Green Microwave Synthesis of Cuprous Oxide

Microparticles And the Photocatalytic Degradation Properties

Weichao Li

1

, Pen Deng

1

, Liexing Zhou

2

, Linkun Xie

1

and Xijuan Chai

1

1

Yunnan Provincial Key Laboratory of Wood Adhesives and Glued Products, Southwest Forestry University, Kunming,

China;

2

Research Center for Analysis and Measurement, Kunming University of Science and Technology, Kunming, China;

Keywords: Cuprous oxide; Microwave synthesis; Microparticles; Photocatalytic degradation properties.

Abstract: Cu

2

O microparticles with three different morphology were prepared by a green, facile and additive free

microwave synthesis method with household common microwave oven. The morphology of cuprous oxide

can be easily controlled by adjusting the amount of glucose added, via which the sphere, cube and

octahedron cuprous oxide were synthesized. The phase, morphologies and optical properties of cuprous

oxide were characterized by XRD, SEM and UV-vis. The photocatalytic efficiency are evaluated by

monitoring the photocatalytic degradation of Methylene blue (MB) solution under visible light irradiation.

The results show that the spherical, cubic and octahedral cuprous oxide exhibited the high degradation

efficiency.

1 INTRODUCTION

Cuprous oxide (Cu

2

O) is a typical P-type

semiconductor material with a band gap of

approximately 2.17 eV, with unique optical and

electrical properties and photoelectrochemically

properties[S. Kakuta et al.,2009;J.Y. Kim et al.,

2009 and D.J. Norris et al. 2001]. With the

development of nanotechnology, Cu

2

O nanoparticles

have widespread applications in solar energy

conversion, photo catalytic degradation of organic

pollutants and catalysis in organic synthesis[D.J.

Norris et al. 2001].

Cu

2

O nanoparticles can be prepared by the solid-

phase synthesis, liquid-phase method and gas-phase

method[H. Pang et al,2010; P. Liu et al.,2011 and

K.D. Bhatte et al.,2010]. Comparatively speaking in

the liquid-phase method, the chemical deposition

method require relatively simple experimental

conditions and are easy to operate, which is often

used. However, in order to obtain nanoparticles with

uniform morphology and particle size, most of the

chemical deposition methods need to use drastic

synthesis conditions like high temperature and

pressure, use of toxic reagents, long reaction time,

and requirement of external additives during the

reaction[F.K. Liu et al.,2004; K.D. Bhatte et al.,2012;

F.K. Liu et al.,2008; G.C. Xi et al.,2008].

Currently microwave assisted synthesis attracts

more attention owing to its advantages like

volumetric heating, fast kinetics, selectivity, less

energy requirements and time economy[QingweiZhu

et al.,2011; Manohar A. et al.,2013]. There are also

some studies about preparation of cuprous oxide

powders by microwave methods. However,

microwave method prepared Cu

2

O nanocomposites

reported in the literature need either the addition of

surfactants[QingweiZhu et al.,2011] or use of toxic

reducer [Manohar A. et al.,2013], or microwave

irradiation time is as long as 0.5-1 hours, or require

special microwave reaction equipment[E. Lu

Hipolito et al.,2017; Jun Liu et al.,2009]. Therefore,

it is still a challenge to develop simple and

controllable routes for the visible-light responsive

Cu

2

O with excellent photocatalytic performance via

microwave assisted synthesis.

Based on the above considerations, this work

described a facile and additive free microwave

method for creating high photocatalytic activity

Cu2O, which synthesize three types of cuprous

oxide microcrystals with household common

microwave oven. The phase, morphologies and

optical properties of three types of cuprous oxide

were characterized by XRD, SEM, and UV-vis.

Their photocatalytic activities are determined by

monitoring the photocatalytic degradation of MB.

2 EXPERIMENT

2.1 Synthesis of Cu

2

O Nanoparticles

Nanocrystalline formation was carried out in

domestic Galanz microwave oven operating at 180

W and frequency of 2.45 GHz. In a typical Cu

2

O

synthesis process, 15ml aqueous solution of sodium

hydroxide (4M) was added slowly into 200ml

aqueous solution of CuSO

4

•5H

2

O (0.1 M) in a

beaker at room temperature (the whole process lasts

for 2min) while stirring for 30min. The calculated

volume of glucose solution (1.0 M) was slowly

added into the above solution and then placed in a

microwave oven. Reaction was performed at 180 W

for 10 minutes. The products were collected by

centrifugation, washed with deionized water and

absolute ethanol, and dried in a vacuum at 50 °C for

24 h.

2.2 Method of Characterization

The morphologies were examined using SEM on a

Hitachi S-4800. The formed Cu2O powder was then

characterised by X-ray diffraction (XRD) (Brukar

D8 advance X-ray diffractometer using

CuKα=1.54060 Å) with scanning 2 theta (θ) angle

ranging from 15° to 100°. UV–vis diffuse

reflectance spectra were obtained by UV–vis

spectrophotometer equipped with an integrated

sphere (TU-1901, China). BaSO4 was used as a

reference for the measurements.

2.2 Photocatalytic Reaction

0.2 g sample of Cu

2

O was dispersed in 10 mg/L MB

solution at 25 ◦C in a 250ml quartz reactor and was

illuminated with a 250 W tungsten lamp. Before

irradiation, the suspensions were sonicated in the

dark for 30 min to make the powder disperse well in

the solution. After that, 1ml of H

2

O

2

was added into

above suspension and then the lamp was turned on

to conduct the photocatalytic reaction at room

temperature while magnetic stirring was kept all

along with the reaction. At regular intervals, 10 ml

of the suspension was sampled and separated by

centrifugation at 8000 rpm for 10 min. The

concentration of remaining pollutant was measured

by its absorbency (A) at 484 nm with a Hitachi UV-

3010 spectrophotometer[P. Chen et al.,2004].

3 EXPERIMENT

3.1 Characterization of Prepared

Cu2O

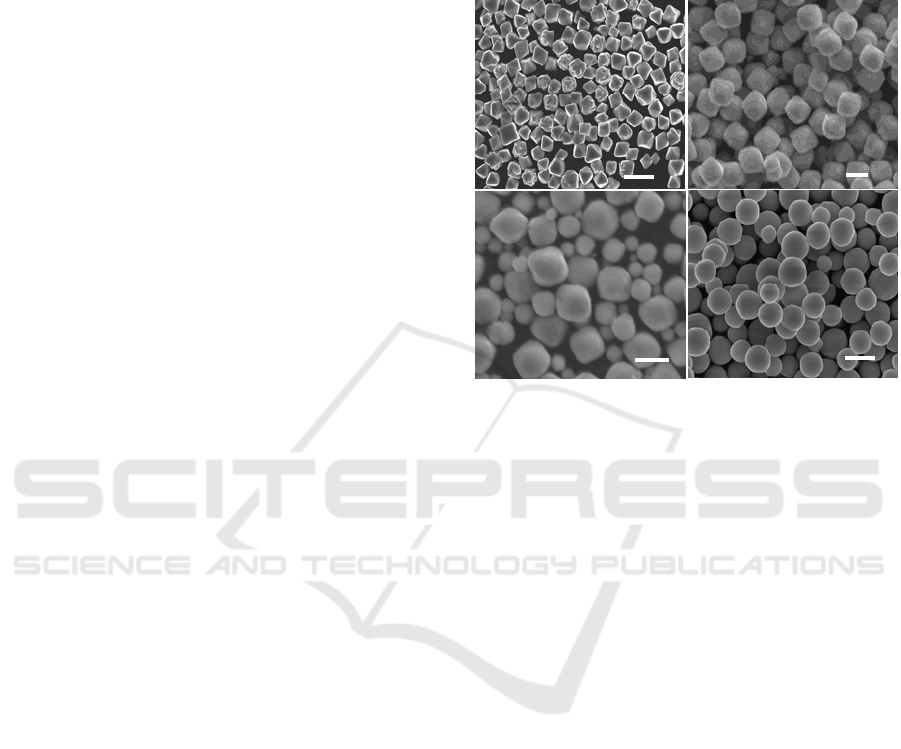

Figure 1: SEM images of the Cu2O samples with different

morphologies.

(a)octahedron, (b) cube, (c) sphere and cube,(d) sphere

Fig. 1 shows the morphology of Cu

2

O sample

prepared at the molar ratio of glucose solution to

copper sulfate of 0.6, 1.0, 1.25 and 2.0 respectively.

Fig.1(a) shows most of the crystals are octahedral

shape with the size about 200-400 nm. Fig.1(b)

discloses cubic shape crystal with the size about 0.8-

1um. The spherical crystals are shown in Fig.1(d)

with the particle size about 200-350nm. The crystals

shown in Fig.(c) have a spherical and square mixed

crystals. As can be seen from Fig.1, the three types

of cuprous oxide particles are well dispersed without

any particles aggregate. The amount of reducing

agent glucose determines the saturation of the Cu

+

in

the system, which determines the mode growth and

the final morphology of the cuprous oxide

nuclei[Xiaoyan Zhou et al.,2014]. The SEM results

the morphology of cuprous oxide should can be

controlled by adjusting the amount of glucose added.

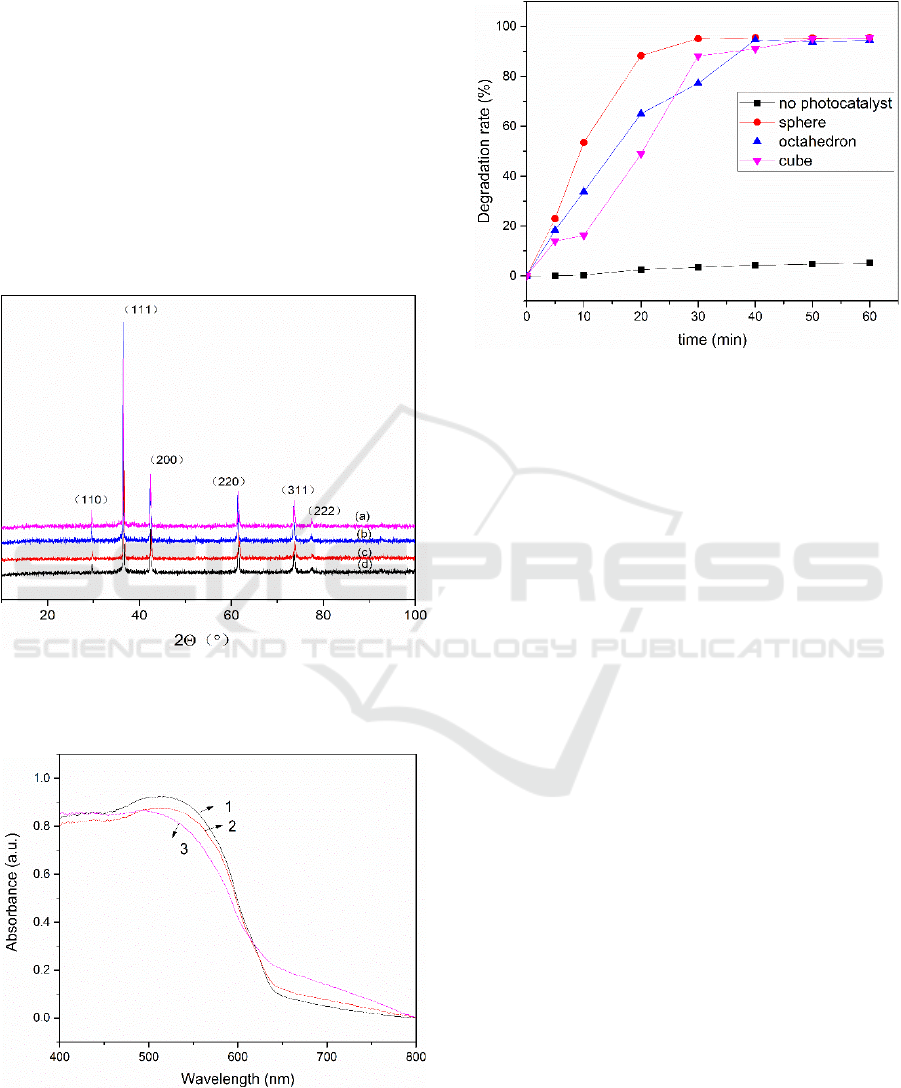

The XRD patterns of four kinds Cu

2

O in Fig. 2

shows that all diffraction peaks, they are (110),

(111), (200), (220), (311) and (222) planes, which

can match well with the standard Joint Committee

on Powder Diffraction Standards (JCPDS) card No.

78-2076. No impurity peaks were observed in this

pattern, which fully demonstrates that the

1um

(c)

500nm

(d)

1um

(b)

500nm

(a)

crystallinity of Cu

2

O is very good and the purity is

high.

The ultraviolet absorption spectra of Cu

2

O

powders was shown in Fig.3, which indicates that

three prepared samples exhibit broad and strong

absorption peaks in the visible region. The sphere,

cube and octahedron Cu

2

O has the maximum

absorption peak at 511nm, 512 nm, and 495 nm

respectively. The forbidden band width of cuprous

oxide is calculated according to a classical

semiconductor formula αEP=K(EP-Eg)

1/2

. The band

gaps calculated for spheres, cubes, and octahedron

Cu

2

O were 2.42 eV, 2.42 eV, and 2.50 eV,

respectively, which corresponds to a typical

nanosize Cu

2

O[W. Wang et al.,2011].

Figure 2: XRD pattern of different morphology of Cu

2

O.

(a) sphere (b)octahedron;(c) cube;(d) mixed shape

Figure3:UV–vis absorption spectra of Cu2O .

(1) sphere (2)octahedron;(3) cube;

3.2 Photocatalytic degradation of MB

Figure 4:Catalytic degradation of MB curves byCu2O.

The photocatalytic abilities of cuprous oxide are

evaluated by the photocatalytic discoloration of

10mgL

-1

MB as shown in Fig.4. It can be seen that

direct decomposition of MB without cuprous oxide

is pretty low. As for the individual cuprous oxide, it

can be found that sphere Cu

2

O shows the highest

photocatalytic activity with the almost complete

discoloration at the beginning 30min. This is due to

the fact that spherical Cu

2

O has a relatively large

specific surface area and can adsorb more substances

at the beginning. However, when the degradation

time exceeded 30 minutes, the cubic and octahedral

cuprous oxide exhibited the same high efficiency of

degradation as the spherical cuprous oxide.

4 CONCLUSIONS

Sphere, cube and octahedron cuprous oxide were

synthesized by a facile and additive free microwave

synthesis with household common microwave oven

via adjusting the amount of glucose. The phase,

morphologies and optical properties of three types of

cuprous oxide were characterized by XRD, SEM,

and UV-vis. SEM images indicate the three types of

cuprous oxide particles are well dispersed without

any particles aggregate. XRD and UV-vis spectrum

show s all diffraction peaks of the three different

morphology Cu

2

O can match well with the

standardCu

2

O peak and all of the Cu

2

O exhibit broad

and strong absorption peaks in the visible region.

The results of photocatalytic efficiency show that the

spherical, cubic and octahedral cuprous oxide

exhibited the high degradation efficiency.

ACKNOWLEDGEMENTS

This work was supported by the National Natural

Science Foundation of China (No. 31660179), Key

Laboratory of Wood Adhesives and Adhesive

Products in Yunnan Province Open Fund(201502)

REFERENCES

1. S. Kakuta, T. Abe, Photocatalytic activity of Cu

2

O

nanoparticles prepared through novel synthesis

method of precursor reduction in the presence of

thiosulfate, Solid State Sciences 11 (2009) 1465–1469.

2.

J.Y. Kim, J.C. Park, A. Kim, A.Y. Kim, H.J. Lee, H.

Song, K.H. Park, Cu

2

O nanocube-catalyzed cross-

coupling of aryl halides with phenols via Ullmann

coupling,European Journal of Inorganic Chemistry

(2009) 4219–4223.

3.

D.J. Norris, Y.A. Vlasov, Chemical approaches to

three-dimensional semiconductor photonic

crystals,Adv. Mater. 13 (2001) 371–376.

4.

H. Pang, F. Gao, Q. Lu, Glycine-assisted double-

solvothermal approach for various cuprous oxide

structures with good catalytic activities,

CrystEngComm12 (2010) 406–412.

5.

P. Liu, Z. Li, W. Cai, M. Fang, X. Luo, Fabrication of

cuprous oxide nanoparticles by laser ablation in PVP

aqueous solution, RSC Advances 1 (2011) 847–851.

6.

K.D. Bhatte, P. Tambade, S.I. Fujita, M. Arai, B.M.

Bhanage, Microwave-assisted additive free synthesis

of nanocrystalline zinc oxide,Powder Technology 203

(2010) 415–418.

7.

K.D. Bhatte, D.N. Sawant, R.A. Watile, B.M.

Bhanage, A rapid, one step microwave assisted

synthesis of nanosize zinc oxide, Materials Letters 69

(2012) 66–68.

8.

F.K. Liu, Y.C. Chang, F.H. Ko, T.C. Chu, Microwave

rapid heating for the synthesis of gold

nanorods,Materials Letters58 (2004) 373–377.

9.

K.D. Bhatte, D.N. Sawant, K.M. Deshmukh, B.M.

Bhanage, Additive free microwave assisted synthesis

of nanocrystalline Mg(OH)

2

and MgO, Particuology

Materials Letters 10 (2012) 384–387.

10.

F.K. Liu, P. X.L. Hu, J.M. Gong, L.Z. Zhang, J.C.

Yu, Continuous size tuning of monodisperse ZnO

colloidal nanocrystal clusters by a microwave-polyol

process and their application for humidity sensing,

Adv. Mater. 20 (2008) 4845–4850.

11.

G.C. Xi, Y.T. He, Q. Zhang, H.Q. Xiao, X. Wang, C.

Wang, Synthesis of crystalline microporous SnO

2

via

a surfactant-assisted microwave heating method: a

general and rapid method for the synthesis of metal

oxide nanostructures, J. Phys. Chem. C 112 (2008)

11645–11649

12.

QingweiZhu,YiheZhang,JiajunWang,FengshanZhou,P

aul K.Chu, Microwave Synthesis of Cuprous Oxide

Micro-/Nanocrystals with Different Morphologies and

Photocatalytic Activities, Journal of Materials Science

& Technology27(2011) 289-295;

13.

Manohar A. Bhosale, Kushal D. Bhatte, Bhalchandra

M. Bhanage, A rapid, one pot microwave assisted

synthesis of nanosize cuprous oxide, Powder

Technology 235 (2013) 516–519;

14.

E. Lu evano-Hipolito, L.M. Torres-Martı´nez, D.

Sanchez-Martı´nez, M.R. Alfaro Cruz, Cu2O

precipitation-assisted with ultrasound and microwave

radiation for photocatalytic hydrogen production,

International Journal of Hydrogen Energy

42(2017)12997-13010

15.

Jun Liu, Shaozhen Wang, Qian Wang, Baoyou Geng,

Microwave chemical route to self-assembled quasi-

spherical Cu2O microarchitectures and their gas-

sensing properties, Sensors and Actuators B 143 (2009)

253–260;

16.

P. Chen, W. Li, T.L. Zhou, Y.P. Jin, M.Y. Gu, J.

Photochem. Photobiol. A: Chem. 168 (2004) 97

17.

Xiaoyan Zhou, Jingjing Shi, Ya Liu, Qingmei Su, Jun

Zhang, Gaohui Du, Microwave-assisted synthesis of

hollow CuO–Cu2O nanosphere/graphene composite as

anode for lithium-ion battery, Journal of Alloys and

Compounds 615 (2014) 390–394

18.

W. Wang, Z. Liao, Y. Wang, X. Wu, F. Qu, X. Zang,

Hydrothermal synthesis of highly symmetric 26-facet

Cu

2

O polyhedral, Crystal Research and Technology

46 (2011) 300–304