Determination of Total Specific Migration of Acrylic Acid and

Acrylic Esters in Food Contact Materials

Meng Qing

1

, Honzhen Zhang

1

, Qingyun Xia

1

and Bohen Huang

1

1

Vkan Test and Certification Co., Ltd, Tianta yi Road Kaitai Avenue, Guangzhou, China

Keywords: Acrylic acid and acrylic esters, Total specific migration, Gas chromatography mass spectrometry (GC -

MS), Food contact materials (FCMs).

Abstract: In this study, we selected a total specific migration indicator including 12 acrylic acid and acrylic esters, i.e.

SML (T) 22 from national food safety standard. After comparison, methyl acetate was selected as the

extracting agent, which was applicable for the treatment of acidic and aqueous simulants. The HP -

INNOWAX polarity column was applied to separate the 12 compounds and the solvent. The GC - MS was

utilized for qualitative and quantitative analysis with optimization of extraction duration, temperature

program, scanning mode as well as the carrier gas flow rate and the sampling volume. The 12 acrylic

compounds present good separation in 12 minutes, and the analytical duration is greatly shortened. The

linearities in different simulants range from 0.047 mg/L to 11.43 mg/L, while the detection limits are from

0.009 mg/L to 0.666 mg/L. The actual products analysis shows that the recoveries are between 81.2% and

81.2%, and the RSDs (n = 6) are within 5.15%. This developed analysis method is fast, economical, non-

toxic, with low detection limit, high precision and high accuracy. It has good applicability and is easy to

promote to use.

1 INTRODUCTION

Acrylic acid and acrylic esters are volatile with

serious odor, and have certain nerve toxicity and

reproductive toxicity. They can contaminate the

atmosphere and the water (Wang et al., 2002), and

are also significantly harmful to human body. Thus

the world health organization's international agency

for research on cancer has listed acrylic acid and its

esters as carcinogens in category 2 or 3. At the

international level, such as the European Union

(European Commission, 2011), as well as the Japan

(Ministry of Health, Labour and Welfare, 2011) has

issued regulations to limit those monomer residues.

Chinese National Health and Family Planning

Commission (NHFPC) together with Food and Drug

Administration has also announced a series of FCMs

related national food safety standards in 2017 (see

the national food safety standards bulletin No.15 of

2016).

According to GB 4806.6 2016 (NFHPC, 2016),

GB 9685-2016 (NFHPC, 2016), the total specific

migration limit indicator [SML (T) 22], quantified in

acrylic acid containing 12 species of acrylate

monomers, 1 species of poly-acrylic acid salt and 1

species of acrylic polymer is limited to under 6

mg/kg. Nowadays all the common FCMs on the

market such as resin, plastic, paint and coating,

paper, ink, adhesives, etc., should meet the national

standard limit requirement. Content determination of

acrylic acid and its esters first started from the

production in chemical industry process, monomer

residue from textile production, air pollution and

waste liquid pollution (Gu et al., 2002; Shi et al.,

2003; Liu et al., 2013a; Liu et al., 2011b; Shentu et

al., 2008), and were mainly carried out by using gas

chromatography (GC) analysis method. Wang

Jianling et al. (Wang et al., 2016; Dong et al., 2013;

Ma et al., 2013) separated 12 acrylic monomers in

GC instrument with non-polar chromatographic

column and carried out the detection of migration

content for water-based FCMs simulants. Lai Ying

and Lin Rui (Lai et al., 2015) using a purge and trap

sampling method, solved the direct sampling

problem of water-based simulants in gas

chromatography, while the shortcoming is that the

acrylic acid could not be trapped. Li ying and Li

Chengfa (Li et al., 2014a; Li et al., 2015b; Li et al.,

2016c;), respectively utilized the solid-phase micro-

extraction-GC-MS method, the head space GC-FID

method, and the high performance liquid

chromatography (HPLC) method to determine a

variety of acrylate and methyl acrylate migration,

but these methods require complex operation, and

qualitative ability are poor. Moreover the general LC

is unable to separate geometric isomers with similar

polarity.

Due to the bigger differences of polarity and

boiling point between the 12 acrylic monomers and

the existence of isomers, it is difficult to separate

them in a single method. From home and abroad, a

mature analysis method which can directly separate

Chinese regulatory acrylic esters and can be used to

determine the total specific migration has not yet

been reported. We separated the 12 compounds and

the solvent by polarity column with the GC - MS,

and optimized the extraction time, temperature

program, scan mode and sampling volume, carrier

gas flow rate, etc.. The method presents feasible and

precise characteristics in determining 12 acrylic acid

and acrylic esters so as to calculate the total specific

migration limit thereafter.

2 TEST

2.1 Instruments and Reagents

GC - MS instrument: Japan Shimadzu GC - MS

QP2010 – plus.

Electronic balance: Switzerland Mettler, 0.1 mg,

XS – 204.

Whirlpool extraction apparatus: Germany IKA,

Vortex Genius 3.

Ultrapure water purification system: American

Millipore, Milli - Q.

Methyl acrylate (> 99.7%, Aladdin), acrylic acid

(> 99.5%, Aladdin), butyl acrylate (> 99%, Aladdin),

benzyl acrylate (> 97%, Aladdin), iso - propyl

acrylate (> 95%, International Laboratory USA); n -

propyl acrylate (> 95%, Alfa Aesa), ethyl acrylate (>

99.5%, Dr. Ehrenstorfer GmbH), n - butyl acrylate

(> 99.5%, Dr. Ehrenstorfer GmbH), sec - butyl

acrylate (> 95%, Chem Service), n - octyl acrylate (>

95%, Chem Service), hydroxyl ethyl acrylate (>

99.5%, Chem Service), tert - butyl acrylate (>

99.5%, Aike import packing). Methyl acetate

reagent is of chromatography grade, and the rest

reagents are of analysis grade.

2.2 Analysis Conditions

2.2.1 GC Conditions

The polar chromatographic column with

polyethylene glycol (PEG), HP - INNOWAX (30m

× 0.25mm × 0.50μm) is adopted. The Injection port

temperature (T

injec

) is 220 ºC, the interface

temperature (T

inter

) is 250 ºC, and ion source

temperature (T

ion

) is 230 ºC. Carrier gas for high

purity helium (He, purity is more than 99.999%) is

used, and the carrier gas flow rate is 1.8 ml/min.

Sampling volume is 1μL with splitless injection

mode. Solvent delay: in pure water and acid

simulation is of 4.5 min; in ethanol simulation is of

6.2 min.

Programmed temperature: the initial temperature

is 40 ºC, then maintain it for 5 min; after that rise the

temperature at a rate of about 20 ºC / min to 70 ºC;

then warm at a rate of about 40 ºC / min to 180 ºC,

finally at a rate of about 20 ºC / min to keep the

temperature for 1 min at 220 ºC.

2.2.2 MS Conditions

Adopt both the full scan (SCAN) and the select ion

scan (SIM) at 5.1 ~ 7.0 min as well as 10.6 ~ 11.0

min for data collection, while only the full scan

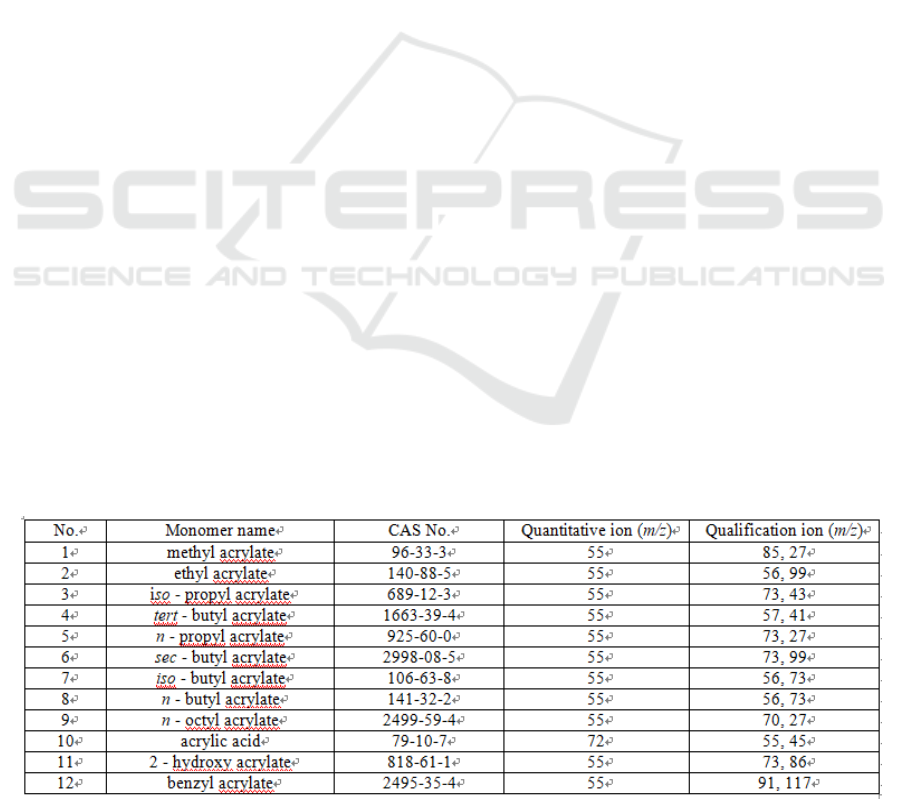

Table 1: Characteristic ions of 12 acrylic acid and acylate monomers

(SCAN) mode for the rest of testing duration. SCAN

range: m/z 25 - 200. Quantitative ions are shown in

Table 1.

2.3 Preparation of Calibration Solution

Weighed respectively 0.100 g standard solution of

acrylic acid and acrylic esters in a 10 ml volumetric

flask, and filled methyl acetate to the volume to

obtain the mixed standard stock solution at the

concentration level of 10000 mg/L. Continued to

dilute step by step with methyl acetate to

concentrations of 0.5, 1.0, 5.0, 10.0, 20.0, 50.0

mg/L.

Prepared five different blank simulants of 4%

acetic acid, water, 10% ethanol, 20% ethanol, 50%

ethanol according to the requirements of GB

5009.156 2016. Measured out 6 copies, 4mL of each

simulants above into 10 mL centrifugal tubes, and

respectively added 0.5, 1.0, 5.0, 10.0, 20.0, 50.0

mg/L mixed standard solutions of 0.4 mL, and

produced a series standard working solutions of

0.05, 0.10, 0.50, 1.00, 2.00, 5.00 mg/L with 6

duplicate samples each. The extraction procedure

was according to step 2.4 extraction operation.

2.4 Total Specific Migration

2.4.1 Migration Test Conditions

Conditions are selected in accordance with GB

31604.1-2015. Considering method detection limit

applicability, the more gentle migration test

conditions are selected as the migration incubating at

40 ºC for 2h.

2.4.2 Food Simulants Selection

In order to analyze as much food simulants as

possible, the 4%acetic acid, pure water, 10%

ethanol, 20% ethanol, 50% ethanol were chosen. Fat

simulant was not considered due to the solvent

influence in baseline separation.

2.4.3 Extraction Operation

Move 4.0 mL migrating solutions or standard

working solutions in 10 mL centrifugal tubes with

plug. To the centrifugal tube respectively add 0.5 g

sodium chloride and 4 mL methyl acetate, and add 1

mL saturated sodium sulfate for 50% ethanol

simulant only, then extract all by vortex (1500

g/min) for 5 min. Carefully take the supernatant

fluid after stratification for 2 min. Samples are ready

to be analyzed with GC – MS after filtration by

0.45μm filter membrane.

2.4.4 Calculation of Total Specific Migration

Total specific migration based on acrylic acid is the

summation of specific migration of 14 target

compounds; this paper provides the specific

migration analysis method of 12 species of acrylic

compounds.

3 RESULTS AND DISCUSSIONS

3.1 Extraction Operation

3.1.1 Selection of Extractant

As there are 12 target compounds containing many

different species as acid, ester, hydro-ester, benzene

ester co-existing in the analysis system, and the

acrylic acid is highly acidic, the solubility for target

compounds must be considered as well as the

immisciblity for liquid-liquid extraction process

between extraction agent and aqueous water, which

actually leave very few options of the solvents.

Small molecule esters and ethers with medium

polarity or weak polarity may be applicable in

theory. After test, methyl acrylate (which possesses

the minimum polarity in the 12 monomers) can only

be separated with methyl acetate solvent, and is

unable to be separated with such medium polar

solvent as ethanol, ethyl ether, methyl tert - butyl

ether, and is susceptible to be interfered by ethyl

acetate. Moreover, in non-polar solvents such as n-

hexane and isooctane, poor baseline separation

effect is shown (seen in Figure 1 to Figure 2).

Ultimately, methyl acetate is chosen as the

extraction solvent for tests thereafter.

Figure 1: Separation of acrylates in hexane.

Figure 2: Separation of acrylates in iso - octanet.

3.1.2 Optimization of Extraction Duration

Take each of 4 ml 4% acetic acid simulant for 6

copies into 10 ml centrifugal tubes with plugs, add

0.4 mL standard solution at the concentration of 10

mg/L, then add 4 ml of methyl acetate, sodium

chloride 0.5 g. Respectively extract for 1 min, 2 min,

5 min, 10 min to determine the average response.

The results show that the response growth of 12

monomers is no longer obvious after 5 min;

therefore extraction time is selected as 5 min for test.

3.2

Instrumental Optimization

Separations of three chromatographic columns are

investigated. GC temperature program and MS

scanning mode were given intensive optimization to

achieve rapid qualitative and quantitative. Besides,

sampling volume and carrier gas flow rate were also

given appropriate consideration. Sampling volume at

splitless injection mode is 1 μL since higher volume

would cause detector saturation. On the premise of

separation, carrier gas flow rate can be set as higher

as possible to achieve faster outflow. After

optimization, chromatograms of mixed standard

solutions of the 12 acrylic monomers are showed in

Figure 3-1 to Figure 3-6, in which the Figure 3-1 to

Figure 3-5 are the SIM m/z 55 graph of acrylic

monomers, and in which the Figure 6 is the SIM m/z

72 graph of acrylic acid. Since methyl acrylate

cannot be separated from ethanol, data of methyl

acrylate is not collected in ethanol simulants.

3.2.1 Chromatographic Column Selection

This paper tested three chromatographic columns to

separate 12 target compounds. They are respectively

column AT SE - 54 (30m × 0.32mm × 0.50μm),

column DB - WAX (30m × 0.25mm × 0.25μm) and

column HP - INNOWAX (30m × 0.25mm ×

0.50μm).

Firstly, target compound methyl acrylate

possesses very weak polarity as well as low boiling

point, and is unable to reach the baseline separation

in non-polar chromatographic column AT SE - 54

even with almost all sorts of solvent. Secondly,

target compound acrylic acid and hydroxyl ethyl

acrylate both present weak responses at AT SE – 54

column maybe is because of stronger polarity, and

peak tailing are obvious at the same time. Based on

the above, a polar chromatographic column with

thicker stationary phase liquid membrane of 0.5μm

HP – INNOWAX is selected.

3.2.2 GC Temperature Program

The peak of target methyl acrylate is different at

different initial column temperature. Because of its

low boiling point and weak polarity, its responses

reduce gradually with the rising initial temperature

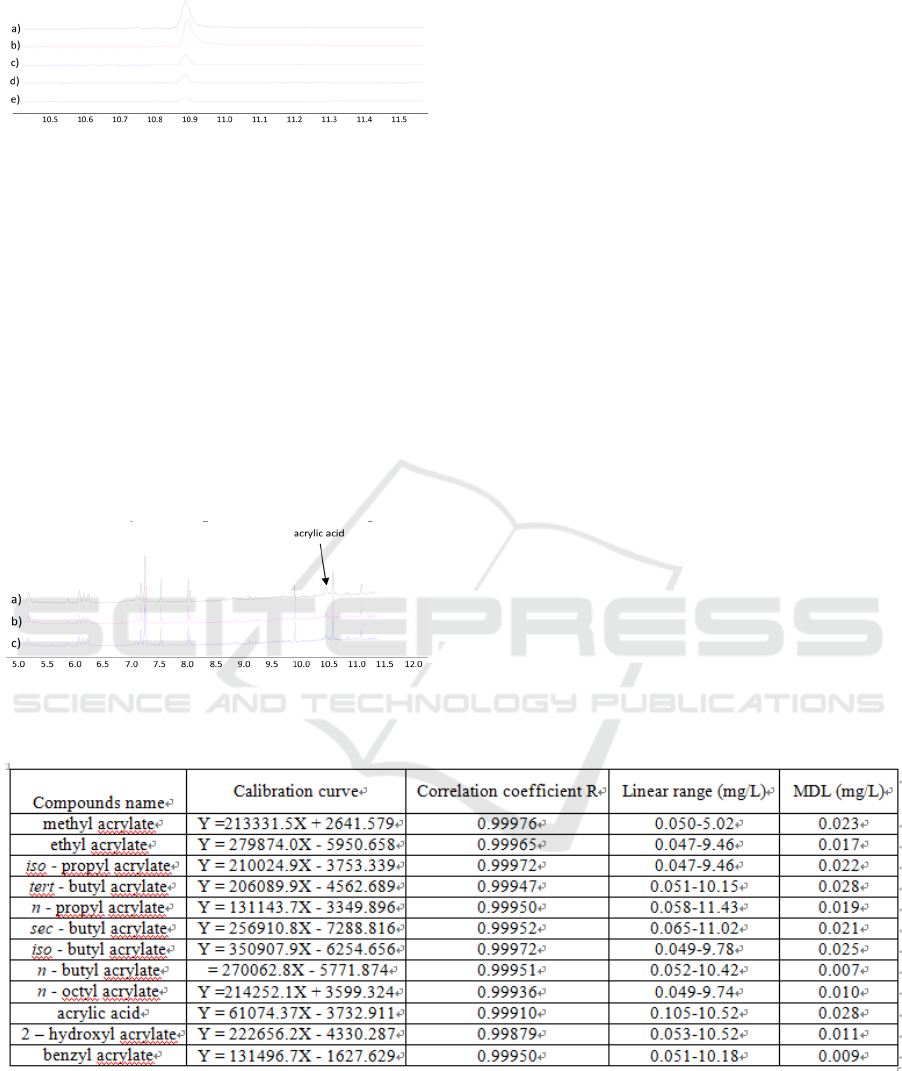

Figure 3-1: 12 Acrylate monomers in 4% acetic acid.

Figure 3-2: 12 Acrylate monomers in water.

Figure 3-3: 11 Acrylate monomers in 10% ethanol.

Figure 3-4: 11 Acrylate monomers in 20% ethanol.

Figure 3-5: 11 Acrylate monomers in 50% ethanol.

Figure 3-6: Acrylic acid in five different simulants.

Number 1-12 represent the corresponding compounds in

Table 1. a) acrylic acid in 4% acetic acid, b) acrylic acid in

10% ethanol, c) acrylic acid in 20% ethanol, d) acrylic

acid in 50% ethanol, e) acrylic acid in aqueous.

despite the same other conditions, and there is even

no outflow when temperature is 60 ºC above. Finally

the initial temperature is set at 40 ºC. For ethyl

acrylate, iso - propyl acrylate and tert - butyl

acrylate, it is more difficult to separate them, thus a

lower rate of warming is adopted at their outflow.

Last but not the least, T

injec

, T

ion

and T

inter

have

influence on acrylic acid response, results show that

when T

injec

is 220 ºC, T

ion

is 230 ºC and T

inter

is 250

ºC, a clearer acrylic acid peak is observed (Figure 4).

Figure 4: GC temperature optimization

a) T

injec

= 220 ºC, T

ion

= 230 ºC, T

inter

= 250 ºC

b) T

injec

= 180 ºC, T

ion

= 230 ºC, T

inter

= 250 ºC

c) T

injec

= 180 ºC, T

ion

= 200 ºC, T

inter

= 250 ºC

3.2.3 MS Scan Mode

The vast majority of the acrylate targets in this test

system is of high sensitivity, so single SCAN mode

is adopted. However, for targets outflow at low

temperature and the acrylic acid, sensitivity can be

relatively low, so simultaneously adopting SCAN

and SIM mode to collect data is recommended.

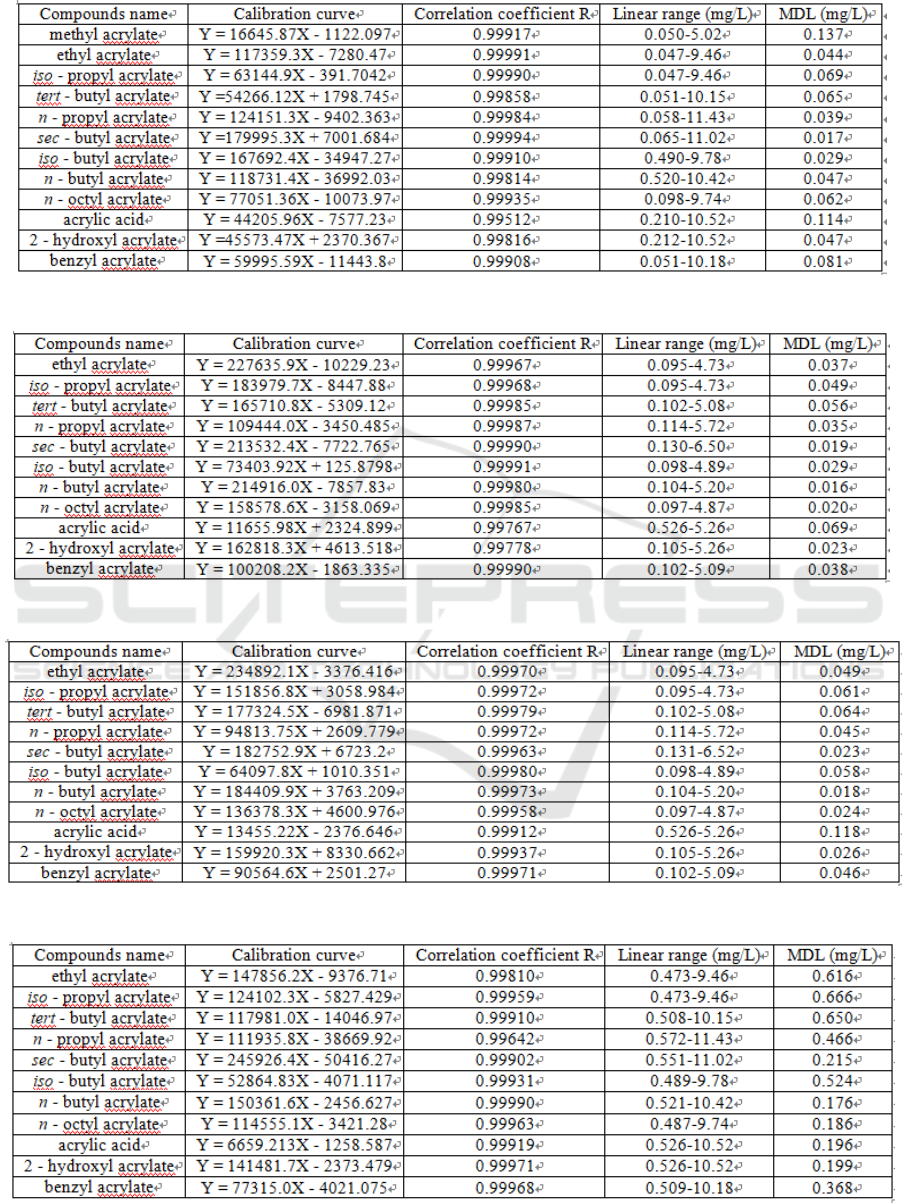

3.3 Linearity and Detection Limit

The linear ranges and the detection limits of 12

acrylic monomers in different simulants are

examined. As shown from Table 2 to Table 6, the

vast majority of the monomers in their

corresponding linear range show a correlation

coefficient of above 0.998. Method detection limits

(MDL) in the calculation of 10 times the signal-to-

noise ratio (10 S/N), are between 0.009 ~ 0.666

mg/L. It can be concluded that 50% ethanol

stimulant has a greater matrix influence, although

the detection limit could still meet the total amount

requirement of under 6 mg/kg.

Table 2: Calibration curve and MDL of 12 acrylic monomers in 4% acetic acid simulant.

Table 3: Calibration curve and MDL of 12 acrylic monomers in aqueous simulant.

Table 4: Calibration curve and MDL of 11 acrylic monomers in 10% ethanol simulant.

Table 5: Calibration curve and MDL of 11 acrylic monomers in 20% ethanol simulant.

Table 6: Calibration curve and MDL of 11 acrylic monomers in 50% ethanol simulant.

3.4 Recovery and Precision

A plastic lid of ABS material is used to incubate

with the five food simulants under 40 ºC,

respectively for 2 h. Then take each the migrated

solutions of 4 ml, and add respectively 0.10, 1.0, 5.0

mg/L mixed standard solution extract according to

the extraction operation in step 2.4. Six duplicate

samples at three concentration levels were required.

Recovery and precision at the three levels were then

tested. Results show that the recovery rate of acrylic

acid and esters in both acid and water simulants

ranges in 81.2% ~ 108.3%, while the relative

standard deviation (RSD, n = 6) of which is within

5.15%.

4 CONCLUSIONS

The National Food Safety Standard involved limit

indicator [SML (22)], a total specific migration

calculated by acrylic acid contains 12 acrylic

monomers, which are rather difficult to quantify by a

single system due to their large differences of

physical and chemical properties. In fact common

LC column cannot separate the four butyl acrylate

isomers. In this study, with the most commonly used

GC-MS in the testing laboratories, we establish aan

instrumental analysis method for determination

migration with acid and aqueous food simulants.

This method has the characteristics of rapidity and

non-toxicity, with low detection limit and high

precision. But in some simulants containing large

amount of ethanol, the methyl acrylate peak is

significantly hindered by residual ethanol solvent.

Another conclusion maybe deduced from the results

as well, that is the ethanol also has different degree

of influence on other monomers’ outflow.

Subsequently, attempt of multiple liquid-liquid

extraction will be made to possibly reduce the

ethanol residual for improved GC analysis; or study

of using headspace sampling will be continued to

explore probably reduced interference of high

concentrations of ethanol simulants.

ACKNOWLEDGEMENTS

This article was supported by Vkan Test &

Certification co., LTD. and the funding of science

and technology projects plan B from China Electric

Apparatus Research Institute (project NO:

SBRV2017054), which herewith acknowledge with

best thanks.

REFERENCES

1. Wang, Z., Yin, Y., Chen, S., Fu, X., Xie, X., and Duan,

S. (2002). Acrylic acid and acrylic ester of acute

toxicity to aquatic organisms. Journal of Jinan

University (Natural Science And Medicine Edition),

pages 75-80.

2. European Commission. (2011). Commission

regulation (EU) No 10/2011 on plastic materials and

articles intended to come into contact with food.

Official Journal of the European Union, pages 15(1):

1-89.

3. Ministry of Health, Labour and Welfare. (2011).

Specifications and Standards for Foods, Food

Additives, etc. Under the Food Sanitation Act

(Abstracts) 2010. Japan External Trade Organization,

pages 1-186.

4. The national health and family planning commission

of the People's Republic of China. (2016). GB 4806.6-

2016, National Food Safety Standard, Food contact

plastics and resins. Standards Press of China (to

appear), Beijing, China .

5. The national health and family planning commission

of the People's Republic of China. (2016). GB 9685-

2016, National Food Safety Standard, Food Contact

materials and products using additives standard.

Standards Press of China, pages 1-384, Beijing,

China .

6. Gu, H., and Shi, Y. (2002). Determination of acrylic

acid and its ester compounds from the atmosphere by

gas chromatography. Chemical Analysis and Meterage,

pages 28-29.

7. Shi, C., Luan, S., and Wu, X. (2003). Determination of

acrylic acid and methyl sulfonic acid content in the

waste liquid by ion chromatography. Analytical

Instrumentation, pages 34-36.

8. Liu, C., Wang, L., Yang, J., Chen, Y., and Li, P.

(2013a). High performance liquid chromatography

method and application for seawater acrylic acid. Acta

Oceanologica Sinica, 35(01):172-176.

9. Liu, D., Chen, X., Wu, M., Li, S., and Dai, Y. (2011b).

A headspace gas chromatography - mass spectrometry

method in determination of adhesives residual

monomer of acrylic esters. Chinese Journal of

Chromatography, 29(12):1179-1182.

10. Shentu, X., and Zhang,W. (2008). Determination of

residual monomer acrylic esters in coatings. Dyeing

and Finishing, pages 33-35.

11. Wang, J., Guan, X., and Liu, T. (2016). GC-MS

Determination of 12 methacrylates migrated from

plastics in contact with foods to aqueous simulants.

Physical Testing and Chemical Analysis Part B:

Chemical Analysis, 52(07):809-814.

12. Dong, Q., Lin, R., Lai, Y., Lin, H., Lin, W., Huang, L.,

Ge, X., Lai, T., and Chen, W. (2013). Determination

of migration of methyl methacrylate in sunflower oil

simulants. Journal of Food Safety and

Quality ,4(04):1067-1071.

13. Ma, M., Qing, J., Zhou, Y., Zhou, Y, and Shen, J.

(2013). Head-space GC determination of residual

amount of monomer in products of

polymethylmethacrylate. Physical Testing and

Chemical Analysis Part B: Chemical Analysis,

49(12):1486-1488+1492.

14. Lai, Y., Lin, R., Lin, W., Ge, X., Dong, Q., and Huang,

Z. (2015). Determination of 16 monomers amount of

migration and migration risk investigation in food

contact materials acrylic resin. Chinese Journal of

Analytical Chemistry, 43(10):1573-1579.

15. Li, Y., Li, C., Chen, X., Liang, F., Bai, S., Liao, W., Li,

Y., and Sun X. (2014a). Determination of five kinds of

acrylate monomers migrated from plastic food-

contacting materials by SPME with GC/MS. Plastics

Science and Technology, 42(01):115-119.

16. Li, Y., Li, C., Sun, X., Chen, X., Chen, Z., Sun, D.,

and Wu, S. (2015b). Gas chromatography

determination of migration of 12 monomers in food

contact materials. Packaging Engineering, 36(11):36-

41+50.

17. Li, C., Li, Y., Liao, W., Chen, X., Sun, X., Li, Y.,

and Bai S. (2016c). Determination of migration

amounts of acrylate monomers by high performance

liquid chromatography in food contact materials.

Journal of Food Safety & Quality, 7(01):322-330.