Microscopic Analysis of Iron and Steel Slag Used as a Source of

Cationic Precipitation Agents in Water Treatment

Rafael Schouwenaars

1*

and Rosa María Ramírez Zamora

2

1

Facultad de Ingeniería, Departamento de Materiales y Manufactura

Universidad Nacional Autónoma de México, Coyocacán, 04510, México

2

Instituto de Ingeniería, Coordinación de Ingeniería Ambiental,

Universidad Nacional Autónoma de México (UNAM), Mexico.

Keywords: Waste valorisation, Slag, Water Treatment, Petrographic Microscopy, Scanning Electron Microscopy.

Abstract: Iron and steel slag represent a high-volume solid waste material from heavy industry. Despite several

applications in the construction industry, most slag is still deposited in landfills, where it represents an

increasing environmental nuisance. Over the last decade, it has been shown that many slags can be used for

environmental remediation, particularly in the treatment of contaminated water resources, where the waste

product can substitute for expensive high-speciality reagents. This is important in reducing the cost of water

treatment. Most authors describe the action of the slag as adsorption; recently, strong evidence has been

presented that they act as a source of ions, which promote precipitation. Considering the complex composition

and mineralogy of slags and large variety of slags produced in the iron and steel industry, precise

identification of candidate materials for specific applications is a challenge. This brief paper will summarise

some applications and show how optical and electron microscopy serve as a tool to identify active

components in the product and help elucidating the contaminant removal mechanisms.

1 INTRODUCTION

Slags are a by-product of extractive metallurgy and

originate from the molten mixture of gang materials,

fluxes and additives used to control the composition

of the melt and purity of the metal. Depending on

cooling velocity, slags will form aggregates or

powders, with amorphous to fine-crystalline

structures. Each metallurgical process will produce

its own specific type of slag. In iron and steel

industry, the most important sources of slag are the

blast furnace (BF) process, the basic oxygen furnace

(BOF), electric arc furnace (EAF) and electric

induction furnace (EIF).

The high CaO content of BOF slag makes it a

valuable resource as a substitute for Portland cement

and increases the resistance of concrete in aggressive

environments. Precise control of cooling speed and

granulometry is required to achieve these results

(Kourounis et al., 2007; Piatak et al., 2015). Other

slags present less useful properties but can be used as

an aggregate in cement and concrete (Maslehuddin et

al., 2003; Qasrawi et al., 2009; Abu-Eishah et al.,

2012). As these uses are economically less attractive,

such products are often disposed of in landfills.

More recently, the use of slag as a resource for

environmental applications has attracted attention.

The use of BOF-slag for the elimination of

phosphorus from agro-industrial wastewater and

wetland remediation was reviewed by (Vohla et al.,

2011;Chazarenc et al., 2008;Barca et al., 2012). A

review on the use of slag in water treatment was

provided by (Mercado-Borrayo et al., 2018 a).

In earlier work, the authors have analysed the

removal of As (III) and (V) with BOF slag

(Schouwenaars et al., 2017), the removal of As and B

by EAF slag (Mercado-Borrayo et al., 2018b) and the

removal of heavy metals by EIF slag

(Mercado-Borrayo et al., 2018c). These papers show

that very high removal efficiencies can be achieved

through process optimisation. It is often assumed that

removal occurs by adsorption. However, the

literature provides clear indications that selective

leaching of cations from the slag and re-precipitation

with the contaminant ions or formation of silicates

(Dimitrova and Mehanjiev, 2000) is responsible for

contaminant removal, as exemplified in Figure 1.

Schouwenaars, R. and Zamora, R.

Microscopic Analysis of Iron and Steel Slag Used as a Source of Cationic Precipitation Agents in Water Treatment.

DOI: 10.5220/0008189102970300

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 297-300

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

297

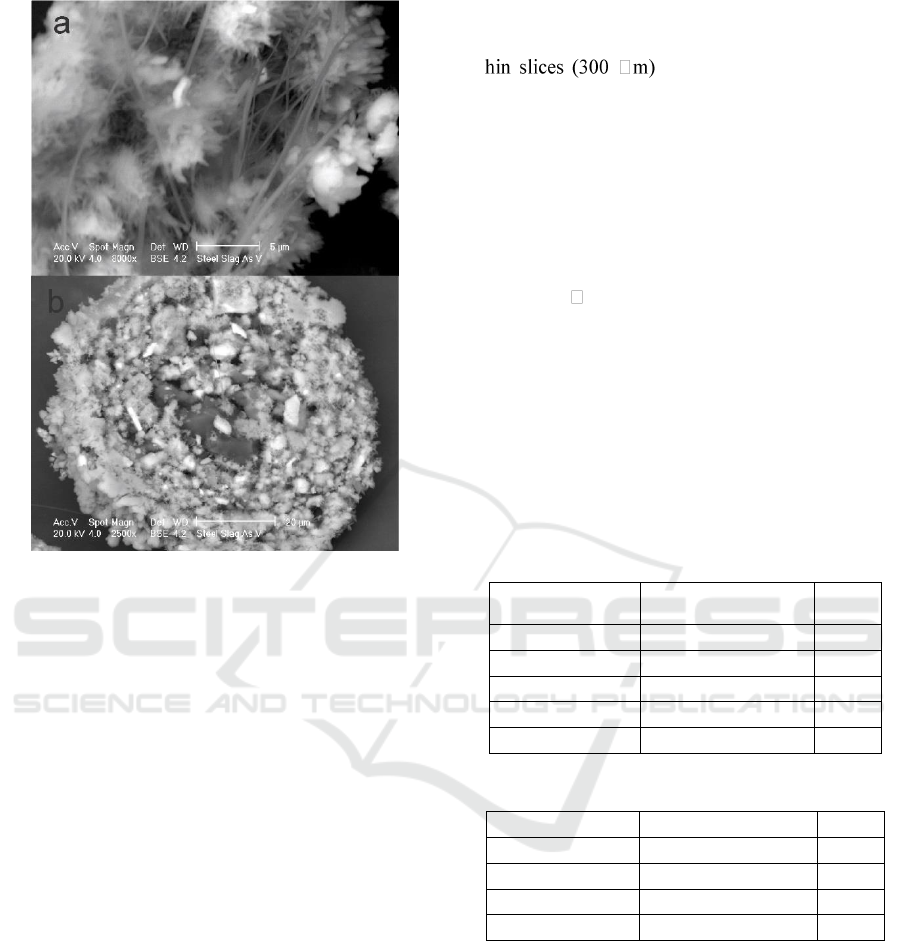

Figure 1: Precipitates formed during treatment of water

contaminated with As (V). a) supernatant formed during

the process. b) precipiation on a slag particle. The

experimental conditions are described by (Schouwenaars et

al., 2017).

Generally, the study of a removal process consists

of the determination of reaction isotherms and/or

kinetics, combined with the characterisation of the

slag by XRD, XRF and SEM. XRF only provides an

approximate quantification of the main elements in

the product. XRD allows for the determination of

crystalline species but cannot detect minority

components or amorphous phases and is

semi-quantitative at best. The benefits and limitations

of SEM, are summarised in the standard work by

(Goldstein et al., 2017). High spatial resolution can

be achieved in combination with localised chemical

analysis by EDX. However, the latter is only

semi-quantitative and spatial resolution is limited by

the electron beam-sample interaction volume, which

is often larger than the size of the individual phases in

a slag material. Specific surface area is determined by

means of physical adsorption of N

2

. A broad

spectrum of characterisation methods was used by

(Mercado-Borrayo et al., 2013). The present work

will not explore new applications for slag in water

treatment but will explore petrographic microscopy

(Nesse, 2009) as an additional tool for slag

characterisation.

2 EXPERIMENTS

T of slag were observed using

polarised light optical microscopy (OM) in reflection

and transmission with a Zeiss AxioImager POL.

Results are presented for an EAF and a BOF slag,

which were described in earlier publications

(Schouwenaars et al., 2017, Mercado Borrayo et al.,

2013, Mercado-Borrayo et al., 2018b).

XRD measurements were performed on an

Empyrean X-ray diffractometer with a Ni filter and

fine focus tube using Cu Kα radiation at a step of 0.05

°/min in a 2 -range of 20 to 90°. Crystalline phases

were identified using the Powder Diffraction File and

the Rietveld method with Fullprof 2000.

3 RESULTS AND DISCUSSION

Table 1 presents the mineral composition, as

determined by XRD, is given in Table 1 for the BOF

and in Table 2 for the EAF.

Table 1: Mineral composition of BOF slag (XRD).

Mineral name

composition

Wt.

%

Brucite

Mg(OH)

2

38.1

Portlandite

Ca(OH)

2

29.9

Ca-Fe oxide

CaFe

2

O

4

12.9

Ca

3

AlFe(SiO

4

)(OH)

8

12.5

Hydrated Larnite

Ca

2

SiO

4

*H

2

O

6.6

Table 2: Mineral composition of EAF slag (XRD).

Mineral name

composition

Wt. %

Wüstite

FeO

54.9

Brucite

Mg(OH)

2

31.3

Merwinite

Ca

3

Mg(SiO4)

2

9.2

Ghelenite

Ca

2

Al

2

SiO

7

4.7

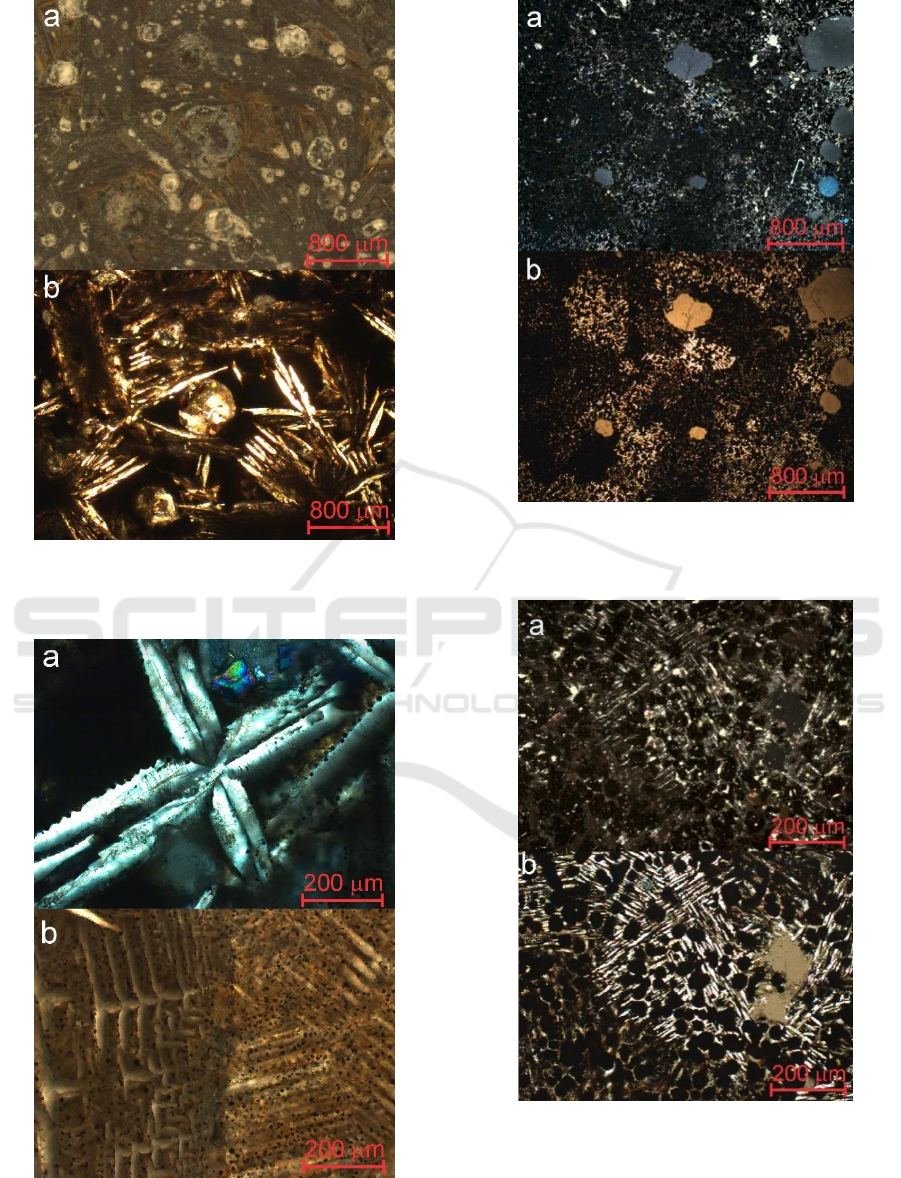

Figure 2 is a low-magnification image of the BOF

slag. Using reflected light, two types of globular

inclusions are seen. Silicate phases are transparent

and appear dark; reflecting particles are probably

CaFe

2

O

4

, which has a cubic (optically isotropic) spinel

structure. In transmitted light, needle-like structures

predominate. The elongated twinned needles are

brucite (Figure 2a). The darker zones in Figure 2b

correspond to portlandite, shown in detail in Figure

3b.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

298

Figure 2: Low-magniifcation images of BOF-slag. a) is the

reflected light image, b) corresponds to transmitted light,

both under crossed polarisers.

Figure 3: Detailed images of the main minerals in the

BOF-slag. a) represents brucite, b) is portlandite

(transmitted light, crossed polarisers).

Figure 4: Low-magnifcation images of EAF-slag. a) is the

reflected light image, b) corresponds to transmitted light,

both under crossed polarisers.

Figure 5: Details of the EAF-slag. a) is the reflected light

image. b) transmitted light, brucite shows up bright. Both

under crossed polarisers.

Figure 4 shows the microstructure of the

EAF-slag. Some strongly reflecting, highly

Microscopic Analysis of Iron and Steel Slag Used as a Source of Cationic Precipitation Agents in Water Treatment

299

anisotropic grains which were not detected by XRF

are probably sulphides. Spherical particles which

appear dark in both transmitted and reflected light

correspond to wüstite. Brucite forms the fine eutectic

structure, probably with wüstite needles.

Structures like the ones in Figure 3b and 5 are too

fine to be analised correctly by EDX in SEM. Also,

different phases will only show grey tone contrast in

SEM. XRD cannot detect phases which are present in

small amounts, nor amorphous components, which

are readily identified in OM. As EDX cannot quantify

oxygen, discrimination between different metal

oxides and hydroxides is often not possible, while it

is fairly straightforward in a petrographic

microscope.

For the present materials, the limited resolution of

OM poses no problem. One drawback is that most

reference works on OM refer to geological materials.

Reference to man-made waste materials is not

available. Additional SEM/EDX analysis of the thin

slices may help to solve this limitation in future work.

4 CONCLUSIONS

Selection of slag materials for specific applications of

environmental engineering requires the identification

of potentially active components. Petrographic

microscopy is a classical tool used by geologists to

elucidate the mineralogical composition of rocks but

is rarely used outside this speciality and has been

partially substituted by SEM. Here it was shown that

it provides valuable details on the microstructure and

phase distribution in slags, especially when combined

with SEM, EDX and XRD. The technique has proven

particularly useful in the analysis of the oxides and

hydroxides of Fe, Mg and Ca, which play a

fundamental role in contaminant removal.

ACKNOWLEDGEMENTS

This work was sponsored by DGAPA project IV100616.

REFERENCES

Abu-Eishah, S.I., El-Dieb, A.S., Bedir, M.S., 2002.

Performance of concrete mixtures made with electric

arc furnace (EAF) steel slag aggregate produced in the

Arabian Gulf region. Constr. Build. Mater, 34, 249.

Barca, C., Troesch, S., Meyer, D., Drissen, P., Andres, Y.,

Chazarenc, F., 2012. Steel slag filters to upgrade

phosphorus removal in constructed wetlands: two years

of field experiments. Environm. sci. tech., 47, 549.

Chazarenc, F., Kacem, M., Gerente, C., Andres, Y., 2008.

Active filters: a mini-review on the use of industrial

by-products for upgrading phosphorus removal from

treatment wetlands. In Proc. 11th Internat. Conf.

Wetland Systems for Water Pollution Control. IWA.

Dimitrova S.V., Mehanjiev D.R., 2000. Interaction of

blast-furnace slag with heavy metal ions in water

solutions. Water Res. 34, 1957.

Goldstein, J.I., Newbury, D.E., Michael, J.R., Ritchie,

N.W., Scott, J.H.J., Joy, D.C. 2017. Scanning electron

microscopy and X-ray microanalysis. Springer.

Kourounis, S. Tsivilis, S. Tsakiridis P.E., Papadimitriou G.

D., Tsibouki Z., 2007. Properties and hydration of

blended cements with steelmaking slag. Cement Concr.

Res. 37 815.

Maslehuddin, M., Sharif, A.M., Shameem, M., Ibrahim,

M., Barry, M.S., 2003. Comparison of properties of

steel slag and crushed limestone aggregate

concretes. Constr. Build. Mater., 17, 105.

Mercado-Borrayo, B.M., Schouwenaars, R.,

González-Chávez, J.L., Ramírez-Zamora, R.M., 2013.

Multi-analytical assessment of iron and steel slag to

estimate the removal of metalloids from contaminated

water. J. Environm. Sci. Health, A, 48, 887.

Mercado-Borrayo, B.M., González-Chávez, J.L.,

Ramírez-Zamora, R.M., Schouwenaars, R., 2018a.

Valorisation of Metallurgical Slag for the Treatment of

Water Pollution: An Emerging Technology for

Resource Conservation and Re-utilization. J. Sust.

Metall., 4, 50.

Mercado-Borrayo, B.M., Solís-López, M., Schouwenaars,

R., Ramírez-Zamora, R.M., 2018b. Application of

metallurgical slag to treat geothermal wastewater with

high concentrations of arsenic and boron. Int. J.

Environm. Sci. Tech., 1.

Mercado-Borrayo, B.M., Contreras, R., Sánchez, A., Font,

X., Schouwenaars, R., Ramírez-Zamora, R.M., 2018c.

Optimisation of the removal conditions for heavy

metals from water: A comparison between steel furnace

slag and CeO2 nanoparticles. Arabian J. Chem.

Nesse, W.D., 2009. Introduction to Optical Mineralogy.

Oxford university press.

Piatak, N.M., Parsons, M.B., Seal R.R., 2015.

Characteristics and environmental aspects of slag: A

review. App. Geochem. 57 236.

Qasrawi, H., Shalabi, F., Asi, I., 2009. Use of low CaO

unprocessed steel slag in concrete as fine

aggregate. Constr. Build. Mater., 23, 1118.

Schouwenaars, R., Montoya-Bautista, C.V., Isaacs-Páez,

E.D., Solís-López, M., Ramírez-Zamora, R.M., 2017.

Removal of arsenic III and V from laboratory solutions

and contaminated groundwater by metallurgical slag

through anion-induced precipitation. Environm. Sci.

pollut. res. 24, 25034.

Vohla, C., Kõiv, M., Bavor, H. J., Chazarenc, F., Mander,

Ü., 2011. Filter materials for phosphorus removal from

wastewater in treatment wetlands—A review. Ecol.l

Eng., 37, 70.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

300