Utilization of Lanthanum Carbonate and Bentonite for Phosphorus

Removal from Domestic Sewage Effluent

Yifan Lu, Huawei Wu, Yan Xia and Mei Huang

*

College of Chemical & Biochemical Engineering, Zhejiang University, Zheda Road, Hangzhou, China

Keywords: lanthanum carbonate, bentonite, adsorption, phosphorus removal, domestic sewage effluent

Abstract: lanthanum carbonate and bentonite were used as adsorbents to remove phosphorus from domestic sewage

effluent. Three batch-mode adsorption experiments (using La

2

(CO

3

)

3,

Bentonite/La

2

(CO

3

)

3

and

Bentonite+La

2

(CO

3

)

3

as adsorbents) were carried out to investigate the effect of adsorbents for the removal

of phosphorus. The experimental results show that Bentonite/La

2

(CO

3

)

3

and Bentonite+La

2

(CO

3

)

3

of

320mg/L can reduce phosphate concentration down to 0.06 mg P/L and 0.04 mg P/L from an initial value of

0.609 mg P/L at the contact time of 48 h, respectively.

1 INTRODUCTION

Excess phosphorus (P) in freshwater bodies is one of

the major causes of eutrophication (Zhu et al., 2016).

The regulations for removing phosphate from

water/wastewater treatment applications are

becoming more stringent (Zhao et al., 2014).

Therefore, phosphorus removal from

water/wastewater has attracted considerable research

interest in the last few decades (Zhang et al., 2011).

And a range of methods have been developed,

mainly including biological, chemical, and physical

treatments. Among these methods, the adsorption

process is promising for phosphate removal,

attributed to its attractive advantages of simple

operation, high removal efficiency and fast

adsorption rate, especially at low phosphate

concentration (Mor et al., 2016). Many inorganic

and organic adsorbents as well as industrial by-

products, and biological wastes have been used in

the treatment of phosphorus in water/wastewater.

Lanthanum-based adsorbents are gaining

attention for the adsorption of phosphorus from

water/wastewater in terms of their high affinity for

phosphate and the lanthanum–phosphate complex

forms, even when present in low concentrations of

phosphorus. Various salts of lanthanum, such as

La

2

(SO

4

)

3

, La(NO

3

)

3

, La(OH)

3

and La

2

O

3

, have

attracted intensive research interest in practical

applications (Zhang et al., 2011; Yang et al., 2011;

Zhang et al., 2016). However, some typical

problems still exist which limit the wide application

of these adsorbents. For example, it is found that

most of their adsorption capacity is greatly declined

in neutral and basic conditions. And the incomplete

accessibility of La to phosphate in bulk samples is

considered to be another reason for the reduced

efficiency of La removal. Benefiting from the low

leaching of lanthanum carbonate during phosphate

adsorption, lanthanum carbonate can exhibit much

higher safety and environmental friendly

characteristics. Moreover, the pH buffering of

carbonate salts is helpful for lanthanum carbonate

show the observed small increase in pH value.

Unfortunately, lanthanum carbonate is mainly used

in the treatment of hyperphosphatemia of chronic

kidney disease (Aaseth et al., 2018), very limited

work has been done for dephosphorization agent

outside the medical field.

The object of present paper is to provide

lanthanum carbonate and bentonite for the treatment

of phosphorus in domestic sewage effluent.

Experimental results clearly indicate that the

combined effect of lanthanum carbonate and

bentonite significantly improved the removal

efficiency of phosphorus in domestic sewage

effluent.

Lu, Y., Wu, H., Xia, Y. and Huang, M.

Utilization of Lanthanum Carbonate and Bentonite for Phosphorus Removal from Domestic Sewage Effluent.

DOI: 10.5220/0008189603230326

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 323-326

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

323

2 MATERIALS AND METHODS

2.1 Materials

All the chemicals used in this study were of

analytical grade and were used without further

purification. Lanthanum chloride hexahydrate

(LaCl

3

·6H

2

O) was provided by Desheng New

Material Co., Ltd. (Shandong, China). Sodium

bicarbonate (NaHCO

3

) and Sodium bicarbonate

heptahydrate (MgSO

4

·7H

2

O) were obtained from

Zhanyun Chemical Co., Ltd. (Shanghai, China).

Sodium hydroxide (NaOH) and potassium

dihydrogen phosphate (KH

2

PO

4

), were purchased

from Sinopharm Chemical Reagent Co., Ltd.

(Shanghai, China). Bentonite was supplied by

Zhejiang Fenghong New Material Co. Ltd, Zhejiang,

China.

2.2 Adsorbate Solution

The phosphorus solutions were collected from rural

domestic sewage effluent in Zhuji, Zhejiang

province, China. And the initial total P

concentrations was 0.609 mg P/L.

2.3 X-Ray Diffraction (XRD) Analysis

The prepared lanthanum carbonate was analyzed

using different equipments to reveal their physical

properties. And the crystal structure of the

adsorbents was analyzed using Bruker D8 Advance

diffractometer (X’Pert Powder, PANalytical,

Netherlands) with Cu-Ka radiation (40 kV, 40 mA)

over the 2θ range of 10-60°.

2.4 Preparation of Lanthanum

Carbonate

Lanthanum carbonate was synthesized via

conventional coprecipitation method. The Mg

2+

solution (MgSO

4

) was added into the 0.4M La

3+

solution (LaCl

3

) at room temperature. Then 1.2M

NaHCO

3

was added droplet under stirring and

allowed to react for another 2hr. After the reaction

mixture was stood for additional 1 hours, the mixed

compounds were filtered and subsequently washed

thoroughly with ethanol and deionized water until

the pH of the effluent solution was neutral. Finally,

the washed samples were oven-dried at 65°C for 12h

to obtain the corresponding lanthanum carbonate

adsorbents.

2.5 Batch Experiments

All batch adsorption experiments were performed in

duplicate at room temperature using 25 ml glass

tubes. Various concentrations (20-320 ppm) of

adsorbents were introduced into 25 ml of adsorbate

solution with an initial total P concentration of 0.609

mg P/L and a pH∼7. The mixing of adsorbents and

adsorbate solution was performed by resting there

for specified time. After that, the suspension was

immediately centrifuged for phase separation. The

supernatant was collected through filtration by using

0.45μm syringe filter, and analyzed to determine the

residual P concentration by Mo-Sb anti-

spectrophotometer method using a UV-Vis

spectrophotometer (HACH, DR900, America).

The removal rate (R) of P was calculated from

the following relation:

100

C

)C-C

R

0

e0

(

(1)

In the above equation C

0

represents initial

concentration whereas C

e

as final level of phosphate

(mg P/L) in aqueous solution.

3 RESULTS AND DISCUSSION

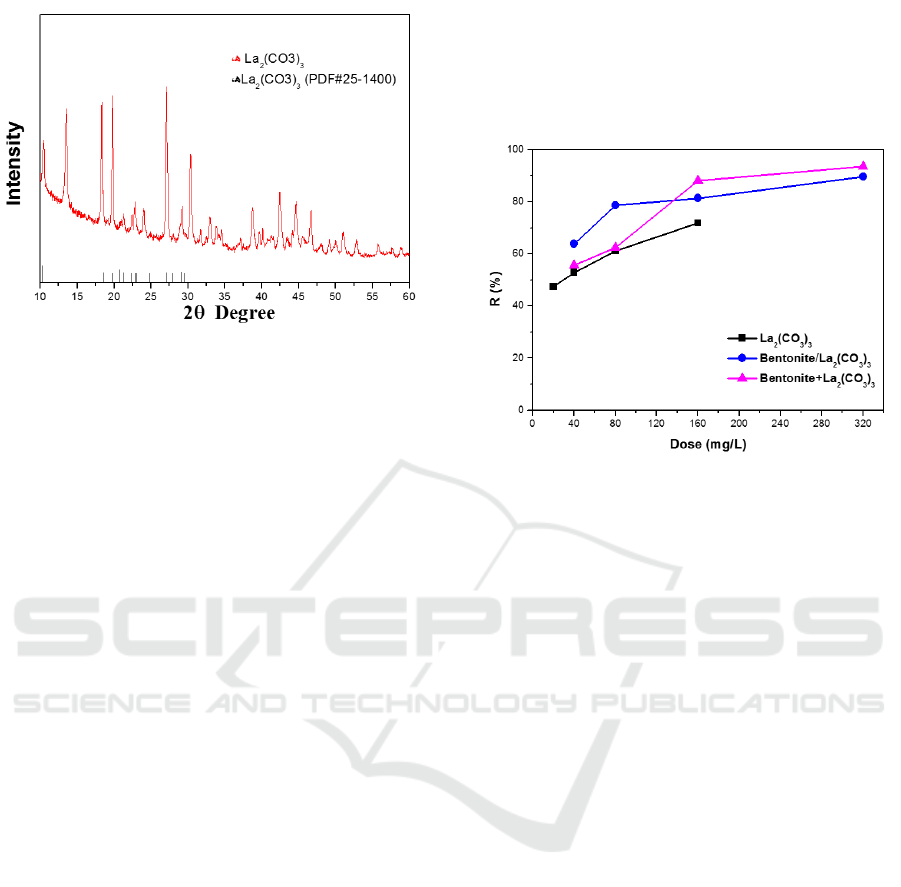

3.1 The X-Ray Diffraction Analysis of

Lanthanum Carbonate Adsorbents

The structure of lanthanum carbonate adsorbents

was confirmed by the XRD analysis. As seen from

Figure 1, the XRD patterns of the as-synthesized

lanthanum carbonate (La

2

(CO

3

)

3

) are typical

structure of lanthanum carbonate with sharp peak at

10.27° corresponding to the (002) plane, which are

highly crystalline structure of La

2

(CO

3

)

3

·8H

2

O (PDF

#25-1400), and broad peaks located at 18.51°,

20.79°, 21.24°, 27.08°, 29.06°, corresponding to the

crystal surfaces of La

2

(CO

3

)

3

·8H

2

O (020), (004),

(022), (220) and (222) planes.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

324

Figure 1: X-ray diffraction analysis of lanthanum

carbonate.

3.2 Adsorption Experiments

Adsorption experiments were conducted using the

synthesized adsorbents to evaluate their affinity

towards phosphorus. In batch experiments, they

were classified into three main categories: batch

experiments I using only lanthanum carbonate as

adsorbent, denoted as La

2

(CO

3

)

3

; batch experiments

II using the mixture of lanthanum carbonate and

bentonite as adsorbent which is Bentonite/

La

2

(CO

3

)

3

; and batch III are batch experiments

which add bentonite first, then followed by

La

2

(CO

3

)

3

, denoted as Bentonite+La

2

(CO

3

)

3

. Their

results for phosphorus removal are shown in Figure

2. It can be seen that as the adsorbents dose

increases, percentage of phosphorus removal

increased in three batch experiments. This might be

due to the increased surface area of the adsorbent

with increased adsorbent dosage. Further, it is

noticed that the maximum removal of phosphorus,

which was achieved using Bentonite/La

2

(CO

3

)

3

or

Bentonite+La

2

(CO

3

)

3

as adsorbents, are 89.6% and

93.6%, respectively. These high phosphorus removal

rates indicate that addition of bentonite can promote

the adsorption of phosphate because of the more

positive charges on the adsorbents. In this way, after

phosphorus component being efficiently adsorbed by

nano-prepared lanthanum carbonate particles, effect

of flocculation by bentonite on nano-products made

the continued separation process efficient and

complete. Then, the improved phosphorus removal

can be obtained from domestic sewage effluent.

Meanwhile, it is found that feeding method also

affects the results of phosphorus removal. As

compare to batch experiments II using the mixture

of lanthanum carbonate and bentonite as adsorbent,

batch experiments III shows higher phosphorus

removal ability. This might be attributed to the

flocculation pretreatment of bentonite in batch

experiments III. So that lanthanum carbonate can

dephosphorize in a cleaner environment and exhibit

better treatment effect.

Figure 2: Effect of different types of adsorbents on

phosphorus removal efficiency.

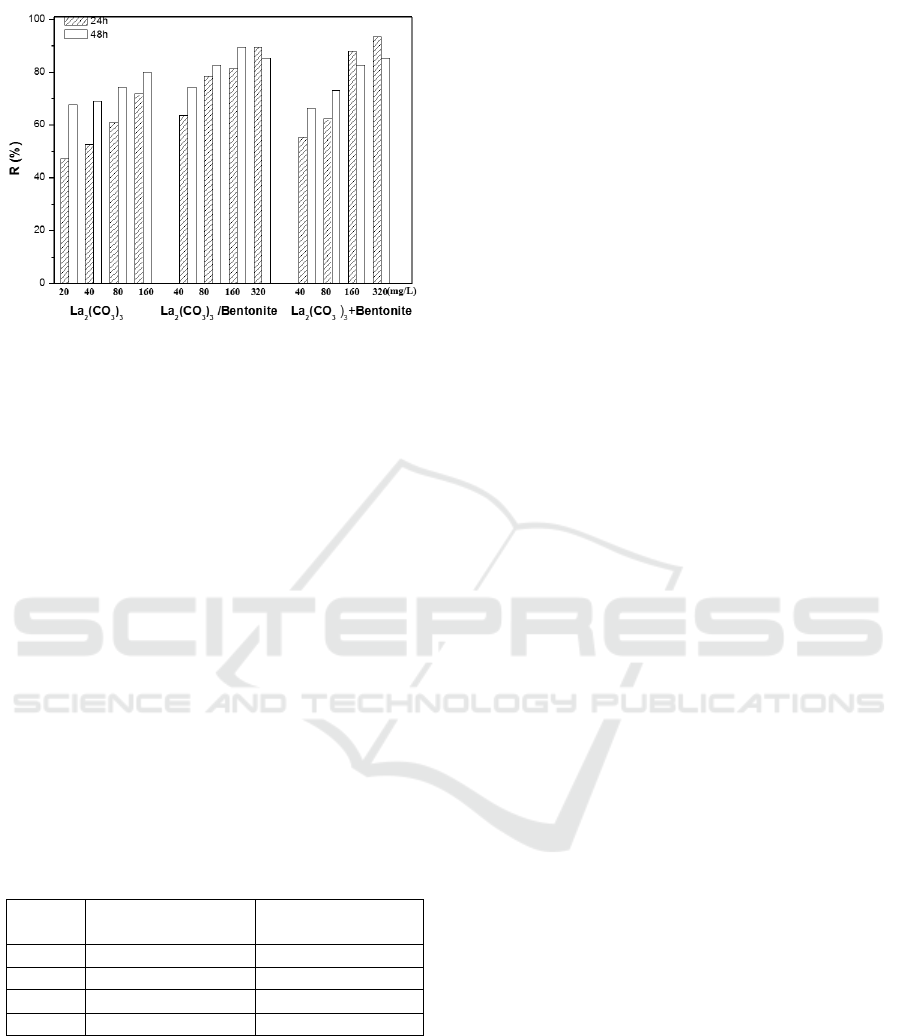

3.3 Effect of Contact Time

In order to investigate the effect of adsorption and

desorption equilibrium on phosphorus treatment,

results of phosphorus removal were investigated at

the contact time of 24hr and 48hr, respectively. It

can be seen in Figure 3 that when using La

2

(CO

3

)

3

alone as the adsorbent, phosphorus removal rates is

positively correlated with the contact time for

different in feed La

2

(CO

3

)

3

concentration. However,

Inconsistent conclusions appeared for the other two

adsorbents, that is, as the initial amount of bentonite

and La

2

(CO

3

)

3

increase, phosphorus removal rate

increases first and then decreases when

Bentonite/La

2

(CO

3

)

3

and Bentonite+ La

2

(CO

3

)

3

were

added into the solution. This phenomena indicates

spontaneous nature of adsorption for phosphorus

removal. When the equilibrium was achieved, no

further increase in phosphorus adsorption was

observed. Furthermore, it seems that phosphorus

removal rate of Bentonite/La

2

(CO

3

)

3

and

Bentonite+La

2

(CO

3

)

3

decreased as the contact time

larger than equilibrium time. This may be due to the

different stability between the two adsorbent

components.

Utilization of Lanthanum Carbonate and Bentonite for Phosphorus Removal from Domestic Sewage Effluent

325

Figure 3: Adsorption of phosphorus with respect to the

contact time.

3.4 Treatment Capacity

The correlation of treatment capacity and

concentration is given in Table 1. It can be seen that

the estimated effluent treatment capacity ranged

1.63-11.36 and 1.63–10.12 mg/g for

Bentonite/La

2

(CO

3

)

3

and Bentonite+La

2

(CO

3

)

3

,

respectively, which clearly indicates their removal

potential for phosphorus treatment. Owing to the

repulsion between the negatively charged PO

4

3−

species and negatively charged surface sites of

bentonite, it is difficult for bentonite itself to adsorb

phosphorus in domestic sewage effluent. Apart from

the samples without bentonite, the best performing

indicated the importance of cooperation between

lanthanum carbonate and bentonite for phosphorus

removal.

Table 1: Phosphorus treatment capacity at different

adsorbents concentration.

Dose

(mg/L)

Bentonite/La

2

(CO

3

)

3

Bentonite+La

2

(CO

3

)

3

40

11.36

10.12

80

6.30

5.58

160

3.41

3.15

320

1.63

1.63

4 CONCLUSIONS

The results of this study indicate that combination of

lanthanum carbonate and bentonite is very good

adsorbents for phosphorus disposal in domestic

sewage effluent. The results obtained for the

phosphorus removal were compared and the findings

showed that Bentonite/La

2

(CO

3

)

3

and

Bentonite+La

2

(CO

3

)

3

have good potential for

removing phosphorus from domestic sewage

effluent as compared to La

2

(CO

3

)

3

. In this work,

89.6% and 93.6% removal of phosphorus were

obtained by using Bentonite/La

2

(CO

3

)

3

and

Bentonite+La

2

(CO

3

)

3

at the dose of 320 mg/L for

48hr in the resting experiment.

ACKNOWLEDGEMENTS

This work was financially supported by National

Science and Technology Major Special Project,

China (2018ZX07208009).

REFERENCES

Aaseth, J., Bjorke-Monsen, A.L., 2018. Lanthanum

Carbonate - A New Phosphate Binding Drug in

Advanced Renal Failure. Curr. Med. Chem.,

25(1),113-117

Mor, S., Chhoden, K., Khaiwal, R., 2016. Application of

agro-waste rice husk ash for the removal of phosphate

from the wastewater. J. Clean. Prod. 129, 673-680.

Yang, J., Zhou, L., Zhao, L., Zhang, H., Yin, J., Wei, G.,

2011. A designed nanoporous material for phosphate

removal with high efficiency. J. Mater. Chem., 21(8),

2489-2494.

Zhao, F., Tang, W.Z., Zhao, D., Meng, Y., 2014a.

Adsorption kinetics, isotherms and mechanisms of

Cd(II), Pb(II), Co(II) and Ni(II) by a modified

magnetic polyacrylamide microcomposite adsorbent.

J. Water Process Eng. 4, 47–57.

Zhang, L., Wan, L., Chang, N., Liu, J., Duan, C., Zhou,

Q., Wang, X., 2011. Removal of phosphate from water

by activated carbon fiber loaded with lanthanum

oxide. J. Hazard. Mater. 190 (1–3), 848–855.

Zhang, J., Shen, Z., Shan, W., Mei, Z., Wang, W., 2011,

Adsorption behavior of phosphate on lanthanum(III)-

coordinated diamino-functionalized 3D hybrid

mesoporous silicates material. Journal of Hazard.

Mater. 186(1), 76-83.

Zhang, Y., Pan, B., Shan, C., Gao, X., 2016. Enhanced

phosphate removal by nanosized hydrated La(III)

oxide confined in crosslinked polystyrene networks.

Environmental Science & Technology, 50(3), 1447-

1454

Zhu, C., Tian, H., Cheng, K., Liu, K., Wang, K., Hua, S.,

Gao, J., Zhou, J., 2016. Potentials of whole process

control of heavy metals emissions from coal-fired

power plants in China. J. Clean. Prod. 114, 343–351.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

326