Experimental Research on the Mechanical Properties of

Cotton Stalk Bale – cement-based Material Reinforced Pile

J Shang

1, 2

and X J Yu

1,*

1

Civil Engineering, Yancheng Institute of Technology, No.1 Xiwang Road,

Yancheng city, Jiangsu, China

2

Anhui University of Science and Technology, Huainan, China

Corresponding author and e-mail: X J Yu, yuxiaojuan@ycit.edu.cn

Abstract. For reducing environmental pollution from the abandonment and incineration of

stalks of crops, a technique that prepares building material with cotton stalk bale and blast

furnace slag was studied and the mechanical properties of environmental friendly, energy

saving cotton stalk bale – cement-based material reinforced pile were studied through

experiment. While cement-soil mixing pile exhibits high compressive strength, its bending

strength is low. Experiment was performed to see whether it is feasible to use cotton stalk

bale as the reinforcement material of cement and soil. The result shows that the addition of

cotton stalk bale increases the toughness, ductility, and mechanical properties, including

compressive and bending strength of cement and soil. Impact of different admixture dosages

of cotton stalk bales and blast furnace slags on the compressive and bending strength and

other mechanical properties of cement and soil were explored. The physical and mechanical

properties of cotton stalk bale–cement-based material reinforced pile were considered.

1. Introduction

A massive amount of agricultural associated wastes such as bamboo and stalk [1] and extensive solid

waste of blast furnace slag from industrial production could have adverse impact on eco-environment

if they are disposed improperly. Smoky haze from burning forest to clear land in Indonesia sparked a

diplomatic dispute with Singapore and other surrounding countries in 2015. Smog from India’s crop

burning sparked panic among citizens in 2016. Haze from crop burning hit a number of cities in

North China in November 2016. These events are just the tip of the iceberg in terms of environmental

pollution caused by primary, rough disposal of agricultural associated waste in large agriculture

producing countries. Therefore, it becomes very urgent to dispose wastes from crop properly and

broaden their use. As an excellent reinforcement material [2-5], stalk was used for engineering

purpose very long ago. The thousand-year-old Great Wall used stalk to lay the wall and reinforce the

foundation. Some scholars have suggested that reinforcement materials like bamboo and stalk may be

added to cement-based materials to improve the mechanical properties of the latter. The mechanical

properties of soil can be increased by adding bamboo chips thereto [6]. Wiwoho M S et al. [7]

studied the use of bamboo waste in place of gravel in aggregate for road pavement. Susila E et al. [8]

explored the combined use of bamboo and pile in the reinforcement of soft soil foundation and found

that the composite reinforcement of bamboo and pile can solve the problem of low-bearing capacity

368

Shang, J. and Yu, X.

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 368-381

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

of soft soil foundation in embankment construction. The experiment showed that the bamboo-pile

reinforcement system can make embankment more stable and safe. Zea Escamilla E et al. [9] used

bamboo material plastered with mortar and cement in building envelope and enabled the same to

exhibit long service life and high efficiency. Gupta S et al. [10] tried to make concrete-soil-bamboo

column composite material by replacing a part of steel and concrete and the tested column withstood

a load of 75kN under 50% of the maximum stress. Cement slab reinforced with bamboo in place of

steel bar can be used as accessible roof of roof panel of cost-effective residence, such as roof panel,

protecting the environment without compromising structural integrity. The addition of bamboo chips

enabled all cement slabs show good ductility before bending failure [11]. Potassium-sodium-soil

polymer was reinforced with bamboo fibers and chips to form bamboo reinforced material – a geo

high polymer and increase the bending strength of soil – bamboo composite. The addition of bamboo

fibers not only increased the bending strength and strain of the composite, but also improved its

toughness, turning the failure mode of the material from brittle failure to ductile failure [12, 13].

Bamboo is a kind of ductile material with a certain tensile strength. It is an ideal substitute of steel

and can be used to support compressed and bent members [14]. Dai Z H et al. [15] proposed a moso

bamboo reinforced soil nail wall – a new retaining structure that uses moso bamboo as soil nail and

pile, as well as bamboo grid shotcrete finishing. The experiment showed 2.5-2.8 time’s pull-out

capacity of bamboo nail in rigid soil and soft clay respectively compared to steel nail, and verified

the stability of the bamboo reinforcement system. Li W T et al. [16] improved the bearing capacity of

bamboo column by pouring cement mortar in bamboo. Based on real project, Dai Z et al. [17] used

bamboo soil nail and bamboo pile in rows as support structure in foundation pit and made finite

element simulation analysis on bamboo soil nail. The result showed that bamboo soil nail and

bamboo pile in rows can increase the stability of foundation pit significantly and are expected to

promote the application of environmental friendly, cost-effective support technology to real projects.

Mansur M A et al. [18] studied the role of bamboo grid in improving the performance of cement

mortar by experiment and found that bamboo grid is highly ductile and brings toughness to cement

mortar, improving the mechanical properties, including tensile strength, bending strength and impact

strength of cement mortar significantly. However, the length of reinforcement of bamboo is limited

due to various shortcomings of bamboo, including uneven material of bamboo whose different parts

have different impact on the mechanical properties of cement-based material, limited length, thin tip,

weak nodes, and unreliable and uneasy connection between bamboo materials. Hong Y et al. [19]

increased the strength of cement soil by adding basalt fiber therein. According to the experiment,

cement soil failed as a whole due to the addition of basalt fiber and exhibited higher strength under

the effect of basalt fiber. Sukontasukkul P et al. [20] enhanced the strength of cement oil significantly

by adding steel bar and polypropylene fiber therein. While the above researches focused on

reinforcement materials indicate that these materials work to a certain extent, there are a number of

things to overcome, including the weak nodes and limited length of reinforcement of bamboo, and

the high cost of reinforcement materials such as basalt fiber and polypropylene fiber. To address

these challenges, this paper puts forward a cotton stalk bale – cement-based material reinforced pile

that is made by pouring cement-based grout into cotton stalk bale, and studies the mechanical

properties of the pile for pointing the way for recycling of cotton stalk waste and industrial blasé

furnace slag and environmental protection.

2. Experimental materials and methods

2.1. Experimental Materials

Soil samples used in the experiment were taken from the soil mass of a foundation pit under

construction in Yancheng. Tests were performed against the soil mass according to the Code for

Design of Building Foundation (GB/T50007-2002) and Standard for Soil Test Method (GB/T50123-

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

369

1999) for determining the physical and mechanical properties of soil as shown in Table 1. Soil used

in the experiment complies with the Specification for Design of Mix Proportion of Cement Soil

(JGJ/T233-2011) and were crushed after drying. Portland cement P.O42.5 from Conch Cement

Factory in Baling, Yancheng, Jiangsu was used.

Blast furnace slag powders from Lianxin Concrete Co., Ltd. in Yancheng, Jiangsu were selected.

Slag is an industrial solid waste that pollutes eco-environment and harms human health. When being

used in reinforced pile, blast furnace slag powders may improve environment and reduce cement

consumption.

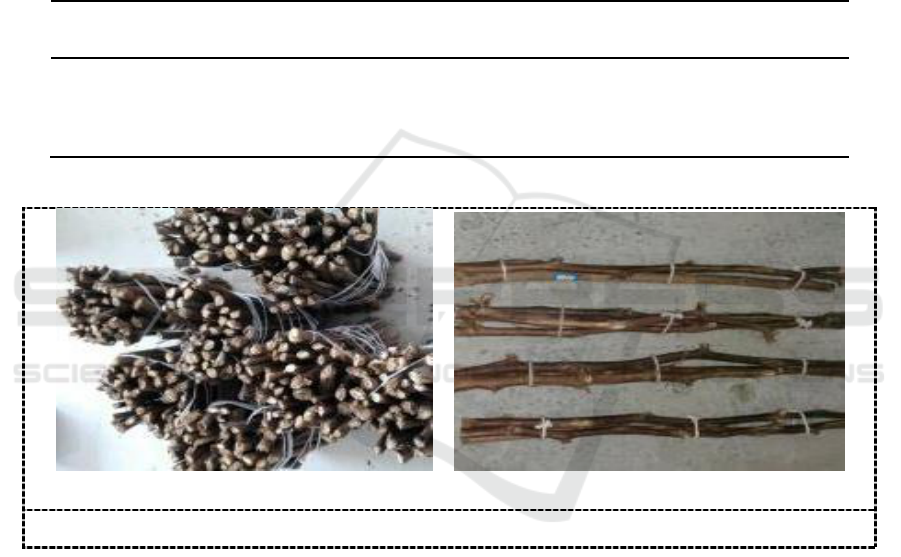

Abandoned cotton stalks were collected from the rural area of Jiangsu and tied into bales of two

varying lengths as shown in Figure 1(a), (b).

Table 1. Basic physical properties of soil specimens.

Water

content

Liquid

limit

Plastic

limit

Plasticity

index

Wet

density

Dry density

coefficient of

permeability

ω /%

ω

L

/%

ω

p

/%

I

p

/%

ρ /(gcm

-

3

)

ρ

d

/(gcm

-3

)

κ/(cms

-1

)

34.3

46.6

21.5

25.1

1.92

1.43

10

-6

(a) Length=10mm (b) Length=40mm

Figure 1. Cotton Stalk Bale.

2.2. A subsection

The experiment adopted the orthogonal method and used factors, including cement admixture dosage,

S95 blast furnace slag powder admixture dosage, and water cement ratio. Specifically, admixture

dosage of cement was 15%, 20% and 35% respectively; admixture dosage of S95 blast furnace slag

powder was 20%, 30% and 35% respectively; admixture dosage of cotton stalks was 0.01g/cm

3

,

0.02g/cm

3

and 0.03g/cm

3

respectively; water cement ratio was 0.5, 0.55 and 0.6 respectively. The

mechanical properties of cotton stalk bale – cement-based material reinforced pile were studied and

its mechanism was analyzed. The admixture dosage of S95 blast furnace slag powder was based on

that of cement.Below is a table composition of the material of cement, blast furnace slag powder,

cotton stalk , water cement ratio in Table 2.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

370

Table 2. Mix proportion.

Code name

Cement

Blast furnace slag

powder

Cotton stalk

Water cement

ratio

1

15%

20%

0.01

0.5

2

15%

30%

0.02

0.55

3

15%

35%

0.03

0.6

4

20%

20%

0.02

0.6

5

20%

30%

0.03

0.5

6

20%

35%

0.01

0.55

7

25%

20%

0.03

0.55

8

25%

30%

0.01

0.6

9

25%

35%

0.02

0.5

2.3. Experimental methods

Test specimens were prepared according to the Test Specification for Cement and Cement Concrete

for Highway Engineering (JGJ/E30-2005) by crushing the soil samples after drying. To ensure

uniform particles of soil samples used, soil samples were sieved with a 5mm sieve. Cement, soil

sample and S95 blast furnace slag powder were weighed based on the mix proportions and put into a

mixer for uniform mixing, and then weighed water was added to mix evenly. Before pouring the

slurry, a layer of release agent was applied to the inside of the test mode to facilitate the release of

test specimen from mode. Cotton stalk bales of varying length of 90mm and 390mm were placed into

test modes. Evenly mixed slurry was poured into a 100mm × 100mm × 100mm cubic test mode and

a 100mm × 100mm × 400mm prismatic test mode respectively, vibrated and compacted on a

vibrating table, and sealed with plastic film after excess slurry was scraped off. Molded specimens

were released after 48h and stored in a place with 20±1℃ temperature and more than 90% relative

humidity for natural curing to the specified age. Specimens of cotton stalk bale – cement-based

material reinforced pile naturally cured to the specified age were taken and tested for compressive

strength and bending strength with WDW-50E Electronic Universal Testing Machine. Loading rate

was controlled at 0.02mm/min, and the mean of three parallel specimens, accurate to 0.1MPa, was

taken for each group of tests. Micro morphology of hydration products of cotton stalk bale – cement-

based material reinforced pile was observed, and bond interface and energy spectrum analysis was

made with QUANTA200 Scanning Electron Microscope from FEI. In the experiment, 162 specimens

were made for mechanical property test. Specimens of two varying dimensions are shown in Figure

2(a) and (b).

(a) 100mm*100mm*100mm (b) 100mm*100mm*400mm

Figure 2. Cement soil solidified sample with cotton stalk.

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

371

3. Results and analyses

3.1. Failure Mode of Reinforced Pile Specimens

The specimens of cotton stalk bale – cement based material reinforced pile failed under compression

in four basic modes.

When a small dosage of stalk was admixed, i.e. low “reinforcement” rate, say 0.01g/cm

3

of cotton

stalk, in combination with low strength of the hardened body and low compressive strength of the

cotton stalk bale – cement-based material reinforced pile in this experiment, the specimen failed in

the form of chipping off as shown in Figure 3. The reason why the specimen failed in this mode is

because hardened bodies wrapped with cotton stalk bale demonstrated low strength, cotton stalk bale

showed low compressive strength due to low dosage of admixture, irregular cross cracks appeared on

the specimen as pressure increased and generally chipped off after compressive failure in the

compressive strength test.

When a small dosage of stalk was admixed, i.e. low “reinforcement” rate, say 0.01g/cm

3

of cotton

stalk, in combination with high strength of the hardened body and high compressive strength of the

cotton stalk bale – cement-based material reinforced pile in this experiment, the specimen failed in

the form of pyramid as shown in Figure 4. Such failure resulted from the Hoop effect. Specifically,

compressive stresses imposed shear stresses in the 45°direction when the specimen was pressed, the

failure plane took the form of a 45°bevel and the part with hardened body fell off took the shape of

a pyramid.

Figure 3. Brittle fracture.

Figure 4. Diagonal conical failure.

When a high dosage of stalk was admixed, i.e. high “reinforcement” rate, say 0.02g/cm

3

or

0.03g/cm

3

of cotton stalk, in combination with high strength of the hardened body and high

compressive strength of the cotton stalk bale – cement-based material reinforced pile in this

experiment, the specimen failed in the form of sliding as shown in Figure 5. The reason why the

specimen failed in this mode is because cotton stalk bales failed as they firstly reached their limit for

compressive load under the action of stress, causing damage to the overall consistency inside the

specimen, and consequently, the external hardened body wrapped with cotton stalk bales fell off.

Cracks developed and extended along cotton stalk bales on the specimen in this mode.

When a high dosage of stalk was admixed, i.e. high “reinforcement” rate, say 0.02g/cm

3

or

0.03g/cm

3

of cotton stalk, in combination with low strength of the hardened body and low

compressive strength of the cotton stalk bale – cement-based material reinforced pile in this

experiment, the specimen failed in the form of network as shown in Figure 6. The reason why the

specimen failed in this mode is because the hardened body wrapped with cotton stalk bales

demonstrated low strength and was unable to withstand stress as they firstly reached their limit for

compressive load due to low strength in the compressive strength test. Here cotton stalk bale in the

specimen helped resist stress and was directly under pressure. Crack appeared on the specimen in the

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

372

same direction as pressure, leading to local falling off of the external hardened body until cotton stalk

bales reached the limit of compression, and the compressive strength was determined at this point.

Figure 5. Sliding failure.

Figure 6. Crack failure.

The specimens of cotton stalk bale – cement-based material reinforced pile failed in 5 basic

modes in the bending strength test. Similar to the compound comprising the cotton stalk bales with

tendrils mesh structure similar to a reinforcement cage and the hardened body generated by cement-

based cementitious mixture that withstands the bending load, bending strength of reinforced pile

specimens was provided by a compound, and the fracture morphology of specimens failed under the

bending load took the form of plastic failure.

When a small dosage of stalk was admixed, i.e. low “reinforcement” rate, say 0.01g/cm

3

of cotton

stalk, in combination with high strength of the hardened body of cement-based cementitious mixture,

and insufficient bearing capacity of the compound comprising cotton stalk bales and the hardened

body generated by cement-based cementitious mixture, the reinforced pile specimen failed under the

bending load in the form of failure caused by excessive deflection as shown in Figure 7. In the

bending strength test, a specimen was divided into three pieces after being placed under the bending

load, resulting in excessive deflection in the middle, i.e. excessive linear displacement, and two

visible cracks appeared in the middle of the specimen.

When a small dosage of stalk was admixed, i.e. low “reinforcement” rate, say 0.01g/cm3 of cotton

stalk, in combination with high strength of the hardened body of cement-based cementitious mixture

in this experiment, the specimen failed in the form of rapture failure of cotton stalk bale as shown in

Figure 8. The reason why the specimen failed in this mode is because the external hardened body

wrapped with cotton stalk bales demonstrated high strength, while a small dosage of cotton stalk

bales was admixed. In the bending strength test, a bending load was applied to the specimen, the

cotton stalk bales withstood the bending load when the external hardened body of cement-based

cementitious mixture reached the bending limit, and finally broke as the bending load increased.

Figure 7. Excessive deflection failure.

Figure 8. Cotton stalk breakage.

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

373

The reinforced pile specimen showed low bearing capacity when the external hardened body of

cement-based cementitious mixture demonstrated low strength. In the bending strength test, a

bending load was applied to the specimen, the external hardened body wrapped with cotton stalk

bales failed in the form of sliding failure of the reinforced pile and the form of lower supporting point

failure with hardened body falling off as shown in Figure 9 and Figure 10.

Figure 9. Sliding failure.

Figure 10. Support point failure.

When a high dosage of stalk was admixed, i.e. high “reinforcement” rate, say 0.02g/cm

3

or

0.03g/cm

3

of cotton stalk, in combination with high strength of the hardened body of cement-based

cementitious mixture, and high bearing capacity of the specimen of the compound comprising cotton

stalk bales and the hardened body generated by cement-based cementitious mixture, the specimen

failed under bending load in the form of the upper load face failure of cotton stalk bale as shown in

Figure11. Because of the high strength of the external hardened body wrapped with cotton stalk bales

and the high dosage of cotton stalk bales admixed, the reinforced pile specimen was placed under a

bending load, the external hardened body of cement-based cementitious mixture and cotton stalk

bales withstood the bending load together and the upper load face failed as the bending load

increased in the bending strength test.

Figure 11. Pressure surface failure.

3.2. The mechanism for cotton stalk bale to toughen cement-based material

Cotton stalk bales may toughen cement-based materials. As the load on specimens increased, cracks

on reinforced pile specimen gradually developed into larger micro-factures, of which the extension

and development can be restricted by cotton stalk bales. When the stress applied to the specimen

reached the ultimate load, a pull-out effect occurs due to the lack of cohesion on part of the interface

between cotton stalk bale and hardened body, consuming large amounts of energy while overcoming

friction between cotton stalk bale and hardened body. Consequently, the destructive effect was

mitigated and a certain degree of ductile failure was observed on the specimen. A firmly bonded

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

374

interface between cotton stalk bale and cement-based material forms a netted structure inside the

hardened body to control the development of the cracks.

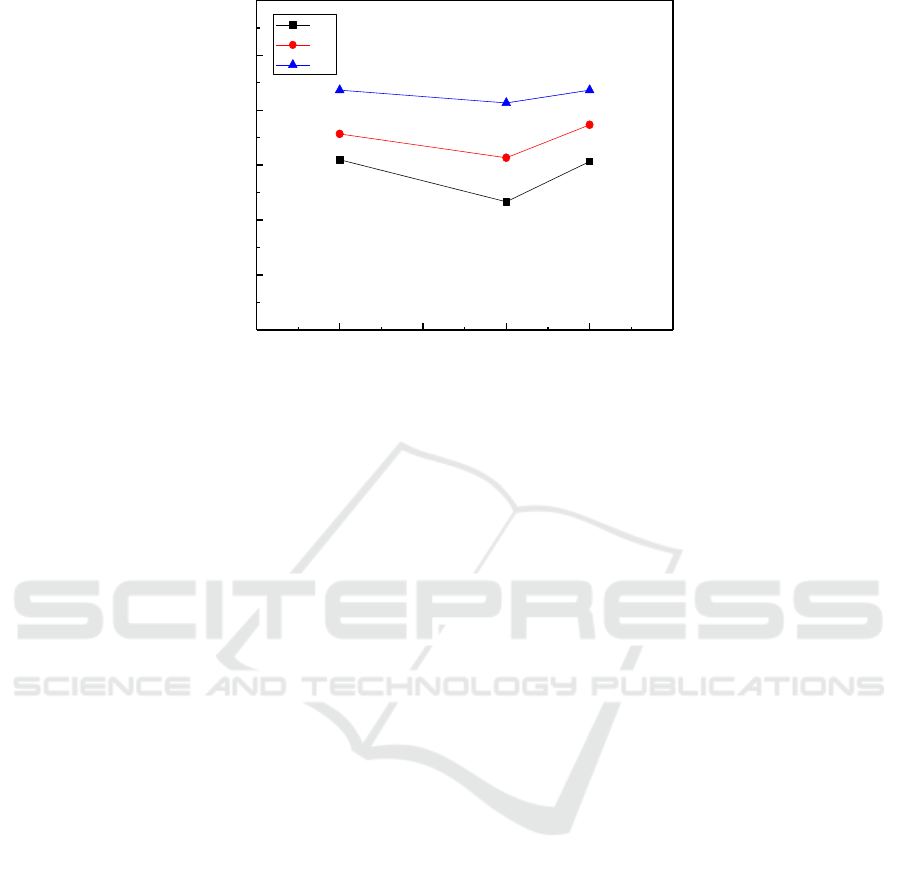

3.3. Impact of admixing blast furnace slag powder on the mechanical properties of cotton stalk bale

– cement-based material reinforced pile

The compressive strength of the specimen of cotton stalk bale – cement-based material reinforced

pile went up significantly as the dosage of S95 blast furnace slag powder admixed increased. The

addition of S95 blast furnace slag powder can prevent cracks caused by heat of hydration inside the

reinforced pile, reduce volume expansion cracks caused by base effect, and absorb substances such as

calcium hydroxide generated from cement hydration so as to lower the volume of calcium hydroxide

crystal, decrease the porosity of the hardened body of reinforced pile, compact the internal structure,

improve the microstructure of the hardened body, and increase the compressive strength of the

specimen. At the age of 28 days, the compressive strength of the specimen increased by 31% for 30%

blast furnace slag powder admixed compared to 20% blast furnace slag powder admixed. The

compressive strength of the specimen increased by 8% for 35% blast furnace slag powder admixed

compared to 30% blast furnace slag powder admixed. Therefore, the optimal mix proportion of S95

blast furnace slag powder that maximized the compressive strength of the specimen was 35%. The

change of compressive strength in relation to the dosage of S95 blast furnace slag powder admixed is

shown in Figure12.

The bending strength of the specimen of cotton stalk bale – cement-based material reinforced pile

increased following a slight decrease as the dosage of S95 blast furnace slag powder admixed

increased. The bending load was withstood by the compound comprising the cotton stalk bales with

tendrils mesh structure similar to a reinforcement cage and the hardened body generated by cement-

based cementitious mixture. In the bending test against the specimen, the bending strength consisted

of the bond force inside the hardened body of cement-based cementitious mixture and the bond stress

of cotton stalk bales. Therefore, the dosage of S95 blast furnace slag powder admixed had less impact

on the bending strength than the dosage of cement and cotton stalk bales admixed. The admixing of

S95 blast furnace slag powder reduced the heat of hydration of grout mix upon curing and improved

the internal adhesion inside the hardened body by reducing the internal porosity. In this experiment,

the optimal mix proportion of S95 blast furnace slag powder that maximized the bending strength of

the specimen was 35%. At the age of 28 days, the bending strength of the specimen reduced by 3%

for 20% blast furnace slag powder admixed compared to 30% blast furnace slag powder admixed.

The bending strength of the specimen increased by 3% for 35% blast furnace slag powder was

admixed compared to 30% blast furnace slag powder admixed. The change of bending strength in

relation to the dosage of S95 blast furnace slag powder admixed is shown in Figure13.

Figure 12. Compressive strength variation with blast furnace slag powder proportion.

15 20 25 30 35 40

0.8

1.2

1.6

2.0

2.4

2.8

Compressive strength (MPa)

Blast furnace slag powder proportion (%)

7d

14d

28d

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

375

Figure 13. Bending strength variation with blast furnace slag powder proportion.

3.4. Impact of dosage of admixing of cotton stalk bales on the mechanical properties of reinforced

pile

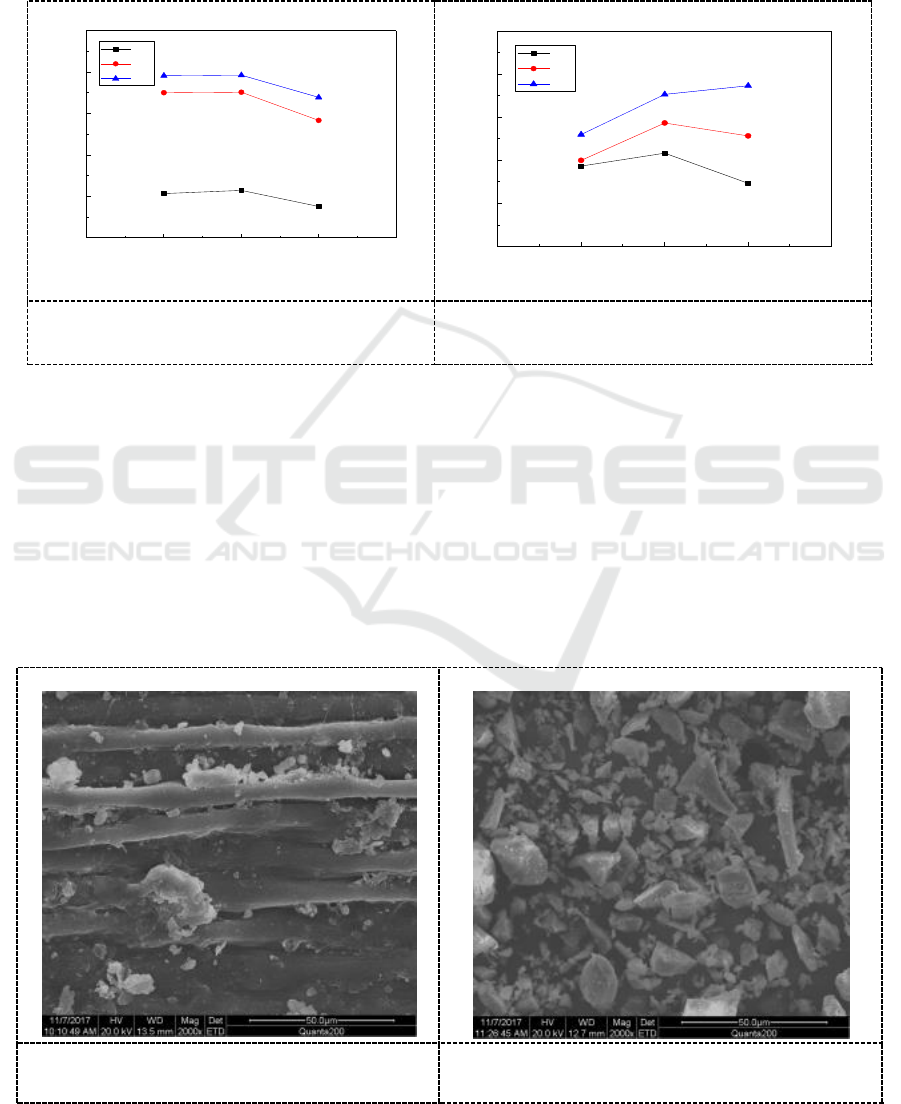

The compressive strength of the specimen of cotton stalk bale – cement-based material reinforced

pile went up significantly as the dosage of cotton stalk bale admixed increased. The load applied to

the specimen was withstood by the hardened body of cement-based cementitious mixture and the

cotton stalk bale together. The compressive capacity of cotton stalks was improved significantly by

tying them into bales. In the compressive strength test against the specimen, the addition of cotton

stalk bale increased the compressive strength of the specimen greatly. When excessive cotton stalk

bale was admixed, say 0.03g/cm

3

in this experiment, the large volume of the cotton stalk bale led to

volume expansion of the protective layer of the external hardened body wrapped with cotton stalk

bales due to squeezing and affected its overall performance, resulting in a slight decline in

compressive strength. At the age of 28 days, the compressive strength of the specimen increased by

0.2% for 0.02g/cm

3

of cotton stalk bale admixed compared to 0.01g/cm

3

of cotton stalk bale admixed.

The compressive strength of the specimen reduced by 6% for 0.03g/cm

3

of cotton stalk bale admixed

compared to 0.02g/cm

3

of cotton stalk bale admixed. Therefore, the optimal mix proportion of cotton

stalk bale that significantly improved the compressive strength of the specimen was 0.02g/cm

3

. The

change of compressive strength in relation to the dosage of cotton stalk bale admixed is shown in

Figure14.

The addition of cotton stalk bale significantly improved the bending strength of the specimen of

reinforced pile. As a kind of “reinforcement” material similar to steel bar, cotton stalk bale played a

role in reinforcing the hardened body of cement-based cementitious mixture. The bending load was

withstood by the compound comprising the cotton stalk bales with tendrils mesh structure similar to a

reinforcement cage and the hardened body generated by cement-based cementitious mixture. The

bending strength of the specimen was provided by the compound, and its bending load was resisted

by the bond force inside the hardened body of cement-based cementitious mixture and the bond

stress of cotton stalk bales. As the netted structure of cotton stalk bale increased the bond stress, an

appropriate increase in the dosage of cotton stalk bale admixed could compact the bonding interface

between the cotton stalk bale and the internal of hardened body to improve the bending strength.

When excessive cotton stalk bale was admixed, its large volume led to volume expansion inside the

hardened body due to squeezing, resulting in a slight decline in bending strength. At the age of 28

days, the bending strength of the specimen increased by 14% for 0.02g/cm

3

of cotton stalk bale

15 20 25 30 35 40

0.3

0.4

0.5

0.6

0.7

0.8

0.9

Bending strength (MPa)

Blast furnace slag powder proportion (%)

7d

14d

28d

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

376

admixed compared to 0.01g/cm

3

of cotton stalk bale admixed. The bending strength of the specimen

reduced by 6% for 0.02g/cm

3

of cotton stalk bale admixed compared to 0.03g/cm

3

of cotton stalk

bale admixed. Therefore, the optimal mix proportion of cotton stalk bale that maximized the bending

strength of the specimen was 0.02g/cm

3

. The change of bending strength in relation to the dosage of

cotton stalk bale admixed is shown in Figure15.

Figure 14. Compressive strength

variation with cotton stalk proportion.

Figure 15. Bending strength variation with

cotton stalk proportion.

3.5. Mechanism analysis

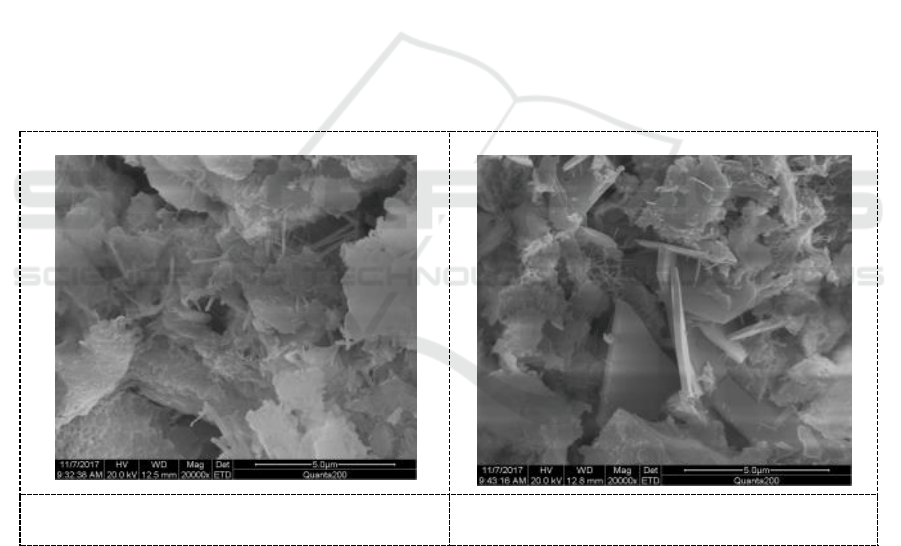

The cotton stalk bale – cement-based material reinforced pile is a kind of material prepared with

cotton stalk bale as “reinforcement” material and Portland cement, soil, S95 blast furnace slag

powder as cementitious mixture in proportion. Its mechanical properties mainly depend on the

coordination of the structural strength of cotton stalk bale as the reinforcement material and the

physical change and chemical reaction of cement-based reinforcement material. Cotton stalks and

different groups of specimens of cotton stalk reinforced pile were analyzed with SEM scanning

electron microscope. The surface micro morphology of cotton stalks is shown in Figure16. Cotton

stalks with rough surface can strengthen the bonding of the interface with the cementitious mixture.

The surface micro morphology of cotton stalks is shown in Figure17.

Figure 16. SEM micrograph of cotton

straw.

Figure 17. SEM micrograph of blast furnace

slag powder.

0.00 0.01 0.02 0.03 0.04

1.2

1.5

1.8

2.1

2.4

2.7

Compressive strength (MPa)

Cotton stalk proportion (g/cm

3

)

7d

14d

28d

0.00 0.01 0.02 0.03 0.04

0.4

0.5

0.6

0.7

0.8

0.9

Bending strength (MPa)

Cotton stalk proportion (g/cm

3

)

7d

14d

28d

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

377

There are hydration and hydrolysis of cement, interaction between soil particles and cement

hydrates, and carbonation in the cotton stalk bale – cement-based material reinforced pile. The curing

action of its mixture mainly comes from the hydration, ion exchange, pozzolanic and carbonizing

reactions of cement. Once water is added in the cement mixture, a hydration reaction between cement

and water, products of the reaction cover the soil particles and enabled the same to gain strength.

Main ingredients of Portland cement include tricalcium silicate, dicalcium silicate, tricalcium

aluminate, tetra calcium aluminoferrite, and gypsum (i.e. calcium sulfate). Hydrates consist of

calcium hydroxide, calcium silicate hydrate gel, calcium ferrite hydrate gel, ettringite and other

hydrate gel.

The cotton stalk bale, as “reinforcement” material, acts as a complete skeleton. Cement-based

cementitious mixture poured in the cotton stalk bale warps up and integrates with the same after

setting and hardening and provides strength after curing. The compressive strength of cotton stalk

bale – cement-based material reinforced pile is provided by the external hardened body and cotton

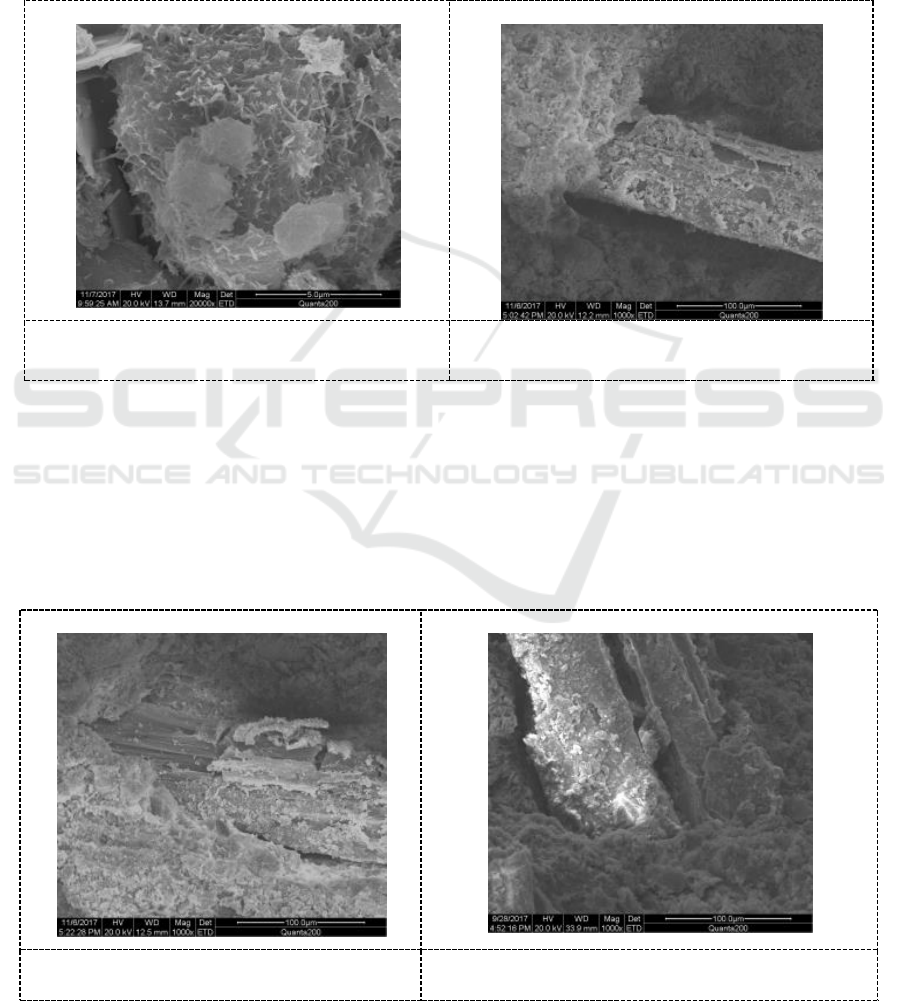

stalk bale. SEM micro morphology of the same magnification of the cement-based hardened bodies

using mix proportions of groups 1, 6 and 7 at age of 28 days is shown in Figure18, Figure19 and

Figure20. Ingredients of micro-area inferred through EDS analysis consist mainly of elements,

including calcium (Ca), aluminum (Al), silicon (Si) and oxygen (O). It can be inferred that the micro-

area consist of a small amount of silicon dioxide (SiO2) and aluminum oxide (Al

2

O

3

) particles

covered by gel in soil and slag, and plenty of substances such as calcium hydroxide crystal

(Ca(OH)

2

), calcium silicate hydrate gel (i.e. CSH gel), calcium aluminate hydrate gel (i.e. CAH gel),

and Calcium sulfoaluminate hydrate (i.e. ettringite).

Figure 18. SEM micrographs of group 1

tested specimen.

Figure 19. SEM micrographs of group 6

tested specimen.

SEM figure of group 1 shows sparse distribution of calcium hydroxide and ettringite crystals,

where the needle shaped substances are ettringite crystals, and crystals covered by CSH gel do not

bind tightly together. With a low content, calcium hydroxide and ettringite crystals of group 1 are

relatively small.

SEM figure of group 6 shows relatively tighter distribution of calcium hydroxide crystals than

group 1 and substances like calcium hydroxide crystal covered by CSH gel, where the needle shaped

substances are ettringite crystals covered by external gel, and crystals bind more tightly than group 1.

The content of calcium hydroxide crystal, CHS gel and ettringite is higher than group 1, and crystals

are relatively large.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

378

SEM figure of group 7 shows even tighter distribution of calcium hydroxide crystals than group 6

and calcium hydroxide crystals tightly covered by CSH gel, where the needle shaped substances are

ettringite crystals covered by external gel, and crystals bind more tightly than group 6. The content of

calcium hydroxide crystal, CSH gel and ettringite is higher and crystals are much larger than group 6.

According to the data of the compressive strength test against the cotton stalk bale – cement-based

material reinforced pile, compressive strength in descending order is group 7 > group 6 > group 1,

verifying that the tighter bonding between crystal structures in SEM micro morphology, the more

crystals, the higher compressive strength.

Figure 20. SEM micrographs of group 7

tested specimen.

Figure 21. SEM micrographs of group 1

cotton straw and cement soil interface.

The bending strength of the cotton stalk bale – cement-based material reinforced pile mainly

comes from the cohesive force inside the external hardened body and at the interface between cotton

stalk bale and hardened body. SEM microanalysis was made on the bonding between the surface

fiber of cotton stalk bale and the internal of hardened body. Micro morphology of the same

magnification of the bonding interface between the cement-based hardened body and the cotton stalk

bale using mix proportions of groups 1, 6 and 7 at age of 28 days is shown in Figure21, Figure22 and

Figure23.

Figure 22. SEM micrographs of group 6

cotton straw and cement soil interface.

Figure 23. SEM micrographs of group 7 cotton

straw and cement soil interface.

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

379

SEM figure shows the bonding part between cotton stalk bale and hardened body consisting of

fibers at the surface of cotton stalk bale and micro morphology of the hardened body. It can be

observed that cotton stalks and hardened body of group 1 do not bond tightly, with gaps in the

bonding part, and the surface is covered by a small amount of gel.

Cotton stalks and hardened body of group 6 bond more tightly, and the surface is covered by

plenty of gels that fully bond with cotton stalks.

Cotton stalks and hardened body of group 7 bond even more tightly than group 7, demonstrating

better bonding effect, and the surface is covered by more gels that fully bond with cotton stalks

compared to group 6.

According to the data of the bending strength test against the cotton stalk bale – cement-based

material reinforced pile, bending strength in descending order is group 7 > group 6 > group 1,

verifying that the tighter bonding of interface between cotton stalks and hardened body in SEM

micro morphology, the more gels on the surface of cotton stalks, the higher interface adhesion, the

higher blending strength.

4. Conclusions

Based on the research on the mechanical properties of the cotton stalk bale – cement-based material

reinforced pile, it can be concluded as follows:

1.The hook structure of tendrils of cotton stalk bale may enhance the bond stress, and the addition

of cotton stalk bale significantly improve the toughness of reinforced pile that demonstrates good

mechanical properties, indicating the “reinforcement” effect of cotton stalk bale and verifying the

feasibility of adding cotton stalk bale to reinforced pile.

2.The addition of cotton stalk bale improve the mechanical properties, and the compressive

strength and bending strength reach 3.4MPa and 1.0MPa, higher than traditional cement-soil pile,

verifying the feasibility of improving cement-soil pile with cotton stalk bale – cement-based material

reinforced pile.

3. The addition of 35% of blast furnace slug powder provides good compressive strength and

bending strength, improving the mechanical properties of reinforced pile.

4. In this experiment, the optimal mix proportions that optimize the mechanical properties of

cotton stalk bale – cement-based material reinforced pile are 25% of cement, 35% of S95 blast

furnace slag powder, 0.02g/cm3 of cotton stalk bale, and 0.5 of water/cement ratio, providing the

theoretical basis for the application of cotton stalk bale – cement-based material reinforced pile for

engineering purposes.

Acknowledgement

This study was supported by National Natural Science Foundation of China (Grant No. 51778556)

and Jiangsu Province Science and Technology Department Social Development Project (Grant No.

BE2015658).

References

[1] Taneli V, Haapala A, Lappalainen R and et al 2016 Utilization of agricultural and forest

industry waste and residues in natural fiber-polymer composites: A review J. Waste

Management 54:62-73

[2] Bederina M and Belhadj B 2016 Improvement of the properties of a sand concrete containing

barley straws-Treatment of the barley straws J. Construction and Building Materials

115:464-477

[3] Azwa Z N, Yousif B F and et al 2013 A review on the degradability of polymeric composites

based on natural fibres J. Materials and Design 47:424-442

[4] Hejazi S M and et al 2012 A simple review of soil reinforcement by using natural and

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

380

synthetic fibers J. Construction and Building Materials 30:100-116

[5] Swan A J, Rteil A and Lovegrove G 2011 Sustainable Earthen and Straw Bale Construction in

North American Buildings: Codes and Practice J. Journal of Materials in Civil Engineering

23(6):866-872

[6] Huang H, Jin S H and Yamamoto H 2011 Study on Strength Characteristics of Reinforced Soil

by Cement and Bamboo Chips J. Applied Mechanics and Materials 71-78:1250-1254

[7] Wiwoho M S, Machicky M and Nawir R. Bamboo 2017 Waste as Part of The Aggregate

Pavement The Way Green Infrastructure in The Future C. MATEC Web of Conferences.

EDP Sciences 138: 03013

[8] Susila E and Agrensa F 2015 Case Study on Soft Soil Improvement using Innovative and Cost-

Effective Reinforcing Techniques J. Journal of Engineering and Technological Sciences

47(2): 207-217

[9] Zea Escamilla E, Habert G and Lopez Muã±Oz L F 2014 Environmental Savings Potential

from the Use of Bahareque (Mortar Cement Plastered Bamboo) in Switzerland J. Key

Engineering Materials 600(600):21-33

[10] Gupta S, Sudhakar P, Kordke C and et al 2008 Experimental verification of bamboo-concrete

composite column with ferro-cement band C. Proc. International Conference on Modern

Bamboo Structure 28(30): 253-258

[11] Chithambaram S J and Kumar S 2017 Flexural behaviour of bamboo based ferrocement slab

panels with flyash J. Construction and Building Materials 134: 641-648

[12] Ribeiro R A S, Ribeiro M G S, Sankar K and et al 2016 Geopolymer-bamboo composite–A

novel sustainable construction material J. Construction and Building Materials 123: 501-

507

[13] Sankar K, Sá Ribeiro R A, Sá Ribeiro M G and et al 2017 Potassium‐Based Geopolymer

Composites Reinforced with Chopped Bamboo Fibers J. Journal of the American Ceramic

Society 100(1): 49-55

[14] Karthik S, Rao P R M and Awoyera P O 2017 Strength properties of bamboo and steel

reinforced concrete containing manufactured sand and mineral admixtures J. Journal of

King Saud University- Engineering Sciences 29(4): 400-406

[15] Dai Z H, Guo W D, Zheng G X and et al 2016 Moso bamboo soil-nailed wall and its 3D

nonlinear numerical analysis J. International Journal of Geomechanics 16(5): 04016012

[16] Li W T, Long Y L, Huang J and et al 2017 Axial load behavior of structural bamboo filled

with concrete and cement mortar J. Construction and Building Materials 148: 273-287

[17] Dai Z, Chen Y, Zheng G and et al 2014 Numerical Analysis on the Mechanism of Bamboo

Soil Nails and Bamboo Piles in Rows for Retaining Deep Foundation Pit J. American

Society of Civil Engineers (242):720-730

[18] Mansur M A and Aziz M A 1983 Study of bamboo-mesh reinforced cement composites J.

International Journal of Cement composites and lightweight concrete 5(3): 165-171

[19] Hong Y, Wu X and Zhang P 2017 Construction Technology and Mechanical Properties of a

Cement-Soil Mixing Pile Reinforced by Basalt Fibre J. Advances in Materials Science and

Engineering

[20] Sukontasukkul P and Jamsawang P 2012 Use of steel and polypropylene fibers to improve

flexural performance of deep soil–cement column J. Construction and Building Materials

29: 201-205

Experimental Research on the Mechanical Properties of Cotton Stalk Bale –cement-based Material Reinforced Pile

381