Series-Parallel Optimization Model for Heat Exchanger Network

Bin Yang

1,2

, Shiqi Liu

1*

and Zhouli Zhao

2

1

School of Mechanical Engineering and Automation, Northeastern University, Shenyang 110819, China

2

Shanghai Baosteel Company, Shanghai 201900,China

Keywords: Series-Parallel Network, Minimum Flow Rate, Mixed-Integer Nonlinear Model, GAMS

Abstract: Based on the parallel heat exchanger network, a series-parallel optimization model of the heat exchanger

network for industrial circulating water system is established. The flow rate and temperature of the heat

exchangers in the network can be calculated automatically. The mathematical formulation exhibit a

mix-integer nonlinear programming (MINLP) structure which can be solved by GAMS. A case study is

done to compare the differences between the series-parallel model and the parallel model. The result shows

that this series-parallel model can reduce fresh water and increase the outlet return temperature obviously.

1 INTRODUCTION

Cooling water system is widely used in factories to

transform waste heat from industrial equipment.

Conventional cooling water systems often use a

parallel heat exchanger network. This will bring a

huge amount of water flow rate and the return

temperature to the cooling tower might be low if the

network is arranged in parallel, which will cause a

poor cooling performance according to the theory of

Kim and Smith (Kim and Smith, 2001). In their

work, the traditional parallel exchanger networks are

changed into series types by applying water pinch

technology so that the bottleneck problems were

solved. However, if the exchangers are changed, the

cooling network might be redesigned, thus the

network will be a lack of flexibility. Therefore,

several authors (Kim et al., 2001; Kim and Smith,

2003; Kuo and Smith, 1998) built mathematical

optimization models to solve the network problem

automatically. Xiao Feng et al. (Xiao et al., 2005)

put forward an intermediate temperature in the water

network design. In this way, the recirculating

cooling water into or out of each cooler would be

from or going to one of the three mains so that the

water flow rate could be reduced and the return

temperature could be increased. Ponce-Ortega et al.

(Ponce-Ortega et al., 2007; Ponce-Ortega et al.,

2010) put forward a mixed-integer nonlinear

programming algorithm for the synthesis of cooling

networks. This work was a development of the

intermediate main which contained several stages

and the capital and utility cost was minimized.

The above papers mainly focused on reducing

the system flow rate and changing the heat

exchanger network structure. This paper proposes a

new series-parallel method to solve the exchanger

network problems. In this method, the water can be

reused so that the total water flow rate will be

reduced.And the outlet temperature can be

increased, which will improve the cooling tower

performance. The mathematical formulation exhibit

a mix-integer nonlinear programming (MINLP)

structure which can be solved by GAMS. A case

study is done to compare flow rate and outlet

temperature between the series-parallel model and

the parallel model.

2 MATHEMATICAL MODEL

In the model formulation, suppose the maximum

amount of heat exchangers is n. HE i and HE j

represents for exchanger i and exchanger j

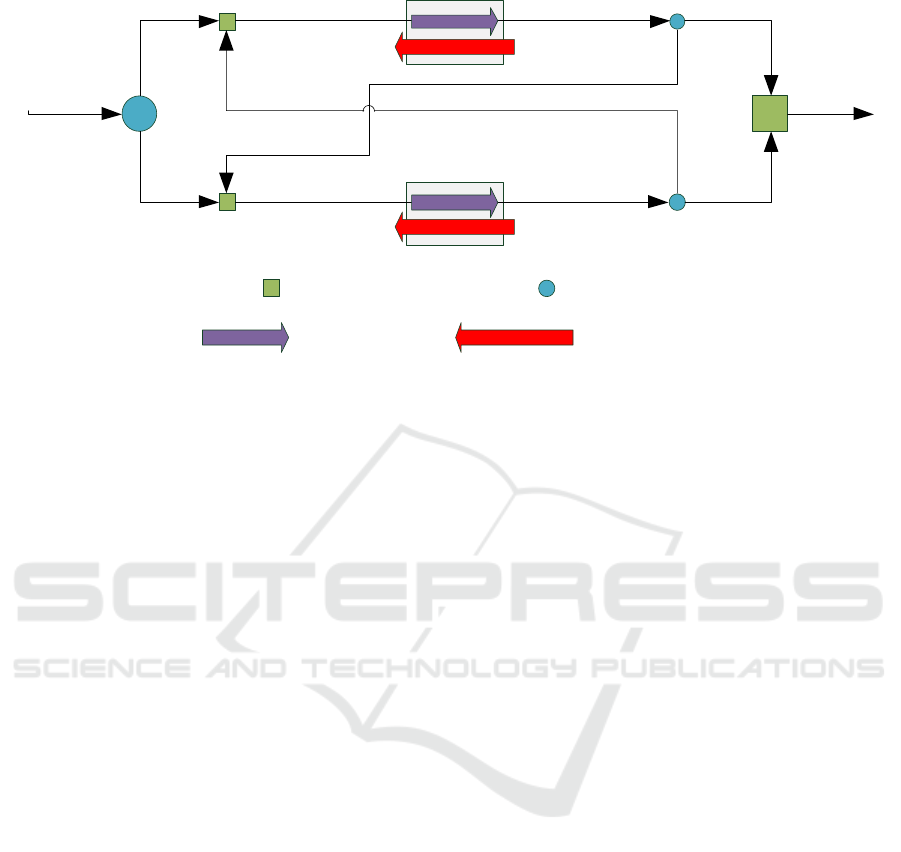

respectively. In Figure 1, the circles represent the

mixing point and the squares represent for splitting

point. At the mixing point of each exchanger, water

mixes by part of fresh water and part of reusing

water from other exchangers. So the inlet mass flow

rate for heat exchanger i can be shown as Eq. (1).

njiiFjiFiF

n

ijj

,,1,)(),()(

,1

inin

(1)

Yang, B., Liu, S. and Zhao, Z.

Series-Parallel Optimization Model for Heat Exchanger Network.

DOI: 10.5220/0008189703270330

In The Second International Conference on Materials Chemistry and Environmental Protection (MEEP 2018), pages 327-330

ISBN: 978-989-758-360-5

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

327

And at the splitting point of each exchanger,

water splits into part of outlet water and part of

reused water to other exchangers. The outlet mass

flow rate is the same as the inlet mass flow rate

which can be shown as Eq. (2).

njiiFjiFiF

n

ijj

,,1,)(),()(

,1

outout

(2)

For each exchanger, the mass flow rate from

other exchangers equals the inlet mass flow rate:

njijiFijF ,,1,),(),(

inout

(3)

The total inlet fresh water is:

n

i

iFF

1

inintotal

)(

(4)

The total outlet reused water is:

n

i

iFF

1

outouttotal

)(

(5)

Kim and Smith’s (Xiao et al., 2005) work shows

that because of different inlet temperature, some

exchangers might not need fresh water or reused

water. So on the right side of Eq.

(1),

)(

in

iF

and

),(

in

jiF

may not exist at the same

time.

),(

in

jiB

and

),(

out

jiB

are composed of binary

variables to limit reused water from exchanger i to j.

And

)(

in

iB

,

)(

out

iB

is to limit the inlet and outlet

mass flow rate. For exchanger i, The upper and

lower bounds of the mass flow constraints are shown

as follows:

njiiBUiFiBL

iniini

,,1,)()()(

(6)

)()()(

outout

iBUiFiBL

ii

(7)

),(),(),(

ininin

jiBUjiFjiBL

ii

(8)

),(),(),(

outoutout

jiBUjiFjiBL

ii

(9)

i

L

and

i

U

are the upper and lower bounds of the

water streams respectively. This paper supposes

each stream has the same upper and lower bounds.

The number of reused streams should be limited to a

certain amount.So the constraints are as follows:

n

1i 1

maxin

),(

n

j

NBjiB

(10)

n

1i 1

maxout

),(

n

j

NBjiB

(11)

jijiBjiB 0),(),(

outin

(12)

Suppose the heat that the hot stream i exchangers

is

)(iq

.The inlet temperature of cold stream i is

)(

in

it

,and the outlet temperature is

)(

out

it

.The heat

balance is shown as Eq.(13).

CPiFititiq )())()(()(

inout

(13)

In Eq.(13) CP represents for heat capacity flow

rate for the cold stream i. At the mixing point, the

inlet temperature of cold stream i is the mixing

temperature by fresh water and other exchangers’

used water, so Eq.(14) needs to be satisfied.

n

ijj

iFTjtjiFitiF

,1

ininoutinin

)()(),()()(

(14)

in

T

represents for the inlet temperature of the

total network. At the splitting point, the temperature

equals the outlet temperature of the cold stream. At

the mixing point return to the cooling tower, in

Eq.(15) outlet temperature

out

T

constraint is shown

as follows.

iF

jF

jiF

in

,

jiF

out

,

ijF

in

,

ijF

out

,

otal

F

int

outtotal

F

iF

in

jF

in

iF

out

jF

out

Mixing point

Splitting point

Cold Medium Hot Medium

HE i

HE j

)(

out

iT

)(

in

iT

Figure 1: The structure of series-parallel exchanger network.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

328

n

i

n

i

iFitiFT

1

outout

1

outout

)()()(

(15)

Ponce-Ortega et al. (Ponce-Ortega et al., 2010)

discussed that the d-value between the inlet

temperature of the hot stream and the outlet

temperature of the cold stream should exceed a

certain value. Thus, the inlet and outlet temperature

of the cold stream cannot exceed a certain value.

The temperature value is expressed as

T

. And the

constraints are as follows.

TiTiT )()(

inHOT,out

(16)

)()(

max,inin

iTiT

(17)

In the series-parallel automated design method,

the purpose is to reduce the fresh water.

)min(

intotal

FOB

(18)

The program is shown above. The objective

function is Eq.(18) to reduce cooling system flow

rate, which can increase the outlet temperature

simultaneously. Eq.(1) to Eq.(5) are equality

constraints and Eq.(6) to Eq.(12) are inequality

constraints and logical constraints to limit heat

exchange cold medium flow rate. Eq.(13) to Eq.(17)

are temperature constraints.

),(

in

jiB

and

),(

out

jiB

are binary variables while others are continuous

variables. There are nonlinear constraints in

Eq.(13)-(15). So the mathematical problem is a

mix-integer nonlinear programming (MINLP).

GAMS is an efficient mathematical tool for solving

optimization problems. This article uses one of the

solvers named DICOPT to solve this MINLP

problem.

3 CASE STUDY

The case study is used to validate the mathematical

problems and compare the traditional parallel heat

exchange network and series-parallel model of this

work. Suppose there are 4 hot streams in the cooling

water system, the hot stream operation data are

shown in the following Table.

Table 1: Hot stream data.

Exchanger

1

2

3

4

Inlet Temperature/℃

50

55

75

75

Outlet Temperature/℃

30

45

45

60

CP(kW/℃)

15

80

20

40

Suppose each heat exchanger contains only one

hot stream and one cold stream. According to the hot

stream data in Table 1, suppose the temperature

difference

T

in Eq.(16) is 10℃. Then the cold

medium data can be calculated in Table 2. The

maximum inlet and outlet temperature and CP are

shown as follows.

Table 2: Cold medium data.

Heat Exchanger

1

2

3

4

Maximum Inlet

Temperature/℃

20

35

35

50

Maximum Outlet

Temperature/℃

40

45

65

65

Maximum CP(kW/℃)

15

80

20

40

According to the model above, the exchanger

network can be designed in a series-parallel method.

The cold stream data is used to solve the model to

optimize the minimum flow rate of the total system.

The problem is solved by GAMS. And the results

are shown as the following Figures and Table.

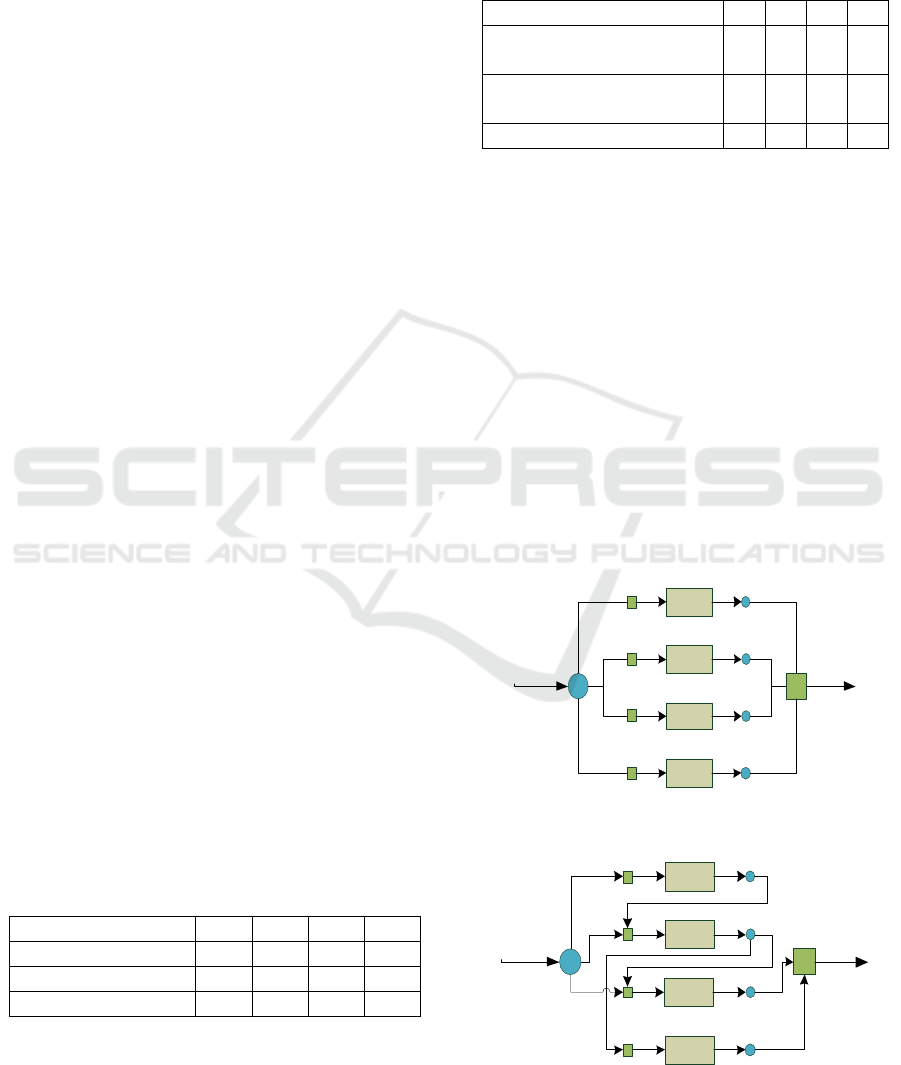

Figure 2 and Figure 3 shows the differences

between the parallel model and the series-parallel

model. In the parallel model, the CP is 155 kW/℃.

Suppose the cooling water specific heat capacity is

4.18 kJ/(kg℃). So the total mass flow rate is

37.1kg/s. While in the series-model the mass flow

rate is 12.4 kg/s. The outlet return temperature of the

parallel is 34.8℃ while that of the series-parallel

model is 64.2℃. According to the theory of Kim and

Smith (Kim and Smith, 2001), the higher the return

temperature of the cooling tower is, the better the

cooling tower performance will become.

HE1

HE2

HE3

HE4

80

15

20

40

155

20°C

34.8°C

Figure 2: Parallel optimization model.

HE1

HE2

HE4

HE3

15

29

8

52

15

32

12

20

20°C

64.2°C

40°C

45°C

65°C

63.8°C

Figure 3: Series-parallel optimization model.

Series-Parallel Optimization Model for Heat Exchanger Network

329

From the below Table 3, we can conclude that

the series-parallel model can save large amount of

fresh water and increase the outlet return

temperature. From the perspective of economic and

energy efficiency, series-parallel model can save

costs and improve tower performance.

Table 3: Comparison of different models

model

Mass Flow

Rate(kg/s)

Outlet

Temperature/℃

parallel

37.1

34.8

series-parallel

12.4

64.2

4 CONCLUSIONS

This work builds a mixed-integer nonlinear

programming (MINLP) algorithm and solves the

model by GAMS. A case study explains that in the

automated series-parallel model, the water flow rate

can be reduced by almost 24.7kg/s and the

temperature might be increased by 29.4℃. The

improved optimization model can reduce operating

costs and improve cooling tower performance which

is important for improving the efficiency of the

entire circulating water system.

ACKNOWLEDGEMENT

This work was financially supported by Science and

technology committee of Shanghai (13dz1201700)

fund.

REFERENCES

Kim, J. K., Savulescu, L., Smith, R., 2001. Design of

cooling systems for effluent temperature reduction[J].

Chemical Engineering Science, 56(5): 1811-1830.

Kim, J. K., Smith, R., 2001. Cooling water system

design[J]. Chemical Engineering Science, 56(12):

3641-3658.

Kim, J. K., Smith, R., 2003. Automated retrofit design of

cooling-water systems[J]. Aiche Journal, 49(7):

1712-1730.

Kuo, W. C. J., Smith, R., 1998. Design of Water-Using

Systems Involving Regeneration[J]. Process Safety &

Environmental Protection, 76(2): 94-114.

Ponce-Ortega, J. M., Serna-González, M.,

Jiménez-Gutiérrez, A., 2007. MINLP synthesis of

optimal cooling networks[J]. Chemical Engineering

Science, 62(21): 5728-5735.

Ponce-Ortega, J. M., Serna-González, M.,

Jiménez-Gutiérrez, A., 2010. Optimization model for

re-circulating cooling water systems[J]. Computers &

Chemical Engineering, 34(2): 177-195.

Xiao, F., Shen, R., Wang, B., 2005. Recirculating

Cooling-Water Network with an Intermediate

Cooling-Water Main[J]. Energy & Fuels, 19(4):

1723-1728.

MEEP 2018 - The Second International Conference on Materials Chemistry and Environmental Protection

330