Study on Active Particle Doped Fluorescent Fiber

Temperature Sensing Technology

Jinling Wu

1

, Hualong Yu

2

and Xiaowei Li

3

1

Institute of Occupation Technical , Hebei Normal University, Shijiazhuang , China

2

Institute of Education, Hebei Normal University, Shijiazhuang , China

3

Shijiazhuang Municipal Public Security Bureau,Shijiazhuang, China

Keywords: Visible wavelength; absorbing glas; flluorescence optic sensor

Abstract: The optic- fiber temperature measurement probe based on ruby is developed. This system is particularly

adapt to the temperature measurement in the rang of 0℃ to130。The calibration graph was shown to be

highly reproducible when the probe is temperature cycled. A change in drive current from 5 to 30mA yields

a spectral shift of the peak emission of only a few nanometers. The drive current to the LED can easily be

kept within the required narrowly defined bounds through the control circuitry.

1 INTRODUCTION

The previous device was configured to take

advantage of infrared radiation and the infrared

absorption characteristics in the sensor. Such a

scheme is, in principle, attractive as a reference for

any absorption-based device, but may be limited by

its operation with infrared radiation. Many processes

involve interactions in the visible part of the

spectrum, e. g., pH indicator dyes and colorimetric

processes, and with the availability of bright LED

and laser diode sources in the visible part of the

spectrum, there is a genuine need for such a

referencing scheme at shorter wavelengths into the

visible. Furthermore, in the device described, the

sensitivity of the resultant sensor was somewhat

limited and did offer scope for potential

improvement. One such method is to consider the

suitability of visible wavelength referencing system

for temperature sensors

2 OPTICAL AND MECHANICAL

DESIGN

In this case the temperature-dependent absorbing

material is a sample of glass, which exhibits a

significant change in its optical properties, on a band

centered at 565nm,the emission wavelength of the

commonly available bright green LED. Crystal ruby

is used as the material producing the reference

fluorescence signal. On the R-line emission bands,

don’t discuss here.

The ruby and absorbing glass sample that

constituted the sensor probe was held together in a

metal cylinder of length 25mm,using large diameter

input and output optical fibers (PCS1000, 1000µm

diameter). At the wavelength of the ruby

fluorescence, the absorbing glass has maximum

transmission and this is sufficiently removed

spectrally not to change significantly with

temperature, up to ~1300C.Beyong this temperature

an unacceptable (>1%)deviation in the otherwise

constant fluorescence ratio occurs and thus the ruby

sample can only be used for referencing when

mounted in a different configuration, in front of the

LED. This is well below the temperature where

catastrophic chemical changes occur in the glass

(several hundred degrees Celsius), and its absorption

properties change irreversibly.

3 SIGNAL PROCESSING SCHEME

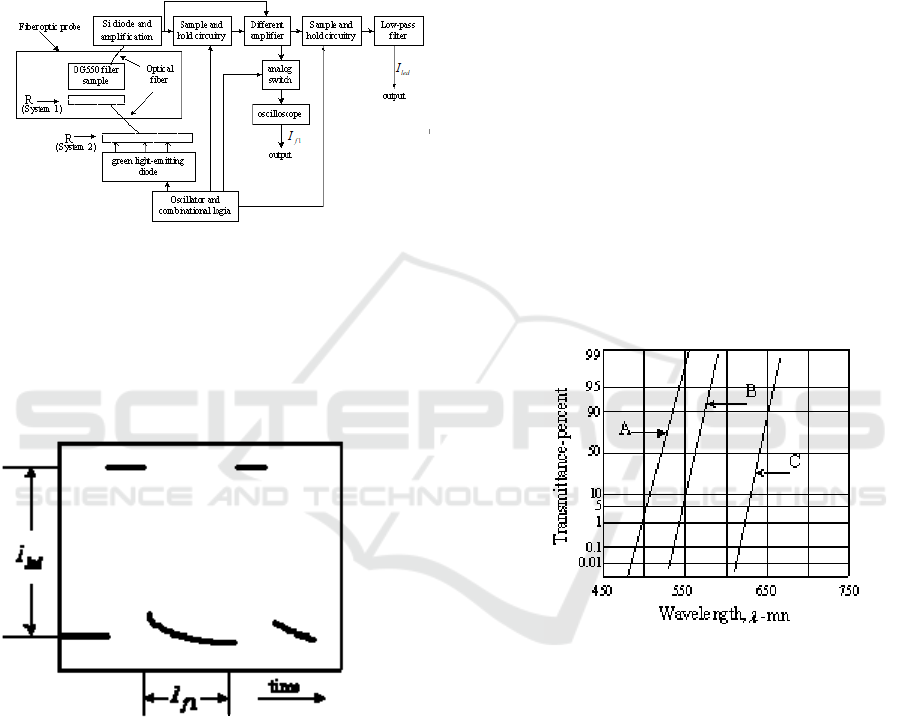

A block diagram of the system, which was designed

to separate, in time, the changes in the temperature-

dependent green light and the fluorescence reference

red light signals, is shown in Figure1.where

systems1 and 2 refer to two different placements of

the ruby sample in order to optimize the

performance of the device. In system1, the ruby

sample is in contact with the absorbing glass and in

system2 it is located in front of the LED, in a

standard optical housing. The LED was modulated

with a pulse, which falls to zero on a time scale of

several Microseconds and thus the signal received

after this time corresponds to the total ruby

Fluorescence signal caused by excitation of the

sample by the green light.

Figure 1. Block diagram of the optoelectronic system.

Thus, a single detector may be used, in this case

a Si p-i-n diode with an integral amplifier, to

amplify the low signal levels experienced. This

obviates the need for two such detectors to separate

each wavelength band and any consequent difficulty

that may occur in their cross referencing. To

Figure 2. The illustration of transmitted intensity of the

green LED signa, And time-integrated ruby fluorescence,

showing temporal Division of signals. Horizontal time scal-

5ms div-1.

eliminate the effect of ambient light variations, a

sample/hold circuit samples the signal when the

LED is off and also where the fluorescence signal

has decayed to its zero level. The sampled value is

then subtracted from the original signal in a

difference amplifier and as a consequence the signal

is referred to level independent of ambient light

variations. It is then processed in two different ways.

The temperature-dependent signal is obtained by

sampling the pulse at its maximum value and a first-

order low-pass filter to minimize fluctuations due to

noise further smooths the corresponding dc output.

The ‘reference’ signal is obtained by electronically

switching out only the fluorescence signal.

Typical pulses from which this information was

obtained are shown as Figure2, illustrating

intensities of the transmitted green signal from the

LED, and the ruby fluorescence pulse of time-

integrated intensity.

4 SYSTEM PERFORMANCE

4.1 Validity of the Referencing

Technique with Ruby

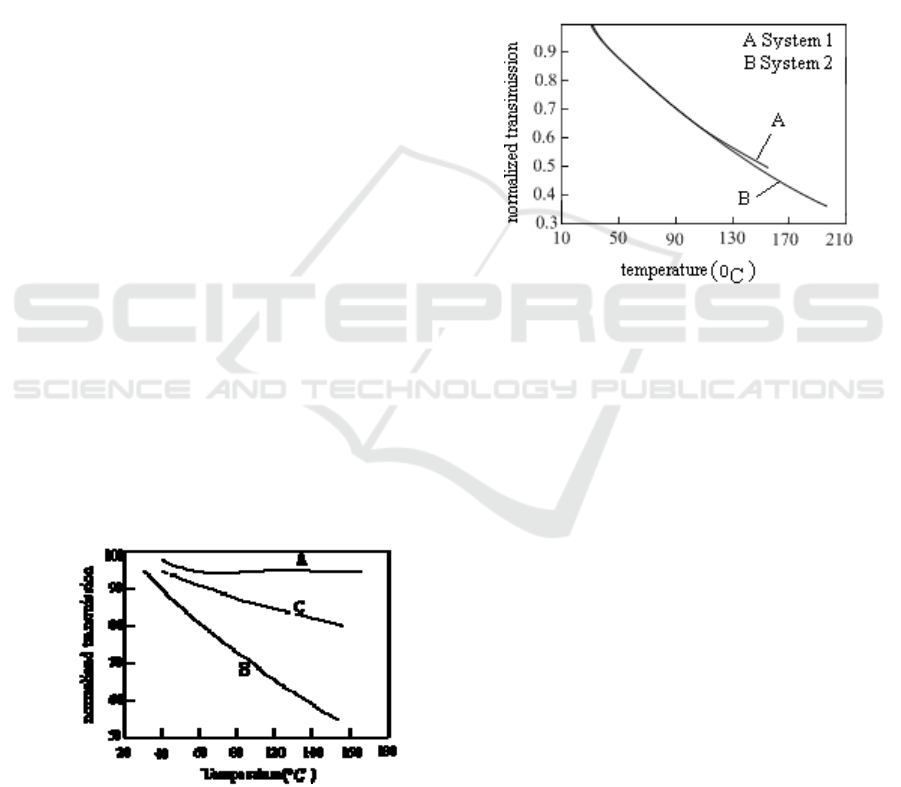

The time-integrated fluorescence signal obtained

from the ruby sample must be a direct measure of the

intensity of the green LED signal which both induces

it and is attenuated in a temperature-dependent way

by the absorbing glass sample Figure3.

Figure 3. Transmittance (at room temperature) of three

Absorption glasses OG515 (A), OG550 (B), RG630(C).

Shows the proof of this principle, where the ratio

of the peak green LED

signal obtained under steady

pumping, , to the time-integrated fluorescence,

is shown as a function of temperature for a probe

made up with only the ruby present and the

absorption of the glass. Over the range 20-1300C, the

ratio is constant to ±1% of the peak value, clearly

showing validity of the referencing technique, as

would Be expected from the constant quantum

efficiency of the ruby. It is important to carry out

such a test as the geometrical changes in the probe

itself can mean significant changes in the intensity of

the green signal reaching the absorbing glass.

Beyond 130,this does not apply to required degree of

accuracy, thus dictating the only probe design, which

may then be used, excluding system1 in favor of

system 2, in the temperature region to 200℃.

4.2 Choice of Absorbing Material

Three absorption edge glasses were tested initially

with the ruby sample housed in front of the

LED.Figure4 shows a series of absorption spectra at

room temperature, of the three filters OG515(A),

OG550(B),and RG630(C),with ,for comparison, the

emission profile of the green LED(L).The calibration

graph of the normalized transmission of these three

materials as a function of temperature in the range

20-130

0

C is shown as Figure8.16.Over this range, for

OG515(A),The maximum change in intensity is ±

1.5%,which is due essentially to the error in the ruby

referencing and noise in the system. The result

indicates OG515 is too far removed from the LED

spectrum to make any real impression on the

transmitted intensity. The calibration graph with RG

630(C), shows a slightly nonlinear profile of

normalized transmission with temperature. The

change in the ratio recorded on this graph was 25%

over the temperature range studied. From the LED

profile in Figure4 it can be seen that main absorption

of RG630 is well beyond the peak wavelength of the

LED. Thus, the percentage change in transmitted

intensity in the probe itself can be improved by using

a glass whose characteristic is optimum near the

center wavelength. OG550 (B), with 45%

transmission at 550nm,shows a 45% change in

intensity over the same temperature range. As a result

this type glass was chosen for the sensor system

investigated.

Figure4. Normalized transmission as a function of

temperature of three absorption glasses (20~300C), A, B, C.

4.3 Calibration Graphs

The normalized transmission factor is plotted as a

function of temperature and is Shown in Figure5 (A),

and (B), for a probe-containing ruby and with the

ruby directly in front of the LED.A slightly nonlinear

response results with the experimental points closely

following the smooth response curve. A small

deviation of the system 1 graph (A) occurs as the

normalized transmission decrease due to the small

decrease in the signal/noise ratio. Up to the 130

0

C

limit. For system2, the smooth function continues up

to the maximum temperature of study, 200℃.

Figure 5. Normalized transmission of probe as a

function of temperature.

5 CONCLUSIONS

A considerably improved performance is seen in this

new device over that discussed using infrared

radiation. The slope of the calibration graph from that

work was 1.7×10

-3

K

-1

and thus it can be seen that

the visible radiation-based device is more sensitive,

with a slope,75

0

C of 4.1× 10

-3

K

-1

.The standard

deviation of the typical reading was measured as

0.11

0

C.Hence,the temperature accuracy of this

reading is ±0.6

0

C using the ‘best-fit’ curve drawn

on Figure5.The calibration graph was shown to be

highly reproducible when the probe is temperature

cycled. Drift of the device is low and problems of

LED ageing will not be significant if the diode is not

severely overrun in terms of the applied current. A

change in drive current from 5 to 30mA yields a

spectral shift of the peak emission of only a few

nanometers. As the ruby absorption bands are broad

this will cause only a negligible change in the

fluorescent intensity of emission and the effect on the

determination of the absorption profile of the OG550

glass will also be very small. The drive current to the

LED can easily be kept within the required narrowly

defined bounds through the control circuitry.

ACKNOWLEDGEMENTS

This project is supported by the Key project of Hebei

Provincial Department of Education

(No.ZD2016040) ; This project is supported by

Hebei science and technology research

item(No.12201708D); The project is supported by

Hebei Normal Universty application fund

(No.L2015k09).

REFERENCES

1. XiaXiang, JianbinShi, FenghongHuang, Mingming

Zheng, Qianchun Deng.Quantum dots-based label-free

fluorescence sensor for sensitive and non-enzymatic

detection of caffeic acid.Talanta, Volume 141, 15

August 2015, Pages 182-187.

2. Tae-Jin Kim, Kyung-A Kim, Sang Hoon Jung.

Development of an endoplasmic reticulum calcium

sensor based on fluorescence resonance energy

transferShort communication. Sensors and Actuators

B: Chemical, Volume 247, August 2017, Pages 520-

525.

3. Florent Lefèvre, Philippe Juneau, Ricardo Izquierdo.

Integration of fluorescence sensors using organic

optoelectronic components for microfluidic

platform.Sensors and Actuators B: Chemical, Volume

221, 31 December 2015, Pages 1314-1320.

4. Chunlei Yang, Wenping Deng,Haiyun Liu, Shen

guang Ge, Mei Yan. Turn-on fluorescence sensor for

glutathione in aqueous solutions using carbon dots–

MnO2 nanocomposites.Sensors and Actuators B:

Chemical, Volume 216, September 2015, Pages 286-

292.

5. Hong zhi Lu, Shoufang Xu. Visualizing BPA by

molecularly imprinted ratiometric fluorescence

sensor based on dual emission

nanoparticles.Biosensors and Bioelectronics, Volume

92, 15 June 2017, Pages 147-153.