

−−

∑

∑

∑∑ ∑∑

(3)

where A and

B

are the average gray value of the

two images. A and B are the gray scale matrices of

the images, which have the same dimension of

mn×

.

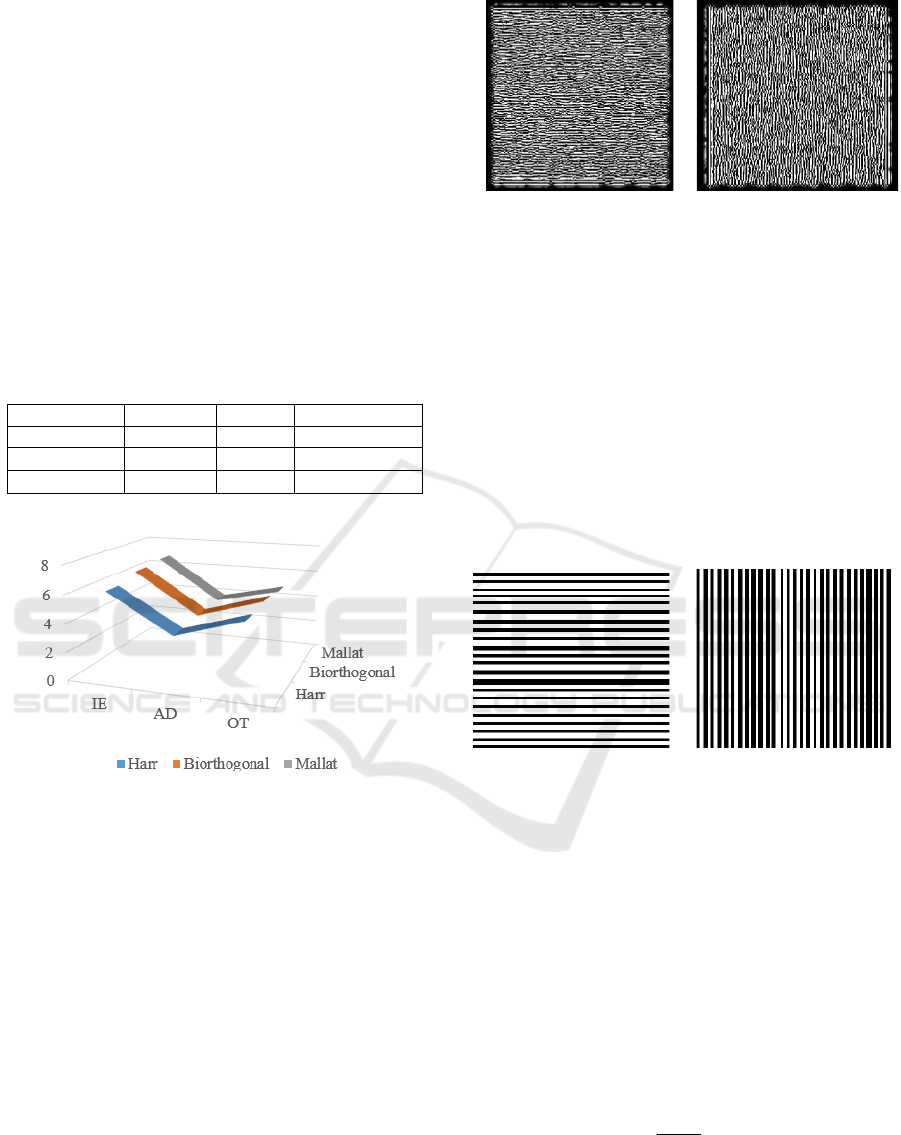

In order to evaluate the reconstructive

performance of the image objectively, three kinds of

wavelet functions Harr, Bior, and Mallat were

selected for comparison. The commonly used

information entropy(IE), average gradient(AG), and

oprating time(OT) three statistical indicators were

used to evaluate the reconstructed images(Jun Yang,

2007). IE represents the amount of information in an

image and is an index to measure the abundance of

information. AG reflects the sharpness, detail and

texture of the image. The larger the first two

indicators, the better the image quality. The specific

statistical results are shown in table 1 and figure 7.

Table 1: Objective evaluation of reconstruction effect.

IE AG OT

Har

r

6.1251 3.5014 4.935156

Biorthogonal

6.6144 3.7380 5.131282

Mallat

6.7628 3.8163

4.852911

Figure 7: Comparison of different wavelet function

reconstruction effects.

From the above, it can be seen that since the

sawtooth of Harr operator reconstructs the image,

the IE is obviously small, and the biorthogonality of

Bior. affects the calculation time, which has the

longest RT. Combining three indexs, the Mallat

operator has the best effect of extracting image

features among the three functions.

The approximate direction of the warp and weft

yarns can be observed after reconstructing. In order

to obtain the warp and weft information more

accurately, it is necessary to binarize the

reconstructed image (Xunming Zhao, 2011).The

global threshold method is applied for image

processing. The binarized image is shown in figure 8.

White represents yarn, and black represents yarn gap

after binarization.

Figure 8: Latitude and longitude binary image.

The warp and weft information of each direction

is basically obtained after binarizing. However, the

obvious discontinuity in the yarn image interferes

the subsequent calculations. To obtain the exact

value of the warp and weft density of the fabric, it is

also necessary to perform morphological processing

and idealization of the yarn image. The idealization

idea is as follows: take one column in the weft

image or take a row in the warp image, and count

the number of 0 pixel values or 1 pixel value in each

column and each row of the binary image separately.

If the pixel value has a mutation from 0 to 1, the

number of yarns adds. The idealized image, shown

in figure 9, is used for the density calculation.

Figure 9: Idealized latitude and longitude images.

3.4 Density Measurement

The warp and weft stripes of the image are obvious

after idealizing. The black and white stripes appear

alternately in the image. The fabric warp and weft

density can be calculated based on the number of

white stripes and pixel conversion coefficient. The

warp and weft density of a fabric is defined as the

number of yarns within 10 cm or 1 inch. The ratio

between the pixel distance S

pixel

and the actual

physical distance S is as formula (4):

pixel

S

R

S

=

(4)

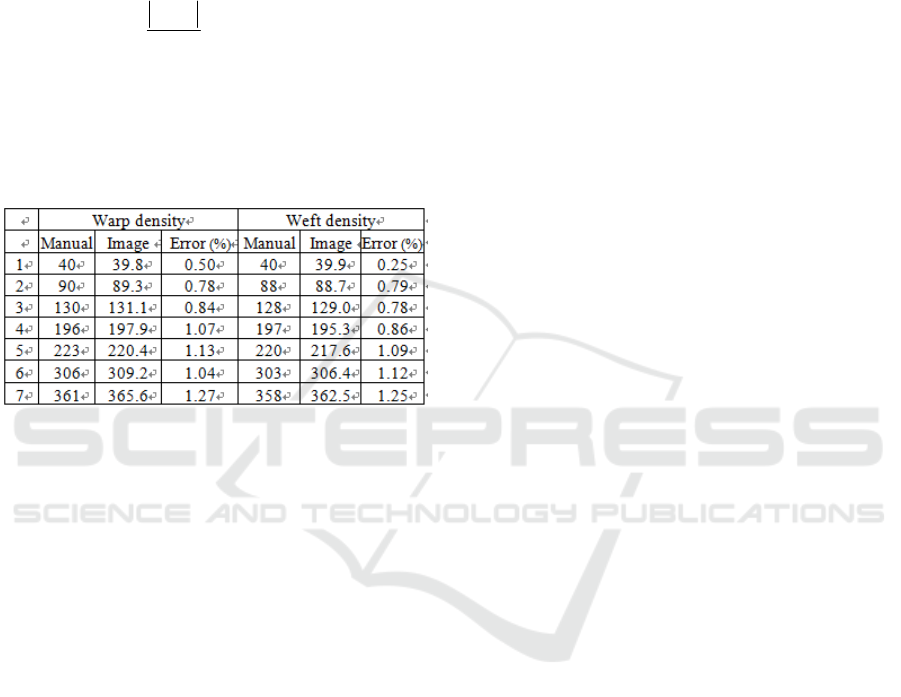

4 COMPARATIVE ANALYSIS

A variety of fabrics with different densities and

different tissue structures were selected to conduct

the measurement of the warp and weft density, and

compared with the results of manual measurements.

The relative error is defined as

= 100%

cd

c

σ

−

×

(5)

where c is the manual measurement result and d is

the image measurement result. The results are shown

in Table 2.

Table 2: Test results of Fabric density.

It can be seen from the experimental results that

the accuracy of the image method is mainly affected

by tightness of fabric warp and weft arrangement

and the type of tissue structure. The higher the warp

and weft density of the fabric, the smaller the

spacing between the yarns, the more difficult the

edge information between adjacent yarns to extract,

the more obvious the error. In general, the error

between the measurement result of image and the

actual is small.

5 CONCLUSIONS

The wavelet basis is introduced into online yarn

density detection of fabrics. Firstly, the collected

images are preprocessed, and the fabric image is

decomposed and reconstructed by multi-scale

wavelet to obtain the decomposed warp and weft

sub-images. Then the image is binarized and

smoothed to obtain the characteristics of warp and

weft yarns. Finally, the yarn density of warp and

weft is calculated. Experiments have verified the

density of different types of pictures and compared

them with manual measurements. The experimental

results show that the method has small measurement

error and is reliable and practical.

ACKNOWLEDGEMENTS

This work was supported by the Science and

Technology Planning Project of Guangdong

province, China (2017A090905047); Science and

Technology Planning Project of Guangzhou, China

(201806010128) and A New Generation of

Intelligent Large-Scale Carton Printing Equipment

Package Development and Industrialization. Thanks

for the helps.

REFERENCES

1. Akiyama, R., Iguro, T., et al., 1986. Detection of

weave types in woven fabrics by observing optical

diffraction patterns. Fiber, 42(10), T574-T579.

2. Xu, B., 1996. Identifying fabric structures with fast

fourier transform techniques. Journal of Northwest

Institute of Textileence & Technology, 66(8), 496-

506.

3. Huang, C., Liu, S. C.,et al., 2000. Woven fabric

analysis by image processing: part i: identification of

weave patterns. Textile Research Journal, 70(6), 481-

485.

4. Feng He, Lijian Li, & Jianming Xu., 2007. Fabric

Density Measurement Based on Adaptive Wavelet

Transform. Journal of Textile Research, 28(2), 32-35.

5. Jianqiang Shen, Zhaofeng Ruan, et al., 2007. A

method for fabric tissue and structure parameters

detection based on wavelet transform. Chinese Journal

of Scientific Instrument, 28(2), 357-362.

6. Zhang, R., & Xin, B. 2016. Automatic measurement

method of yarn dyed woven fabric density via wavelet

transform fusion technique. Journal of Fiber

Bioengineering & Informatics, 9(2), 115-132.

7. Ji Shi, Wenyu Tu, et al., 2012. Fabric defect image

preprocessing based on wavelet packet and image

fusion. Silk, 49(8), 30-33.

8. Kaicheng Fu, Zhuxin Zhang, et al. 2016. Detection of

sar image roads based on canny-roa operator and

hough transform. Modern Electronic Technology,

39(23), 1-4.

9. Jun Yang, & Zhongming Zhao. 2007. Multifocus

image fusion method based on curvelet transform.

Optoelectronic Engineering, 34(6), 67-71.

10. Xunming Zhao, Zhongmin Deng, & Youting Qi. 2011.

Automatic detection of warp and weft densities of

woven fabrics based on wavelet transform. Advances

in Textile Science and Technology (5), 45-47.