Optic-fiber Sensor Based on Fluorescence Spectrum Analysis

Jinling Wu

1

, Hualong Yu

2

and Junhai Yang

3

1

Institute of Occupation Technical , Hebei Normal University, Shijiazhuang , China

2

Institute of Education, Hebei Normal University, Shijiazhuang , China

3

Shijiazhuang Municipal Public Security Bureau,Shijiazhuang, China

Keywords: Fluorescence optic-fiber thermometer; ruby material; Fluorescence Spectrum Analysis.

Abstract: A kind of fluorescence optic-fiber thermometer is devised based on the solid-state ruby fluorescence

material. The characteristic of fluorescence material absorption and emission is analysised, and the optic-

fiber temperature measurement probe based on ruby is developed. This system is particularly adapt to the

temperature measurement in the rang of 20℃ to 600℃. During the cause of experimentation, this

temperature measurement method is proved to be effective and useful for its highly resolution and precision.

1 INTRODUCTION

Apart from being a desirable precious gem stone,

ruby is well-known as the laser crystal used in the

world’s first successful operation of a laser. It is also

among the earliest of materials for which the

fluorescence lifetime properties were proposed for

thermometric applications [1]. The actual use of

ruby as the sensor element in a fiber optic

fluorescence lifetime thermometer was perhaps first

reported by Grattan [2] [3]. In this thermometer

system, an LED was used as the excitation light

source and a silicon PIN diode was employed for the

detection of the fluorescence signal. Using that

system, temperature measurement was achieved

over the region from room temperature to

1700C.This thermometer system described below is

devised in an effort to extend the measurement range

of this compact and low-cost system and further

improve and conveniently extend its performance.

2 DESCRIPTION OF THE DEVICE

This ruby fluorescence thermometer is schematically

depicted in Figure 1.A green LED was used as the

excitation source, which can pump into the strong

absorption band centered at 550nm[4], as show in

the absorption spectrum of ruby in figure 2.As the

radiation of the green LED contains a weak emission

band in the red portion of visible spectrum, which

overlaps part of the fluorescence emission spectrum,

a short pass optical filter, F1 shown in Figure1, with

a cut-off wavelength at 630nm is used to eliminate

this red ‘tail’ of the LED emission. The fluorescence

emission spectrum is obviously at longer

wavelengths, as shown in Figure3, with the strongest

emission on the R-lines (around694nm). Thus, a

readily available long-pass doped glass filter could

then be used as the filter, F2 in figure1, to isolate the

excitation light from the fluorescence emission at the

detector stage. However in order to achieve better

isolation, an ‘off-the-shelf’ band-pass interference

filter with the pass-band centered at 694.3nm and a

bandwidth of 12nm, designed for laser uses, was

employed as the F2 instead in Figure1.

Figure1. The ruby fluorescence lifetime based fiber optic

thermometer system.

F1: short-pass optical filter; F2: R-line band-pass optical

filter.

LPF

y

De l a y

Ta

Photo-

detector

LED

Dr i ve r

Green LED

Temperature probe

mi x

v

∫

−

r

v

cc

Vk

=

ω

m

v

c

v

VCO

τ

0

xT =

Optical Fibers

Lifetime output

F2

F1

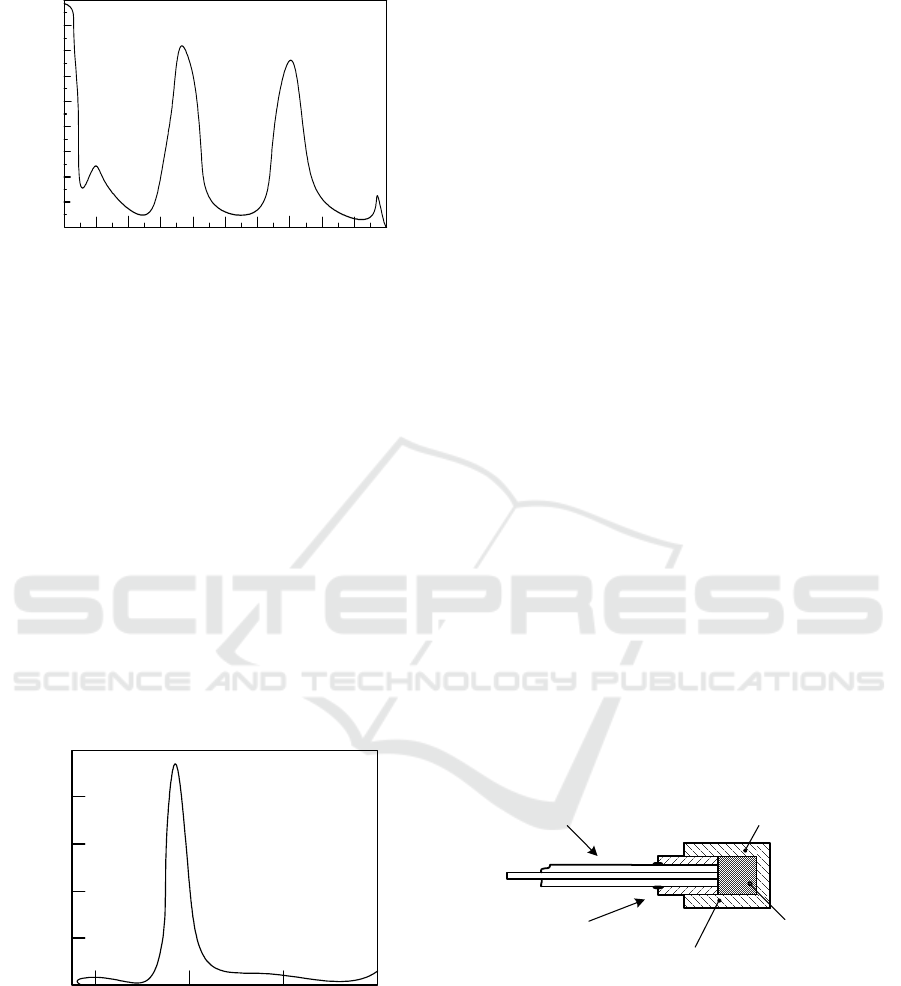

Figure 2.The absorption spectrum of ruby.

In this system, gold-coated silica fibers were first

used to fabricate the probe for temperature

measurement up to 6000C.The core diameter of the

fiber used was 400µm. The probe was configured in

the reflection-type configuration, it is shown in

figure 4.

Due to the relatively low emission intensity of

the LED light source then available, the intensity of

the induced fluorescence respond which could be

detection of several nanowatts. Thus a

comparatively poor signal-to-noise ratio of the

detected fluorescence response was observed, An

even less favorable signal-to-noise ratio would be

expected at higher temperatures due to decrease in

the fluorescence intensity with the increasing

temperature.

Figure3.The emission spectrum of ruby.

To tackle the poor signal-to-noise ratio problem

the ‘phase and modulation method’ [3] to measure

the fluorescence life time, with the employment a

fixed frequency, high Q-value bandpass electronic

filter to the wideband noise in the fluorescence

signal. Though the effectiveness of this scheme

adequately demonstrated, its measurement range is

limited by the fixed single modulation frequency,

and a slight drift in the parameters of the high Q-

value bandpass filter could introduce error in the

phase measurement.

To solve this problems, the PLD-PMSR[5]

technique was applied to the ruby based

thermometer system, as shown in Figure1.Here,the

phase shift ratio,α,is chosen to be 3/8,an optimum

value according to the discussion given earlier, and

tugging of he lifetime to period conversion.

3 THE DESIGN OF HIGH-

TEMPERATURE FIBER PROBE

The novel feature of the temperature probe used is

the use of gold-coated fibers, which h are well suited

to the specific application allow high temperatures to

be reached, as they have more favorable

characteristics for such high temperature regions

than the plastic-clad silica (PCS) fibers used in

earlier work[3]. Which is soldered using gold-

working techniques developed specifically to secure

it to the end of the optical fibers. This enabled a

strong and secure joint to be made and produced a

probe, which could be totally immersed in the hot

region, where the measurement is to be made. As the

fiber was small, the gold and crystal were of small

mass, and so the thermal response of the device

could be relatively rapid and the cost of expensive

material kept low. The aim was to measure

continuously over the range from room temperature

to 6000C.

Figure 4.Schematic of the fiber-optic probe used with the

ruby fluorescence lifetime based thermometer described in

this system.

The feasibility of developing such a high-

temperature fiber optic probe was based on the

availability of fibers with a high-temperature cality.

Normal plastic-clad silica (PSC) fiber is limited to a

maximum operating temperature of 1500C but in

order to exploit the much higher temperature

700

Absorption Coefficient,

200

300

400 500

600

Wa v e l e n g t h , n m

cm

-

1

0

0.4

0.8

1.2

1.6

2.0

2.4

2.8

3.2

650

Wavelength, nm

800

E

m

i

s

s

i

o

n

i

n

t

e

n

s

i

t

y

700

750

10

0

2

4

6

8

Al

2

O

3

:0.1%Cr

3+

Ruby crystal

a brass tube bonding the fiber

bundle

A brass cap holding the sensor material

Solder joint

Gold-coated

optical fibers

capability of sapphire-based sensor materials such as

ruby, another type of fiber is needed, such as that

available in gold coated form, fabricated, and of the

types available the highest temperature capability

has an upper limit of 7500C.This considerable

improvement over PCS fibers is achieved through

the use of a thin gold coating on the silica material.

The probe was constructed[6] with four 400-μm

fibers using two of them to carry the excitation light

and two to receive the fluorescence a compromise of

flexibility and sufficient fiber end-face arear. The

fibers were of fused silica core and doped silica

cladding. The numerical aperture was 0.22 and the

clad-to-core ratio of diameter used was 1:1.1[7].A

particular advantage of such fiber was that the metal

coating offered the additional possibility of a direct

metal to metal seal between this fiber coating and

the metal capsule containing the ruby material. The

thinness of the fiber coating,however, meant that

considerable research was needed to develop

optimum techniques for achieving this joint,

avoiding stripping the coating from the fibers and

overheating the joint[7].

A number of probe-fabrication techniques were

tried before a successful and reproducible technique

was established, such as using gold solders and

fluxes , and a low temperature flux was finally

chosen as the most suitable. It proved impossible, as

expected, to use a conventional soldering iron and a

soldering iron burner combination for jointing as this

crude approach merely resulted in the stripping of

the gold from the fiber. The probe was fabricated

using a modified vacuum-deposition plant. The

method was described in detail in reference and a

schematic of device is shown in figure4.

4. THE EXPERIMENTATION OF

THE THERMOMETER

SYSTEM

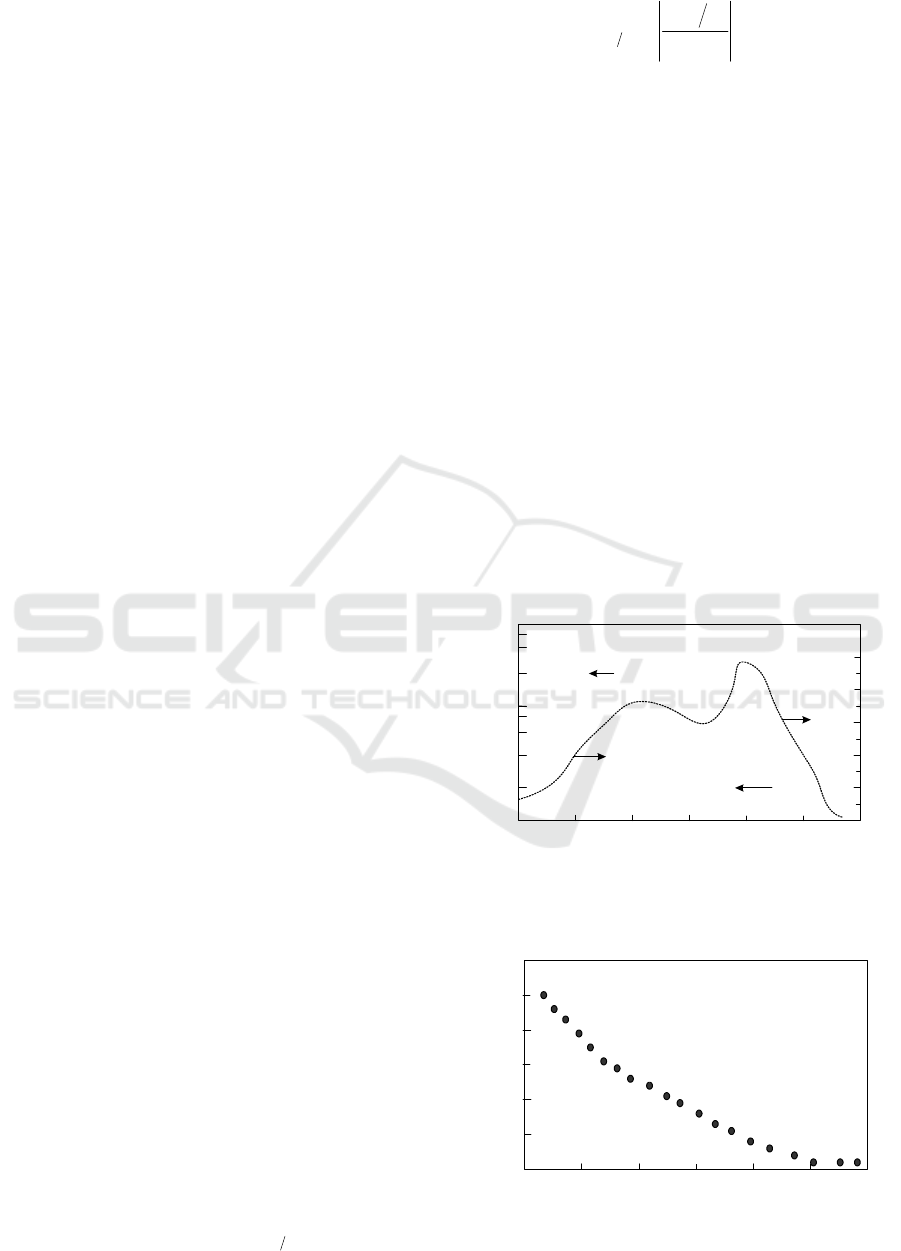

The fluorescence lifetime output was monitored via

the period of the modulation frequency as indicated

in Figure1, and a characteristic calibration curve is

shown in figure5 on a logarithmicscale, over a range

from 30

0

C to 50

0

C.In the region between 150

0

C and

450

0

C, maximum sensitivity is seen. Beyond

500

0

C,the calibration curve tends to ‘flatten out’

quite dramatically, and the sensitivity of

measurement achievable in this region is limited, as

shown by the dashed line in Figure5, which

represents the relative temperature sensitivity of the

observed fluorescence lifetime,

ττ

Δ

s , defined as:

()

T

s

Δ

Δ

=

Δ

ττ

ττ

(1)

Where

τ

is the observed lifetime;

τ

Δ

and

T

Δ

are the increments of the lifetime and

temperature.

The intensity of the fluorescence emission with

temperature change[10], detected at the

photodetector stage, is shown in Figure6.It falls off

rapidly with temperature increase over the whole

temperature region. This result doesn’t contract the

earlier experimental evidence of Burns and

Nathan[11] who showed that the fluorescence

quantum efficiency of the ruby fluorescence,

integranted over the entire band from 620nm to 770

nm, is independent of temperature in the region

from –1960C to 2400C,for the emission detected

here is only the R-line part of the total fluorescence

emission. The reduction in R-line emission intensity

with temperature increase, from room temperature to

2400C,was mainly due to the increasing thermal

elevation of the excited Cr

3+

ions from the 2Estate to

the

4

T2state.This is supported by the research on the

temperature dependence of ruby fluorescence which

shows an increase in broadband emission with

temperature increase over the above region.

Figure 5. Chracteristic calibration curve for the ruby

fluorescence based thermometer in the region from roo

temperature to –5500C.

Figure 6. The ruby intensity recorded in the experiment.

600

100

200

300 400

500

0.1

8

2

4

6

1

2

4

3

1

0

0.2

0.4

0.6

0.8

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

**

Relative Sensitivity,%/

0

C

Observed Lifetime,ms

Temperature,

0

C

600

100

200

300 400

500

100

0

20

40

60

80

T e m p e ra tu re ,

0

C

F luorescence intensity,%

Intrinsically, the ruby fluorescence lifetime is not

suitable for the sensing of temperature below a

temperature approximately defined by the water

freezing point(0

0

C),as its temperature sensitivity is

quite low over that region. Low sensitivity has also

limited the performance of the ruby based

thermometer system up to 50

0

C,and thus poor

measurement reproducibility was found at 40

0

C for

the system shown in Figure1,where the long-term

drift in the time-constant of the entire electronic

system, especially that of the high-gain

photodetector, could be much higher than the

resolvable change in the fluorescence lifetime.

5 CONCLUSIONS

As with all other thermometer systems based on the

fluorescence of refractory materials, the highest

temperature which could be measured is generally

limited by the difficulty in the detection of the

extremely short lifetime under increasingly poor

signal-to-noise conditions, caused by low

fluorescence efficiency and shortening lifetime at

high temperature. From the data in the

experimentation at 6000C the fluorescence intensity

is reduced to 0.7% of its maximum value, occurring

at 3400C,and the fluorescence lifetime is 1μs. A

cost-effective solution to further extending the high

temperaturr measurement limit of a fluorescence

based thermometer can be found through the use of

other fluorescent materials, such as using alexandrite

as the sensing material.

ACKNOWLEDGEMENTS

This project is supported by the Key project of Hebei

Provincial Department of Education

(No.ZD2016040) ; This project is supported by

Hebei science and technology research

item(No.12201708D); The project is supported by

Hebei Normal Universty application fund

(No.L2015k09).

REFERENCES

1. Quero, M. Consales, A. Crescitelli, A. Ricciard, E.

Esposito, A. Cutolo, A. Cusano Two dimensional

hybrid metallo-dielectric nanostructures directly

realized on the tip of optical fibers for sensing

applications Proc. SPIE, 8774 (2013), pp. 1-10.

2. Consales, A. Ricciardi, A. Crescitelli, E. Esposito, A.

Cutolo, A. CusanoLab-on-fiber technology: toward

multifunctional optical nanoprobes ACS Nano, 6 (4)

(2012), pp. 3163-3170.

3. Yuan, C. Zhao, M. Ye, J. Kang, Z. Zhang, S. JinA

Fresnel reflection-based optical fiber sensor system for

remote refractive index measurement using an OTDR

Photon. Sens., 4 (1) (2014), pp. 48-52.

4. C. Chen, Y.-S. Yu, R. Yang, C. Wang, J.-C. Guo, Y.

Xue, Q.-D. Chen, H.-B. SunReflective optical fiber

sensors based on tilted fiber Bragg gratings fabricated

with femtosecond laserJ. Lightwave Technol., 31 (3)

(2012), pp. 455-460.

5. Vallan, M.L. Casalicchio, M. Olivero, G. PerroneTwo-

dimensional displacement sensor based on plastic

optical fibers IEEE Trans. Instrum. Meas., 62 (5)

(2013), pp. 1233-1240.

6. Orĺowska, P. Słupski, M. Świątkowski, P. Kunicki, A.

Sankowska, T. GotszalkLight tensity Fibre Optic

Sensor for MEMS displacement nd vibration

metrology Opt. Laser Technol., 65 (2015), pp. 159-163.

7. J. Basu, A. Thirumurugan, A.R. Dinesh, C. Anandan,

K.S. RajamOptical oxygen sensor coating based on the

fluorescent quenching of a new pyrene derivative Sens.

Actuators, 104 (2005), pp. 15-22