Enhanced Coagulation for Landfill Leachate Pretreatment

W K Bai

1

, F Liu

2

and H You

1, 2,*

1

Environmental school,Harbin Institute of Technology,Harbin 150090, P. R. China

2

School of Marine Science and Technology,Harbin Institute of Technology

(Weihai),Weihai 264209, P. R. China

Corresponding author and e-mail: H You, youhong@hit.edu.cn

Abstract. Coagulation was used in this paper to pretreat the waste incineration plant leachate

to reduce the subsequent processing load. This work strengthened the traditional coagulation

by compound coagulant and two-time coagulation. Results showed that the coagulation effect

of poly aluminum chloride and polymeric ferric sulfate compound coagulant is better than

that of polymeric aluminum chloride alone. The turbidity decreased from 74.0 NTU to 21.2

NTU, and the COD removal rate increased from 29.7% to 33%. In the case of the same

dosage, the effect of two-time coagulation is stronger than that of one-time coagulation.

1. Introduction

A large amount of high concentration leachate was produced in the waste incineration plant, which is

mostly produced by garbage stacking 5~7d [1]. The leachate of waste incineration plant is

characterized by high COD concentration, high metal content, large variation of water quality and

quantity, imbalance of nutrient proportion and low pH [2]. Because there are a lot of refractory

organic matter in leachate, the traditional biological treatment methods are limited [3], which is more

difficult for the high concentration leachate in the waste incineration plant. Physical and chemical

methods have been used by more and more researchers to deal with landfill leachate, such as

photocatalytic oxidation [4], electrolysis Fenton [5], membrane treatment method [6] and so on.

Coagulation is one of the most commonly-used physical and chemical methods [7]. Pretreatment of

landfill leachate by coagulation could flocculate and precipitate part of the refractory organic matter

and remove toxic substances from leachate, and provide a good operation environment for biological

treatment.

The traditional coagulant treatment of landfill leachate need a large dosage of coagulant and have

poor coagulation effect. In order to solve these problems, compound coagulant [8] and two-time

coagulation are used to treat landfill leachate. The combination of coagulants is polyaluminum

chloride (PAC) and polyferric sulfate (PFS). The two-time coagulation is after one coagulation,

coagulant is added to the effluent again.

Bai, W., Liu, F. and You, H.

Enhanced Coagulation for Landfill Leachate Pretreatment.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 431-436

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

431

2. Materials and methods

2.1. Leachate

The landfill leachate was obtained from Weihai municipal solid waste incineration plant. The raw

water data of leachate are shown in Table 1.

Table 1. Water quality of leachate.

COD(mg/L)

NH

4

+

-N(mg/L)

pH

turbidity(NTU)

PO

4

3-

(mg/L)

67550

2310

5.98

1718

479.51

2.2. Methods

2.2.1. Traditional coagulation. PAC and PFS were separately added to the leachate with different

dosage and pH. Stirring conditions are 300 r/min for 30 s, 120 r/min for 60 s, 40 r/min for 10 min.

The supernatant was measured after the static precipitation of 10 min.

2.2.2. Compound coagulant. PAC and PFS composite coagulant was separately added to the leachate

with different PAC/PFS ratio, pH and dosage. Stirring conditions are 300 r/min for 30 s, 120 r/min

for 60 s, 40 r/min for 10 min. The supernatant was measured after the static precipitation of 10 min.

2.2.3. Two-time coagulation. After first coagulation, coagulant was added to the supernatant and then

the leachate was coagulated again. PAC and PFS composite coagulant was added to the leachate wirh

different respective dosage of two times coagulation. Stirring conditions of two times coagulation are

300 r/min for 30 s, 120 r/min for 60 s, 40 r/min for 10 min. The supernatant was measured after the

static precipitation of 10 min.

3. Results and discussion

3.1. Influence of coagulation conditions on traditional coagulation

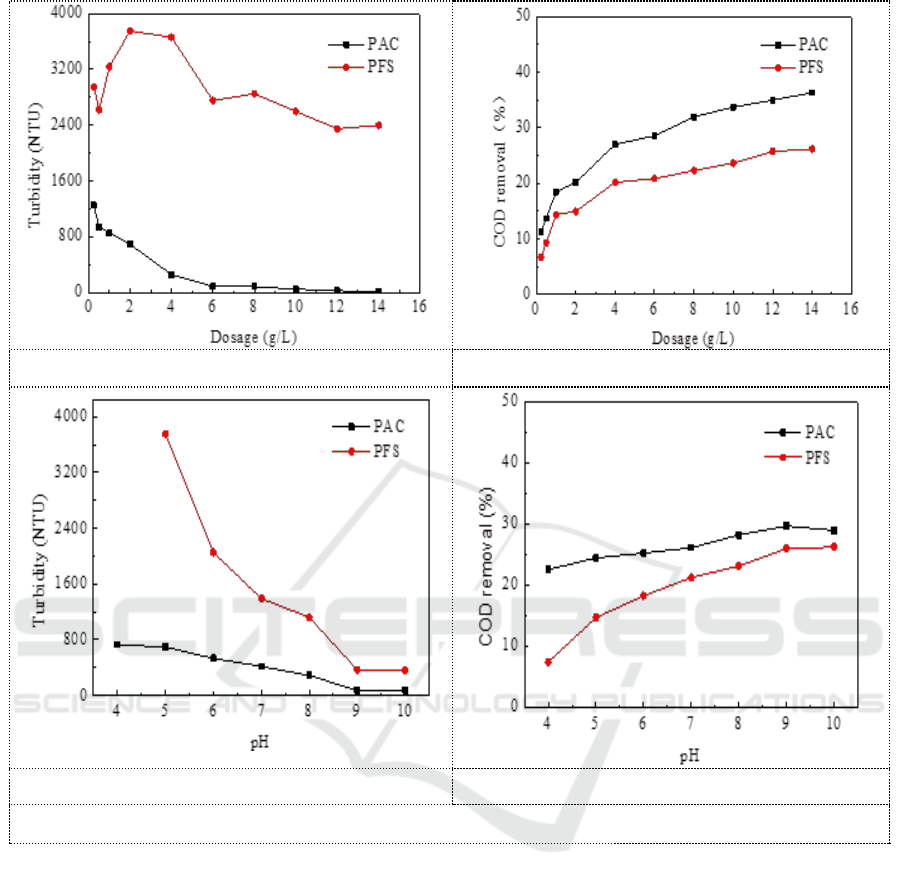

PAC and PFS were separately added with different dosage and pH. Figure 1 showed the removal

effect of these two coagulants on turbidity and COD under different conditions. As can be seen from

Figure 1a and 1b, the removal efficiency of turbidity and COD by PAC is significantly better than

that of PFS. The turbidity and the COD of the supernatant gradually decrease with the increasing of

coagulant dosage. It is not completely in line with the conventional coagulation for the composition

of the leachate is too complicated and the turbidity is too high. There is no case that the particle is

stable again with increasing dosage of coagulant, resulting in a poor coagulation effect. The decrease

rate of turbidity turned slowly with a dosage of 4 g/L. So the dosage was fixed as 4 g/L, and change

the pH. Figure 1c and 1d showed that the turbidity value gradually decreased with the increasing of

pH value. The best coagulation effect was achieved with PAC addition and pH=9. The turbidity of

the supernatant was 74 NTU and the turbidity removal rate was 95.7%. The COD was 47517 mg/L

and the COD removal rate was 29.7%.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

432

a. Effect of coagulant dosage on turbidity

b. Effect of coagulant dosage on COD removal

c. Effect of pH on turbidity

d. Effect of pH on COD removal

Figure 1. Comparison of coagulation effect of PAC and PFS under different conditions.

3.2. Influence of coagulation conditions on compound coagulant

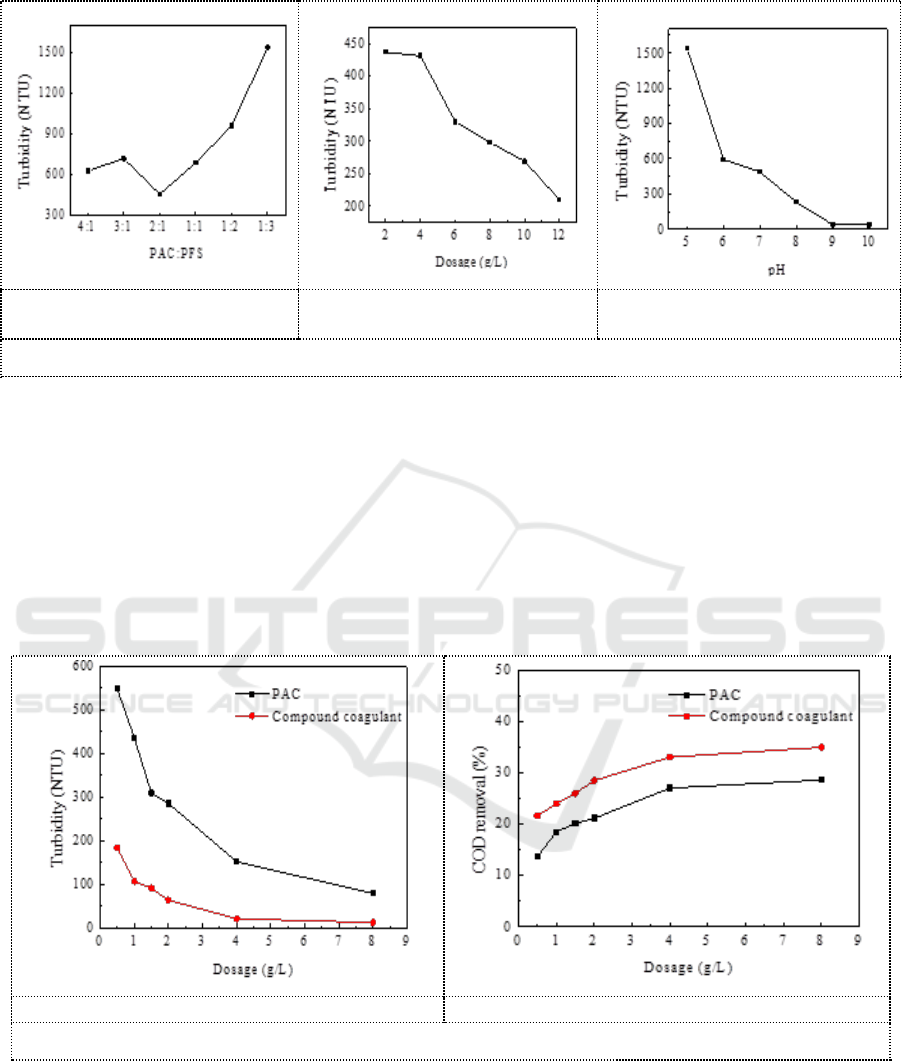

Figure 2 showed the coagulation efficiency of compound coagulants under different conditions by

changing PAC and PFS coagulation ratio, dosage and pH respectively. It can be seen from Figure 2a

that the turbidity of the supernatant is the lowest when PAC: PFS is 2:1. The PAC/PFS ratio of the

compound coagulant used in the next experiment is 2:1. It can be seen from Figure 2b that the

turbidity of the supernatant decreases with the increasing of coagulant dosage. As the dosage of

coagulant continues to increase, there was no re-stabilization of the particles. It can be seen from

Figure 2c that the turbidity of the supernatant decreases with the increasing of the pH value.

Turbidity reaches minimum (37 NTU) when pH= 9.

Enhanced Coagulation for Landfill Leachate Pretreatment

433

a. Influence of PAC/PFS ratio

on turbidity.

b .Effect of compound coagulant

dosage on turbidity.

c .The effect of pH on turbidity.

Figure 2. Effect of coagulation conditions on PAC/PFS coagulation.

3.3. Comparison of compound coagulation and traditional coagulation effect

When pH =9, compound coagulants (PAC: PFS =2:1) and PAC are separately added to the leachate.

Figure 3 showed the coagulation effect of the compound coagulant and the PAC under the same

conditions with the increasing of coagulant dosage. The COD and turbidity removal efficiency of the

compound coagulant is obviously stronger than that of PAC. Taking 4g/L as a reference, when the

dosage of compound coagulant was 4 g/L, the turbidity was 21.2 NTU and the turbidity removal rate

was 98.8%, the COD was 45233 mg/L and the COD removal rate was 33.0%. When PAC was added,

the turbidity was 74.0 NTU, the turbidity removal rate was 95.7%, the COD was 47517 mg/L and the

COD removal rate was 29.7% under the same conditions.

a .Comparison of turbidity.

b. Comparison of COD removal.

Figure 3. Comparison of coagulation effect between PAC coagulant and compound coagulant.

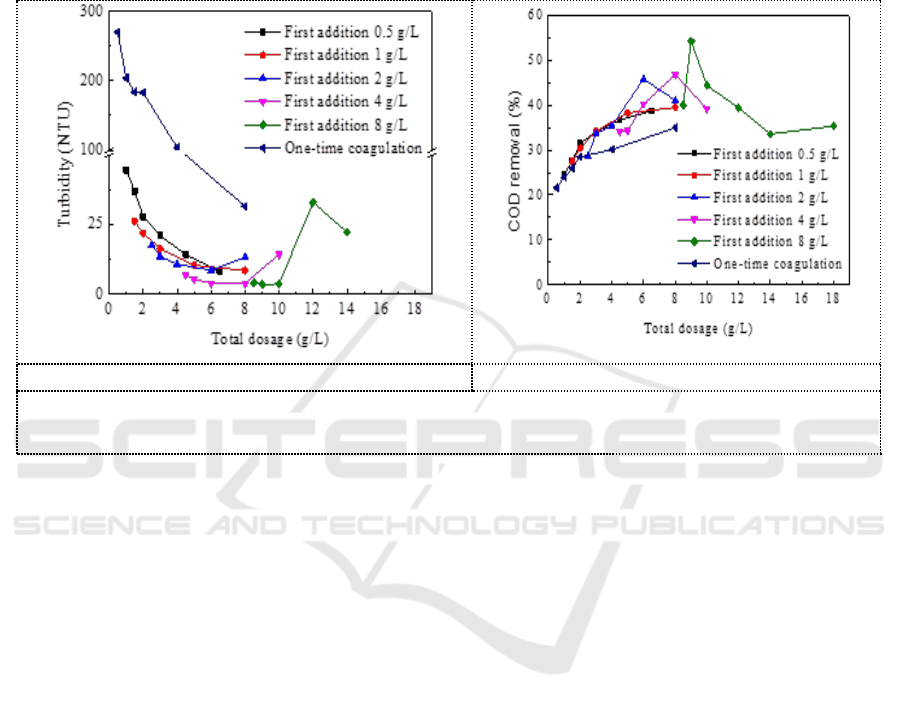

3.4. Comparison of two-time coagulation and one-time coagulation

When pH = 9, recoagulate on the basis of first coagulant with compound coagulant dosage of 0.5 g/L,

1 g/L, 2 g/L, 4 g/L, 8 g/L. Figure 4 showed the effect of the total compound coagulant dosage of two-

time coagulation on turbidity and COD removal. It can be seen that the effect of two-time

coagulation on the removal of turbidity and COD is significantly better than that of one-time

coagulation and the secondary coagulation is more likely to reach the optimal dosage of coagulant.

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

434

When the first coagulation dosage was 4 g/L, the second dosage was 0.5 g/L with a total dosage of

4.5 g/L, the turbidity of the two-time coagulation supernatant was 6.8 NTU. While the turbidity of

the supernatant is 95.0 NTU with one-time coagulation (4.5g/L). When the first coagulation dosage

was 8 g/L, and the second dosage was 1 g/L with a total dosage was 9g/L, the COD removal rate of

two-time coagulation was 54.3%. While the COD removal rate was 35% with one-time coagulation

(9g/L).

a. Comparison of turbidity removal.

b. Comparison of COD removal.

Figure 4. Comparison of coagulation effect between two-time coagulation and one-time

coagulation.

4. Conclusions

The coagulation effect of PAC and PFS compounding is obviously better than that of traditional

single coagulation. And the turbidity from 74 NTU to 21.2 NTU, the COD removal rate rose from

29.7% to 33%.

The coagulation effect of two-time coagulation is better than that of one-time coagulation,

because the two-time coagulation processes fully exerted the effect of contact flocculation that is the

larger mature flocs adsorb the tiny floc in the water on the surface and remove it from the water.

When the dosage of coagulant is the same, the removal rate of turbidity and COD is obviously

improved. And the turbidity decreased from 95 NTU to 6.85 NTU and the removal rate of COD

increased from 35% to 54.3%.

At the same time, the two-time coagulation also has the advantages that the coagulant dosage is

greatly reduced, the amount of coagulation supernatant is greatly increased, the turbidity of the

supernatant can be very low, the flocs are large and the sedimentation is fast. It is foreseeable that the

two-time coagulation secondary coagulation method could be further applied in the field of high

turbidity water treatment.

Acknowledgement

This work was supported by Natural Science Foundation of Shandong Province (ZR2017MEE020).

References

[1] Zhang H, Sun L P, Ying A N, Gao S Q and Wang A Q 2010 Research Advances in

Characteristics of MSW Landfill Leachate Sichuan Environment 29 (2) pp 113-118

[2] Xiao C B, Pang B L, Ren Y S, Wen X, Gao Y G and X Z Gao 2012 Landfill leachate treatment

Enhanced Coagulation for Landfill Leachate Pretreatment

435

project in refuse incineration power plant China Water & Wastewater 28(10) pp 77-79

[3] Gao J, Oloibiri V, Chys M, Audenaert W, Decostere B, Y He and et al 2015 The present status

of landfill leachate treatment and its development trend from a technological point of view

Reviews in Environmental Science & Bio/Technology 14(1) pp 93-122

[4] Yan F, Li J, Xiao G and Pan W 2010 Treatment of landfill leachate by coupling system of

titanium dioxide and ultrasonic Chinese Journal Of Environmental Engineering 4(2) pp

383-386

[5] Sabour M R, Lak M G and Rabbani O 2011 Evaluation of the main parameters affecting the

fenton oxidation process in municipal landfill leachate treatment Waste Manag Res 29(4)

pp 397-405

[6] Fu J T, Wang L, Li X W, Yang S X, Zhang L Q and Ma L 2017 A pilot study on the reduction

of leachate from waste incinerati on power plant by stro membrane Membrane Science &

Technology 37(2) pp 120-123

[7] Bashir M J K, Xian T M, Shehzad A, Sethupahi S, Aun N C and Amr S A 2016 Sequential

treatment for landfill leachate by applying coagulation-adsorption process Geosystem

Engineering 20(1) pp 9-20

[8] Shang P, Liu T L and Kong X J 2011 Pretreatment of landfill leachate using PAC, PFS

coagulation and chemical precipitation China Water & Wastewater 27(1) pp 65-67

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

436