Environmental Impact Associated with Shale Gas Extraction

X N Li

*

, G L Liu, F S Zhang and Y J Lu

Oil Chemistry Key Laboratory, CNPC (Research Institute of Petroleum Exploration

and Development, PetroChina), Beijing, China

Corresponding author and e-mail: X N Li, LIXUENING@petrochina.com.cn

Abstract. Countries around the world are now stepping up efforts to develop the extraction of

shale gas resource. Shale gas, as an unconventional energy with huge reserves and broad

development prospects, has an increasing impact on the global energy market. However, the

environmental impact brought by shale gas extraction has also attracted wide attention from

the society. For example, ground water and air pollution and the negative influence on local

ecological system caused by hydraulic fracturing have become the focus of attention from the

society and public opinion. In this paper, the environmental impact caused by hydraulic

fracturing on local water resource, surface water and ground water contamination, air

pollution, and induced earthquakes are summarized and discussed. In the future, this analysis

will have guiding significance for environmental protection in the process of shale gas

extraction.

1. Introduction

Shale gas refers to the unconventional natural gas that is trapped within the reservoir rock series

dominated by rich shale. It is a continuous generation of biochemical gas, thermal genetic gas or the

mixture of the two, which can exist in natural fractures and pores with very low permeability. Since

shale gas is a clean and high efficient energy resource, it is becoming a hotspot in new energy

research area. Shale gas is also regarded as a vital strategic resource, and in recent years, lots of

countries have increased the development strength on shale gas extraction. US energy information

administration (EIA) estimates the technically recoverable shale gas is 1.87×10

14

m

3

in the US,

constituting 26 % of the domestic natural gas resources [1]. China has 1.35×10

14

m

3

shale gas

reserves, mostly in Sichuan and Tarim basin, and the technically recoverable shale gas is 2.5×10

13

m

3

[2].

2. Environmental issues on shale gas extraction

The main environmental risks related to shale gas extraction include water, air quality and habitat

classification. So far, the impact of water and air quality is the most heated debated. The potential

negative environmental impacts are a major obstacle to shale gas development in many parts of the

world [3].

Li, X., Liu, G., Zhang, F. and Lu, Y.

Environmental Impact Associated with Shale Gas Extraction.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 89-93

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

89

2.1. Hydraulic fracturing process

The process of extracting nature gas from shale gas formation is called hydraulic fracturing. The

hydraulic fracturing process utilizes fluid and proppants to generate small fractures in the tight shale

formation, creating pathways for the gases and oils to go from the reservoir to the wellbore. The

fracturing fluid is usually consists of water, proppants, and chemical additives. Specifically, the

fracturing fluid is pumped under very high pressure through the perforations on the horizontal well

[4]. The fracturing fluid and mainly the high pressure help to open up the existing fractures or crack

the shale and create new fractures that extend out into the surrounding rock. Once been cracked up,

these fractures can continue to propagate for hundreds of feet and then be prop up by the proppants.

Thus, the natural gas and the oil that exist in the shale are able to come out to the wellbore. However,

in many cases, the horizontal well is too long to maintain sufficient pressure to fracture the shale

across its entire length. To solve this problem, the well is then divided into several stages separated

by plugs [5].

The hydraulic fracturing starts from the farthest stage to the nearest stage from the wellhead. The

high pressure first comes to the farthest stage of the horizontal well and starts fracturing, after this

stage is finished, this area is locked up with a plug. Then the high pressure comes to the previous

stage, which is nearer to the start of the wellhead and repeats the same technological process. The

plugs of each stage are later drilled through and the well is depressurized. After the pressure is

released, the shale gas and shale oil go into the well driven by the pressure gradient, as well as the

fracturing fluid and formation water [6].

2.2. Water lifecycle for hydraulic fracturing process

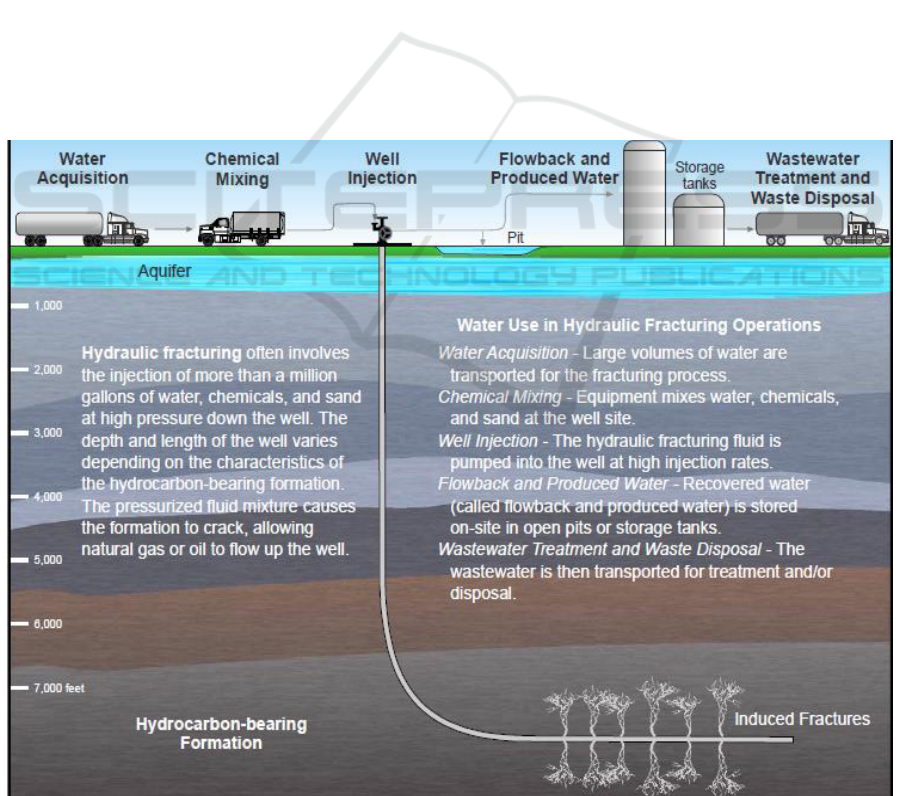

Figure 1. Water lifecycle in hydraulic fracturing process [8].

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

90

Shale gas production needs lots of water. Water management is one of the major challenges faced by

the unconventional oil and gas operators. The total cost of water management can be as high as 12 %

of the operation cost of a shale gas extraction well [7].

The specific water lifecycle in hydraulic fracturing process is showed in Figure 1, which includes

water acquisition, chemical mixing, well injection, flowback and produced water storage, and

wastewater treatment and waste disposal. Potential environmental issues caused by each process is

discussed as follow.

2.3. Environmental impact on water resource

Water makes up more than 87 wt% of the hydraulic fracturing fluid. The hydraulic fracturing process

requires large amount of water being injected into the formation in a short period of time. The water

mainly comes from surface water and ground water resource, and sometimes the water comes from

municipal water and reused water. At shale gas extraction places, the large amount of water needed

for hydraulic fracturing process will compete with other water uses and endanger aquatic habitats.

2.4. Surface water and groundwater contamination

During chemical mixing process, a variety of chemicals are used in hydraulic fracturing fluid to

complete the fracturing job. These chemicals are mixed with water and proppants before injection,

and some of them have negative effects on human health as well as the ecosystem [9]. In accidental

events, it is possible for the chemicals to be released into the environment through leaks and spills,

contaminating the surface water, groundwater and soil.

During the well injection process, the main environmental concern is to protect the groundwater

aquifer, which is a major source for drinking water supply. Different problems will be faced

depending on the well completion practices. Well completion needs to be carried out in either typical

deep shale gas formations or shallower shale gas formations. During the well construction, several

layers of casing and cement are supposed to isolate the fluids and gases inside the well from outside

geological formation. Specifically, the surface casing is designed to extend below the base of the

deepest groundwater aquifer and be cemented all the way to the ground surface, which is expected to

effectively isolate groundwater aquifer from the drilling environment [10]. However, failures in

casing and cementing of the well might cause the leak of fracturing fluids or shale gas/oil from the

well into the groundwater aquifer. Drilling through ground water aquifer also might disturb and alter

ground water redox conditions and pressure gradients. At the end of the production life of the well,

the well needs to be properly plugged to prevent fracturing fluid and flowback water migration that

could contaminate soils and ground water [11].

The hydraulic fracturing process also generates a large amount of flowback water. The flowback

water contain various naturally occurring substances in the formation, such as gases, oil and grease,

total suspend solids (TSS), total dissolved solids (TDS), NORM (naturally occurring radioactive

substances) [12]. Additionally, residual of chemical additives used in the fracturing fluid can be

found in the flowback water. The flowback water is usually treated on-site or transported to other

facilities to be treated or disposed of. Inadequate treatment before discharge or disposal or accidental

spill during transportation could lead to contamination of surface and groundwater resource. Once it

is not handled properly, these actions will cause serious environmental contamination, since ground

water aquifer is difficult to recover.

2.5. Cause of air pollution

Most of the shale gas sites are located in arid regions, where water is quite cherished. Thus, reliable

access to water supply is quite difficult to achieve in these areas, especially during drought seasons.

To solve this problem, fresh water is transported to the site by heavy-duty trucks. The diesel powered

heavy-duty trucks cause emissions of pollutants that affect the local air quality [13]. The immediate

Environmental Impact Associated with Shale Gas Extraction

91

pollutants are VOCs, NOx, and PM2.5 and PM10. Moreover, the presence of high level of VOCs

andPM 2.5 and PM 10 is known to harm the human respiratory system [14]. Also, many types of

equipment used for hydraulic fracturing such as compressors and pumps require fuel combustion.

These activities increase atmospheric emission of air pollutants, which affects the local air quality.

During shale gas extraction process, another potential air pollutant is the crystalline silica dust

originated from the silica proppant. It is generated during the transportation and mixing of sand into

the fracturing fluid. The acute toxicity of silica is low to moderate. However, crystalline silica has

chronic effects to cause silicosis, which is a progressive lung disease which may result in lung cancer

in humans. In the United State, the National Institute for Occupational Safety and Health (NIOSH)

conducted a field study of silica exposure in 11 hydraulic fracturing sites in five different states [15].

Among the 116 samples collected, 79% samples have levels of crystalline silica that exceeded

NIOSH recommended exposure limits (REL, 0.05 mg/m

3

). 31% samples showed silica exposures >

10 times higher than REL and one sample is more than 100 times higher. The shocking results

highlighted the high occupational health risk associated with handling silica proppant.

After the hydraulic fracturing process, the fluid that returns to the surface before the well is put in

production is referred to as flowback water. The produced water is the fluid that returns to the surface

after the well is put to production. The flowback water and produced water are usually stored in on-

site tanks or pits before being treated, or transported for treatment and disposal. The storage tanks

and pits need to be properly managed to avoid potential leaks and storm water overflow. In addition

to surface and groundwater contamination, fugitive VOC emission from the flowback and produced

water might also be a concern for air pollution.

2.6. Induced earthquakes

It is well known that earthquakes can be induced by surface and underground mining, impoundment

of reservoirs, and injection or withdrawal of fluids and gases into or from the subsurface formation.

Both hydraulic fracturing and deep well injection of wastewater could result in induced seismicity

[16, 17].

The hydraulic fracturing process may induce a large number of micro-earthquakes which usually

lower than 1.0 magnitude. There are a few incidences when earthquakes large enough to be felt were

attributed to hydraulic fracturing activities; the biggest one happened at the Horn River Basin in

Canada in 2013 with a magnitude of 3.8, which did not pose significant risk. The investigation

carried out by British Columbia Oil and Gas Commission concluded that the event was caused by

fluid injection during hydraulic fracturing in proximity of pre-existing faults [18]. In 2014, a

hydraulic fracturing job was suspended in north England due to a potential link between its activity

and two seismicity reports of 2.3 and 1.5 in magnitude near the well [19].

Deep well injection of shale gas produced water has also been related to earthquakes. In

Youngstown, Ohio, 10 small earthquakes (all < 3.9 in magnitude) were recorded from April to

November, 2016. These earthquakes were linked to the operation of a Class II deep injection well

used to dispose of produced water as the fluid increased pore pressure along a pre-existing subsurface

faults located close to the wellbore [20]. Disposal wells are also linked to the increase in the seismic

activities in Oklahoma, including a 4.0 magnitude earthquake that occurred on October 15, 2013 [21].

3. Discussion and conclusions

Overall, the environmental impact associated with shale gas extraction mainly include habitat

division, fracturing fluid spills and leaks, local air quality, water resource, ground water aquifer, and

seismicity. Among them, the pollution on ground water aquifer and local air quality are the biggest

environmental issue caused by shale gas extraction. These problems should attract the government's

attention, since these environmental damage could harm the health of local residents, and these

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

92

environmental damage is difficult to recover. Thus, the government should strengthen supervision

and make relevant laws to prevent the environmental pollution caused by shale gas extraction.

References

[1] EIA 2017 Annual Energy Outlook

[2] Christopher A S, Guido D J, John R D and et al 2011 Shale Gas: Applying technology to solve

America's energy challenges National Energy Technology Laboratory (3):159-170

[3] Willow A J, Zak R, Vilaplana D and et al 2014 The contested landscape of unconventional

energy development Journal of Environmental Studies and Science (4):56-64

[4] Paul S, Miaka L A and et al 2012 Shale gas extraction in the UK: a review of hydraulic

fracturing. The Royal Society and The Royal Academy of Engineering

[5] Vaughan A and Purell D 2010 Frac Attack: Risks, Hype and Financial Reality of Hydraulic

Fracturing in the Shale Play Tudor, Pickering, Holt & Co. and Reservoir Research Partners

[6] U. S. Department of Energy 2009 Modern Shale Gas Development in the United States: A

primer. Oklahoma Ground Water Protection Council

[7] Veil J A 2010 Final Report: Water Management Technologies Used by Marcellus Shale Gas

Producers National Energy Technology Laboratory

[8] Source: United States Environmental Protection Agency

[9] Sally E, Michelle E W and et al 2011 Rapid Expansion of Natural Gas Development Poses a

Threat to Surface Water Front Ecol Environ 9(9):503-511

[10] Goodwin S, Carlson K and et al 2012 Life cycle analysis of water use and intensity of oil and

gas recovery in Wattenberg field, Colo. Oil & Gas Journal 110(5): 48

[11] Michalski R and Ficek A 2016 Environmental pollution by chemical substances used in the

shale gas extraction-a review Desalination and Water Treatment 57( 3): 1336-1343

[12] Llewellyn G T, Dorman F, Westland J L and et al 2015 Evaluating a groundwater supply

contamination incident attributed to Marcellus Shale gas development Proceedings of the

National Academy of Sciences 112( 20): 6325-6330

[13] Rich A, Grover J P and Sattler M L 2014 An exploratory study of air emissions associated

with shale gas development and production in the Barnett Shale Journal of the Air

&

Waste

Management Association 64( 1):61-72

[14] Peischl J, Ryerson T B, Aikin K C and et al 2015 Quantifying atmospheric methane emissions

from the Haynesville, Fayetteville , and northeastern Marcellus shale gas production regions

Journal of Geophysical

R

esearch: Atmospheres 120( 5):2119-2139

[15] Norman W D, Jasinski R J and et al 2012 Worker Exposure to Silica During Hydraulic

Fracturing, Hydraulic Fracturing Process and Compositions

[16] Ellsworth W L 2013 Injection-Induced Earthquakes Science 341:142

[17] Van der Elst N J, Savage H M and et al 2013 Enhanced remote earthquake triggering at fluid-

injection sites in the midwestern United States Science 341: 164-167

[18] Oil B C and G Commission 2012 Investigation of observed seismicity in the Horn River Basin.

British Colombia Oil and Gas Report

[19] Clarke H, Eisner L, Styles P and et al 2014 Felt seismicity associated with shale gas hydraulic

fracturing: The first documented example in Europe Geophysical Research Letters

41( 23):8308-8314

[20] Kim W Y 2014 Induced seismicity associated with fluid injection into a deep well in

Youngstown, Ohio. Journal of Geophysical Research

[21] Keranen K M, Savage H M and et al 2013 Potentially induced earthquakes in Oklahoma, USA

Geology 41(6): 699-702

Environmental Impact Associated with Shale Gas Extraction

93