Optimization of Nano Coral-Based Synthesis Calcium Phosphate with

Concentration Variation of Phosphoric Acid and Sintering

Temperature

Siswanto, Mayasari Hariyanto and Siti Nurmala

Department of Physics, Faculty of Science and Technology, Universitas Airlangga, Surabaya, Indonesia

Keywords: Calcium Phosphate, Coral, Phosphoric Acid Concentration, Sintering Temperature

Abstract: Research on the optimization of calcium phosphate formation has been carried out. The material used is

nanocoral with varying concentrations of phosphoric acid and sintering temperature. The method used is

precipitation method. There were three variations of molar concentration of phosphoric acid used, namely

1M; 1.5M; and 2M. While the variations in sintering temperature were 800ᵒC, 850ᵒC, 900ᵒC and 950ᵒC

respectively. Nano-sized powders were obtained through mechano-chemical processes of fossilized corals

using High Energy Milling (HEM) for 20 hours, which is 64.93nm. X-Ray Diffraction (XRD) observation

results showed that the Calcium Phosphate phase formed is Hydroxyapatite (HAp), β-Tricalcium Phosphate

(β-TCP) and Tetra Calcium Phosphate (TTCP). The TTCP phase only occurred at 950

0

C. The largest

volume of HAp fraction occurred at the molar concentration of 1.5 M of phosphoric acid with sintering

temperature of 850ᵒC, which is 70.7% and the remaining β-TCP phase is 29.2%. The crystallinity

percentage that occurred in these conditions is 94.95%.

1 INTRODUCTION

The Indonesian Ministry of Health Research and

Development Agency (RISKERDAS, 2013), stated

that there was approximately 5.8% of fractured

injury sufferers in Indonesia. This figure increased

by 0.7% compared to the same incident in 2007.

Those injury cases are caused by various factors

including traffic accidents, natural disasters and

bone cancerous.

Improvements to bone injury can be done by

using filler, scafold or implant. Until now, 90% of

the material is still imported. Someone who has bone

damage spends about 70% of treatment cost for

implants. This fact shows the importance of

independence in providing medical materials

including calcium phosphate biomaterials.

Calcium phosphate is the main mineral

constituent of bones and teeth. Calcium phosphate

can induce a biological response during bone

renewal or formation by performing bone mineral

absorption. When absorption occurs, the results of

calcium phosphate degradation (calcium and

phosphate ions) will be metabolized by the body

naturally. In general, human bones consist of 60%

inorganic ingredients, 30% organic matter, and 15%

water (Krishna et. al., 2007). Inorganic material is

bone mineral containing sub-microscopic

Hydroxyapatite [Ca

10

(PO

4

)

6

(OH)

2

]. Other inorganic

minerals are magnesium (Mg), fluoride (F), Chloride

(Cl), sodium (Na) and potassium (K). There is about

34.00% of calcium (Ca) compounds and 15% of

phosphorus (P) compounds in human bones (Darwis,

D. & Warastuti, Y., 2008). Calcium phosphate can

be obtained from the synthesis of natural materials

with high calcium, one of which is coral.

Research on coral rock used for raw materials

implant has been carried out by previous

researchers. A research conducted by Indarwati

(2007) on coral rock analysis using XRD (X-Ray

Diffraction) test showed that the composition of the

coral is 91.696% CaCO

3

(Aragonite) compound,

3.677% MgSiO

3

, and 4.626% FeSi. From the results

of the analysis, it appears that the coral contains very

high calcium carbonate (CaCO3) compounds.

Calcium carbonate compounds (CaCO

3

) can be

converted into HAp through various processes. One

of them is through the calcination process to form

CaO and Ca(OH)

2

compounds. Furthermore,

calcium phosphate compounds can be formed by

Siswanto, ., Hariyanto, M. and Nurmala, S.

Optimization of Nano Coral-Based Synthesis Calcium Phosphate with Concentration Variation of Phosphoric Acid and Sintering Temperature.

DOI: 10.5220/0007545104650468

In Proceedings of the 2nd International Conference Postgraduate School (ICPS 2018), pages 465-468

ISBN: 978-989-758-348-3

Copyright

c

2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

465

reacting them with phosphoric acid which is sintered

at a certain temperature.

Therefore, this study focused on the formation

of calcium phosphate by optimizing the process

parameters of phosphoric acid’s molar concentration

and sintering temperature variations. This is based

on the fact that coral is a natural mineral that

contains many compounds so that the right molar

concentration of phosphoric acid is needed. In

addition, the formation process also requires the

right sintering temperature. To accelerate the

reaction process of calcium phosphate formation in

this study, the expansion of surface area of the touch

reaction through the size of nanoparticles was

carried out. The smaller the particle size, the wider

the surface area of the touch (Ferraz, 2014).

2 MATERIAL AND METHODS

Coral used in this study came from the sea in

Banyuwangi, East Java, Indonesia. Phosphoric acid

(H

3

PO

4

) with a purity of 99.8% Aldrick, aquadest

and glycerol.

This research was done through two stages of

nano coral and calcium phosphate formation. The

first stage was the formation of nano coral using top

down method, which converts large particles into

nano-sized particles through the milling process. The

corals were cleaned from dirt and dried in the open

space. Then, the coral was destroyed manually to be

smaller particles. Once becoming sufficiently

smooth, the sample was sieved using a 200 mesh

sieve to facilitate the milling process. Then, the

result of the sieve was milled using HEM-3D (High

Energy Milling-3 Dimension) for 20 hours with

comparison between samples of 1:20 to ball mill.

The formation of calcium phosphate based on

nano coral was performed using precipitation

method. The molarity of phosphoric acid used varies

i.e. 1.0M; 1.5M; 2.0M, while the sintering

temperature was carried out at four different

temperatures i.e. 800

0

C; 850

0

C; 900

0

C; and 950

0

C.

So, there were 12 samples used in this research.

3 RESULT AND DISCUSSION

The corals used in this study came from the

Banyuwangi sea of East Java (figure 1a). The type

of coral is fossilized coral. The coral was then

broken into small sizes using a hammer (Figure 1b).

To facilitate the milling process, the results of the

coral pieces were crushed using a mortar then

filtered using a 200 mesh sieve (Figure 1c). The

results of the filter were milled using HEM-3D for

20 hours to change the size of the nanoparticles. The

results of the observation of Particle Size Analyzer

(PSA) on the results of the treatment showed that the

size obtained was 64.93 nm (Figure 2).

Figure 1: The process of sample preparation (a) coral has

been cleaned, (b) coral has been dissolved, (c) coral has

been refined.

Figure 2: The results of PSA test of coral powder

Nano coral XRD diffractogram was done to

determine the content of the compound. Figure 3

shows a sample of nano coral diffractogram. By

using the Search-Match program (see Figure 3), it

can be found that the coral consists of 78.6% CaCO

3

(calcite) compounds and 21.4% Ca

2

O

5

Si

compounds. The CaCO

3

calcination process causes

the change of the compound to CaO and CO

2

as

shown in Equation 1. Furthermore, the milling

process of calcined coral can cause a thermal

reaction that produces water vapor. In the vial, the

moisture formed can react with CaO which produces

Ca(OH)

2

, as stated in Equation (2). This can be seen

in Figure 4 diffractogram, the coral produced 95.8%

Ca(OH)

2

and 4.2% CaO. The presence of CaO is

still suspected because the reaction process in the

vial is still less than optimal. This can be caused by

short time for milling and improper comparison of

ball vials.

CaCO

3

900 ºC

CaO + CO

2

……………(1)

CaO + H

2

O Ca(OH)

2

……….. …...(2)

ICPS 2018 - 2nd International Conference Postgraduate School

466

Figure 3: The results of XRD observation (a) nano coral

(b) nano coral calcined at 900

0

C

Calcium phosphate was formed by the reaction

of calcium hydroxide (Ca(OH)

2

) and phosphoric

acid (H

3

PO

4

), as shown in Equation (3). The

treatment of phosphorus acid molar variation was

done because the results of XRD (see Figure 4) still

contained CaO as impurity form of Ca(OH)

2

. In this

study, there were 3 variations of phosphoric acid

molarity used i.e. 1M, 1.5M and 2M. In addition, the

process of ceramic formation generally is strongly

influenced by the sintering temperature. In this

study, four variations of sintering temperature were

carried out. Therefore, every variation of molar

above was performed by four variations of sintering

temperature which are 800

0

C; 850

0

C; 900

0

C; and

950

0

C, so there were total of 12 samples used in this

study. The results of observations of 12 samples are

displayed in Figure 5, Figure 6, and Figure 7.

5Ca(OH)

2

+3H

3

PO

4

→Ca

5

(PO

4

)

3

(OH) +9H

2

O (3)

Figure 4: XRD observations of 1 M calcium phosphate

sample with sintering temperature at

(a) 800

0

C, (b) 850

0

C, (c) 900

0

C, and (d) 950

0

C

Figure 5: XRD observations of 1.5M calcium phosphate

sample with sintering temperature at (a) 800

0

C, (b) 850

0

C,

(c) 900

0

C, and (d) 950

0

C

Figure 6: XRD observations of 1 M calcium phosphate

sample with sintering temperature at (a) 800

0

C, (b) 850

0

C,

(c) 900

0

C, and (d) 950

0

C

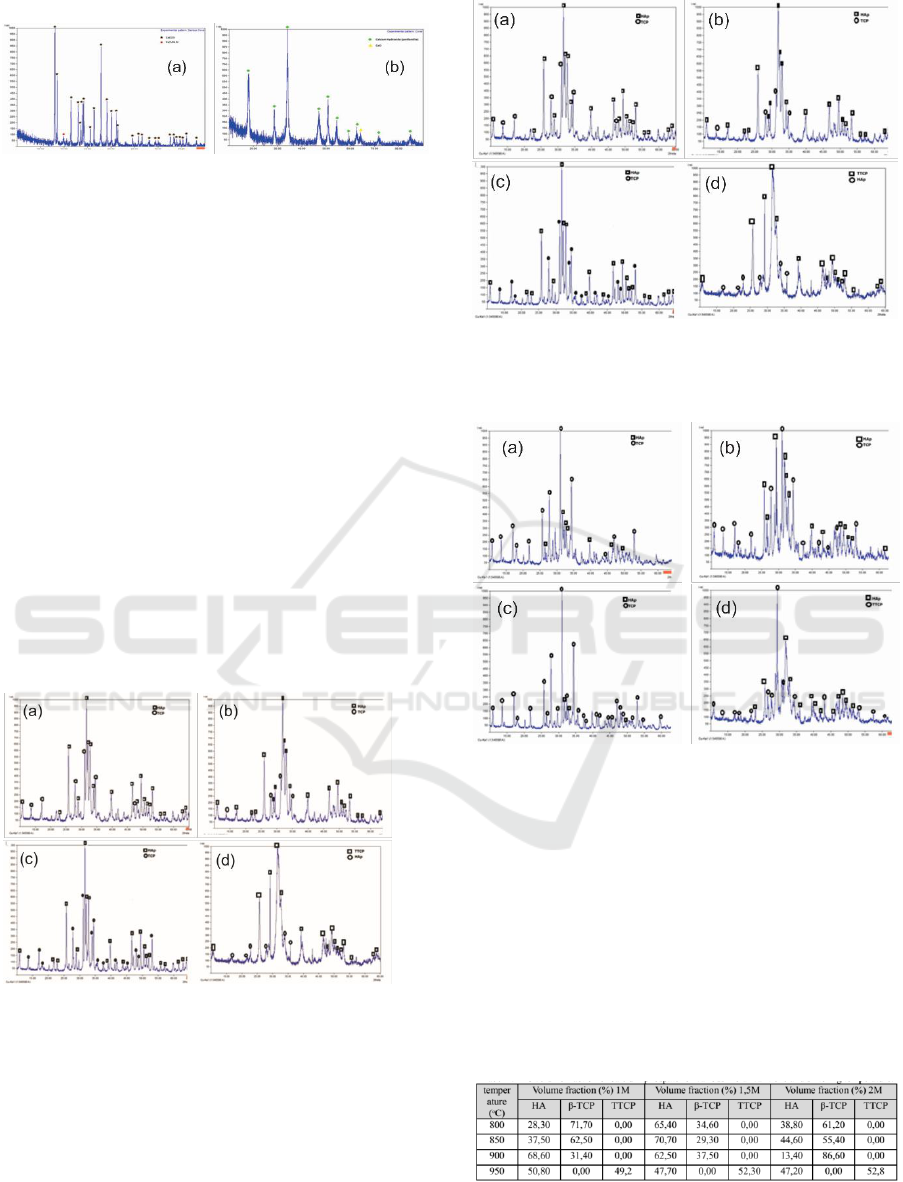

The identification of the XRD in Figure 4, Figure

5, and Figure 6 shows that the calcium phosphate

formed is the HAp (Hydroxyapatite), TCP (Tri

Calcium Phosphate), and TTCP (Tetra Calcium

Phosphate) phases. In full, the volume fraction from

these three phases for various molar concentration

and sintering temperature are shown in Table 1.

Tabel 1: The volume fraction of calcium phosphate for

various molar concentration and sintering temperature

From Table 1, it appears that the stable calcium

phosphate phase, Hap, is highly dependent on

molarity of phosphoric acid and sintering

Optimization of Nano Coral-Based Synthesis Calcium Phosphate with Concentration Variation of Phosphoric Acid and Sintering

Temperature

467

temperature. This optimum phase occurred at a

sintering temperature of 900

0

C with molarity of 1M

phosphoric acid. In addition, this phase is also

optimized at 850

0

C sintering temperature with 1.5M

phosphoric acid molarity. This also occurred with

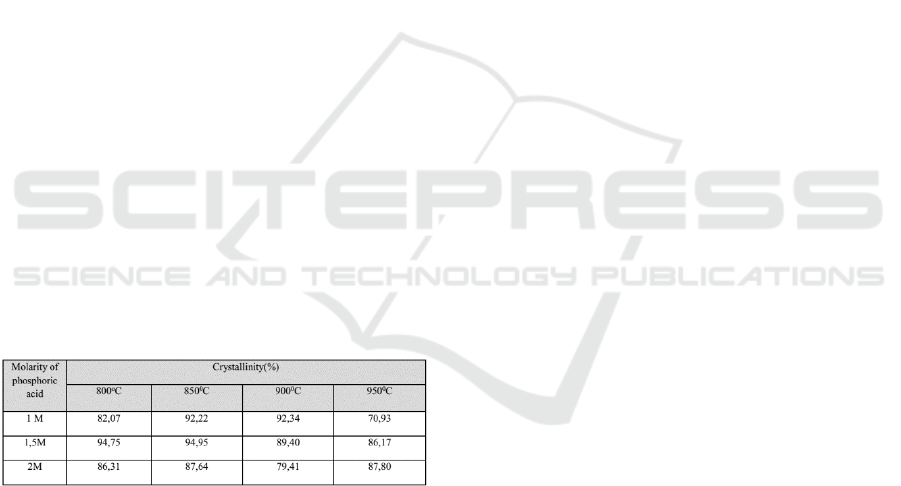

the crystallinity formed, as stated in Table 2.

Human bone crystallinity is in the range of 69%

to 87% (Balgies, 2011), while the dominant phase of

calcium phosphate in bone is HAp with a Ca / P

ratio of 1.67. The Ca / P ratio of β-TCP and TTCP

compounds are 1.50 and 2.0, respectively (Kerry L.

and Hull, P., 2011). Based on these references, there

are five crystallinity samples that fulfil the

requirements as bone filler. Based on the heating

process, 950

0

C sintering temperature is the most

effective compared to other sintering temperatures.

Based on its molarity, the 2M molar concentration of

phosphoric acid is the most effective. This is

allegedly caused by chemical reactions that occur

between CaO and H

2

O is less than perfect, so that

Ca(OH)

2

is formed and there is still residual CaO

(Sokolova,2012). The number of HAp phases, β-

TCP phase and TTCP phase affect the Ca / P ratio of

the material. The ratio of the three phases in a row is

1.67, 1.50 and 2.00. By using the mean principle

from Table 1, the ratio of Ca / P of the sample can

be determined. When viewed from the molarity of

phosphoric acid, the 1.5M molarity has the best

value of 1.67. However, when viewed from the

sintering temperature, 900

0

C is the most optimal

temperature, which gives a Ca / P ratio of 1.61

Tabel 2 : Crystallinity of Hydroxyapatite

4 CONCLUSIONS

From the series of analysis and discussion that

has been done, some conclusions can be drawn.

First, the sintering process causes the transformation

of the structure phase from amorphous to crystal.

The crystallinity of calcium phosphate is influenced

by the sintering temperature and the molar

concentration of phosphoric acid. The sintering

temperature of 800

0

C and 850

0

C give the optimum

crystallinity. Second, the mole amount of phosphoric

acid greatly influences both the phase and

crystallinity. Finally, the stable phase of HAp was

optimally formed at 850

0

C with 1.5M phosphate

molarity of both volume fraction and crystallinity.

ACKNOWLEDGEMENTS

The authors would like to thank the Ministries of

Research, Technology, and Higher Education for its

support through the Exceptional Applied Research

in Higher Education program (Penelitian Terapan

Unggulan Perguruan Tinggi or PTUPT), 2018 fiscal

year.

REFERENCES

Balgies. (2011). Synthesis and Characterization of

Hydroxyapatite from Ranga Shellfish Shells

Final Project of Physics Program Study,

IPB (Institut Pertanian Bogor).

Darwis, D., & Warastuti, Y. (2008). Synthesis and

Characterization Composite of

Hydroxyapatite (HA) for synthetic Bone

Graft, Jurnal Ilmiah Aplikasi Isotop dan

Radiasi, 4 No.2.

Ferraz, M. P., J., M. F., & M., M. C. (2014).

Hydroxyapatite Nanoparticles: A Review of

Preparation Methodologies (Vol. 2). J.

Appl. Biomaterials Biomechanics.

Indarwati, D. (2007). Analysis of Coral as Implant

Material, Final Project of Physics Program

Sudy, University of Airlangga , Surabaya.

Kerry L. and Hull, P. (2011). Study Guide to

Accompany Human Form, Human Function

Essentials of Anatomy & Physiology (Vol.

I). Sherbrooke, Quebec, Canada: Lippincott

Williams & Wilkins, a Wolters Kluwer

business.

Krishna, D. S. R. A. Siddharthan, S. K.Seshadri, T.

S. S. Kumar, 2007, A Novel Route for

Synthesis of Nanocrystalline

Hydroxyapatite FromEggshell Waste.

Material Medicine,Vol 18, p. 1735-1743

Sokolova, M., Kreicbergs, I., Zalite, V., & Berzina-

Cimdina, L. (2012). The impact of Ca(OH)

2

suspension concentration on hydroxyapatite

synthesis. Proceedings of the Eurasia 12

Conference on Chemical Science, Corfu,

Greece, 16-21 April

ICPS 2018 - 2nd International Conference Postgraduate School

468