Study on Pressure Drop Characteristics of Oil-water Two-

phase Annular Flow in Horizontal and Inclined Pipes

Y Ling

1,*

, H B Zhang

1

, Y X Pan

2

, Q Wang

1

and Z P Shang

1

1

Department of Earth Science and Engineering, Hohai University, Jiangsu, Nanjing

210098, China

2

Department of Civil Engineering, Shaoxing Uiversit, Zhejiang, Shaoxing, 31200,

China

Corresponding author and e-mail: Y Ling, 1170747017@qq.com

Abstract. Annular flow pattern is an important flow pattern in oil-water two-phase flow,

especially plays an important role in drag reduction of heavy oil. But there are few researches

on the flow characteristics of two-phase annular flow with low viscosity. In order to study the

characteristics, the paper studied the slip ratio and pressure drop under different inclination

angles. In the study, the flow pattern and pressure drop are measured and recorded by high

speed camera, differential pressure gauge and automatic fast closing valve. The experimental

results compare with the results predicted by the two-fluid model, the homogeneous flow

model and VOF model. The results show that the friction pressure increases with the apparent

velocity and decreases with pipe inclination. Compared with the experimental data, the

accuracy of the two-fluid model is low, the VOF model is the most accurate, but the

calculation is large.The four homogeneous flow models are higher. Because the coefficient of

friction is given by the Reynolds number, so the accuracy of the predicted annular pressure

drop is high.

1. Introduction

The mixed flow of oil and water is a phenomenon often encountered in the oil industry. The study of

its flow law has important scientific value and wide engineering application value. However, due to

the complexity of the oil-water two-phase flow, it is necessary to design a reasonable model program

to conduct an in-depth study on its characteristics. Two-phase or multiphas flow is different from the

single-phase. Multiphase flow contains immiscible phases, each with a set of flow variables, so the

flow parameters increase several times. In the flow process,due to the distribution of each phase

changes, there is a velocity slip between each phase and the interaction between phases will have an

impact on the overall flow. Different flow patterns are affected by factors such as inlet velocity and

pipe inclination. Different flow patterns have different flow law. In general, the flow law under a

certain flow pattern can not be applid to other flow patterns. [1-3]

For the division of two-phase flow pattern, there can be divided into stratified flow, dispersed

flow, slug flow, block flow, interrupted flow and annular flow due to the the different flow

conditions or pipeline parameters. For oil-water two-phase flow, the annular flow is very important

for pipeline transportation and oil exploitation because of its special section phase distribution. Its

170

Ling, Y., Zhang, H., Pan, Y., Wang, Q. and Shang, Z.

Study on Pressure Drop Characteristics of Oil-water Two-phase Annular Flow in Horizontal and Inclined Pipes.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 170-177

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

water phase forms an annular contact with the wall, while the oil phase is distributed at the core of

the pipe and does not contact the wall. Because heavy oil can effectively reduce friction pressure

drop, increase production efficiency and reduce equipment loss, the research literatures about heavy

oil are much more. However, there are a few literatures about the study of the flow characteristics of

two-phase toroidal flow with light oil, the frictional pressure drop and the slope of phase cross-

section in horizontal and inclined pipes. The two fluid model, four homogeneous flow model and

VOF model can predict the friction pressure drop of the oil and water two phase flow according to

the related parameters.[4-14] Based on the data measured in the experiment, this paper studies the

pressure drop characteristics of annular flow by the obtain experimental data of slip ratio and

pressure drop, compared with the predicted results of different numerical simulations.

2. Experimental system and data acquisition

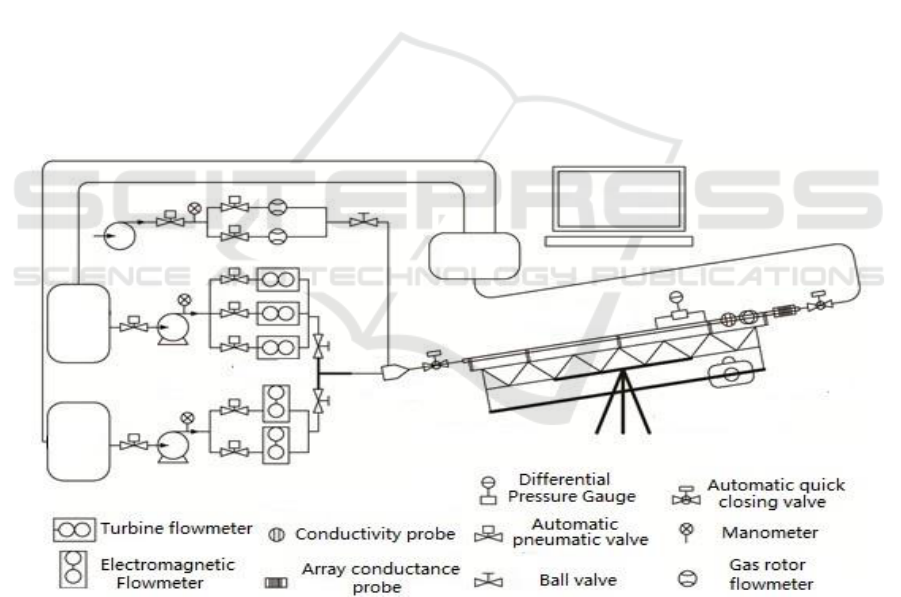

The experiment is carried out in the multi-phase flow laboratory of Daqing Oilfield. Figure 1 shows

the experiment device, it mainly includes circulation system, control system and measurement system.

The circulation system includes the supply equipment, the test section, the separation device The

circulation system includes the supply equipment, the test pipe section and the separating unit. The

supply equipment including the oil and water supply, and both the storage tank and the storage water

tank volume are 1 m

3

. The oil phase flow realize high precision control through three pipelines and

ajusted pump speed by frequency converter, and water phase flow realize it through two pipelines

and ajusted pump speed by frequency converter. The oil and water phase flow-rate is measured in

real time by the turbine flowmeter and the electromagnetic flowmeter respectively. The maximum

flow rate of oil phase and water phase is 60 m3 / d and its control error is ± 1%.

Figure 1. Schematic of the multiphase-flow test facility.

3. Test results and analysis

3.1. Annular flow pattern

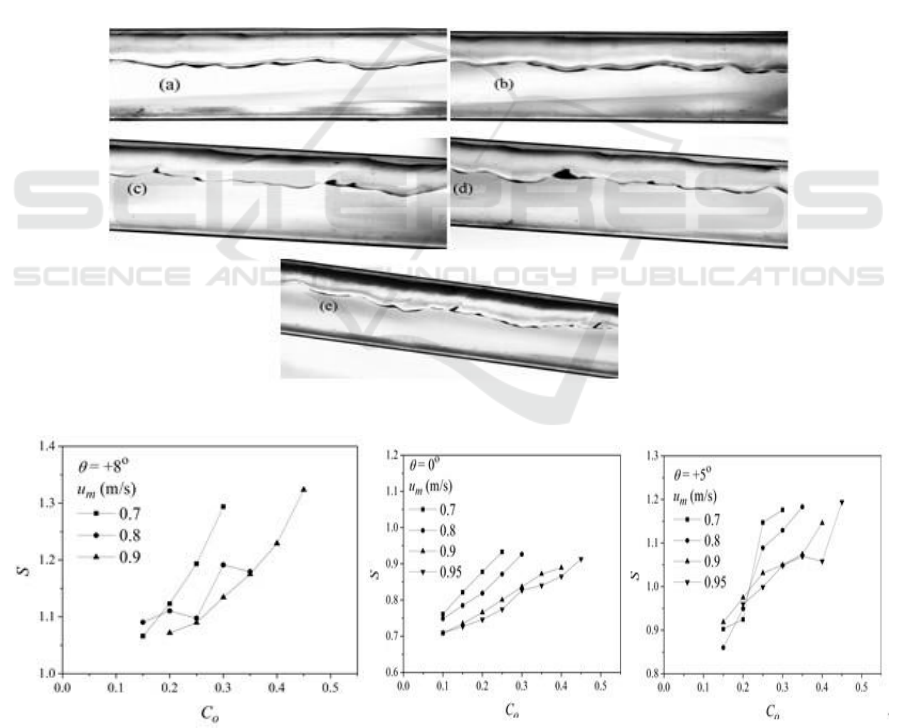

In the experiment, the distribution of the phase in the pipeline is recorded by high-speed camera, and

the flow pattern under different dip angles was given in Figure 2. It can be seen from the figure, the

annular flow as oil phase is surrounded by water, oil phase are all concentrated in the center of the

Study on Pressure Drop Characteristics of Oil-water Two-phase Annular Flow in Horizontal and Inclined Pipes

171

pipe, no contact with the wall, and water along the well wall to form an annular liquid, two-phase

were maintained, divided into positive and eccentric annular flow. The annular flow in the horizontal

wells mainly occurs in the range of 80%-95% water content, while the inclined wells are mainly in

the water content of 80%-90% within the ring flow. In the horizontal and inclined annular flow, the

interface between oil and water is smoother, while the lower interface is wavy interface.

3.2. The slip ratio of annular flow

Water pipe than the true flow velocity of the two phases is called the slip ratio and the slip ratio is

present at the interface source of friction stress. Figure 3 shows the relationship between the different

slip ratio (S) and the inlet oil content (C

0)

. The slip ratio has an increasing relationship with the inlet

oil content in the given dip angle. The increasing rate is related to the inlet velocity and the

inclination angle. It decreases with the increase of inlet velocity and increases with the increase of

well inclination angle. This shows that the inclination of the well has a great influence on the flow

velocity difference. Because the direction of the force by the oil phase volume and flow direction

angle is from 0°-90° degrees in the updip direction of oil wells. When the well inclination increases,

the volume force component in the direction of flow increases, resulting in accelerated flow of oil

phase.

Figure 2. Annular flow pattern u

m

= 0.74 m/s, C

w

= 0.80, = (a) 0

o

(b) +1

o

(c) +3

o

(d) +5

o

(e) +8

o

.

Figure 3. The relation between slip ratio and oil cut for AN flow.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

172

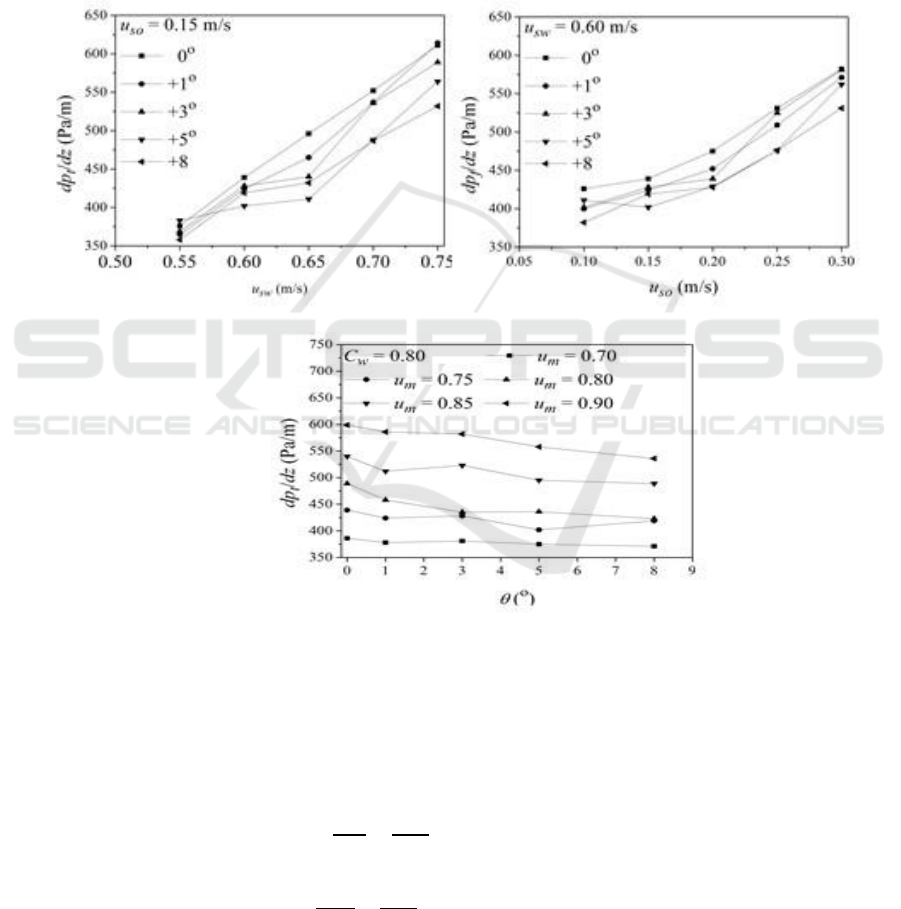

3.3. Friction pressure drop

In the study of pipeline flow, pressure drop is an important parameter to solve the problem of oil

industry, and it is significant to improve the efficiency of industrial production. The frictional

pressure drop of oil-water two-phase is not only influence by the apparent velocity, but also the

pipeline inclinaton. The pressure drop changes under different pipe dip angles were tested in the

above experimental system. In Figure 4, it shows the variation of the friction pressure drop with the

apparent velocity of water and oil phase. The friction pressure drop of the five kinds of wells is a

nearly increasing. In Figure 5 , it shows the relationship between the frictional pressure drop and the

pipeline inclination when the inlet moisture content C

w

= 0.80 and the mixing flow rate increases

from 0.70 m / s to 0.90 m / s .

Figure 4. Frictional pressure drop as a function of superficial velocity.

Figure 5. Frictional pressure drop as a function of pipe inclination.

3.4. Numerical calculation of friction pressure drop

The homogeneous flow model, the two-fluid model and the VOF model can be used to calculate the

pressure drop of the two-phase flow.[7-11] Based on the obtained section rate, the pressure drop can

be predicted, including the total pressure drop and the friction pressure drop:

0

0

0

- sin

- sin

t i i

f

ii

w

dp S

g

dz A

dp

S

g

dz A

(1)

Study on Pressure Drop Characteristics of Oil-water Two-phase Annular Flow in Horizontal and Inclined Pipes

173

Where

is the total pressure drop,

is the friction pressure drop,

is the oil-water interface

length,

is the oil-water interface shear stress,

is the oil cross-sectional area,

is the oil

density,and

is the cross- inclination.

In addition to the two-fluid model, more scholars use homogeneous flow model to predict

pressure drop [8-10]. The homogeneous flow model assumes that there is no relative velocity in the

two phase flow. The action mechanism of resistance is the same. The mixing the phase is

homogeneous. The mixed viscosity is calculated according to the difference of continuous flow, and

the friction pressure drop is calculated by the Blasius equation

2

2

t m m m

dp f

dz D

(2)

Where D is the diameter of the pipe and m is the average density of the two phases. The value is

obtained by averaging each phase, ie:

; fm is the friction coefficient between the

fluid and the pipe . By Blasius hypothesis, its form can be fm = CRe-n, the value is as follows:

35

0.25

1

, 2100

0.079

- ,2.1 10 10

Re

m

m

m

m

m

R

R

f

R

(3)

Where Rem is the mixed Reynolds number for two-phase flow,

,and

different scholars give different calculation methods for mixed viscosity m. Jana

[8]

et al give the

calculation of formula (4):

0

11

mw

xx

(4)

Where x is the oil phase weight fraction. Flores et al suggest that the mixed viscosity in the oil-

water two-phase dispersion stream takes the viscosity of the continuous phase. In addition, Arney

[11]

gives the calculation method of friction coefficient of different fluid and tube wall in the

homogeneous model, as shown in the following equation (5):

0.25

0.136

Re

m

m

f

(5)

Where the Reynolds number Rem is calculated as follows:

4

0

Re 1 1

m m w

m

w

D

(6)

The mixed density is

, where

.

Bannwart predict the pressure drop of aqueous two-phase flow friction according to the single-

phase frictional pressure drop, the following equation:

0.1

,

0.286

n

f

ww

dp

pC

n

dz L

(7)

Where Δpw is the single-phase frictional pressure drop. The calculation method is as follows (8) :

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

174

2

2

w w m

w

fL

p

D

(8)

Where the friction coefficient

, which Reynolds number

.

VOF is a surface tracking method that is fixed under a fixed Euler grid. Oil-water two-phase fluid

is immiscible with each other, the frictional pressure drop can be solved according to the formula its

momentum equation:

( ) ( )

T

vv p v v g F

t

(9)

Where

()

T

vv

is viscous force. The constitutive equation plug into the momentum equation,

and then integrate.The equation of friction pressure drop can be obtained, that is, the N-S equation.

Table 1. Prediction accuracy of each model.

Two-fluid model

Flores

Jana

Arney

Bannwart

VOF

APE

0o

25.08

-10.12

-3.22

-8.26

-3.76

0.19

+1o

19.56

-7.14

0.18

-5.19

-0.15

-1.93

+3o

19.25

-4.84

2.13

-3.09

2.25

-1.83

+5o

18.39

-2.19

5.29

-0.25

5.45

-2.73

+8o

21.41

0.33

7.08

1.92

7.53

-3.28

AAPE

0o

25.08

10.12

4.87

8.26

4.94

1.99

+1o

19.56

7.15

3.65

5.43

3.53

2.07

+3o

19.25

5.27

4.21

4.20

4.33

2.08

+5o

18.39

3.31

6.23

3.53

6.40

2.73

+8o

21.41

3.55

7.99

4.66

8.37

3.28

SD

0o

26.04

10.63

6.21

9.15

6.30

2.23

+1o

21.73

8.01

5.09

6.54

5.01

2.29

+3o

20.68

6.21

5.27

5.09

5.44

2.27

+5o

22.80

4.56

8.21

4.62

8.41

3.32

+8o

24.20

4.24

9.41

5.15

9.83

3.55

Horizontal and inclined oil-water two-phase annular flow frictional pressure drop are predicted by

two-fluid model and homogeneous flow model which include the four models given by Flores, Jana,

Arney and Bannwart respectively, and the VOF model Flow field characteristics. Analysis for the

prediction accuracy of the model, the calculated predicted and experimental values comparison.In

Table 1, by comparing the corresponding errors, including the average percentage error (APE), the

average absolute percentage error (AAPE) and the standard error (SD) shows that the VOF model

results in the pressure drop closest to the experimental data, the two-fluid model predictive results

much larger than the experimental value, and the four homogeneous flow model is between the two.

Although the VOF model is ideal, it is not economical to calculate the voltage drop for large

calculation . In addition, the VOF model in the inclined well underestimates the pressure drop value.

As the well angle increases, the deviation of the pressure drop calculation result and the experimental

data becomes larger. The two-fluid model is higher than the actual pressure drop in all well angles,

Study on Pressure Drop Characteristics of Oil-water Two-phase Annular Flow in Horizontal and Inclined Pipes

175

because the two-fluid model is mainly used to calculate the stratified flow rate and pressure drop,

while ignoring the pipe wall is surrounded by water friction coefficient decreases ,such as a circular

flow or a two-phase flow in which the wall is prewashed by water.

4. Conclusions

In this paper, the flow characteristics of horizontal and inclined oil-water two-phase annular flow are

studied, and the shear rate, phase-slip ratio and pressure distribution are analyzed. The relationship

between the slip ratio and the oil content of the inlet was analyzed by using the two - fluid model and

the VOF model. The friction pressure drop is calculated by the two-fluid model, the four

homogeneous flow models and the VOF model. The main conclusions are as follows:

1) The slip ratio of annular flow is in increasing relation with the oil content in the inlet, and the

increasing rate is related to both the inlet velocity pipe and the dip, and decreases with the

increase of inlet velocity, and increases with the inclination of the well.

2) The total pressure drop of the annular flow increases with the apparent flow velocity,while

dcreases with pipe inclination. The friction pressure drop of the VOF model is obtained by

using the two-fluid model. Compared with the VOF model and the results of the four

homogeneous flow models, the deviation from the experimental data is the largest, and the

deviation of the friction pressure calculated by the VOF model is the smallest in the middle.

The homogeneous phase flow model is used to predict the pressure drop in a dispersed flow

but the prediction results are better in a toroidal flow where the pipe wall is in contact with

the water phase due to the very simple phase of contact with the pipe wall in the toroidal flow

which is related to Reynolds number and the friction coefficient is stable.

Fund project

National Science and Technology major project "large-scale oil and gas fields and coalbed methane

development" sub-topics (2016ZX05019001-011)

National Natural Science Foundation of China (41374116)

National Natural Science Foundation of China (416774113)

References

[1] Zhai L S, Jin N D, Zong Y B and et al 2015 Experimental flow pattern map, slippage and

time–frequency representation of oil–water two-phase flow in horizontal small

diameter pipes. Int. J. Multiphase Flow 76 p168-186.

[2] Jana A K, Das G and Das P K 2006 Flow regime identification of two-phase liquid–liquid

upflow through vertical pipe. 61 p1500-1515

[3] Lum J Y L, Al-Wahaibi T and Angeli P 2006, Upward and downward inclination oil–

water flows. Int. J. Multiphase Flow 32 p413-435

[4] Rodriguez O M H, Bannwart A C and de Carvalho C H M 2009 Pressure loss in core-

annular flow: Modeling, experimental investigation and full-scale experiments J.

Petrol. Sci. Eng. 65 67-75

[5] Jiang F, Wang Y J, Ou J J andet al 2014 Numerical Simulation of Oil-Water Core Annular

Flow in a U-Bend Based on the Eulerian Model. Chem. Eng. Technol p 659-666

[6] Kumara W, Halvorsen B and Melaaen M C 2009 Velocity and turbulence measurements

of oil-water flow in horizontal and slightly inclined pipes using PIV. Computational

Methods in Multiphase Flow V, p277.

[7] Kumara W A S, Halvorsen B M and Melaaen M C 2010 Particle image velocimetry for

characterizing the flow structure of oil–water flow in horizontal and slightly

inclined pipes. Chem. Eng. Sci. p4332-4349

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

176

[8] Jana A K, Ghoshal P, Das G and et al 2007 An Analysis of Pressure Drop and Holdup for

Liquid-Liquid Upflow through Vertical Pipes. Chem. Eng. Technol, p 920–925.

[9] Xu J Y, Li D H, Guo J and et al 2010 Investigations of phase inversion and frictional

pressure gradients in upward and downward oil–water flow in vertical pipes. Int. J.

Multiphase Flow p930-939

[10] Bannwart A C 1999 A simple model for pressure gradient in horizontal core. Journal of

Brazilian Society of Mechanical Sciences p223-244

[11] Arney M S, Bai R, Guevara E and et al 1993 Friction factor and holdup studies for

lubricated pipelining—I. Experiments and correlations Int. J. Multiphase Flow p1061-

1076

[12] Burlutskii E. 2017 CFD study of oil-in-water two-phase flow in horizontal and vertical

pipes. Journal of Petroleum Science and Engineering

[13] Pouraria H, Seo J K and Paik J K. 2016 Numerical modelling of two-phase oil– water

flow patterns in a subsea pipeline. Ocean Engineering 115 p135-148

[14] Shi J, Gourma M and Yeung H 2017 CFD simulation of horizontal oil-water flow with

matched density and medium viscosity ratio in different flow regimes. Journal of

Petroleum Science and Engineering, 151 p373-383

Study on Pressure Drop Characteristics of Oil-water Two-phase Annular Flow in Horizontal and Inclined Pipes

177