Integration and Value-added Mode of WEEE Recycling

Industrial Chain based on Eco-industrial Parks

S P Lu*, X Q Li and D L Tang

School of Civil Engineering and Architecture, East China University of Technology,

Nanchang, Jiangxi, 330013 China

Corresponding author and e-mail: S P Lu, Lsplxq2005@126.com

Abstract. WEEE is a typical stream of urban mines. It contains a large number of precious

metals. Recycling and reusing WEEE can provide economic gains and mitigate

environmental impacts. Firstly, based on the theory of industrial chain, it was analyzed of the

necessity of WEEE recycling industrial chain (WRIC) established in China. The differences

were compared between WRIC and general product’s industrial chain (GPIC). The current

structural status of Chinese WRIC was discussed. By applying field investigation methods,

two types of industrial chain integration mode (ICIM) were put forward based on eco-

industrial parks, including the type based on recycled raw materials enterprises and the other

type based on recycled products enterprises as the core chain. The value-added mode of

WRIC was emphatically discussed and the better WRIC structure was proposed. Finally

related suggestions were put forward to upgrade the WRIC value.

1. Introduction

In recent decades, with the rapid development of science and technology, continuously enhanced

views of people's personalization and innovative consumption, electrical and electronic equipments

(EEE) flood into global market with unprecedented speed. The number of waste electrical and

electronic equipments (WEEE) is also growing at an alarming rate. UNEP estimated that the world

produced about 60 million tons of WEEE per year[1]. Historically, in EU the WEEE was observed to

increase by 16-28% in every five years, which is three times faster than the generation of average

annual municipal solid waste. China is a typical country in manufacturing, consuming and exporting

a large number of EEE. In 2016 it was more than 1000 million units of the production of TV sets,

refrigerators, electric water heaters, air conditioners, computers and other major home appliances in

China. Meanwhile, China has also begun to enter end-of-life peak of EEE and there are more than

100 million units of EEE being scrapped every year according to theoretical calculation[2]. WEEE is

becoming an emerging issue owing to adverse consequences on the natural environment and the

human health. WEEE disposal may have commercial opportunities, because they contain precious

metals, such as gold, aluminium, copper, silver, bronze, and other rare metals. WEEE Management

has been one of the biggest challenges of current worldwide concern.

Nowadays, many countries have drafted some laws to dispose WEEE. The European Commission

addressed the need for the legislation about the escalating problem of WEEE. This was later taken

into the form of the WEEE Directive[3]. Lots of researches have discussed WEEE from different

416

Lu, S., Li, X. and Tang, D.

Integration and Value-added Mode of WEEE Recycling Industrial Chain based on Eco-industrial Parks.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 416-423

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

aspects, particularly about the composition and value, influences on environment, recovery, disposal

and recycling[4-5]. In most developed countries, it is a responsibility of producers and residents to

recovery, reuse and recycle WEEE. The most important purpose is to avoid and reduce the pollution

caused by WEEE. Therefore, WEEE is mostly exported to developing countries, such as China, India

and Vietnam[6]. But in China, WEEE recycling and processing enterprises make more profit as the

important purpose by excavating useful resources of WEEE. Under the premise of protecting natural

environment, it becomes the emphasis to Chinese government how WEEE enterprises make WEEE

recycling and maximize enterprise value. This article firstly introduced the theory of WRIC; secondly,

it analyzed the structure about WRIC in China compared with the operation system of WEEE

recycling in Germany; thirdly, it elaborated two integration modes of WEEE industrial chain based

on eco-industrial parks; finally, it used the industrial chain value-added theory to rebuilt the structure

of WRIC.

2. Theoretical analysis about WRIC

2.1. WEEE

WEEE mainly contains the waste of refrigerators, air conditionings, washing machines, TV sets,

computers, mobile phones, etc. It is divided into ten categories according to WEEE Directive. The

WEEE composition is quite complex and contains vast toxic chemicals, which can cause significant

pollution to environment and be harmful to human if discarded discretionarily. Meanwhile, WEEE

contains enormous and precious resources, such as gold, silver, copper, tin, chromium, platinum,

palladium, etc. WEEE is main component of "urban mines". Its grade is dozens or even hundreds

times of natural resources’ grade.

As WEEE is rich in extremely high recycling value, in recent years the huge processing networks

of WEEE have shaped spontaneously in Chinese southeastern coastal areas, especially Guiyu town,

Qingyuan of Guangdong Province, Ningbo and Taizhou of Zhejiang Province. Before 2002, some

WEEE processing enterprises only facused on their own economic benefits and paid little attention to

environment pollution. In 2002 the government initiated the implementation of “circle area

management” to WEEE processing enterprises and it has established dozens of demonstration

industrial parks since then such as Zhangzhou of Fujian province, Taicang of Jiangsu province,

Zhenhai District of Ningbo, Ziya-Tianjing recycling economic industrial zone. Enclosing these

industrial parks, the WEEE disposal enterprises have formed certain industrial chains, but the chains

operate at low level with less value-added of each segment, and the enterprises’ profit margins are

extremely low. Therefore the research on WRIC to increase its value has extremely vital significance

to promote industrial development.

2.2. Industrial chain

Nowadays, with the development of economy and technology, the range of market competition has

transferred from single enterprise to the whole industrial chain. As a type of new organization,

industrial chain has become the main organization type of obtaining the advantages of market

competitive. Industrial chain theory has been also widely concerned by scholars and industries. But

there is not a unified definition on industrial chain. Generally, the definition about industrial chain is

mainly from three aspects: (1) the process of industrial economic activities; (2) the process of value

transferred and created; (3) industrial organization patterns[7]. We think that the first two definitions

are rather similar to supply chain and value chain. Therefore we approve further of the third

viewpoint; think that industrial chain is the organizational form of industrial activities, and the

methodic linkage mode about related economic activities, processes, production phases or economic

businesses in the process of producing goods and services. On the whole, industrial chain is the

organization of the spatial aggregate of related enterprises based on the theory of the value chain; the

Integration and Value-added Mode of WEEE Recycling Industrial Chain based on Eco-industrial Parks

417

result of division and cooperation within some industries and belongs to the meso-level between

microscopic and macroscopic view.

In general, an industry has only an industrial chain, but its structure is not immutable. In fact, the

structure is changing constantly. The main factors of precipitating the change are technique,

transaction cost, market structure and the development degree of its auxiliary industry.

2.3. WRIC

WRIC is defined as a mode of industrial organization by which related industrial activities are

connected in the processes of WEEE recovery and optimal recycling based on the inherent technical

association of WEEE industry. Through industrial division of labor and cooperation, WRIC can add

the value of the enterprises of the industrial chain. Compared to GPIC, there are numerous

differences such as structure, value-added linkages, as shown in Table 1. WRIC based on eco-

industrial parks belongs to the type of cluster industrial chain (e.g., in Zhenhai District, and Ziya-

Tianjing recycling economic industrial zone).

Table 1. The differences between WRIC and GPIC.

Item

GPIC

WRIC

Purpose

To provide consumers with products and

services, in order to create value

To provide raw materials to related industries

mainly, second-hand or remanufactured products,

in order to recycle value and create value

Structure

Including complete processes and order of

products’ research and design, supply of raw

materials, manufacturing, distribution, services,

etc.

The lack of research and design, distribution

services link flexibility

Value-added

linkages

The linkages of value-added are mainly R & D

and distribution; obey the spatial distribution of

"smile curve"

The value-added distribution does not obey "smile

curve", the range of value-added is narrow

Supply of raw

materials

Determined by market demand; generally more

stable

Influenced by the amount of WEEE recycling,

with great uncertainty

Organizational

type

Commercial form of market-oriented

Strong externality and more government

regulations

3. Integration modes of WRIC based on eco-industrial parks

3.1. WEEE operation mode in some developed countries

Nowadays, the operation system of WEEE recycling is relatively well in some developed countries

such as Germany and Japan. The government plays an important role in WEEE recycling; it requires

manufacturers to recovery their EEE products in order to protect environment and alleviate the

ecological pressure. The regulation of extended producer responsibility (EPR) has been established.

EPR is defined as a policy approach in which producers bear significant responsibility, financial

and/or physical, for the treatment or disposal of products[8]. In Germany the government plays an

important role in WEEE recycling system, including establishing the management and coordination

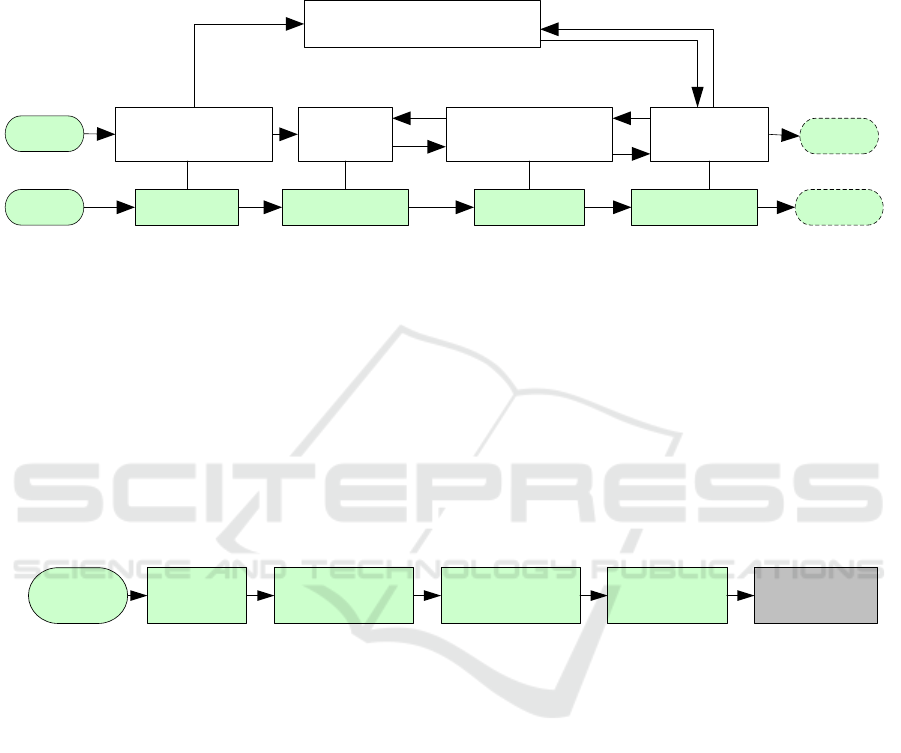

agency. The recycling system is still competition-oriented mode, shown Figure 1. In this system,

EEE producers afford WEEE recovery and disposition fee by WEEE Directive, but producers are

allowed to transfer the fee to consumers; commission disposition plants and third-party logistics

companies perform transportation and disposition responsibility in the form of contracts. Disposition

plants undertake the responsibility of placing dustbins in garbage collection points, arranging

logistics and transport, sorting, dismantling and smashing WEEE. Under processing capacity

permitted, those enterprises endeavor to obtain more WEEE to maximize their profit. Thus the

market shapes mutual competition. The result of competition reduces the cost. The disposition cost of

WEEE covers recovery, classification, dismantling, processing and other fields.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

418

Figure 1 shows that all organizations are closely connected and constitute a more stable WRIC

from collection to recycling stages through the EAR-WEEE management organization in Germany.

The most important purpose of establishing WRIC is to facilitate government better managing

WEEE, and make WEEE recover, reuse and recycle to avoid environment pollution in developed

countries. On this basis, the purpose is to enhance the value of the whole process.

Figure 1. WEEE recycling system based on EPR in Germany.

3.2. The WEEE industrial chain modes based on eco-industrial parks

In China the WEEE recycling system is different from that in developed countries. The main purpose

of WEEE collection and processing enterprises is to obtain profits by utilizing WEEE renewable

resources, such as non-ferrous metals, ferrous metals, precious metals and scrap plastic.

Consequently those processing enterprises not only utilize domestic WEEE, but also import a large

number of foreign WEEE. According to certain statistical data, above 70% of WEEE was shipped to

China which was imported from developed countries, such as United States, Japan and Germany. As

numerous enterprises of WEEE processing appear and flock together, WRIC gradually shapes,

shown in Figure 2.

Figure 2. The current WRIC structure.

There are multiple modes in the integration process of industrial chain. Yang explained the diverse

modes about the integration of industrial chain based on the effectiveness of scale economy and the

economy of transaction cost[9]. In order to protect environment, the Chinese government has

established dozens of eco-industrial demonstration parks of renewable resources and adopted

centralized management to the enterprises in order to avoid environmental pollution caused by

decentralized management. Based on eco-industrial parks two types of integration structure of WRIC

have been shaped.

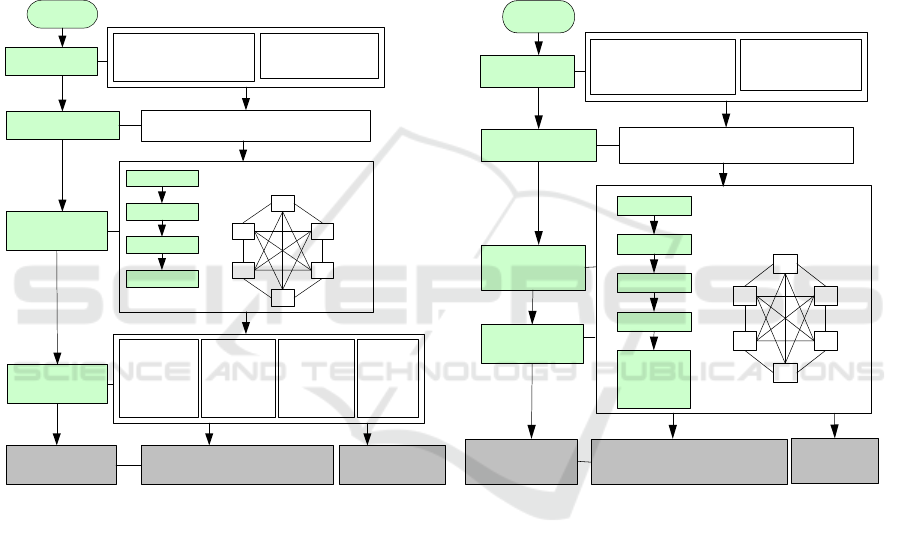

3.2.1. The industrial chain integration mode (ICIM) based on recycled raw materials enterprises as

core chain. By applying field investigation methods, this ICIM is shown in Figure3. The mode is

comprised of upstream collection and transportation enterprises, processing enterprises of parks and

downstream fine-deep processing enterprises. On the basis of the mode, a large number of WEEE

primary processing enterprises are gathered into eco-industrial parks of renewable resources. These

enterprises mainly complete primary processing of WEEE and make WEEE be processed into

primary semi-finished raw materials such as recycling scrap aluminum, scrap copper, scrap iron,

waste plastics. Then these products are sold to the fine-deep processing enterprises outside industrial

WEEE Market

WEEE

WEEE community

collection places

Logistics

enterprises

Professional

processing enterprises

Manufacturers

inform transportation

WEEE

inform dispozition

Recycling materials

EEE

EAR-WEEE management

organization

Filled full, inform

EAR carrying away

Report product information

Collection Transportation Dispose Manufacture

WEEE Collection Transportation

Fine & deep

processing

Manufacture

& Consume

Primary

processing

WEEE WEEE

Renewable raw

materials

Recycled products

or Goods

Integration and Value-added Mode of WEEE Recycling Industrial Chain based on Eco-industrial Parks

419

parks. The enterprises smelt and manufacture these raw materials, and transform them into various

industrial material products such as ingots, aluminum ingots, stainless steel products, plastic particles.

Compared with foreign WEEE operation modes, domestic EEE manufacturers do not play an

important role in the industrial chain and it is low of correlation with other enterprises because the

EPR regulation has not been established so far in China. According to this mode, the enterprises form

a mesh structure in some industrial park. It is quite short of the length of industrial chain in the park;

the added-value of the products is rather low. There is not enough tight linkage degree between

midstream processing enterprises of industries parks and downstream fine-deep processing

enterprises. Undoubtedly this mode is a very good choice to gather numerous fine-deep processing

enterprises around industrial parks. It belongs to this mode of the ICIM of Zhenhai-Ningbo

renewable resource eco-industrial park. The industrial chain oriented by scrap steel, scrap non-

ferrous metals processing enterprise has been shaped.

Figure 3. The ICIM based on recycled raw

materials enterprises as core chain.

Figure 4. The ICIM based on recycled

products enterprises as core chain.

3.2.2. The ICIM based on recycled products enterprises as core chain. The mode is taken shape

according to the final products of WRIC, shown in Figure 4. In eco-industrial parks, WEEE is

disposed primarily by midstream enterprises; then is manufactured into related intermediate or final

consumable products such as aluminum ingots, copper rod, steel and stainless steel products, cable

and plastic products. The ICIM constitutes the process of step-utilization resources. The key to

improve the utilization efficiency of resources is reasonable resource allocation of each part of

industrial chain. Ziya-Tianjing recycling economic industrial zone covers the enterprises of WEEE

primary and fine-deep processing, and has formed this ICIM type in the region.

3.2.3. ICIM analysis. Figure 3 and Figure 4 show that the left side portion of the two modes is

identical and the WRIC structure is current link status of WRIC in China. Based on different

integration degree of enterprises in industrial parks, different ICIMs are formed. In Figure 3,

midstream enterprises are loosely connected with downstream enterprises. However in Figure 4,

WEEE

Collection

Transportation

Primary

processing

Fine & deep

processing

Manufacture

& Consume

Domestic collection

enterprises and

individuals

Foreign WEEE

export companies

Logistics enterprises

Classification

Fracture

Dismantling

Sorting

A

B C

D

...

N

Industrial Park

Primary processing enterprises

(PPE)

WEEE

WEEE

Iron & steel

processing

enterprises

Nonferrous

metal

processing

enterprises

Plastics

processing

enterprises

Other

Related

enterpri-

ses

Renewable raw materials

EEE related manufacturing

enterprises

Recycled products

Distributor

or consumer

Goods

WEEE

Collection

Transportation

Primary

processing

Fine & Deep

processing

Manufacture

or Consume

Domestic collection

enterprises and

individuals

Foreign WEEE

export companies

Logistics enterprises

Classification

Fracture

Dismantling

Sorting

A

B C

D

...

N

Primary processing enterprises

and Fine & deep manufacture

enterprises

WEEE

WEEE

EEE related manufacturing

enterprises

Recycled products

Fine & deep

processing and

manufacture

Goods

Distributor

or consumer

Industrial Park

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

420

midstream and downstream enterprises are gathered in an industrial park; hence it can form a

thorough cluster industrial chain and can also take advantage of achieving resource step-utilization,

reducing costs, aggrandizing the stability and it enhance the value of the industrial chain.

4. The value-added mode of WRIC based on eco-industrial parks

4.1. The value-added principle of industrial chain

The formation mechanism of industrial chain is composed of four aspects, including promoting

systematic value, economizing gross costs, boosting value innovation and improving innovation

power. These constitute value-created mechanism and transform the operation impetus of industrial

chain. The "smile curve", proposed by Stan Shih of Acer founder, expresses that the proportion of

value-added distribution is asymmetrical in different links of product R&D, supply of raw materials,

intermediate products processing, finished goods assembly, sales, service, etc. In general the value-

added by the upstream R & D accounts for about 60% of the new created value; the value created by

manufacturing sector is the lowest, no more than 15% of the value. In the era of knowledge economy,

the value-added is decided mainly by creative knowledge, including “hard” technologies (e.g.,

patents, technology, etc.) and “soft” technologies (e.g., advanced management, organizational

methods, technology standard system, etc.)[10]. Because WRIC lacks R&D phase and distribution

services are under the control mainly by related industries manufacturers, the value-added of the

main bodies of WRIC is rather little. This leads to low profit of WEEE collection and processing

enterprises; the technology and equipment of enterprises are extremely backward and cause serious

secondary pollution. So it is quite important of enterprise subsistence to advance the level of

knowledge and technology about WRIC.

4.2. The value-added mode of WRIC

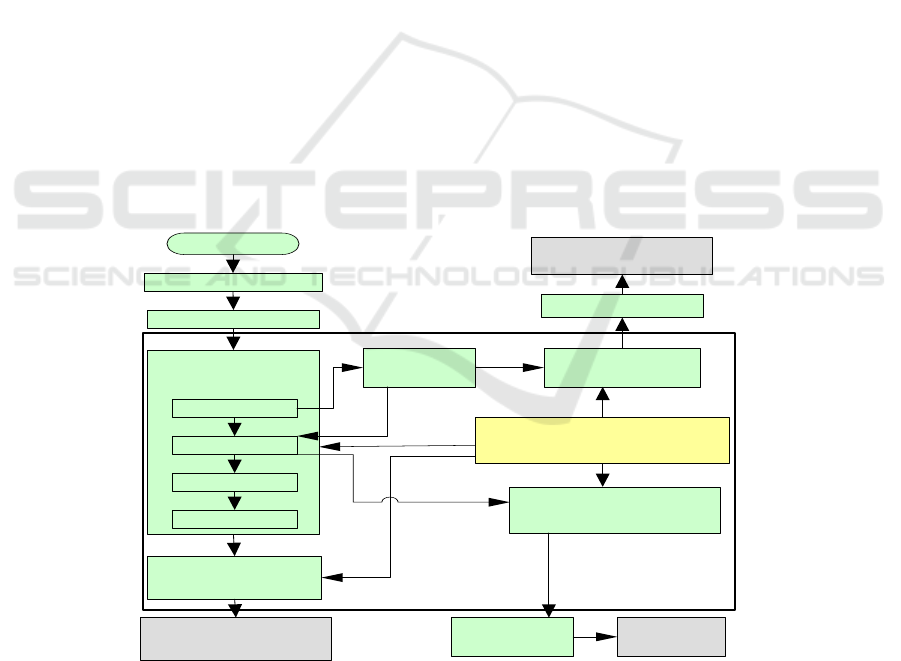

Figure 5. The value-added mode of WRIC based on eco-industrial parks.

To optimize obtaining and creating the value of WEEE, processing enterprises can't dispose WEEE

by using almost the same way, namely dismantling, broken or molten WEEE to obtain the primary

resources. These enterprises should adopt technical and economical assessments of WEEE firstly;

WEEE

Transportation

Collection

Classification

Fracture

Dismantling

Sorting

Primary

processing

WEEE

Appraisal

Green

remediation

Distributor

Secondhand

market

Remanufacturing

Fine & deep

processing

Manufacture &

Consume

Distributor Consume

WEEE

WEEE

Reusable

components

Whole

EEE

Secondhand products

Primary products

Technology and

management service

S

S

S

S

S

Remanufactured

products

Industrial Park

Note: S-Service

Integration and Value-added Mode of WEEE Recycling Industrial Chain based on Eco-industrial Parks

421

then make the EEE reused after a reasonable repair and remanufacture of the useful components of

WEEE. These linkages demand higher technology and knowledge, so the corresponding technology

and management consulting services are required to support these activities. According to the

analysis, the value-added restructure of WRIC can be established based on eco-industrial parks,

shown in Figure 5. The value-added linkages of the restructure are mainly the assessment, green

repair, remanufacturing, technology and management consulting services about WEEE.

4.3. Relevant suggestions

In order to achieve the value-added of WRIC, enterprises and government departments should do

well relevant works, details as follow:

Enterprises should develop and introduce advanced technology, equipment, management and

organization methods. For example, according to statistics, transport costs accounted for 50%

of the overall cost of WEEE disposition in Germany, so enterprises should strengthen

cooperation with logistics enterprises to reduce transportation cost.

Government departments should speed up the development of industrial technology and

management services market. These services agencies can enhance technical level and

increase industrial value by participating in various outsourcing businesses and providing

R&D services, technical services and management consulting services etc.

Government departments should establish corresponding technical standard system that

make enterprises operation standardized, and enforce the enterprise qualification license of

WEEE processing. These measures will compel enterprises to focus on one or several

specific types of WEEE disposition and promote WRIC modularization operation.

5. Conclusions

The paper analyzed the differences between GPIC and WRIC from the aspects of industrial purpose,

structure, value-added linkages, supply of raw materials and organizational type. The authors

summarized the current structure of Chinese WRIC, compared with WEEE operation modes in

developed countries based on the investigation of domestic eco-industrial parks; put forward two

kinds of ICIM, including one based on recycled raw materials enterprises and the other based on

recycled products enterprises as the core chain. The authors think that Chinese current WRIC is

under low-level operation, lacks high value linkages and most of enterprises obtain extremely low

profit. Because value-added is decided mainly by creative knowledge including “hard” technologies

and “soft” technologies, the authors think that the value-added linkages of the restructure are mainly

the assessment, green repair, remanufacturing, technology and management consulting services about

WEEE. According to the principles, the authors proposed better WRIC structure. The research is

vital significance to promote the development of WEEE recycling industry.

Acknowledgments

The authors gratefully acknowledge the financial support from Jiangxi Natural Science Foundation

Project “Research on the Innovation of Household Hazardous Waste Recycling Model Based on

EPR” (No. 20171BAA208028), Education Department Science and Technology Project of Jiangxi

(No. GJJ160546), National Social Science Foundation Major Project of China (No. 15ZDC030).

References

[1] Akcil A 2016 WEEE: Booming for sustainable recycling Waste Management 57(SI) 1-2

[2] Jiang X J, Liu J X, Yan K and et al 2016 Prediction of electronic waste amount and metal

cumulative amount features Nonferrous Metals Science and Engineering 7(5) 104-109

[3] Salhofer S, Steuer B, R. Ramusch P B 2016 WEEE management in Europe and China: A

comparison Waste Management 57(SI) 27-35

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

422

[4] Ikhlayel M 2017 Environmental impacts and benefits of state-of-the-art technologies for E-

waste management Waste Management 68(10), 458-474

[5] Awasthi A K and Li J H 2017 An overview of the potential of eco-friendly hybrid strategy for

metal recycling from WEEE. Resources Conservation & Recycling, 126(11), 228-239

[6] Song X L, Wang J W and Yang J X 2017 An updated review and conceptual model for

optimizing WEEE management in China from a life cycle perspective Frontiers of

Environmental Science & Engineering, 11(5) 224-235

[7] Li X A 2014 Interregional IndustrlaI Relocation and Industrial Chain Integration Beijing:

Social Science Literature Press 23.

[8] Du H Z and Jin M 2017. The practice of the extended producer responsibility system in China

Beijing: Science Pres 4-5

[9] Yang R 2014 Research on the theory of industrial chain competitiveness[doctoral thesis]

Shanghai: Fudan University 46-50

[10] Gai W Q and Jing Z W 2009 Value-added theory based on different model of industrial

chain.Economic Management Journal 31(12) 39-47

Integration and Value-added Mode of WEEE Recycling Industrial Chain based on Eco-industrial Parks

423