Straight-Reading Electric Measurement Technique for Polymer

Flooding Injection Wells

Shaogong Zhu

1

, Dekui Xu

1

,Wangfu Zhou

1

,Chongjiang Liu

1

,Xingliang Song

1

,Kuilong Li

1

,

Haicheng Li

1

,Fuming Liang

1

,Guanglei Gao

1

,Jundong Tang

1

,Xiaofeng Li

1

,Yu Han

1

and

Jianyun Li

1

1

Daqing Oilfield Production Engineering & Research Institute, Daqing, China

Keywords: Polymer flooding; flow test; test and adjust simultaneousy; mechatronic control technology.

Abstract: In Daqing oilfield, the polymer flooding wells with more than 3 layers have reached 50%, For conventional

steel wire fishing and layer flow test method, the working is cumbersome in operation, heavy in workload

and long in measuring and adjusting time. To this problem conducted a polymer flooding injection straight-

reading electric measuring technology research. With advanced mechatronic control technology, using test

and adjust simultaneousy methods, real-time monitoring of parameters such as docking status, flow rate,

pressure, and temperature during the polymer flooding injection wells layer flow test. The result shows that

3-5 layer single-well measurement efficiency has improved by more than 2 times. Polymer flooding

injection straight-reading electric measuring technology achieved the goal of completing the multi-layer

flow deploy with once down the well, test efficiency and test pass rate has significantly improved and has a

good promotion and application prospects.

1 INTRODUCTION

Daqing oilfield is a large-scale deposited sand oil

field, belongs to the heterogeneous reservoir

sandstone reservoir, with the deepening of the

polymer flooding, the displacement gradually shift

to low permeability layers, however, there are many

vertical layers in the oil layer, strong heterogeneity,

serious inter-layer interference, and difficulty in

stratified testing[1-3]. Polymer flooding injection

Wells from 2007 to 2017 increase at an annual rate

of 1000, the test workload increased by more than

4000 Wells, in order to ensure the normal injection,

need to increase the test equipment and labor costs

about 10 million yuan each year, at the same time,

the traditional testing technology uses matching

method, need to repeatedly fishing plugs to replace

throttling cores, labor intensity is bigger but test

efficiency is lower[4-5]. In order to improve the test

efficiency and the injection rate, the technology of

straight-reading electric measurement for polymer

flooding is developed[6].

2 COLUMN SELECTION

In recent years, Daqing oilfield development various

polymer flooding dispensation technologies, such as

cylindrical structure, annular decompression groove,

spindle pole, improved spindle pole and streamlined

step-down, in order to determine the best injection

process as the base string of polymer flooding

straight--reading electric measurement, comparing

the five dispensing columns used in the oilfield.

2.1 Indoor Comparison Evaluation

First of all, five in-house dispensing tools were

tested for indoor fishing and hydraulic performance

evaluation, the results shows: Streamlined step-

down dispensing tool has the highest fishing success

rate, the highest throttling pressure difference at the

same flow rate and the lowest sticking loss rate.

2.2 Field Comparison and Evaluation

For comprehensive contrast polymer injection tools,

has conducted field comparison of hydraulic

characteristics, mainly selected the larger application

streamlined step-down groove, cone spindle pole,

spindle pole three kinds of tools. When the flow rate

is 60m

3

/d, the cone spindle pole has lower throttling

pressure difference than streamlined step-down

groove. And the spindle (4 balls/140mm) is 52mm

longer than the streamlined step-down groove (8

slots/88mm), but the throttle pressure difference is

0.21MPa lower than streamlined step-down groove.

By contrast, the streamlined step-down groove has

good performance .

In comparison of field sticking loss rate, cone

spindle pole have a higher rate of sticking loss, and

there is a linear relationship between the sticking

loss and the flow rate of the spindle pole, the

sticking loss increases with the increase of the flow

rate. The sticking loss of the streamlined step-down

groove increases gradually with the increase of flow,

and finally tends to be stable .

Considering indoor and field contrast,

streamlined step-down groove structure points

injection tools with high throttle pressure difference,

low viscosity loss, measurement technology is fully

compatible with water injection, the column the

technical advantages such as can simultaneously

meet the need for flooding of different injection

media.

2.3 Column Setting

Comparing the test of polymer flooding points

injection column, select streamlined step-down

groove structure corresponds to the integration

points separate process for polymer flooding

injection Wells straight--reading of electric

measurement technology of the column, the process

is based on the interval property selection pressure

regulator or molecular weight regulator. In low

permeability reservoirs, Low molecular weight

regulators are used to reduce polymer molecular

weight, increase oil layer degree of use and volume

of exposure[7-9].

The whole process integration of separate

injection technology field application of more than

6000 Wells, after layered injection, compared with

normal polymer separate injection Wells, Oil layer

use are improved, using layer increased from 68.2%

to 73.9%, the use of thickness ratio from 73.9% to

80.9%. At the same time, the pipe column is

compatible with the water, it also can meet the

requirements of subsequent water flooding, and

reduces the cost.

3 POLYMER FLOODING WELL

STRAIGHT-READING

ELECTRIC MEASUREMENT

TECHNOLOGY

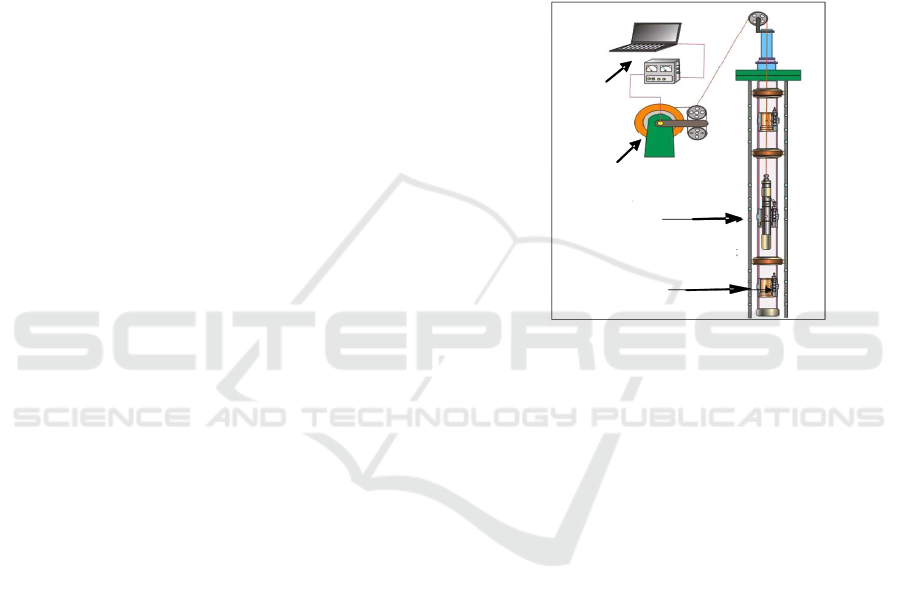

Relying on the integration of the whole process of

technology column, designed the polymer flooding

straight-reading electric measurement technology,

mainly including ground control system, straight-

reading electric measuring instrument, adjustable

plug, cable winch system(as shown in figure 1).

cable winch system

straight-reading electric

measurin

g

instrument

adjustable

ground control system

Figure 1: Structure diagram of polymer flooding well

straight-reading electric measurement technology.

3.1 Process Principle

First, in polymer flooding injection wells into the

whole process of injection column, according to the

requirement of the solution set the polymer flooding

adjustable pressure plug or adjustable molecular

plug under the corresponding layer, and then uses

the steel cable with straight- reading meter to the

purpose layer, then docking with adjustable pressure

plug or adjustable molecular plug, through adjusting

the plug slot number or nozzle to control the single

flow rate, molecular weight, until meet the

requirements of injection allocation scheme, which

can realize the continuous adjustable, quantitative

control and real-time monitoring, to improve the

efficiency of the layered testing.

3.2 Control System

The control system is composed of computer and

power supply system. The whole system has

functions such as flow protection, power supply

conversion, cable voltage compensation, signal

processing, data acquisition and data

communication. When applications, ground control

part have a communication signals, to complete the

collection of flow, temperature and pressure, and

real-time display and control the down hole working

conditions of the instruments, which can realize data

admission control, data storage, report output and

parameters tuning, etc. (as shown in figure 2).

Figure 2: Structure diagram of ground control system.

3.3 Straight-Reading Electric Measuring

Instrument

Straight-reading electric measuring instrument

mainly by mechanical arm, the control part,

measuring parts, steering mechanism and so on, by

receiving the ground sends commands, adjusting

arm, release and adjustable plug docking, flow

testing adjustment, temperature, the stress state of

measurement and testing is done at the same. And

has the data signal modulation and demodulation

and transmission function (as shown in figure 3).

Figure 3: Physical drawing of the instrument.

3.4 Adjustable Plugging Device

The adjustable plug is the actuator of the straight-

reading electric measurement system, which is the

core part of the whole system. It is divided into two

types: adjustable partial pressure plug and adjustable

molecular plug.

3.4.1 Adjustable Partial Pressure Plug

From the design points of polymer flooding process

integration injection process pressure regulating

elements, use of non-newtonian fluid mechanics

theory and the flow field simulation software,

optimize the pressure regulating element structure

parameters, by adjusting the throttle element of

effective length, control single injection pressure,

achieves stepless adjustment of the first-level

dispensing tool from low pressure loss to high

pressure loss, to meet the needs of different

injection.

3.4.2 Adjustable Molecular Plug

The existing separation technology adopts single

water nozzle to adjust the molecular, and the

adjustment range is less than 30% when the flow

injection quantity (20-50m3/d) is lower, and when

the injection scheme is changed, it needs to be put

out the water mouth, which is cumbersome and

inefficient. New type adjustable molecular plug by

adjusting the number of nozzle to control the

polymer solution degree of shear, to achieve high

shear, low pressure loss, the continuous adjustable

molecular weight, the injection of polymer

molecular weight are best match of reservoir

permeability, maximize the effective use of low

permeable reservoirs.

3.5 Cable Winch System

To ensure the running of the measurement and

control system, developed a special cable winch

system, adopts the cylinder and the steel cable wire

roller double drum structure, steel wire used for plug

fishing, steel cable for test, two drum independent

operation, common hydraulic drive system,

operation convenient, flexible. The tension system

shows the cable tension in the process, which is

beneficial to construction operation and improve

cable life. Winch uses two kinds of mechanical and

electronic counting methods to realize

complementary advantages and ensure the accuracy

of depth.

4 FIELD APPLICATION

By the end of 2017, straight-reading electric

measurement technology in the application of more

than 300 Wells, 3-5 layer average single well test

time reduced to 2.5 days from 5.2 days, measuring

efficiency could be improved by more than 2 times.

It can be seen from the comparison with

conventional steel wire test, that the more the

number of single Wells layer is divided, the more

obvious the effect of electric measurement is, and

the efficiency of the well above 5 layers is nearly 3

times than normal test .

5 CONCLUSIONS

4.1 the straight-reading electric measurement

technology realizes the straight-reading test and the

continuous adjustment of layered flow, and the

measuring efficiency is more than twice than the

conventional process.

4.2 the polymer flooding straight-reading electric

measurement technology is compatible with the

water, and remains unchanged in the management of

the underground pipe column composition,

technology and test data.

4.3 by contrast, uniform polymer flooding

injection pipe column, expansion of polymer

flooding injection well straight-reading electric

measurement technology field application scale, and

improve the measurement and adjustment process.

4.4 the next step is to carry out the new type of

polymer flooding automatic measurement and

adjustment technology, so that the polymer flooding

can be developed intelligently and digitally.

REFERENCES

1. Liu,H, Yuan,T, Li,J,L. 1999. Polymer flooding

downhole single - tube injection technology,ACTA

Petrolei SINICA.

2. Zhou,J, Zhang X,Z, Ma,Z,H.2009.Tectonic frame

work and basin evolution in Northeast China, OiL &

Gasgeology.

3. Liu,H, Yan,J,W, Xue,F,Y, 2004. Status quo and future

development of production engineering at high water

cul stage in Daqing oilfield, Petroleum Geology &

Oilfield Development in Daqing.

4. Wan,R,F. 2000. Oil production engineering manual,

Oil industry press.

5. Jin,Y,S, Chao,H,Q, Zhao,S,Y. 2003, Oil production

geological engineering, Oil industry press.

6. Hu,B,Z. 2006, Stratified production technology of

heterogeneous multilayer sandstone oil field, Oil

industry press.

7. Pei,X,H, Liang,F,M, Cui,H,Q, et al.2006, Polymer

flooding eccentric quality sorting injection technology,

Petroleum Geology & Oilfield Development in

Daqing.

8. Chen,X,H, Duan,H. 2004, Principle and Application

of Separate Zone Polymer Flooding in Multi Zone

Reservoirs, Petroleum Geology & Oilfield

Development in Daqing.

9. Li,H,C. 2012, Overview of Separate Injection

Technique for Polymer Flooding in Daqing Oilfield,

Oil & Gas Geology