Research on Binder of Binded NdFeB Magnets from

Injection Molding

Wan zhong Qin

1

1

Tianjin Vocational Institute, Tianjin 300410, China

Keywords: Binder; injection molding; NdFeB magnet ; mechanical property; magnetic property .

Abstract: The injection molding of magnetic powder could cost-effectively mass-produce net shape magnets. The

important influence of binder to the molding process and applied properties of injection molding magnet

was discussed. Based on the test and analysis of physical and mechanical properties of the three type

important binders, the effect of binder on the magnetic property, molding process property and mechanical

property of injection molding magnets were investigated. The injection molding bonded NdFeB magnets

with better combined properties were prepared. The research and develop directions of the binder were

probed.

1 INTRODUCTION

Magnetic material is one of the important functional

materials. As third generation permanent magnetic

material, NdFeB rare-earth permanent magnetic

magnet has been extensively used in computer,

move-phone, acoustics equipment, electric motor

and so on; because of its small volume, small

weight, high magnetic property, high properties-

price ratio etc[1]. NdFeB magnets include sintered

NdFeB and bonded NdFeB. The production

technologys of bonded NdFeB magnet include

pressing molding, injection molding and extruding

molding mainly. Pressing molding has been used for

mass-production. The injection molding of NdFeB

magnets have many features such as accurate

dimensional tolerances, high productivity, low

production cost, combined molding and easy achieve

complicated geometries, so it has very good

developing prospects[2]. But the injection molding

of NdFeB magnets not only need to resolve the

oxidation and hardly flow problems in melt mixing

and injection molding of NdFeB magnetic powder,

but also to reduce wearing of NdFeB magnetic

powder with the screw and the mould, so lead to the

injection molding difficult[3-4]. At present, the

research on bonded NdFeB magnets prepared by

injection molding is in start stage. The properties of

three type binders and the effects of binder on the

molding process and applied properties of injection

molding bonded NdFeB magnets were investigated

in this test.

2 THE PROPERTIES THAT

BINDER SHOULD POSSESSED

Bonded magnet is a compound material that consists

of permanent magnetic powder, binder and

additives. The magnetic property of magnet is

offered by permanent magnetic powder; but the

shape, size, strength, corrosion resistance and

fluidity for molding of magnet are offered by the

binder mainly; so it is very important to research and

develop the binder. The two main effects of binder

in injection molding magnet are: ① Make flowing

and turning of magnetic particle possible when

magnet molding. ② To bonding the magnetic

powder together effectively to offer shape and

mechanical property for magnet[5-6].

To see macroscopically, the injection molding

process of NdFeB magnet exactly is the flowing

process of magnetic particles. The fluidity of alloy

powder is bad which decided by it’s shape and

outward; but the high polymer binder possess of

good fluidity at liquid state and the flowing demand

of magnetic particle can be satisfied, furthermore it

has definite shape and mechanical property. The

viscosity of binder must be suitable. When the

viscosity is too high, although the magnetic

mechanical property is good, but the fluidity is bad

that will hinder magnetic particle from turning and

orienting and make the mold cavity filling failure,

then damage the magnetic property and outward of

magnet. When the viscosity is too low, the magnetic

powder will be separated from binder and lead to

injecting process failure. To see microcosmically,

bonding exactly is a mechanical linking of magnetic

powder and binder. Which include liquid state

binder moistens solid state magnetic powder and

forming physical and chemical bonding force

between them. So the properties which the binder

should possess as follow.

2.1 The Injection Technology Property

of Binder

The binder should possess excellent fluidity for

injection molding technology, so we can add stearate

or polyolefine to decrease the fluidity of injection

molding mix. The molding temperature of resin

must be suitable, and the space between melting

temperature and thermo-division temperature should

be great enough to ensure molding operation,

magnetic property, magnet quality and productivity.

2.2 The Physical and Chemical

Property of Resin Binder

The resin absorbs moisture in the moist environment

and lead to rare-earth permanent magnetic powder

corroded, so the easy absorb moisture resin need to

be modified to rise it’s corrosion resistance. Besides

the important employing property of binder such as

heat-resistance, environment-resistance, ageing-

resistance can be modified if necessary.

2.3 To Ensure the Size Accuracy of

Magnet

Comparing with other forming technology, the

injection molding NdFeB magnet can achieve better

size precision, but the affect elements more and

complicated such as the shrinkage rate, fluidity,

expanding coefficient of binder, and the shrinking

rate with remarkable affect among them. The

difference of shrinkage rate for different binder is

great, large shrinkage rate benefit to raise density

and magnetic property of magnet, but small

shrinkage is better to ensure the size precision.

2.4 Effects of Binder to Injection

Molding NdFeB Magnet Properties

According to the magnetic property of ideal

permanent magnet, the magnetic property of bonded

magnet can be expressed as follow:

Br = P · A · μ

0

M

s

(BH)max = Br

2

/ 4

In the expression:Br —Br of bonded magnet

(BH)max—(BH)max of bonded magnet

μ

0

M

s

—Br of ideal magnet(density is 100%,

orienting degree is 100%)

P —percentage volume of magnetic powder in

bonded magnet

A —orienting degree

Show in the expression, the magnetic property

of bonded permanent magnet decided by the density

and orienting degree of magnet. The binder is no-

magnetic material and binder and pore decrease the

magnet density, and decrease the magnetic property

of magnet certainly. So the content of binder should

be as low as possible when it satisfied the

technology and employ property.

The injected magnet ensure certain pressure

when forming, if the compression density of pure

magnetic powder is dp(g/cm3) and the real density is

dt(g/cm3), then the volume percentage of magnetic

powder is Vf :

Vf = dp / dt×100%(Vo.%)

The volume content of magnetic powder in

magnet should below this value, and the remained

space should be filled by binder. In fact the content

of binder is more because the fluidity of compound

needs to be considered sufficiently. This section

must be in two

2.5 Effects of Binder to Injection

Molding Nd FeB Magnet

Mechanical Properties

The mechanical property of bonded magnet is

decided by the type and content of binder. Although

increase magnetic powder loadage can rise magnet

magnetic property, but lead to the mechanical

property decrease. Besides adding sufficient binder,

we need to modify the binder to ensure the

mechanical property of magnet. For example add

plasticizing agent, strengthening agent, coupling

agent to gain high strength, good toughness and

pretty outward appearance.

2.6 The Main Component of Injection

Molding NdFeB Magnet

The binder is different according to the uses of

injection molding magnet. Generally it is high

polymer binder consist of a few composition that

include resin, coupling agent, plasticizing agent,

strengthening agent, stabilizing agent, antioxidant,

burning resistance agent etc.. Resin and coupling

agent are necessary compositions, the others can be

selected according to the technology and property.

Resin is the basic and most important

composition of binder, generally it is synthetic high-

molecular compound, include resinoid and

thermoplastic resin. Only very rarely do we find that

resinoid is used for binder because of it’s difficult

control of injection technology and difficult

reprocessing of the solidified pouring system

material. But the thermoplastic resin without

shortcoming above, and can gain fairly good

fluidity, accurate production size, fairly good

magnet property. Generally the resins can be used

for binder are: PA, PPS, PE, PBT, PP, PC and so on,

and PA and PPS are the most in use. All of them are

engineering plastics that with very low viscosity and

excellent injection molding property at melting state

and can ensure maximum loadge of magnetic

powder.

Coupling agent is a high-molecular additive that

one side of the molecular contain unit reacting with

NdFeB and the other side contain unit reacting with

binder, so the inorganic material and organic

material can be coupled by chemical bond. Besides

the NdFeB powder is extremely easy oxidized when

the temperature more than 150℃, then lead to

magnetic property decrease rapidly, so the magnetic

powder need anti-oxidation treatment. After the

surface treated by coupling agent, the property of

NdFeB magnetic powder can keep stabilization at

high temperature and 100% humidity environment,

and the anti-oxidation property of the magnet made

by the magnetic powder raised remarkably.

3 TEST METHOD

For the binder PA, heat-resistance PA, and PPS:

According to the ASTM methods, drying the binder

and injection molding the testing samples use

injecting machine and accurate mould, then testing

the physical and mechanical property of binder use

special equipments.

For injection molding magnet: The ferroxcube

magnetic powder particle is fine and no high

temperature oxidation problem, so the injection

molding is easy relativity. The MQP-B NdFeB

magnetic powder is adjusted on particle size, coated

with coating agent and surface treated with coupling

agent; then is mixed with drying binder, lubricant,

antioxidant according to different loadage of

magnetic powder in high speed mixer. And then the

compound is melted and mixed and extruded in the

double screw extruder and cutting. At last, injecting

mold appropriate property testing samples use

injecting machine and accurate mould. According to

the Chinese GB method, test physical property,

mechanical property and magnetic property of

magnet by special equipments.

4 TEST RESULTS AND

DISCUSSION

4.1 Polyamide Resin Binder

Polyamide resin is a type of high-molecular

compound which contain many repeated amide unit

(-NH-CO-) in the molecular main chain and is

popular named PA. PA is made from

polyiondensation reaction of carbonic acid and

amine, or polymerization reaction of amide, so it can

be classified as many kinds according to the unit for

polymerization reaction, for example PA6, PA66,

PA12, PA6/66, PA6/12 etc.. PA is a thermoplastic

resin and with excellent strength, toughness, heat-

resistance property, wear-resistance, corrosion-

resistance property and so on, and is nonpoisonous.

So it is used as engineering plastics extensively.

PA have the specific property of suck up

moisture because it contain the amide unit which is

close to moisture. The saturation moisture capacity

(at 23℃) of PA6, PA12, PA66, PA6/6T are 9.5%,

1.8%, 8.5%, 7% respectively. So the moisture

capacity of PA is need to pay special attention when

design magnet product. PA need to be modified

when used for injection molding magnet binder by

add additives, for example plasticizing agent,

strengthening agent, stabilizing agent, lubricant etc.

to modify the strength, toughness, heat-resistance,

fluidity, molding property etc.. The properties of PA

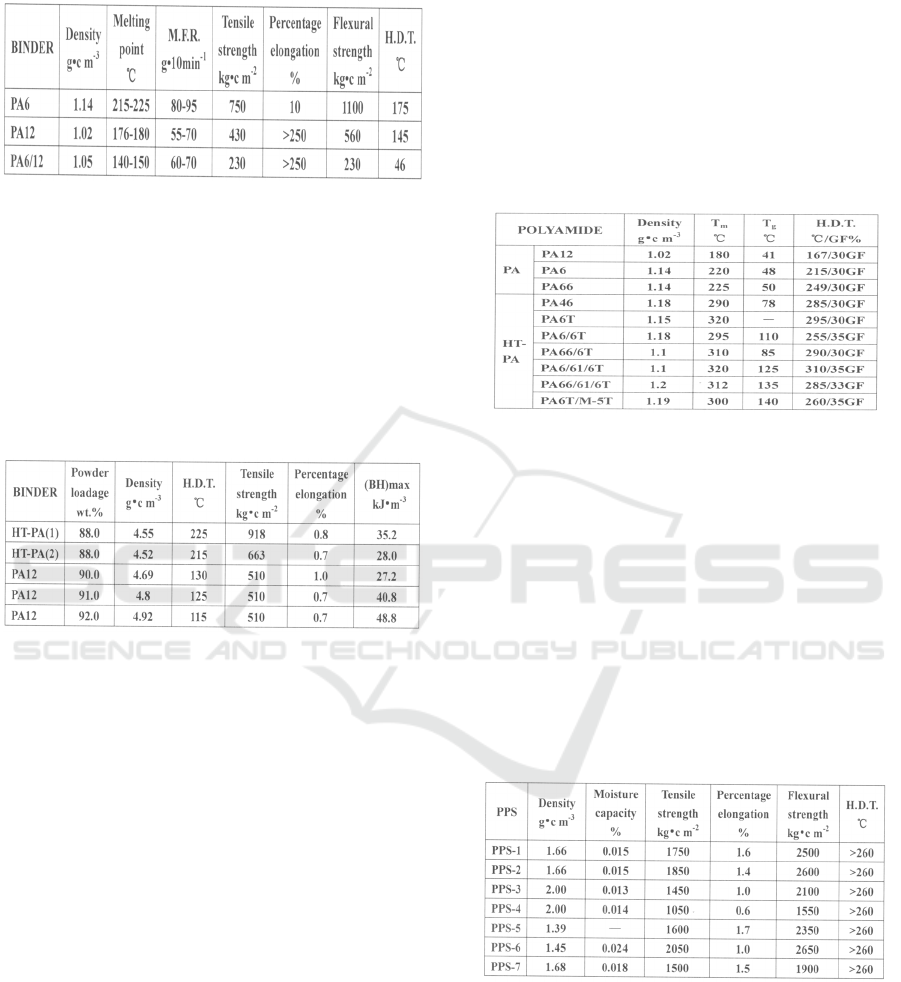

are shown in table 1.

Table1: General physical properties of polyamide resin.

In the production of injection molding permanent

magnet, use polyamide resin as binder have

excellent blending processing property, forming

property, physical property, magnetic property

compared with other thermoplastic resin.

Characteristic of injection molding NdFeB magnet is

shown in table 2.

Table 2: Characteristics of injection molding NdFeB

magnet.

4.2 Heat-resisting Polyamide Resin

Binder

To raise the properties of bonded magnet, study on

permanent magnetic powder is important no doubt,

but research on binder polymer is fairly important

too. In the field of automobile, electrical appliances

and electronic industry, besides magnetic

characteristics, the magnet generally need to possess

high-level heat-resistance, durability, heat-impact

resistance, size stability, high-strength, forming

property, reprocessing property etc., and many of

these properties are related to binder. The bonded

permanent magnet is applying to automobile field

along with the high-property and low-cost change of

rare-earth permanent magnetic powder. In the

automobile engine room, the working temperature

can achieve to 130℃, so the magnet should can long

time working at -40℃~140℃. Only heat-resistance

polyamide can meet the demand above. Polyamides

include fat-family and benzenoid-family two types.

The benzenoid-family PA have higher heat-

resistance and strength than fat-family PA(include

PA6, PA12, PA66) because it contain more upright

and strong benzene molecular chain. The heat-

resistance of benzenoid-family PA is higher than

PA12 and lower than PPS. The testing result is

shown in table 3, T

g

is glass transition temperature,

T

m

is melting temperature, GF% is glass fiber

content added.

Table 3: Heat-characteristics of polyamide.

4.3 Poly Phenylene Sulfide Resin

Binder

Poly phenylene sulfide is a engineering plastic with

high property. At the initial developing stage, the

PPS was cross-linking type resin and too brittle to

use although it have many excellent properties. In

recent years, the new developed PPS is straight

chain type resin and changed the brittle property

remarkably. The typical property of PPS is shown in

table 4.

Table 4: Characteristics of PPS.

Comparing with other binder, the characteristics

of new-type PPS as follow: ①Good heat-resistance:

heat distortion temperature is more than 260℃ and

can be continuous using at 200~220 ℃; ②High

strength and rigidity: with high tensile strength,

flexural strength, flexural modulus; ③Excellent size

stability, linear expansion coefficient extreme low,

forming shrinkage small; ④Excellent corrosion

resistance: no solvent can dissolve PPS below 200℃

; ⑤Forming process property and fluidity fine.

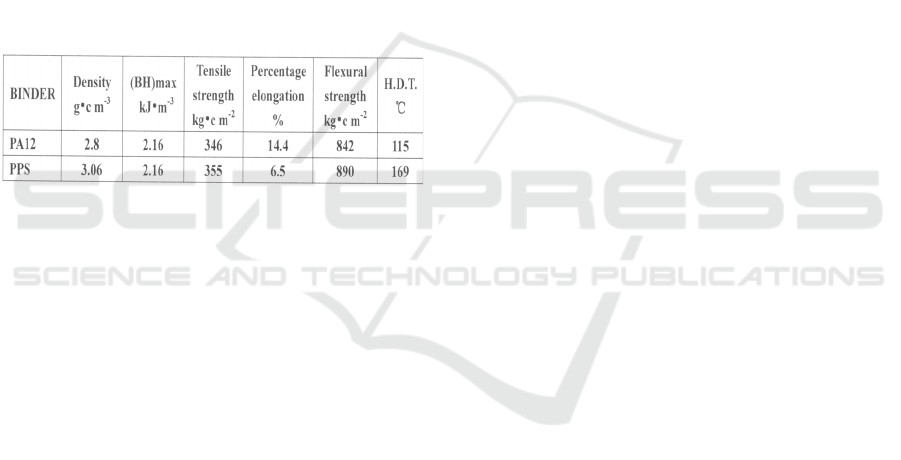

The properties of injection molding magnet by

different binder are shown in table 5 (isotropic

ferroxcube). The new-type PPS resin have the sticky

and firm characteristic which the straight chain type

macromolecule peculiar. Comparing with the

injection molding magnet bonded by PA, the magnet

bonded by PPS has characteristics as follows:

①The same magnetic feature; ②Hardness and

flexural modulus high; ③Excellent heat-resistance;

④The same tensile strength and flexural strength;

⑤Small linear expansion coefficient and forming

shrinkage; ⑥Small moisture capacity and heat

expansion coefficient. It is expected that more PPS

bonded injection molding magnet will be applied in

automobile because it has excellent heat-resistance.

Table 5: Property of injection molding magnet.

5 THE RESEARCH AND

DEVELOP DIRECTIONS OF

THE BINDER

The application prospects of injection molding

NdFeB magnet is very promising and the magnet

output will increase rapidly. In view the important

function of binder, the research and develop

direction of binder should be concentrated on the

following aspects.

①To develop binder with better bond strength

and fluidity. One of the main reason to decrease

bonded magnet magnetic property is the adding of

binder, so the increasing of (BH)max need to

develop better binder to reduce the binder content

and raising the orienting degree of magnetic particle.

②To develop new type additive and related

treatment technology to raise the coupling property

of NdFeB magnetic powder and binder, and to

modify forming technology and property of injection

molding magnet.

③Proper treating the magnetic powder with

physical or chemical method before mixing the

NdFeB magnetic powder and binder to modify

surface state of magnetic powder and it’s combing

force with binder. At the same time the magnetic

property is raised too.

④To develop heat-resistance binder. Injection

molding NdFeB magnet applied in automobile will

be a vast market, but one of the key problems need

to be solved is the heat-resistance of magnet. The

heat-resistance is mainly decided by binder, so the

developing of heat-resistance binder provoke

extensive interest of related people.

ACKNOWLEDGEMENTS

This work was financially supported by the Tianjin

Natural Science Foundation (08JCYBJC14000).

REFERENCES

1. S.Z. Zhou, Q.F. Dong. Supermagnets: Rare-Earth

Permanent Magnet Materials Based on Ferrous Alloy

(Metallurgy Industry Press, China 1999).

2. Y. LUO. The developing situation of rare-earth

bonded magnet in Japan. Electrical

Material,2003(1):31-34.

3. T.J. LV, H.Y. GUAN, Y. LI. Studies on NdFeB

magnetic plastics and its injection moulding. China

Plastics,2003,17 (9):49~54.

4. Garrell M G, Albert J S. Mechanical properties of

nylon bonded Nd-Fe-B permanent magnets. Journal of

Magnetism and Magnetic Materials, 2003, 257:32~43.

5. J.W. YE, Y. LIU,D.Y. SONG. Effects of binder on

property of bonded NdFeB magnets by injection

molding . Journal of Function Materials and Devices,

2005,11(1):53~57.

6. B.H. DUAN, X.H. QU, Z.Y. LIU. Preparation of high

property bonded NdFeB magnets by injection

molding. Journal of CHINA Nonferrous Metal,

2004,14(10):1653~1657.