Isolation and Characterization of Chromium Reducing

Bacteria

Y Gao

1

, Q Cheng

1

, T T Hu

1

, H J Ji

1

, Z Y Zhu

1

, Q Xu

2

, A M Li

2

and Y Yang

1,3,*

1

School of Minerals Processing and Bioengineering, Central South University,

Changsha, Hunan, China, 410083

2

Hunan Coal Science Research Institute, Changsha, Hunan, China, 410004

Central South University, 932 South Lushan Road, Changsha, 410083, China.

3

Key Laboratory of Biometallurgy of Ministry of Education, Changsha, Hunan,

China, 410083

Corresponding author and E-mail: Y Yang , csuyangyu@csu.edu.cn.

Abstract. Removal of highly toxic Cr (VI) using bioremediation can start a new way for

effective treatment of chromium contamination. Therefore, the chromate-reducing strain G-13

under alkaline conditions was isolated from chromium factory. G-13 was identified as

Micrococcus sp..The strain of G-13 was selected to study the resistance of Cr (VI) and its

ability to reduce Cr (VI) under different culture conditions. The results showed that the

optimum temperature and pH for the strain were found to be 30℃ and 7.0 or 8.0, respectively.

The percent reduction of Cr(VI) for 50,100, 200, 400 and 500 mg/L of initial concentration at

96 h of incubation were 82.1%, 63.6%, 34.5%, 21.2% and 9.1%, respectively. The

Micrococcus sp.G-13 strain was remarkable under the condition of glycerol and sodium

lactate as the electron donor, which could reduce 50 mg/L Cr (VI) to 0 within 36 h, and the

reduction rate was 100%. Consequently, the isolation of bacteria can be exploited for the

bioremediation of Cr (VI) pollution. It is hoped that this study can provide theoretical basis

for the treatment of environmental chromium pollution.

1. Introduction

Chromium is one of the most widely and heavily used heavy metals in various industrial processes,

such as metallurgy, wood preservation, nuclear power plants and

so on[1]. The widespread use of

chromium compounds can result in large quantities of chromium being released into the environment

[2]. Therefore, chromium contamination has been often reported in many industrial sites due to

improper disposals, poor storage and accidental leakages measures. In natural systems, chromium

generally exists in two stable oxidation states, hexavalent chromium (Cr (VI)) and trivalent

chromium (Cr (III))[3].Soluble hexavalent chromium [Cr (VI)], such as [CrO

4

2-

, HCrO

4

-

] is highly

toxic, and shows mutagenic and carcinogenic effects on biological systems due to its strong oxidizing

nature [4].While trivalent chromium (Cr (III)) like [Cr (OH)

3

] is an essential micronutrient for

organisms (50-200 ug/day). It is 100-fold less toxic than Cr (VI) due to its lower cell permeability

and insolubility [5].

Since Cr (VI) poses a great threat to humans, cleaning up this contaminant from soil and water is

Gao, Y., Cheng, Q., Hu, T., Ji, H., Zhu, Z., Xu, Q., Li, A. and Yang, Y.

Isolation and Characterization of Chromium Reducing Bacteria.

In Proceedings of the International Workshop on Environmental Management, Science and Engineering (IWEMSE 2018), pages 605-613

ISBN: 978-989-758-344-5

Copyright © 2018 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

605

essential and reduction to Cr (III) may be considered a satisfactory solution in eliminating the

toxicity of Cr (VI)[6]. Over the past few decades, several technologies based on this reason have

been developed to remove chromium from the environment. Far-ranging conventional methodologies

have been used for the removal of Cr (VI) from industrial wastewaters including ion-exchange resins

[7], filtration [8], chemical precipitation [9], chemical oxidation or reduction and so on [10].

However, these methods tend to generate large amount of secondary waste products, resulting in

secondary pollution of the environment. Thus, to overcome these disadvantages, it is important to

develop an innovative, cost-effective and eco-friendly methods for extraction of hazardous materials

present in environment.

Microbial remediation, is a potential alternative for the removal of chromium [Cr (VI)] in

environmental studies because of the advantages of its environmental friendliness, cost effectiveness

compared with conventional methods [11]. Soil microorganisms play a dominant role in reducing the

toxic charge of heavy metals through conversion of toxic Cr(VI) to relatively nontoxic Cr(III)[12].In

some cases, the microorganisms remediation occurs spontaneously that reduces the toxic Cr(VI) to

Cr(III) because the essential materials required for bacterial growth are naturally present at the

contaminated sites[13,14].Hence, the present study is aimed at the isolation of potential hexavalent

chromium reducing bacteria from a contaminated soil and to study their hexavalent chromium

reduction characteristics.

2. Materials and methods

2.1. Sample collection

Soil sample was collected from the surface horizon (0-10 cm) of the chromium pollution sites of a

chromate factory in Changsha, China. Soil samples collected in sterilized plastic bags were brought

to the laboratory and stored at 4°C refrigerated condition until use.

2.2. Preparation of media

The medium selected was Luria Broth (LB) medium to isolate and the reduction characteristics of

chromium-reducing bacteria. The medium specific ingredients [15] was tryptone 10 g/L, yeast extract

5 g/L, NaCl 5 g/L,MgSO

4

.

7H

2

O 0.2 g/L,K

2

HPO

4

0.05 g/L, distilled water 1 L, Agar 2%(w/v).The pH

value of the medium was adjusted to 8.0 by adding aliquots of either 1 mol/L H

2

HSO

4

or 1 mol/L

NaOH. The medium were autoclaved at 121°C for 20 min.

2.3. Isolation of Cr (VI) - tolerant bacterial strains

Isolation of the bacterial culture was done by an enrichment culture technique [16]. Luria Broth was

amended with filter sterilized 200 mg/L K

2

Cr

2

O

7

as Cr(VI) and 10 g soil which was incubated at

30°C ,170 r/min for 12 h on a rotary shaker. After 12 h enriched bacterial strains were isolated by

plating on Luria agar plate amended with 200 mg/L of K

2

Cr

2

O

7

.This process was serially diluted with

sterile water of soil sample and plated onto Luria Broth (LB) agar and incubated at 30°C for 24–36 h

to isolate Cr (VI)-resistant bacteria. Bacterial colonies of different morphologies were obtained

through many round streaking and purification on the same agar medium. From this preliminary

screening strains showing resistance to chromium were selected for further studies. The ability of the

isolates to reduce Cr (VI) was determined by Cr (VI) reduction experiments.

2.4. Screening of Cr (VI)-reducing strain

The selected Cr (VI)-resistant strain were inoculated into 100 mL of liquid LB medium containing 50

mg/L of Cr(VI) as K

2

Cr

2

O

7

and incubated in an orbital shaker(170 r/min) at 30°C .1 mL liquid of

culture were taken out in sterilized tube at regular time interval and were centrifuged at 10,000 r/min

for 5 min at room temperature. The supernatant was used to measure Cr (VI) concentration at 540 nm

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

606

using UV 754 N model spectrophotometer.

2.5. Identification of the isolated strain

The isolated strain was identified based on standard biochemical tests [17]. In addition, molecular

identification was done by 16S rRNA analysis using universal bacterial 16S rRNA gene primers

27F (5’-AGAGTTTGATCCTGGCTGGCTCAG-3’) and 1492R

(5’-GGTTACCTTGTTACGACTT-3’) for polymerase chain reaction (PCR) amplification of the

16S rRNA gene [18]. Purified PCR products were conducted by Platinum Sequencing Company,

Shanghai, China. The resulting 16S rRNA gene sequences were initially analyzed with known 16S

rRNA sequences in the GenBank database to identify the most similar sequence alignment and to

download the corresponding sequence. The phylogenetic tree was then constructed by

neighbor-joining method using the MEGA 7.0 package version.

2.6. Determination of optimum growth temperature and pH of the isolated strain

For optimum growth of the bacterial isolates, two parameters, i.e., temperature and pH were

considered [19]. For the determination of optimum temperature, the logarithmic strain seed solution

were inoculated into sterilized 100 mL LB medium at 5% inoculum concentration (250 mL culture

flasks, pH 9.0) and incubated at 25°C , 30°C , 35°C , 40°C and 45°C , respectively. In addition, to

determine the optimum pH of the strain, a set of liquid LB medium of the same specifications was

prepared and the pH values were set to 3.0, 5.0, 7.0, 8.0, 9.0, 10.0 and 11.0, respectively. Then

inoculated with 5% inoculum concentration into the sterilized LB medium, placed in 30°C , 170 r/min

incubated on a rotary shaker, observed at regular time intervals the OD

600

value of the culture

medium, each experiment was carried out in triplicate. Data are the mean of three replications.

2.7. Determination of chromium reduction experiments

2.7.1. Effects of initial chromium concentration on chromium reduction. To determine the effect of

initial chromium concentration on Cr (VI) removal of strain, the logarithmic strain seed solution of

G-13 was inoculated into sterilized 100 mL LB liquid medium at a 5% inoculum concentration (250

mL culture flasks, pH 9.0) amended with variable concentration of Cr (VI) as K

2

CrO

4

[20],

respectively 50, 100, 200, 400 and 500 mg/L and incubated on a rotary shaker at 30°C , 170 r/min.

The chromium removal was measured at regular time intervals by measuring the residual Cr (VI) in

the cell-free supernatant. Each experiment was carried out in triplicate. Data are the mean of three

replications.

2.7.2. Effects of various electron donors on chromium reduction. To determine the effect of carbon

source on Cr (VI) removal of strain, the logarithmic strain seed solution of G-13 was inoculated with

5% inoculum concentration into 100 mL LB liquid medium (250 mL culture flasks, 50 mg/L Cr (VI),

pH 9.0) amended with a certain concentration of carbon source as electron donors [21], respectively

glucose, sucrose, sodium lactate, glycerol and incubated on a rotary shaker at 30°C , 170 r/min. The

chromium removal was measured at regular time intervals by measuring the residual Cr (VI) in the

cell-free supernatant following centrifugation. Each experiment was carried out in triplicate. Data are

the mean of three replications.

2.8. Analytical methods

Cr (VI) concentration in the supernatant was determined colorimetrically with a spectrophotometer

using diphenylcarbazide reagent in acid solution method. The reagent was prepared by adding 0.2 g

of diphenylcarbazide to 50 mL of acetone and then made up to a final volume of 100 mL with

distilled water. To the cooling solution were added 12.5 mL H

2

SO

4

© and H

2

PO

4

©, respectively. The

Isolation and Characterization of Chromium Reducing Bacteria

607

reagent was stored in a brown bottle at 4°C until used. The residual Cr (VI) concentration in the

culture was measured at 540 nm by UV 754N model spectrophotometer. The growth of cells was

routinely monitored by measuring optical density (OD) at 600 nm.

3. Results and discussion

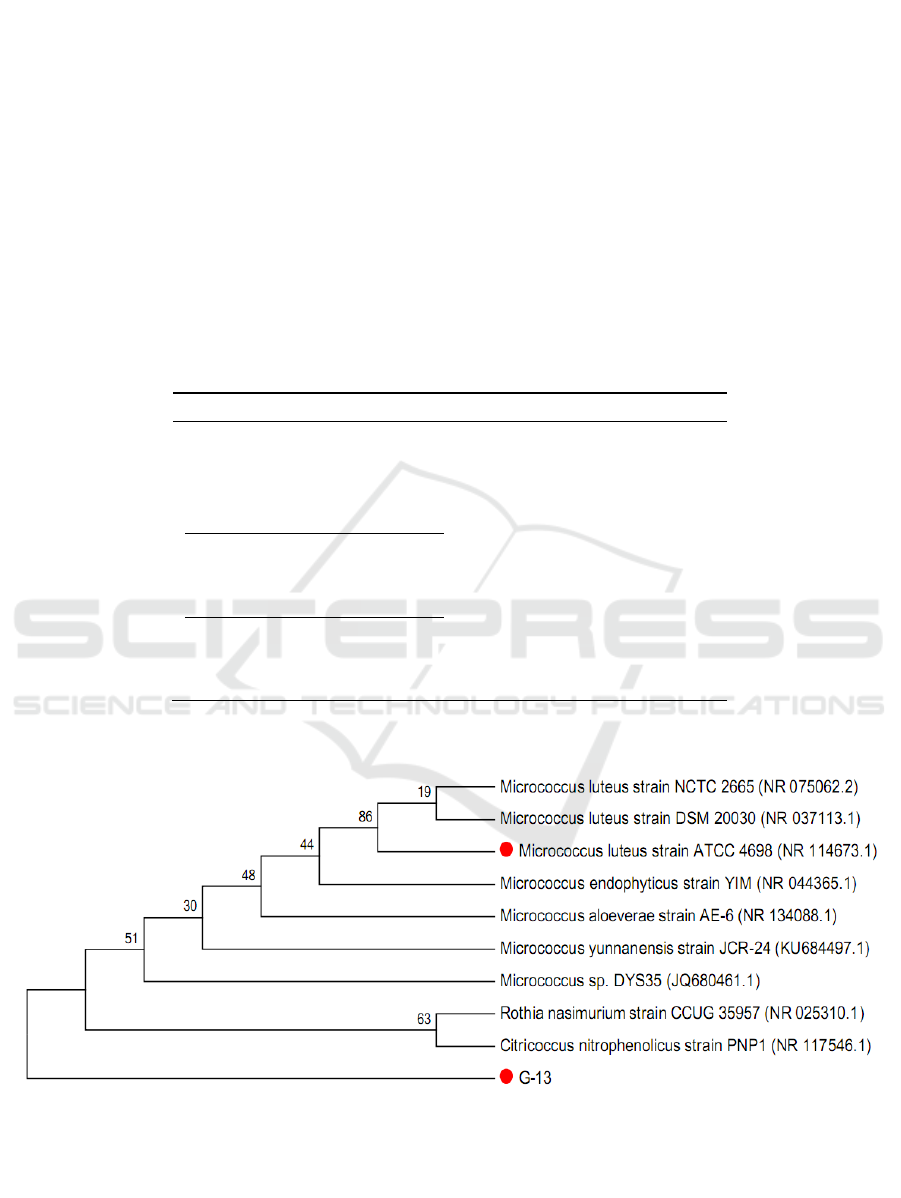

3.1. Identification of the isolated Cr (VI)-reducing strain

The colony morphology, cell morphology and biochemical test results of the isolated strain are

presented in Table 1 and the partial amplification sequences was sequenced by 16S rRNA gene. The

result was compared using the BLSAT function provided by NCBI database to identify the most

similar sequence alignment. The results revealed that the strain was 99 % homologous to

Micrococcus luteus strain ATCC 4698 (NR 114673.1) (Figure 1).Hence, the isolates strain was

identified from this result as Micrococcus sp.

Table 1. Cell morphology and biochemical test results for the isolate strain.

Biochemical characteristics

Results

Cell / Colony morphology

Round

Colony Color

Yellow

Colony edge

Smooth

Motility

+

Gram staining

+

V-P test

-

Citrate test

+

Indole test

+

Voges-proskauer

-

Lactose fermentation test

+

Note: positive : +; negative : -

Figure 1. Phylogenetic tree based on 16S rRNA gene sequence for Micrococcus sp.G-13.

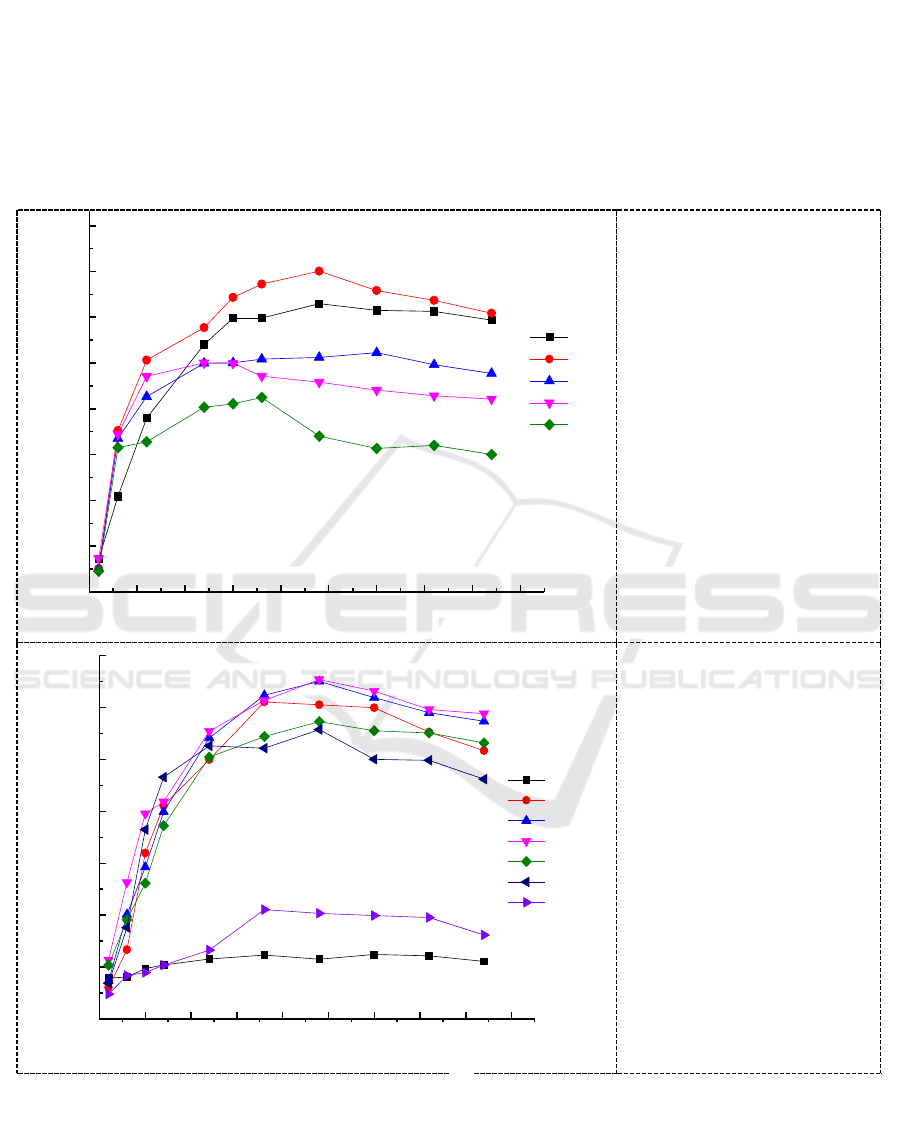

3.2. Determination of optimum growth temperature and pH of the isolated strain

Temperature and pH play a crucial role in the growth rate and chromium reduction of the

Micrococcus sp.G-13 strain. The variation in temperature and pH of the LB medium affects the

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

608

viability of the cells, the activity of chromium reductases and causes changes in the ionic form of

active sites [22].Therefore, the optimum growth temperature and pH of the isolated bacteria

Micrococcus sp.G-13 were studied and the results are shown in Figure 2.In the temperature range of

25 ~ 45°C , the Micrococcus sp. G-13 has the best growth trend at 30°C . However, the Micrococcus

sp. G-13 strain can also grow in other temperature ranges but its growth is significantly inhibited at

45°C , which may be due to the decrease of membrane fluidity hindered cell growth. In addition, it

was found that the optimum pH of Micrococcus sp. G-13 was pH 7.0 or pH 8.0, but it cannot tolerate

extreme acid and extreme alkali environments (Figure 3).

Figure 2. Growth curve of

the Micrococcus sp. G -13

strain at different

temperatures.

Figure 3. Growth curve of

the Micrococcus sp. G -13

strain at different pH .

3.3. Effects of initial chromium concentration on chromium reduction

Research reported that the concentration of Cr (VI) in the process of chromium reduction can affect

the growth and chromium reduction of chromium reduction strain [23].With the increase of

chromium concentration, the reduction rate of chromium gradually decreased and the total reduction

0 10 20 30 40 50 60 70 80 90

0.0

0.3

0.6

0.9

1.2

1.5

1.8

2.1

2.4

25℃

30℃

35℃

40℃

45℃

OD

600

Time(h)

0 10 20 30 40 50 60 70 80 90

0.0

0.3

0.6

0.9

1.2

1.5

1.8

2.1

pH 3

pH 5

pH 7

pH 8

pH 9

pH 10

pH 11

OD

600

Time(h)

Isolation and Characterization of Chromium Reducing Bacteria

609

time of chromium increased. The effect of initial concentration on biomass growth and Cr (VI)

reduction by Micrococcus sp.G-13 was studied over an initial concentration range of 50 mg/L~500

mg/L and the results are shown in Figure 4. Higher amount of biomass concentration was observed at

an initial concentration of 50~200 mg/L and increase in initial concentration of Cr (VI) decreased the

biomass concentration. The growth of the Micrococcus sp.G-13 strain was significantly delayed at

500 mg/L Cr (VI) concentration compared to 400 mg/L, it may be that when the initial concentration

of chromium in the culture medium exceeded a certain limited concentration, the toxic effects on the

cells of the strain and Cr (VI) reducing strain is irreversibly inactivated.

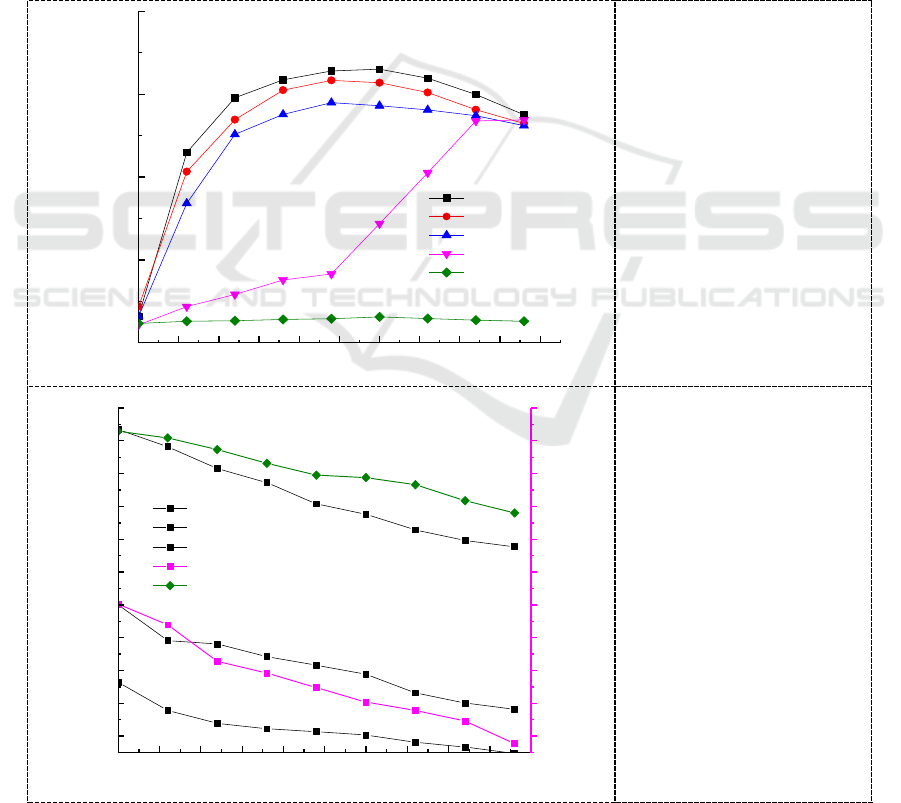

Bacterial Cr (VI) reduction is enzyme mediated. Rate of this enzyme-catalyzed reaction increases

with the increase in the number of active collisions, as Cr (VI) occupies more enzyme active sites

[20]. Consequently, Cr (VI) reduction increases with reflecting increased enzyme activity until Cr

(VI) concentration saturates the enzyme, but the rate of reduction was decreased with increase in

incubation time and Cr (VI) concentration. The trend observed in the present study was the maximum

Cr (VI) reduction obtained for 50,100,200,400 and 500 mg/L of initial concentration at 96 h of

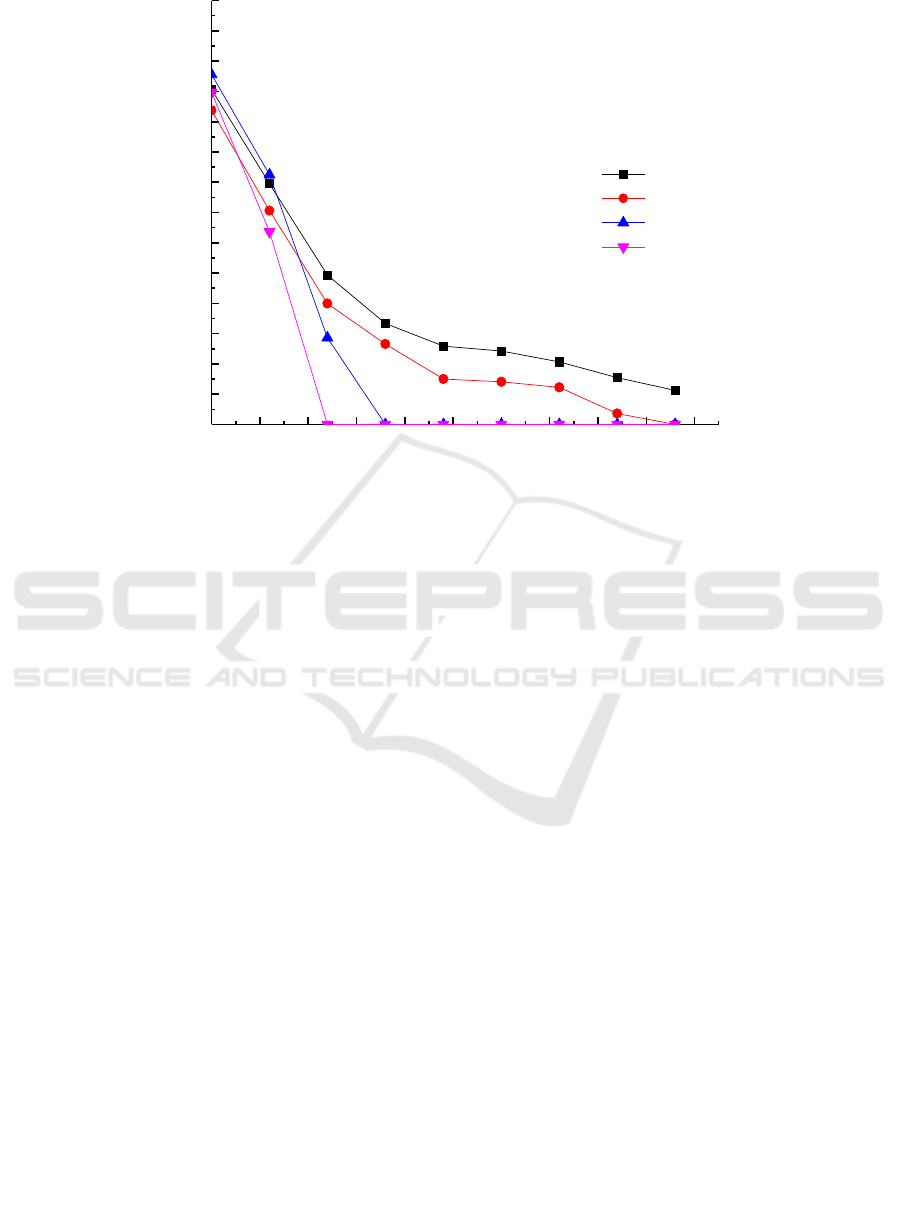

incubation were 82.1%, 63.6%, 34.5%, 21.2% and 9.1%, respectively (Figure 5).

Figure 4. Growth curve

of the Micrococcus sp. G

-13 strain at different

initial Cr (VI)

concentrations.

0 10 20 30 40 50 60 70 80 90 100

20

40

60

80

100

120

140

160

180

200

220

Cr(Ⅵ) (mg/L)

50mg/L

100mg/L

200mg/L

400mg/L

500mg/L

Time(h)

Cr(Ⅵ) (mg/L)

320

340

360

380

400

420

440

460

480

500

520

Figure 5. Chromium

reducing ability the

Micrococcus sp. G -13

strain at different initial

Cr (VI) concentrations.

0 10 20 30 40 50 60 70 80 90 100

0.0

0.5

1.0

1.5

2.0

50mg/L

100mg/L

200mg/L

400mg/L

500mg/L

OD

600

Time(h)

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

610

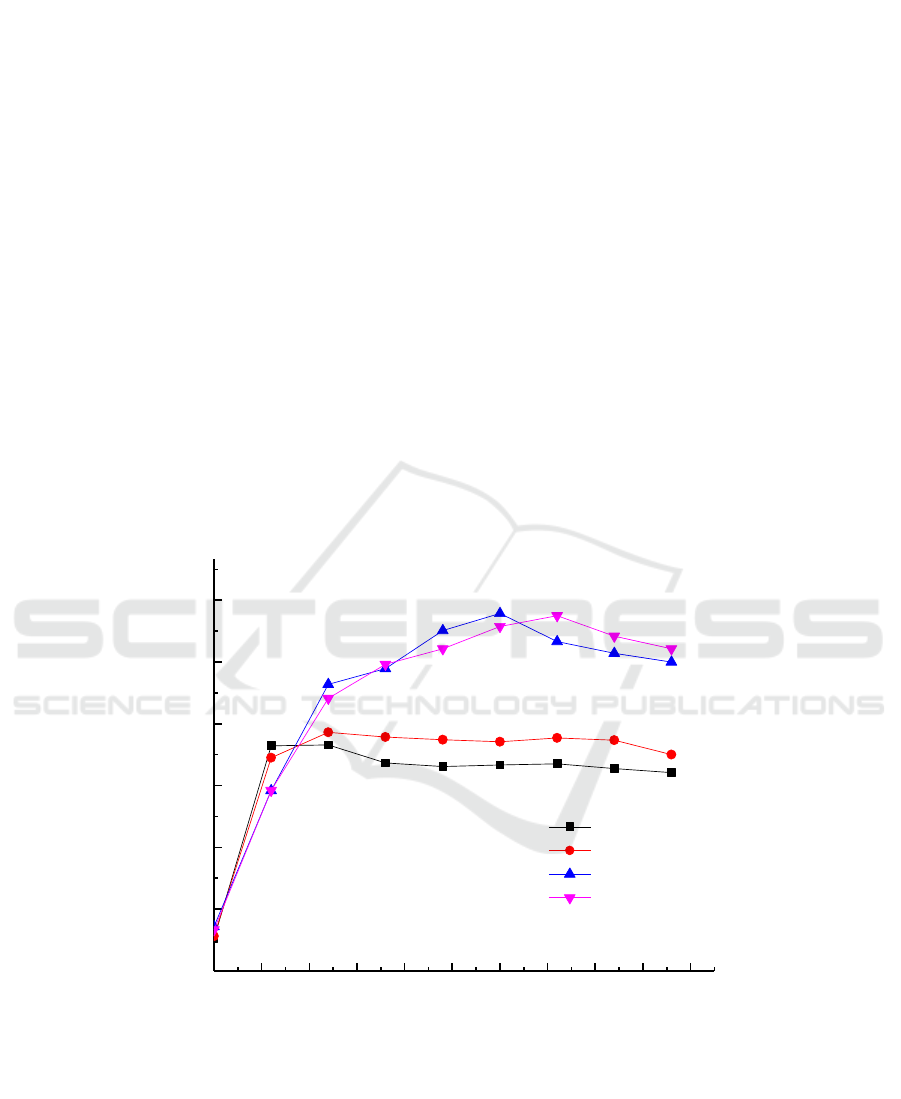

3.4. Effects of various electron donors/carbon sources on chromium reduction

The types of carbon sources include four types of carbohydrates, organic acids and lipids which can

be used as electron donors in the process of oxidative reduction to participate in the transmission of

electrons in the process of microbial growth. However, Cr (VI) reducing strains often preferentially

utilize energetically more favorable electron donors in the process of Cr (VI) reduction [24]. The

commonly of known electron donors are low molecular weight carbohydrates, organic acids, and

fatty acids. Since microbes will give priority to the use of electron donors that are more conducive to

growth, it is extremely important to select the appropriate electron donor to improve the reduction

capacity of Cr (VI). Hence the influence of electron donors such as glucose, sucrose, sodium lactate

and glycerin on chromium reduction of the strain G-13 were studied (Figure 6).

The study found that the growth of the cells was affected in the medium of different carbon source

types with the increase of time and the growth trend was: sodium lactate> glycerol> sucrose> glucose.

The results showed that the growth tendency of the Micrococcus sp.G-13 strain was the best in the

culture medium containing sodium lactate and glycerol. Simultaneously, the results obtained from the

Figure 7 that the reduction rate of Cr (VI) in the Micrococcus sp.G-13 strain was significantly

increased under the condition of glycerol and sodium lactate as the electron donor, which can be 50

mg/L Cr (VI) reduced to 0 in 36 h, the reduction rate of 100%.In the presence of four electron donors,

the chromium reduction rate was glycerol> sodium lactate> sucrose> glucose. The results indicated

that low molecular weight carbohydrates as electron donors may inhibit the growth of the strain,

thereby inhibiting the ability of Cr (VI) reduction.

0 10 20 30 40 50 60 70 80 90 100

0.0

0.3

0.6

0.9

1.2

1.5

1.8

glucose

surcose

sodium lactate

glycerol

OD

600

Time(h)

Figure 4. Growth curve of the Micrococcus sp. G -13 strain at different electron donor.

Isolation and Characterization of Chromium Reducing Bacteria

611

0 10 20 30 40 50 60 70 80 90 100

0

5

10

15

20

25

30

35

40

45

50

55

60

65

70

glucose

surcose

sodium lactate

glycerol

Cr(Ⅵ) (mg/L)

Time(h)

Figure 5. Chromium reducing ability the Micrococcus sp. G -13 strain at different electron donor.

4. Conclusions

At present, chromium is widely used in industrial activities, resulting in a large area of environmental

chromium contamination. Therefore, search for alternative techniques for treatment of Cr (VI)

contaminated environment came into existence. Microbial remediation as a technology with

enormous potential that has attracted much attention to remedy chromium contaminated environment,

So in the present study, the microbial reduction of Cr (VI) using Micrococcus sp.G-13 strain isolated

from chromium-contaminated environment was investigated. Simultaneously, the effects of

parameters such as temperature, pH, initial chromium concentration and carbon sources on the

growth and chromium reduction ability of the Micrococcus sp.G-13 strain were studied and the

optimum conditions for the reduction of chromium were achieved. This study found that the

optimum temperature and pH for the strain were found to be 30°C and 7.0 or 8.0, respectively.

Furthermore, the reduction of Cr (VI) increased with increased biomass and decreased with increase

in initial Cr (VI) concentration. At the same time, research found that the great increase reduction rate

of Cr (VI) for the Micrococcus sp.G-13 strain when the addition of glycerol and sodium lactate to do

electronic donor. All the results indicated the necessity to study the various parameters of the

chromium reduction rate of the strain. Therefore, it can be concluded that future studies can focus on

how to use advanced biotechnology to optimize the culture conditions of strains and reduction

mechanism of chromium bacteria to improve the reduction rate of Cr (VI).

Acknowledgements

This work was financially supported by the Major Science and Technology Program of Hunan

Province, China (2016SK2046); Special Funds for Fundamental Scientific Research Business of

Central South University (Changsha, China) (2017zzts362)

References

[1] Mahmood Q, Raja I A, Khan A and Sultan S 2012 Ecological Engineering vol 42 (Amsterdam:

Elsevier) pp 256-259

IWEMSE 2018 - International Workshop on Environmental Management, Science and Engineering

612

[2] Iyengar C A and Usha M S 2016 Biologija vol 62 (Germany: researchgate)

[3] Zahoor A and Rehman A 2009 Journal of Environmental Sciences vol 21 (Amsterdam:

Elsevier) pp 814-820

[4] Malik A 2007 Environment International vol 33 (New York: Wiley–Interscience) p 122

[5] Wang Y, Chai L, Liao Q,Tang C,Liao Y and Peng B 2016 Geomicrobiology Journal vol 33

(United Kingdom: Taylor & Francis) pp 222-229

[6] Gheju M and Balcu I 2011 Journal of Hazardous Materials vol 196 (United Kingdom: Europe

PMC) pp 131-138

[7] Alidokht L, Khataee A R, Reyhanitabar A and Oustan S 2011 Desalination vol 270

(Amsterdam: Elsevier) pp 105-110

[8] Liu Y G, Zeng X G M, Li X and Gao H 2006 Process Biochemistry vol 41 (Amsterdam:

Elsevier) pp 1981-1986

[9] Yang G and Xia J 2011 Environmental Science & Technology vol 45 (United Kingdom:

Europe PMC) pp 8605-6

[10] Park D, Yun Y S and Park J M 2005 Process Biochemistry vol 40 (Amsterdam: Elsevier) pp

2559-2565

[11] Choppala G K, Bolan N S, Megharaj M, Chen Z and Naidu R 2012 Journal of Environmental

Quality vol 41 (Bethesda: National Center for Biotechnology Information) pp 1175-1184

[12] Park D, Lim S R, Yun Y S and Park J M 2008 Bioresource Technology vol 99 (Bethesda:

National Center for Biotechnology Information) pp 8810-8

[13] Sundar K, Mukherjee A, Sadiq M and Chandrasekaran N 2011 Journal of Hazardous

Materials vol 187 (Amsterdam: Elsevier) p 553

[14] Zhong Y, Qiu X, Chen D, Li N, Xu Q and Li H 2016 Scientific Reports vol 6(London: Nature)

p 31090

[15] Santos E D C D, Silva I S, Simões T H N, Simioni K C M, Oliveira V M and Grossman M J

2012 International Biodeterioration & Biodegradation vol 70 (Amsterdam: Elsevier) pp

104-110

[16] He Z, Li S, Wang L and Zhong H 2014 Water Air & Soil Pollution vol 225 (Heidelberg:

Springer) pp 1-10

[17] Ravikumar S, Baylon M G, Si J P and Choi J I 2017 Microbial Cell Factories vol 16

(Bethesda: National Center for Biotechnology Information) p 62

[18] He Z G, Gao F L, Tao S, Hu Y H and Chao H 2009 Journal of Hazardous Materials vol 163

(United Kingdom: CAB Direct) pp 869-873

[19] Wani R, Kodam K M, Gawai K R and Dhakephalkar P K 2007 Applied Microbiology &

Biotechnology vol 75 (Netherlands: Europe PMC) pp 627-32

[20] Narayani M and Vidya Shetty K 2013 Science & Technology vol 43 (United Kingdom: Taylor

& Francis) pp 955-1009

[21] Ilias M, Rafiqullah I M, Debnath B C, Mannan K S B and Hoq M M 2011 Indian Journal of

Microbiology vol 51 (Heidelberg: Springer) pp 76-81

[22] Stasinakis A S, Thomaidis N S, Mamais D, Papanikolaou E C, Tsakon A and Lekkas T D 2003

Water Research vol 37 (Amsterdam: Elsevier) pp 2140-8

[23] Mangaiyarkarasi M S M, Vincent S, Janarthanan S, Rao T S and Tata B V R 2011 Saudi

Journal of Biological Sciences vol 18 (Amsterdam: Elsevier) p 157

[24] Okeke B C 2008 Journal of Industrial Microbiology & Biotechnology vol 35 (Michigan:

ProQuest) pp 1571-9

Isolation and Characterization of Chromium Reducing Bacteria

613