Simultaneous H

2

Production with Carbon Storage by Enhanced

Olivine Weathering in Laboratory-scale: An Investigation of CO

2

Effect

Jiajie Wang

*

, Kengo Nakamura, Noriaki Watanabe, Atsushi Okamoto and Takeshi Komai

Graduate School of Environmental Studies, Tohoku University, Aramaki, Aoba-Ku, Sendai, Japan

Keywords: H

2

production, CO

2

storage, Rock-water reaction, Olivine, CO

2

-rich.

Abstract: Hydration of olivine ((Mg

,

Fe)

2

SiO

4

) potentially offers significant H

2

supply. However, because of the low

Fe(II) dissolution rate, H

2

production rate is poorly limited. In the present study, to investigate the CO

2

effect

on H

2

generation and minerals evolution, CO

2

-rich (0.5 mol/L NaHCO

3

) reaction condition was created in the

ongoing olivine hydration experiment. H

2

production was continuing with a slight increasing rate after CO

2

addition. Results indicate CO

2

-rich hydrothermal reaction condition (300

o

C, 10 MPa) promoted both olivine

and brucite (Mg,Fe(OH)

2

) dissolution, which led to additional Fe(II) releasing, and consequent H

2

generation.

CO

2

was simultaneous hydrogenated to formic acid (HCOOH) by generated H

2

and carbonated to magnesite

(MgCO

3

). 0.52 mol of CO

2

was trapped in per kg of olivine in 72 h. This study suggests simultaneous multiple

energy productions and CO

2

storage can be realized by olivine weathering process when using a CO

2

-rich

hydrothermal condition.

1 INTRODUCTION

In 2016, the atmospheric carbon dioxide (CO

2

) is

403.3 ppm, having increased by 45% compared with

the pre-industrial level of 280 ppm and still increasing

at a rate of 2 ppm per year (NOAA, 2016). Among

which, up to 65% were attributed to fossil fuel

combustion (Kularatne et al., 2018). Control of global

warming and the exploration of CO

2

-free energy

sources are the main challenges in the 21st century.

Hydrogen (H

2

) is a clean CO

2

-free energy carrier.

However, most current H

2

production processes (e.g.,

steam reforming of CH

4

) need high temperature,

which was supported by the combustion of fossil

fuels. Also, this process generates CO

2

as a reaction

product (Malvoisin et al., 2013).

In recent years, H

2

was discovered from a variety

of geologic fluids. It is commonly produced during

the hydration of rocks, owing to the oxidation of

reduced Fe present in the mineral (Kelley, 1996;

Lollar et al., 2008) at hydrothermal conditions.

Olivine ((Mg,Fe)

2

SiO

4

) is the predominant mineral of

ultramafic rock, the hydration of olivine (also called

serpentinization) potentially offers significant H

2

supply. However, the rate of H

2

generation from

olivine hydration is poorly limited. The low H

2

generation rate is partially attributed to the low

olivine dissolution rate, which can be enhanced by

varying reaction conditions, such as elevating

reaction temperature. Research reported the optimum

temperature H

2

production from olivine hydration

was 300-400

o

C (Berndt et al., 1996; McCollom and

Seewald, 2001). On the other hand, dissolved Fe(II)

prone to be incorporated into brucite (Mg,Fe(OH)

2

),

the secondary mineral of olivine hydration. This

process decreases dissolved Fe(II) in the fluid, thus

fewer Fe(II) can be oxidized, which severely

suppresses H

2

yield (Klein et al., 2009).

The presence of bicarbonates (HCO

3

-

) can

promote olivine and brucite dissolution (Matter and

Kelemen, 2009; Gerdemann et al., 2007; Harrison et

al., 2013). High concentrations of HCO

3

-

in solution

plays as a buffer to maintain relatively weakly

alkaline pH, which has an enhancement in olivine

dissolution. (Harrison et al., 2013) proposed HCO

3

-

can significantly promote brucite dissolution. Thus,

the CO

2

-rich condition potentially enhances Fe(II)

being dissolved, then H

2

production will be

accelerated. Although researches concerning

hydrocarbon generation based on serpentinization

process have used NaHCO

3

as the source of inorganic

carbon, the chemical reactions between HCO

3

-

and

Wang, J., Nakamura, K., Watanabe, N., Okamoto, A. and Komai, T.

Simultaneous H2 Production with Carbon Storage by Enhanced Olivine Weathering in Laboratory-scale: An Investigation of CO2 Effect.

DOI: 10.5220/0008186000830087

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 83-87

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

83

minerals was rarely considered, partially because of

the extremely low concentration of HCO

3

-

(Berndt et

al., 1996; McCollom and Seewald, 2001).

Olivine carbonation process also occurs with the

presence of CO

2

. The CO

2

-rich condition, typically

0.64 M NaHCO

3

, favors olivine carbonation at < 200

o

C (Matter and Kelemen, 2009; Gerdemann et al.,

2007). However, previous studies mainly focus on

olivine serpentinization or carbonation separately,

because they occur at different temperature range.

Whether serpentinization and carbonation can

proceed simultaneously, and the effects of CO

2

-rich

fluid on serpentinization and H

2

production are less

clear.

This study was designed to investigate the

changes in H

2

generation, fluid chemistry and

secondary minerals generations after CO

2

-rich fluid

addition. The role of CO

2

on olivine serpentinization

and carbonation were revealed, as well as the

reactions for dissolved carbon: hydrogenated or

mineralized. Gas, fluid and mineral samples were

withdrawn during the reaction to reveal the

mineralogical changes over time.

2 MATERIALS AND METHODS

2.1 Materials

Purchased olivine grains were chosen for

experimental investigation, which was collected from

Damaping (China). Then olivine was ball-milled

(Pulverisette 6, Fritsch) to diameter <45 μm. The

composition of the olivine was measured using

Electron probe micro-analyzer (EPMA) and was

defined as Mg

1.8

Fe

0.2

SiO

4

. The effect of CO

2

on

olivine weathering was investigated using NaHCO

3

(Kanto Chemical, Japan).

2.2 Experimental Setup and Analytical

Methods

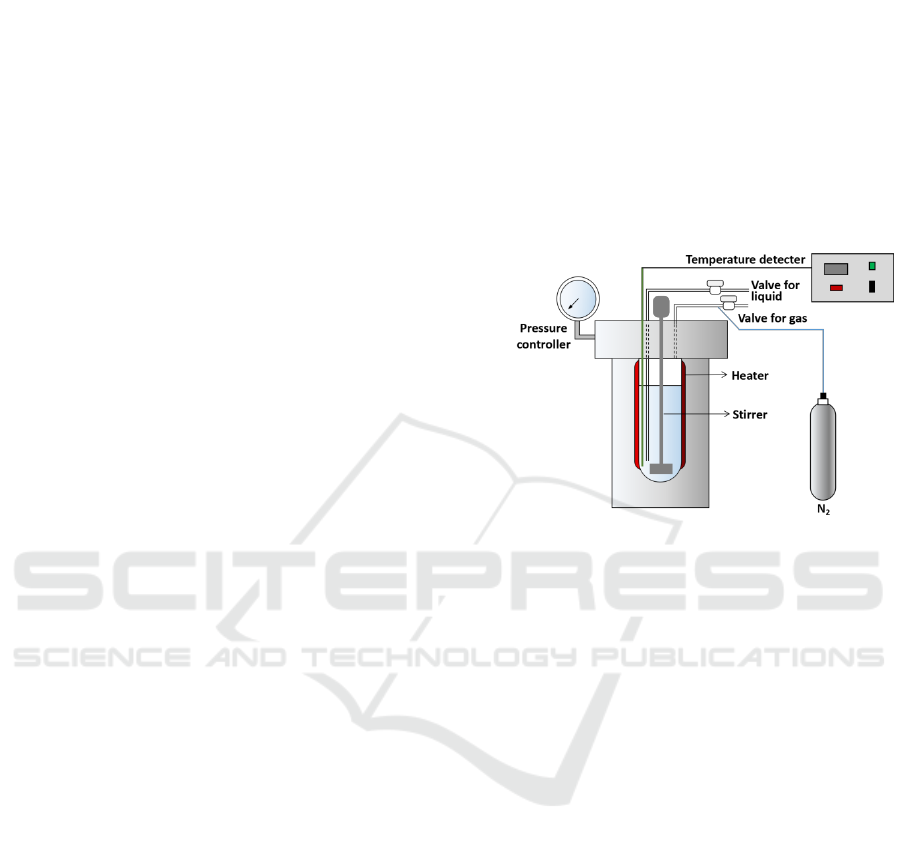

Experiments were performed in a closed-batch

reactor made of Hastelloy-C with an internal volume

of 170 mL (Figure 1). In each experiment, 100 mL

slurry prepared with 5±0.01 g of olivine powders and

Milli-Q water was poured into the reactor. Then the

reactor was closed and purged with N

2

gas for 10

minutes to remove dissolved O

2

in the solution and

the upper headspace. Then air outlet was closed and

N

2

gas continues to be injected to reach a certain

pressure. The reactor was well sealed to increase the

temperature to 300 °C, with the final pressure reached

10 MPa. After 72 h reaction, the reactor was opened

and NaHCO

3

was added to create CO

2

-rich (0.5

mol/L NaHCO

3

) reaction condition. Then the reactor

was sealed and the original reaction conditions (300

o

C and 10 MPa) were reset. Gas, liquid and solid

samples were withdrawn along the reaction via

sampling tubes. Solid samples withdrawn at the

reaction time of 72 and 144 h were named as O72 and

O72-C72, respectively. After 144 h, experiments

were stopped by reducing the temperature of the

reactor using recirculated cooling water. The mineral

powder was filtered and dried at 50 °C for 24 h in an

oven before further analysis.

Figure 1: Schematic diagram of the experimental set-up.

Liquid samples were analyzed using ion

chromatography (IC; 761 Compact IC, Metrohm,

Switzerland) coupled with a Metrosep Organic Acids

column (Metrohm, Switzerland), and Inductively

Coupled Plasma equipped with an Atomic Emission

Spectrometry (ICP-AES). Gas species were analyzed

using gas chromatography (GC; GC-3200, GL

Science, Japan) equipped with a thermal conductivity

detector (TCD). Mineral compositions and crystalline

structures of the minerals were measured using XRD

(Multiflex, Rigaku, Japan) with Cu Kα radiation (λ=

1.54 Å) operated at 40 kV and 20 mA, and with a 2θ

step size of 0.02° from 10° to 45°. The surface

morphologies of the minerals were observed using

scanning electron microscopy (SEM; SU-8000,

Hitachi, Japan). Thermogravimetric analyses (TGA)

of the solid samples were performed using a thermos-

dilatometer (Thermo plus EVO TG 8120, Rigaku,

Japan). The temperature was increased from room

temperature to 1000 °C at a rate of 10 °C per minutes.

The H

2

O contents of brucite and serpentine

(Mg

3

Si

2

O

5

(OH)

4

), CO

2

contents of magnesite

(MgCO

3

) could be determined separately from the

weight loss observed in different temperature ranges.

Then the mass losses due to different minerals could

be identified, and the final mineral composition was

estimated.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

84

3 RESULTS AND DISCUSSION

3.1 Energy Production

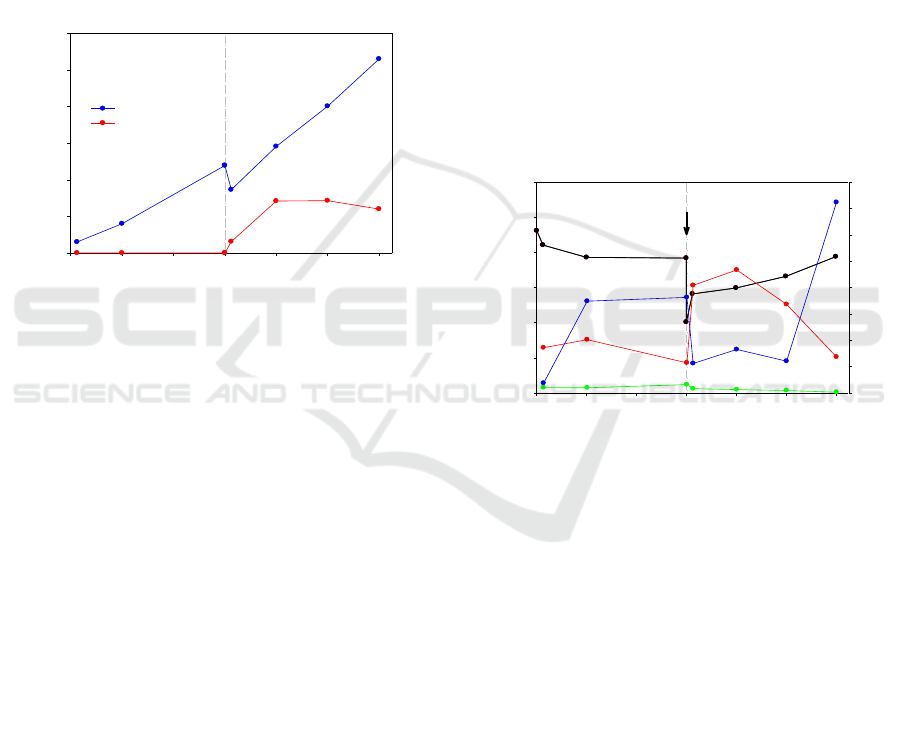

During the reaction, gas and liquid samples were

withdrawn at the reaction time of 3, 24, 72, 75, 96,

120 and 144 h. Gaseous H

2

and liquid HCOOH were

experimental detected as the main products in the

present study. Products yields were measured three

times, and the average ones are summarized in Figure

2. CH

4

was also detected after 72 h reaction. However,

the concentration was too low (several μmol) to be

quantified with sufficient accuracy.

Figure 2: H

2

and HCOOH productions as function of time.

In the first 72 h, the slurry was CO

2

-free. H

2

yield

increased to 47.8 mmol/kg of olivine with olivine

hydration proceeding, suggesting that Fe(II)

dissolved from olivine was oxidized to Fe(III).

HCOOH was not detected in this stage, indicating

dissolved carbon was almost removed out from

solution via N

2

bubbling process. After 72 h reaction,

NaHCO

3

was added into the reactor to create a

concentration of 0.5 mol/L. The accumulated H

2

yield

increased to 106.0 mmol/kg of olivine after reaction

for another 72 h. The continuous generation of H

2

in

the CO

2

-rich condition indicates that Fe(II) oxidation

was not retarded. The average H

2

production rate was

increased from 0.61 mmol/kg·h before NaHCO

3

addition to 1.03 mmol/kg·h after NaHCO

3

addition.

(Klein and McCollom, 2013) reported the CO

2

addition would severely retarded H

2

production from

olivine because of dissolved Fe(II) was easier to be

incorporated into magnesite rather than be oxidized.

Compares it with the present study, the reaction

temperature may play an important role on judging

the CO

2

effect on H

2

production. Their reaction

temperature is 230

o

C while that of the present study

is 300

o

C. HCOOH was generated in the first 3h after

NaHCO

3

addition and reached stable at 28.4 mmol/kg

of olivine after 24 h. CH

4

concentration did not

increase even at the CO

2

-

rich condition with higher

HCOOH and H

2

concentrations.

3.2 Fluid Chemistry

Fluid compositions of the samples withdrawn during

the reaction are summarized in Figure 3. During the

first 72 h reaction in carbon-free condition, pH of the

slurry decreased from initial 10.62 to 9.84. Dissolved

SiO

2(aq)

concentration increased from initial 0.34 to

0.40 mol/L in the first 24 h, then followed by a slight

decrease to 0.23 mmol/L. Mg

2+

concentration

increased from initial value 0.08 to a plateau of 0.73

mmol/L, whereas Ca

2+

concentration increased

slightly from initial value 0.04 to 0.06 mmol/L. The

much smaller increase in Ca

2+

concentration is

attributed to the low Ca composition in initial olivine

particles. As the reaction progress, which was

attributed to olivine dissolution.

Figure 3: Fluid composition as a function of time.

The addition of NaHCO

3

caused rapid changes in

the fluid chemistry. Solution pH decreased from 9.84

to 8.02 immediately because of the buffering of

NaHCO

3

. In the subsequent reaction, the pH

increased to 9.49 gradually with the reaction time

reaching 144 h. The increase of pH was partially

attributed to the dissolution of olivine particles. With

the addition of NaHCO

3

, SiO

2(aq)

concentration

increased significantly from 0.23 to 0.82 mmol/L in 3

h, which indicates the enhancement on olivine

dissolution (Klein and McCollom, 2013; Gadikota et

al., 2014). As the reaction process, SiO

2(aq)

concentration eventually decreased again to 0.27

mmol/L. Mg

2+

concentration decreased immediately

from 0.73 to 0.22 mmol/L, whereas Ca

2+

concentration decreased from 0.06 to 0.03 in 3 h after

the addition of NaHCO

3

. It indicates the carbonation

process conducted quickly after CO

2

was added. At

the last 24 h of the reaction, the Mg

2+

concentration

carbon-free

reaction time (h)

0 24 48 72 96 120 144

H

2

and HCOOH yield (mmol/kg of olivine)

0

20

40

60

80

100

120

H

2

HCOOH

carbon-rich

(0) (24)

(48) (72)

0 24 48 72 96 120 144

pH

6

7

8

9

10

11

12

Si (mM)

,

Mg(mM),

Ca (mM)

0.0

.2

.4

.6

.8

1.0

1.2

1.4

1.6

carbon-free

carbon-rich

Addition of NaHCO

3

(0.5 M)

reaction time (h)

Simultaneous H2 Production with Carbon Storage by Enhanced Olivine Weathering in Laboratory-scale: An Investigation of CO2 Effect

85

increased sharply to 1.45 mmol/L, infers the retarded

carbonation process.

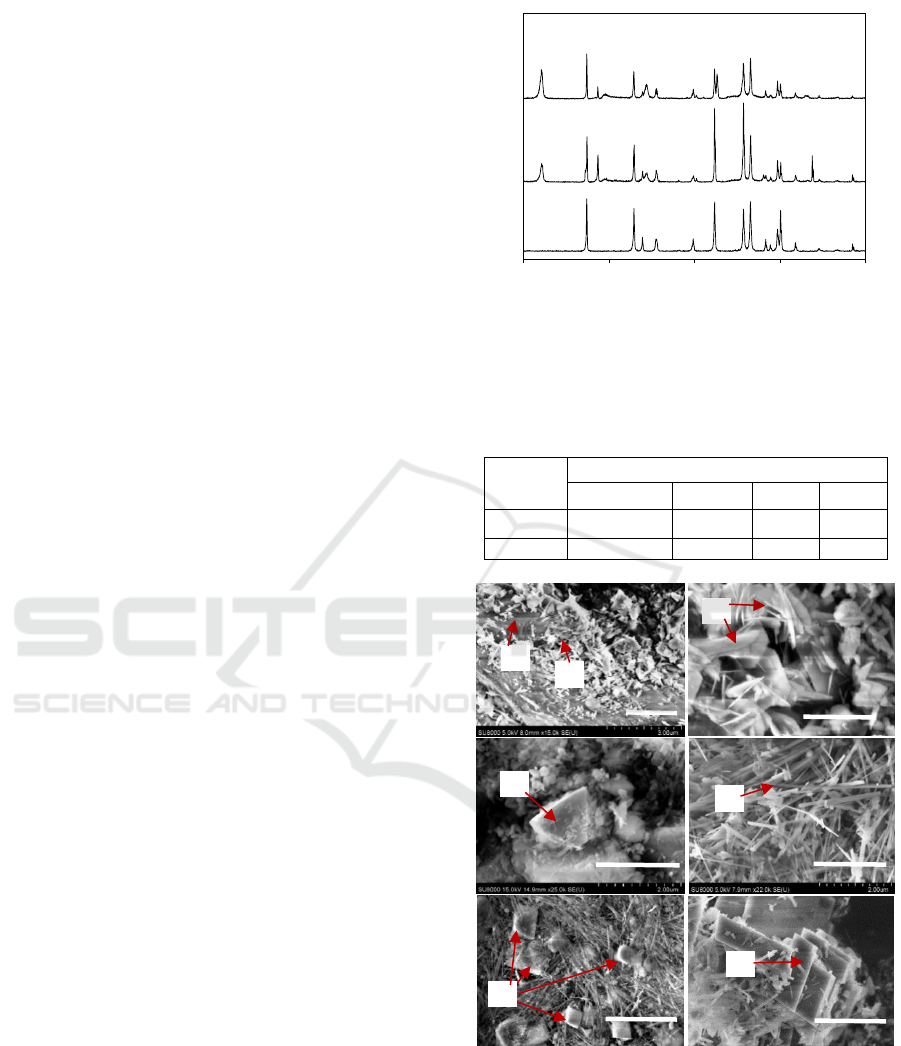

3.3 Mineral Changes

Solid after reactions were analysed using XRD to

identify mineral compositions. The results are shown

in Figure 4. The main mineral products before carbon

injection are serpentine, brucite and magnetite

(Fe

3

O

4

). Evident serpentine peaks were observed at

12.2°, 19.4° and 24.5° after 72 h reaction in CO

2

-free

condition. It infers serpentinization was the main

process for olivine weathering at this stage. Peaks at

18.8

o

and 38.1

o

are referred to brucite (Schaef et al.,

2011). Magnetite peak was found at 30.2

o

. No

magnesite peak was detected. After creating a CO

2

-

rich condition in the reactor and continuing the

reaction for another 72 h, stronger serpentine peaks

were observed from the solid sample. It indicates the

promoted serpentine generation. The peak occurred

around 32.8

o

belongs to magnesite (Rahmani et al.,

2016), which indicates the carbonation process. In

addition, brucite content was severely decreased with

much smaller brucite peaks be observed.

SEM imaging has revealed a clear evolution of

morphology of crystal face during olivine weathering

process. The dominant serpentine polymorph found is

chrysotile. Before the CO

2

addition, chrysotile fibers

have a diameter of 10-100 nm and are less than 1 μm

in length (Figure 5(a)). Brucite and few magnetites

were generated with several μm in size (Figure 5(b,

c)). After reacting in CO

2

-rich condition for another

72 h, serpentine fibrous became longer with more

than 2 μm in length (Figure 5(d)). Brucite was hardly

observed. Brucite potentially incorporates Fe(II). The

addition of NaHCO

3

in present study promoted

Fe(II)-bearing brucite dissolution, thus enhanced

Fe(II) being released, which potentially accelerated

H

2

generation. More magnetite particles were

observed according to SEM imaging (Figure 5(e)).

However, the changes in mineral yield cannot be

determined, since the observed area using SEM

observations is very limited. Magnetite is the

secondary mineral contains Fe(III), the formation of

magnetite infers the oxidation of Fe(II). In addition,

magnetite is a well-studied catalyst for CO

2

reduction, which particular catalyzes CH

4

generation.

However, in the present study, CH

4

yield was low, the

reason still needs to be explored. Magnesite, the main

products of CO

2

mineralization, was generated after

NaHCO

3

addition, as to be shown in Figure 5(f) with

rhomb shape.

Figure 4: XRD patterns of olivine, olivine after 72 h

reaction in CO

2

-free condition (O72) and after an additional

72 h reaction in CO

2

-rich condition (O72-C72). O: olivine,

S: serpentine, B: brucite, M: magnesite, Mt: magnetite.

Table 1: TGA results of mineral compositions.

Sample

Product amount (wt.%) from TGA

Serpentine

Magnesite

Brucite

Olivine

O72

12.65

0.00

0.45

86.76

O72-C72

31.05

4.07

0.00

64.33

Figure 5: SEM images of minerals after reacting for 72 h (a,

b, c) and 144 h (d, e, f). O: olivine, S: serpentine, B: brucite,

Mt: magnetite, M: magnesite.

To quantify the mineral compositions after

reactions, TGA was used. The calculated results are

shown in Table 1. The weight percent of serpentine

generated in the CO

2

-free condition in 72 h is 12.65

wt.%. After reacting in CO

2

-rich condition for

2 theta (

o

)

10 20 30 40 50

Intensity (a.u.)

O72

O

O

S

O

B

M

O72-C72

S

O

B

O

O

O

S

O

O

O

S

O

Mt

O

Mt

O

O

B

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Olivine

O

(a)

(c)

(d)

(e)

2 μm

2 µm

5 μm

5 μm

O

B

Mt

M

S

(b)

(f)

Mt

S

2 μm

2 μm

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

86

another 72 h, serpentine composition increased by

18.40 wt.%. It indicates serpentinization process was

slightly promoted in the presence of CO

2

. Magnesite

was generated in the second stage of the experiment

with CO

2

. The yield was 4.07 wt.% of solid collected

after 72 h reaction, equivalent to trapping of 0.52 mol

of CO

2

per kg of olivine. Brucite was consumed after

CO

2

addition as no weight loss belongs to brucite was

detected in the O72-C72 solid sample.

4 CONCLUSIONS

The present study traced the changes in H

2

yield, fluid

chemistry and minerals after CO

2

addition as a

function of time. H

2

generation was continuing at the

CO

2

-free and CO

2

-rich condition. The production rate

was increased slightly after the addition of NaHCO

3

.

Olivine and brucite dissolution were accelerated in

CO

2

-rich condition, which may be attributed to pH

decrease caused by NaHCO

3

addition. The

dissolution of Fe(II)-contained brucite contributed

Fe(II) releasing, thus promoted H

2

production. Our

experiment results suggest simultaneous energy

production and CO

2

storage can be realized when

using CO

2

-rich hydrothermal condition in olivine

weathering process.

ACKNOWLEDGEMENTS

The authors thank Kawabe Yoshishige in AIST

(Japan) for helping ICP-AES analysis. The authors

also thank reviewers who gave helpful suggestions.

This work was supported by JSPS KAKENHI Grant

Number JP18J12695.

REFERENCES

Berndt, M., Allen, D. and Seyfried, W., 1996. Reduction of

CO

2

during serpentinization of olivine at 300 °C and

500 bar. Geology, 24(4), pp.351-354.

Gadikota, G., Matter, J., Kelemen, P. and Park, A., 2014.

Chemical and morphological changes during olivine

carbonation for CO

2

storage in the presence of NaCl

and NaHCO

3

. Physical Chemistry Chemical Physics,

16(10), pp.4679.

Gerdemann, S., O'Connor, W., Dahlin, D., Penner, L. and

Rush, H., 2007. Ex Situ Aqueous Mineral Carbonation.

Environmental Science & Technology, 41(7), pp. 2587-

2593.

Harrison, A., Power, I. and Dipple, G., 2012. Accelerated

Carbonation of Brucite in Mine Tailings for Carbon

Sequestration. Environmental Science & Technology,

47(1), pp. 126-134.

Kelley, D., 1996. Methane-rich fluids in the oceanic crust.

Journal of Geophysical Research: Solid Earth,

101(B2), pp. 2943-2962.

Klein, F. and McCollom, T., 2013. From serpentinization

to carbonation: New insights from a CO

2

injection

experiment. Earth and Planetary Science Letters, 379,

pp. 137-145.

Klein, F., Bach, W., Jöns, N., McCollom, T., Moskowitz, B.

and Berquó, T., 2009. Iron partitioning and hydrogen

generation during serpentinization of abyssal

peridotites from 15

o

N on the Mid-Atlantic Ridge.

Geochimica et Cosmochimica Acta, 73, pp. 6868-6893.

Kularatne, K., Sissmann, O., Kohler, E., Chardin, M.,

Noirez, S. and Martinez, I., 2018. Simultaneous ex-situ

CO

2

mineral sequestration and hydrogen production

from olivine-bearing mine tailings. Applied

Geochemistry, 95, pp. 195-205.

Lollar, B., Lacrampe-Couloume, G., Voglesonger, K.,

Onstott, T., Pratt, L. and Slater, G., 2008. Isotopic

signatures of CH

4

and higher hydrocarbon gases from

Precambrian Shield sites: A model for abiogenic

polymerization of hydrocarbons. Geochimica et

Cosmochimica Acta, 72(19), pp. 4778-4795.

Malvoisin, B., Brunet, F., Carlut, J., Montes-Hernandez, G.,

Findling, N., Lanson, M., Vidal, O., Bottero, J. and

Goffé, B., 2013. High-purity hydrogen gas from the

reaction between BOF steel slag and water in the 473–

673 K range. International Journal of Hydrogen

Energy, 38(18), pp. 7382-7393.

Matter, J. and Kelemen, P., 2009. Permanent storage of

carbon dioxide in geological reservoirs by mineral

carbonation. Nature Geoscience, 2(12), pp. 837-841.

McCollom, T. and Seewald, J., 2001. A reassessment of the

potential for reduction of dissolved CO

2

to

hydrocarbons during serpentinization of olivine.

Geochimica et Cosmochimica Acta, 65(21), pp. 3769-

3778.

NOAA, 2016. Trends in Atmospheric Carbon Dioxide.

Rahmani, O., Highfield, J., Junin, R., Tyrer, M. and Pour,

A.B., 2016. Experimental Investigation and Simplistic

Geochemical Modeling of CO

2

Mineral Carbonation

Using the Mount Tawai Peridotite. Molecules, 21(353).

Schaef, H.T., Windisch Jr., C.F., McGrail, B.P., Martin,

P.F., and Rosso, K.M., 2011. Brucite [Mg(OH

2

)]

carbonation in wet supercritical CO

2

: An in situ high

pressure X-ray diffraction study. Geochimica et

Cosmochimica Acta, 75, pp. 7458-7471.

Simultaneous H2 Production with Carbon Storage by Enhanced Olivine Weathering in Laboratory-scale: An Investigation of CO2 Effect

87