Selective Separation of Cu (II) and Cd (II) from Aqueous Solution by

Shear Induced Dissociation and Ultrafiltration Using Rotating Disk

Membrane

Shuyun Tang and Yunren Qiu

*

School of Chemistry and Chemical Engineering, Central South University, Changsha 410083, China

Keywords: Complexation-ultrafiltration, Rotating disk membrane, Shear induced dissociation, Dynamic filtration,

Selective separation, Regeneration.

Abstract: Selective separation of Cu (II) and Cd (II) from aqueous solution by shear induced dissociation and

ultrafiltration have been investigated using rotating disk membrane (RDM) and polyacrylic acid sodium

(PAAS) as complexing agent. The shear rate distribution on the membrane surface has been calculated at a

certain rotating speed. The polymer-metal complex can dissociate when the shear rate exceeds the critical

shear rate (γ

c

), the smallest shear rate at which the polymer-metal complex starts to dissociate. The

difference of the critical shear rates of the polymer-metal complexes can be used to separate different metal

ions from aqueous solution. The critical shear rate of PAA-Cd complex (γ

c,Cd

) is greater than that of PAA-

Cu complex (γ

c,Cu

) at pH 6.0. Cu (II) and Cd (II) can be separated when shear rate is greater than 8.0×10

4

s

-1

at pH 6, P/M 27.5. Moreover, the regeneration of PAAS has been also finished at γ>1.31×10

5

s

-1

. Compared

with the acidification, shear induced dissociation, is a novel and green technology for recovery of heavy

metal ions and polymer from aqueous solutions without the consumption of acid and alkali.

1 INTRODUCTION

Electroplating wastewater streams contain much Cu

(II) and Cd (II), which are harmful to human (Manis,

et al., 2013). Complexation-ultrafiltration is

an excellent way to remove heavy metals due to its

high efficiency and no secondary pollution (Qiu and

Mao, 2013). It is necessary to separate various heavy

metal ions in the treatment of wastewater for the

recovery of metal ions.

The inorganic acids are used to acidify the

complexes solution and then diafiltration

experiments is performed to recover polymer and

heavy metal in conventional acidification

decomplexation method (Shao, et al., 2013), but it is

easy to cause secondary pollution due to the use of

the chemicals of acid and alkali, and is not

convenient for the recovery of heavy metals.

In our previous work, polyacrylic acid sodium

(PAAS) is applied to remove various heavy metal

ions from aqueous solutions by complexation-

ultrafiltration using rotating disk membrane (RDM).

RDM filtration consists in creating the shear rate on

the membrane surface by a relative motion between

the fixed membrane and a disk rotating (Jaffrin,

2008). The stabilities of polymer-metal complexes in

the shear field have been studied and the results

show that the polymer-metal complexes can

dissociate when the shear rate is higher than the

critical shear rate γ

c

, the smallest shear rate

at which

the polymer-metal complex starts to dissociate (Gao

et al., 2018; Chen and Qiu, 2018; Tang and Qiu,

2018). In this work, shear induced dissociation and

ultrafiltration, is applied to separate Cu (II) and Cd

(II) and regenerate PAAS from the mixed aqueous

solution, which is novel and green technology

without the consumption of acid and alkali.

2 EXPERIMENTAL

2.1 Chemicals, Membrane and Set-up

PAAS with average molecular weight 250 kDa was

purchased from Wako Pure Chemical Industries,

Japan. The PAAS solutions were pretreated by

diafiltration to remove small molecular weight

PAAS. Cadmium nitrate tetrahydrate and copper

Tang, S. and Qiu, Y.

Selective Separation of Cu (II) and Cd (II) from Aqueous Solution by Shear Induced Dissociation and Ultrafiltration Using Rotating Disk Membrane.

DOI: 10.5220/0008189503190322

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 319-322

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

319

nitrate hydrate were used to prepare the aqueous

solution. Hydrochloric acid and sodium hydroxide

were used to adjust aqueous pH. All solutions in the

experiment were prepared with deionized water.

Polyether sulphone (PES) flat ultrafiltration

membrane with MWCO 10 kDa was supplied by

Shanghai Yuling Filter Equipment Co, Ltd.

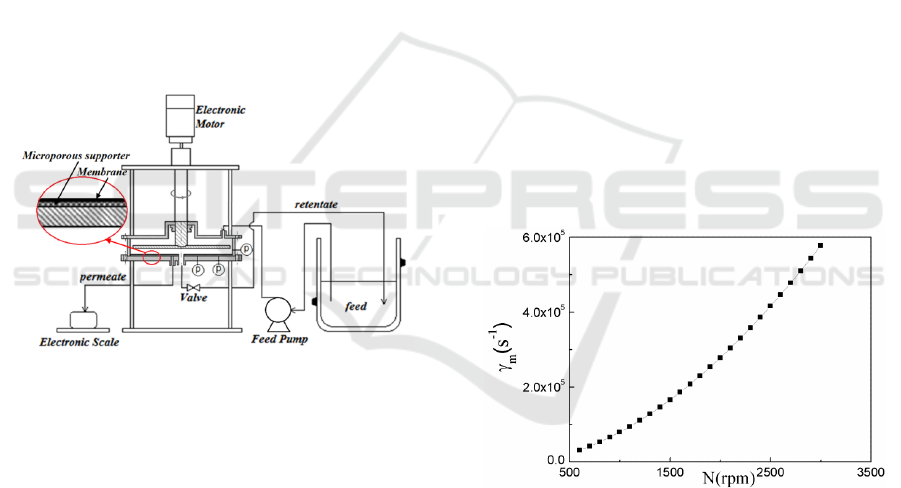

The device consists of a cylindrical housing

containing a metal disk. The rotating shaft which

connects with the motor outside the housing is

located at the centre of feed inlet side of the housing

and can provide the rotating speed of 0~3000 rpm.

The flat PES ultrafiltration membrane is fixed on the

retentate outlet side of the cavity. The depth of

housing is 30 mm, and the inner radius of the

housing is 88 mm which is same as the radius of the

membrane. The detailed structure is shown in Figure

1. The radius of the rotating disk is 80 mm, the

thickness is 4 mm, the six blades are evenly

distributed around the centre of the disk and the

blade height is 2 mm and the distance from the

membrane surface is 14 mm.

Figure 1: Schematic of filtration device.

2.2 Experimental Procedure

The metal ions fully reacted with polymers after two

hours under the specified pH and P/M (mass ratio of

polymer to metal ions) conditions, and then pumped

into the device by peristaltic pump. The

concentrations of metal ions were 10 mg/L.

According to our previous studies (Chen and Qiu,

2018; Tang and Qiu, 2018), the separation efficiency

of Cu (II) and Cd (II) was investigated using 550

mg/L PAAS and pH=6.0 to make heavy metal

completely complexed in a static filtration. At pH

6.0, the critical shear rates of PAA-Cd complex (γ

c,Cd

)

and PAA-Cu complex (γ

c,Cu

) were 8.0×10

4

s

-1

,

1.31×10

5

s

-1

, respectively. The initial operating

pressure of the device was controlled at 10 kPa.

Then, the diafiltration experiments were carried out

at different rotating speeds to separate Cu (II) and

Cd (II) and regenerate PAAS. The concentration of

PAAS was measured with chemical oxygen demand

(COD). The concentration of heavy metal was

measured by atomic absorption spectrophotometry.

All experiments were carried out at 25°C.

3 RESULTS AND DISCUSSION

3.1 The Shear Rate on the Membrane

Surface

The distributions of shear rate on the membrane

surface was explored by the recent research of the

present authors(Tang and Qiu, 2018).

γ

ml

=0.77υ

-0.5

(

kω

)

1.5

r (1)

γ

mt

=0.0296υ

-0.8

(

kω

)

1.8

r

1.6

(2)

where γ

ml

and γ

mt

represent the shear rates at laminar

and turbulent state, respectively (s

-1

). υ is kinematic

viscosity of test fluid (m

2

/s). ω is the angular

velocity of the disk (rad/s). r is the radius (m). The

velocity factor k of the six rectangular blades is

0.79(Chen and Qiu, 2018; Tang and Qiu, 2018).

Figure 2 shows the variation of the shear rate on

the edge of membrane surface with rotating speed.

The shear rate increases with the rotating speed.

Figure 2: Variation of shear rate with rotating speed.

3.2 Effect of Rotating Speed on the

Rejection of Cu (II) and Cd (II)

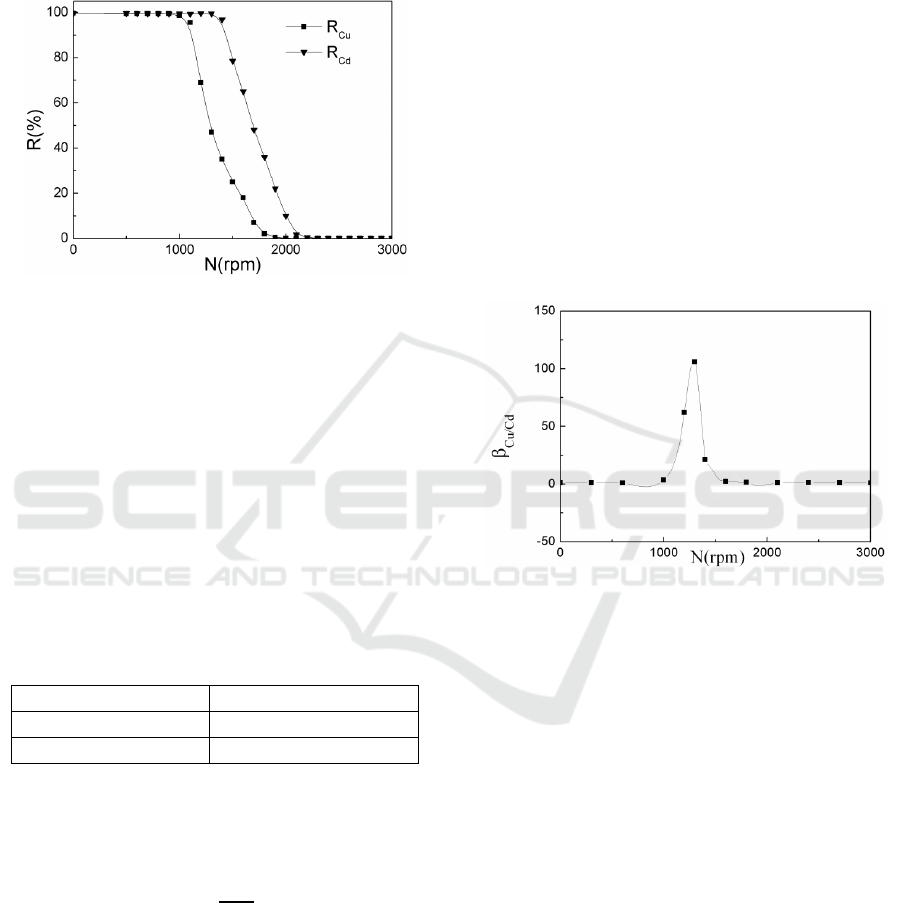

In the previous studies, the rejection of Cu (II) was

99.5% when the rotating speed was lower than 1000

rpm at pH 6.0, P/M=25, and the rejection of Cd (II)

could reach 99.7% when the rotating speed was less

than 1320 rpm at pH 6.0, P/M=30(Chen and Qiu,

2018; Tang and Qiu, 2018). Effect of rotating speed

on the rejection of Cu (II) and Cd (II) was

investigated using 550 mg/L PAAS and pH 6.0 to

make heavy metal ions completely complexed in a

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

320

static filtration. As shown in Figure 3, the R

Cu

remains stable when the rotating speed is lower than

1000 rpm, while the R

Cu

has a sudden drop when the

rotating speed exceeds 1000 rpm. Similar variations

can be found in R

Cd

.

Figure 3: Effect of rotating speed on the rejection of Cu

(II) and Cd (II) (pH 6.0, P/M=27.5).

The critical shear rate of complexes is the

smallest shear rate at which the complex begins to

dissociate and the value is only related to the

geometry of the device at a certain pH. So, the

critical shear rates (γ

c

) of PAA-Cu and PAA-Cd at

pH 6.0 can be calculated by Eqs. (1) and (2), and the

calculation results are shown in Table 1. The critical

shear rate of PAA-Cd is greater than that of PAA-

Cu, indicating that the shear stability of PAA-Cd is

stronger than that of PAA-Cu at pH 6.0. The

experimental results provide support for the

following shear induced separation.

Table 1: The γ

c

of PAA-Cd and PAA-Cu at pH 6.0.

Complex

γ

c

/ s

-1

PAA-Cu complex

8.0×10

4

PAA-Cd complex

1.31×10

5

3.3 Selective Separation Coefficient

The selective separation coefficient(Uludag, et al.,

1998) (β

Cu/Cd

) of the both metals can be defined as:

β

Cu/Cd

=

1-R

Cu

1-R

Cd

(3)

where R

Cu

and R

Cd

are Cu (II) and Cd (II) rejections,

respectively.

β

Cu/Cd

obtained at rotating speed from 0 to 3000

rpm at pH 6.0 is shown in Figure 4. It is clearly seen

that β

Cu/Cd

firstly keeps invariable when the rotating

speed is lower than 1000 rpm, but after this it shows

a remarkable increase followed by a significant

drop. This can be explained as follows: when the

shear rate on the membrane surface is lower than the

critical shear rate of PAA-Cu complex and PAA-Cd

complexe, both of the PAA-Cu complex and PAA-

Cd complex remain stable. When the rotating speed

exceeds 1000 rpm, the shear rate on the membrane

surface is higher than the critical shear rate of PAA-

Cu complex, causing the dissociation of the PAA-Cu

complex and the decrease of R

Cu

, while PAA-Cd

complex remains stable and R

Cd

keeps constant.

Therefore, β

Cu/Cd

shows an enlargement trend. When

the shear rate is higher than the critical shear rate of

PAA-Cd complex, PAA-Cd complex also begins to

dissociate, R

Cd

declines and β

Cu/Cd

also decreases.

Therefore, it may be preferable for selective

separation to choose a suitable rotating speed, such

as 1300 rpm, at which the shear rate is between

8.0×10

4

s

-1

and 1.31×10

5

s

-1

. The greatest selection

separation coefficient can be obtained at 1300 rpm,

as shown in Figure 4.

Figure 4: Effect of rotating speed on selective separation

coefficient β

Cu/Cd

.

3.4 Selective Separation of Cu (II) and

Cd (II) and Regeneration of PAAS

by Shear Induced Dissociation and

ultrafiltration

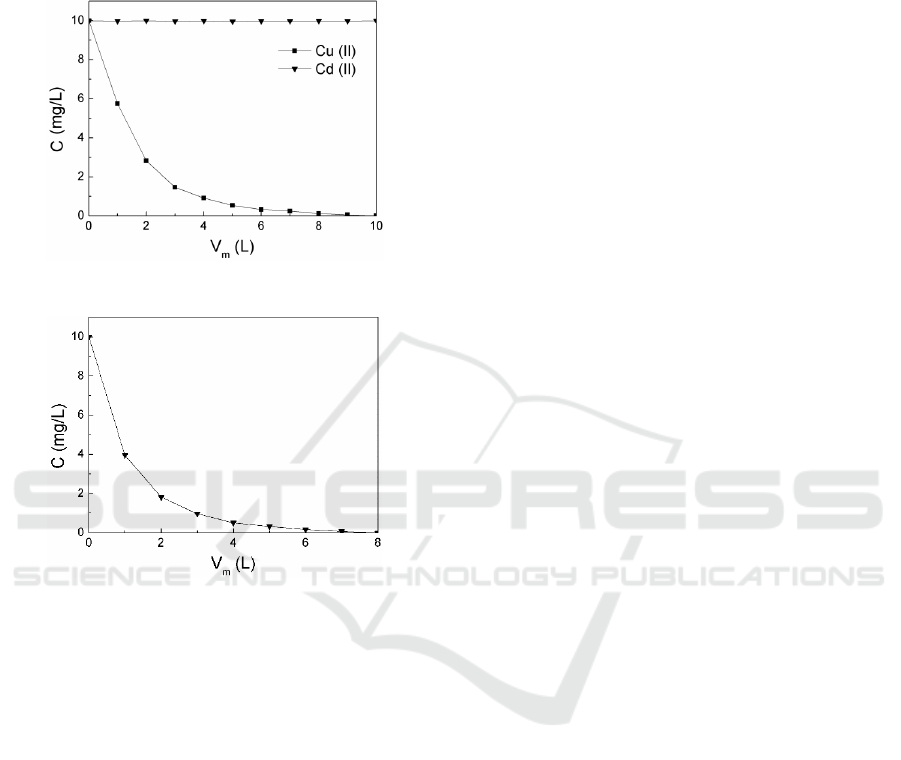

The selective separation and the regeneration

experiments were carried out at pH 6.0 and

P/M=27.5. In rotating disk diafiltration experiments,

an amount of de-ionized water was add to the feed

tank simultaneously and continuously to keep the

volume of the feed remain constant. The rotating

speed was adjusted to 1300 rpm for diafiltration

experiments to separate Cu (II) and Cd (II).

The PAA-Cu complex easily dissociates due to

its smaller critical shear rate, and the free Cu (II)

permeates the membrane into the permeate. Figure 5

is the variation of the concentration of

residual copper (C

Cu

) and the concentration

of cadmium (C

Cd

) in the retentate with the volume

of make-up water (V

m

) at 1300 rpm. It can be seen

that C

Cu

decreases obviously but C

Cd

keeps constant,

Selective Separation of Cu (II) and Cd (II) from Aqueous Solution by Shear Induced Dissociation and Ultrafiltration Using Rotating Disk

Membrane

321

because PAA-Cu complex dissociates and PAA-Cd

complex keeps stable at this rotating speed. When

V

m

increases to10.0 L, the content of residual copper

in the retentate is very little, and the separation of Cu

(II) and Cd (II) is achieved.

Figure 5: Variation of C

Cu

and C

Cd

with V

m

Figure 6: Variation of C

Cd

with V

m

After Cu (II) was removed, the rotating speed

increased to 2000 rpm, PAA-Cd complex would

dissociate and the dissociated Cd (II) was collected

in permeate, the PAAS remained in the retentate, as

shown in Figure 6. The concentration of Cd (II) in

the retentate decreases as the addition of make-up

water, the PAA-Cd complex is completely

dissociated when V

m

reaches 7.0 L, and the PAAS is

regenerated.

4 CONCLUSIONS

Selective separation of Cu (II) and Cd (II) from

aqueous solution by shear induced dissociation and

ultrafiltration have been investigated using rotating

disk membrane and PAAS as complexing agent. At

pH 6, P/M 27.5, the separation of Cu (II) and Cd (II)

has been achieved at 1300 rpm from simulated

aqueous solution, and the regeneration of PAAS has

been finished at 2000 rpm from polymer-metal

complex solution. Compared with acidification,

shear induced dissociation, is a novel and green

technology for recovery of heavy metal ions and

polymer from aqueous solutions without the

consumption of acid and alkali.

ACKNOWLEDGEMENTS

This work was supported by the National Natural

Science Foundation of China (NO. 21476265).

REFERENCES

Chen, L., Qiu,Y., 2018. Removal of Cd (II) from dilute

aqueous solutions by complexation– ultrafiltration

using rotating disk membrane and the shear stability of

PAA–Cd complex. Chinese J. Chem. Eng.

https://doi.org/10.1016/j.cjche.2018.06.026

Gao, J., Qiu, Y., Hou, B., Zhang, Q., Zhang, X., 2018.

Treatment of wastewater containing nickel by

complexation- ultrafiltration using sodium

polyacrylate and the stability of PAA-Ni complex in

the shear field. Chem. Eng. J. 334, 1878–1885.

https://doi.org/10.1016/j.cej.2017.11.087

Jaffrin, M.Y., 2008. Dynamic shear-enhanced membrane

filtration: A review of rotating disks, rotating

membranes and vibrating systems. J. Memb. Sci. 324,

7-25. https://doi.org/10.1016/j.memsci.2008.06.050

Manis, A., Soldenhoff, K., Jusuf, E., Lucien, F., 2003.

Separation of copper from sulfuric acid by

nanofiltration. Fifth Int. Membr. Sci. Technol. Conf.

Qiu, Y. R., Mao, L. J., 2013. Removal of heavy metal ions

from aqueous solution by ultrafiltration assisted with

copolymer of maleic acid and acrylic acid.

Desalination 329, 78–85.

https://doi.org/10.1016/j.desal.2013.09.012

Shao, J., Qin, S., Davidson, J., Li, W., He, Y., Zhou, H.S.,

2013. Recovery of nickel from aqueous solutions by

complexation-ultrafiltration process with sodium

polyacrylate and polyethylenimine. J. Hazard. Mater.

244-245, 472–477.

https://doi.org/10.1016/j.jhazmat.2012.10.070

Tang, S.Y., Qiu, Y. R., 2018. Removal of copper(II) ions

from aqueous solutions by complexation–

ultrafiltration using rotating disk membrane and the

shear stability of PAA–Cu complex. Chem. Eng. Res.

Des. 136, 712–720.

https://doi.org/10.1016/j.cherd.2018.06.030

Uludag, Y., Hilmi, O., Mu, J., 1998. Effect of operating

parameters on selective separation of heavy metals

from binary mixtures via polymer enhanced

ultrafiltration. J. Memb. Sci. 140, 251-266.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

322