The Effect of Concentration Ratio of Gelatine and

Polyvinylpyrrolidone as Binders on the Physical Properties of Red

Ginger (Zingiber officinale Rosc.) Extract Lozenges

Inding Gusmayadi, Priyanto

Faculty of Pharmacy and Sciences Universitas Muhammadiyah Prof. DR. HAMKA, Indonesia

Keywords: Red ginger extract, Lozenge.

Abstract: Lozenges require the tablet hardness of 7-14 Kgf to be a suitable binder. Gelatine can be used to meet the

requirement as it creates granules with bad flow time. PVP produces granules with better flow time but it

takes a large quantity to reach the lozenges hardness desired. This study aimed to determine the effect of the

concentration ratio of gelatine and PVP as binders on the physical properties of red-ginger extract lozenges.

Lozenges made employing the wet granulation method following the ratio of gelatine and PVP of 1:1, 1:2,

1:3, 1:4 and 1:5. The hardness test results of the formula 1 to 5 are 9, 14, 16, 13 and 12 Kgf respectively and

the friability test results were 0,4%, 0,7%, 0,2%, 0,3% and 0,6% accordingly. The combination of gelatine

and PVP as binders provide a significant difference in the hardness and friability of the tablets.

1 INTRODUCTION

Ginger, one of the most commonly used herbs in

food worldwide, has a wide range of medicinal uses

including carminative, antiemetic, spasmolytic,

antiflatulent, antitussive, hepato-protective, anti-

platelet aggregation and hypolipidemic effects.

Ginger has a strong odour generated by a mixture of

phenolic compounds that can stimulate thermogenic

receptors leading to the antiemetic effect (Heinrich

et al. 2009). Generally, herbal preparations of red

ginger are consumed as the instant powder. The use

of instant powder in the treatment is less practical

and therefore the dosage form needs to be developed

to be more practical and effective (Badan

Pengawasan Obat and Makanan Republik Indonesia

2012).

The lozenge is a practical choice to develop a

dosage form of red ginger. The lozenge is a solid

preparation that will dissolve or break down slowly

in the mouth (Agoes 2008). Two types of lozenges

are widely used, i.e. hard candy and compressed

tablet lozenges (Peters 1989). Compressed tablet

lozenges can be created using direct compression,

dry granulation or wet granulation. The wet

granulation method benefits to facilitate the

agglomeration process in the formula so that it will

result in the excellent physical properties and mass

of the tablets (Siregar and Wikarsa 2010).

The differences in physical properties of

lozenges and conventional tablets are the hardness of

7-14 Kgf, the diameter of 0.625-0.75 inches and the

weight range of 1.5-4.0 grams. The pre-formulation

of lozenge excipients should be filler, sweetener,

lubricant, glidant, flavoring agent and binder to

produce the good quality of lozenge physical

properties required (Hadisoewignyo and Fudholi

2013, Siregar and Wikarsa 2010). The binder is an

excipient in a tablet formula providing a cohesive

force between particles thus compromising a

compact and robust structure (Anwar 2012). The

binding effect in the lozenge component is essential

to produce greater hardness compared to the level of

conventional tablet hardness. The bonding agent is

divided into two groups: the synthetic and the

natural binder.

The natural binding agents that can be used are

starch, gum, tragacanth and gelatine. Gelatine has a

characteristic that inhibits the disintegration time

and thus it is suitable to be used as a binder on a

lozenge (Voigt 1995). Gelatine solution of 2-10%

can be used as a binder of the tablet formula (Anwar

2012). The use of gelatine as a binder on a wet

granulation can produce poor granule flows (Hamed

Gusmayadi, I. and Priyanto, .

The Effect of Concentration Ratio of Gelatine and Polyvinylpyrrolidone as Binders on the Physical Properties of Red Ginger (Zingiber officinale Rosc.) Extract Lozenges.

DOI: 10.5220/0008240901470153

In Proceedings of the 1st Muhammadiyah International Conference on Health and Pharmaceutical Development (MICH-PhD 2018), pages 147-153

ISBN: 978-989-758-349-0

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

147

et al. 2005). The viscous properties of natural-

sourced gelatine can increase the size of granules

which in turn increases the granular flow time. This

property can be improved by combining a natural

and a synthetic binder (Agubata et al. 2012).

One of the synthetic binders that can be used in

lozenge compression is polyvinylpyrrolidone (PVP)

in the range 0.5-5% (Rowe et al. 2009). A large

amount PVP is needed to be used as a lozenge

binder. Previous research reported that 3% of PVP in

the formula yielded a hardness of 6.23 Kgf (Sari and

Astuti 2010). It takes 10% of PVP to produce the

optimum lozenge ginger extract hardness of 14.63

kg (Mutmainah 2005), while the combination of

PVP (4.7%) and gelatine (9.3%) creates the

physical properties of tablets fitting the tablet

hardness and fragility requirements of 13.04 Kgf and

0.215% respectively (Liauw 2012). This research

examined the combination of PVP and gelatine for

ginger extract as an active ingredient. It aimed to

obtain the optimum combination to achieve the

maximum hardness and the minimum fragility on

ginger extract lozenges.

Based on the previous review, this research

investigated the effect of gelatine (4.0-6.7%) and

PVP (1.3-4%) combination on the physical

properties of red ginger extract lozenge employing

wet granulation method. The combination of

gelatine and PVP was performed in various

concentrations of 1: 1 (formula I), 1: 2 (formula II),

1: 3 (formula III), 1: 4 (formula IV) and 1: 5

(formula V). The combination of Gelatine and PVP

was not 0:1, 1:1, and 1:0 due to the trial results of

the combination of gelatine less than 4% did not

meet the requirement of lozenges hardness. The

quality of lozenges was assessed based on the

physical properties: (1) the evaluation of the tablet

mass includes the compressibility test, the flow time,

the angle of repose, the particle size distribution; and

(2) lozenge evaluation includes the organoleptic, the

weight uniformity, the size uniformity, the hardness

and friability test (Siregar and Wikarsa 2010).

2 MATERIALS AND METHOD

2.1 Materials

Materials used included the dry red ginger extract

(PT Haldin Pacific Semesta), PVP K-30 (Kimia

Farma), gelatine (Kimia Farma), dextrose (Kimia

Farma), mannitol (Kimia Farma), Talc (Kimia

Farma), and Magnesium Stearate (Kimia Farma).

2.2 Methods

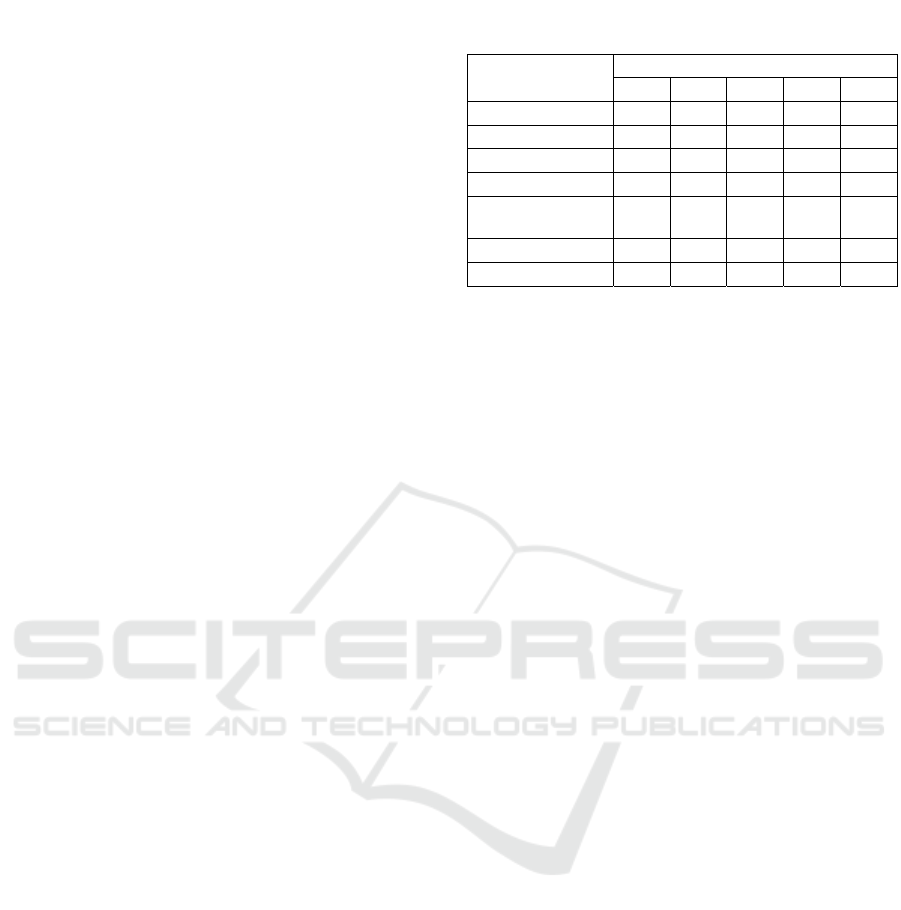

2.2.1 Lozenges Formula

Lozenges were made in five formulas namely F1,

F2, F3, F4 and F5. The five formulas had different

ratios of gelatine and PVP combinations as the

binding agents of 1000 mg tablet (see Table 1).

2.2.2 Lozenges Production

All materials were prepared and weighed. The red

ginger extract was put into the container, the

mannitol and dextrose were added and stirred

resulting in a homogeneous mixture. The PVP

solution was prepared by dissolving it in the 70%

ethanol (1: 5) and the gelatine solution was prepared

by hydrating the gelatine in cold water (1:2) for 24

hours before mixing and heating. PVP solution and

gelatine solution were added in warm conditions

slowly and stirred to be homogeneous and mass was

wet enough could be formed into granules.

The mass was sieved using a 12-mesh sieve and

then put into an oven at ± 50 ° C for ± 24 hours. The

granules were then sieved back with an 18-mesh

sieve. The magnesium stearate and talc were added

and mixed homogeneously. The granule evaluation

was then conducted. The granules were prepared and

put into the hopper. The tablet weight and hardness

were set. The lower punch was set if the hardness

was less than 7.0-14 Kgf. The upper punch was set if

the tablet weight was less than 1000 mg. The engine

ran until all granules transform into tablets.

2.2.3 The Evaluation of Extract, Granules,

and Tablets

The evaluation of dried red ginger extract included

the organoleptic, loss on drying, ash residue,

solubility, particle size and phytochemical extract

tests.

Table 1: Lozenges Formula.

Materials

Formula (%)

1 2 3 4 5

Ginger Extract 30 30 30 30 30

Dextrose 20 20 20 20 20

PVP 4 2,7 2 1,6 1,3

Gelatine 4 5,3 6 6,4 6,7

Magnesium

Stearate

1 1 1 1 1

Talc 2 2 2 2 2

Mannitol ad 100 100 100 100 100

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

148

The evaluation of granules included the flow

time, the angle of repose, the compressibility, the

granule size distribution and the loss on drying.

The lozenge evaluation included the

organoleptic, uniformity size, weight uniformity,

tablet fragility and tablet hardness tests.

3 RESULTS AND DISCUSSION

The dry extract obtained from PT. Haldin was then

determined. The result of the extract determination

from LIPI Cibinong showed that the dry extract

observed was Red Ginger which belongs to the

Zingiberaceae tribe. The result of the organoleptic

test on the dry red ginger extract is the fine yellow-

brown powder with spicy taste and red ginger

specific smell. The LOD test to examine the

moisture of the dry extract of red ginger was

conducted to prevent the powder become moist

which can accelerate the microbial growth. The

LOD test result was 5,61%. This shows that the

moisture of the extract meets the requirements, i.e.

no more than 10% (Departemen Kesehatan RI

1980).

The LOD extract test used a moisture balance

employing the gravimetric principle. This tool

measured the moist in the extracts that evaporated

from the heat generated by the appliance. The

extract moisture may be due to the water or organic

solvents used during the extraction process. So, it is

not specific to measure the water in the extract. If

the extract is made using an organic solvent, the tool

can detect the remaining solvent in the extract as the

amount produced. The results showed that the water

in the extract was 5.6%. Based on Hadisoewignyo

and Fudholi (2013), the extract classifies into the

non-hygroscopic category (<10%).

The residual test of dry red ginger extract ash

aimed to investigate the inorganic impurities in the

extract. The larger ash in the material shows the

higher mineral in the material. According to

Departemen Kesehatan RI (1980), the residual ash

requirement of excellent red ginger rhizome extract

should be no more than 5.0%. The results showed

that the ash residue obtained was 4.7%, so it can be

concluded that the dry ginger extract meets the

requirements of the excellent ash content.

The results of the phytochemical screening test

showed that the red ginger extract contained the

alkaloid, flavonoid, saponin, terpenoid, and

glycoside compounds. The purpose of the test is to

examine the active substance of the gingerol

compound, a phenol-derived compound. This

compound does not break when it is processed at

temperatures below 70℃ but it will be converted

into shogaol compounds that increase the spicy

flavour of the red ginger extract (Heinrich et al.

2009). Due to the stability of this compound

indicated by the spicy flavour and the same spot on

the TLC test, it can be concluded that the extract as

an active substance does not suffer damage during

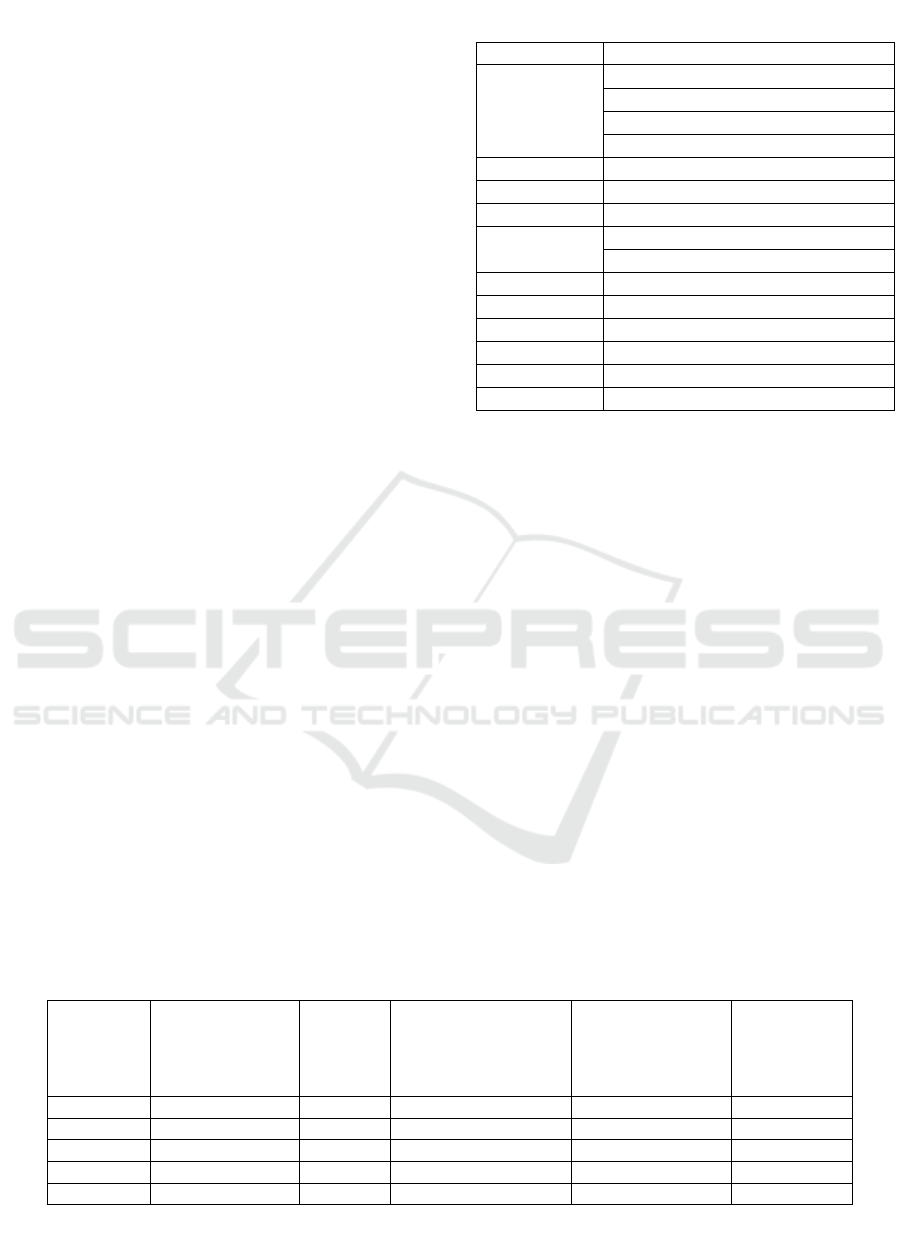

Table 2: The results of evaluation of red ginger extract.

Parameter Results

Organoleptic

Color : Yellow-Brown

Odor : Specific Ginger Odor

Taste : Spicy

Form : Fine Powder

LOD 5,61 %

Ash Residue 4,6912%

Solubility 100 mg dissolve in 1,73 mL of water

Particle size

93,79% passing the 80-mesh sieve

80,47% passing the 100-mesh sieve

Flavonoid +

Saponin +

Tannin -

Phenol +

Triterpenoid -

Steroid -

Table 3: The results of the granule evaluation.

Formula

Flow Time

(g/sec)

Angle of

Repose

Compressibility (%) LOD (%)

Granule Size

(μm)

F1 10,21 ± 0,17 28º58" 2,7 ± 0,36 3,70 ± 0,16 826

F2 9,51 ± 0,37 27º01" 2,6 ± 0,09 3,45 ± 0,29 817

F3 9,09 ± 0,14 27º38" 2,5 ± 0,43 3,27 ± 0,23 798

F4 9,74 ± 0,18 27º51" 2,6 ± 0,26 3,28 ± 0,15 813

F5 10,76 ± 0,67 30º41" 2,8 ± 0,51 4,38 ± 0,45 859

The Effect of Concentration Ratio of Gelatine and Polyvinylpyrrolidone as Binders on the Physical Properties of Red Ginger (Zingiber

officinale Rosc.) Extract Lozenges

149

the granule drying process and can be used to

produce tablet employing the wet granulation

method.

The solubility test was performed to determine

the solubility of the extract. The solubility test was

carried out using water as a solvent resulting in 100

mg of ginger extract dissolved in 1.73 mL of water.

It can be concluded that one part of the extract is

soluble in 17 parts of waters (1:17). The solubility

nature of the extract is soluble in water (Departemen

Kesehatan RI 1979). Based on the result of particle

size analysis (table 2), it was found that 93,79% of

the dried red ginger extract can pass through the 80-

mesh sieve and 80,47% of the extract can pass

through the 100-mesh sieve. The amount of extract

that can pass through 80-mesh sieve in the test is

larger than the certificate analysis of 80%.

In this study, the dry ginger extract is used.

Based on the amount of rendemen dry extract that is

49.5%. The dose of the red ginger extract according

to Zick et al. (2008) is 150 mg. Thus, this study uses

300 mg per tablet.

3.1 The Results of Granule Evaluation

The purpose of the granule evaluation is to examine

the quality of granules in each formula concerning

the excellent granule requirements meeting the

requirements for the compression process to tablets.

The granule loss on drying (LOD) test aims to

investigate how many volatile materials include

water in the drying process and to determine the

moisture of the granules. The results (table 3)

showed that the same ratio (1:1) in F1 resulting a

greater LOD value than F2, while F5 had the biggest

LOD value. This is due to the amount of solvent in

each formula. In a ratio of 1:1, the amount of PVP

used was more than the other formulas, requiring

more ethanol. Although the nature of ethanol was

more volatile than water as a gelatine solvent, a

large amount of gelatine in F5 may affect the PVP

character to be more sensitive to moisture (Siregar

and Wikarsa 2010).

Therefore, F5 with the highest gelatine

concentration had the highest LOD value. The LOD

values in F2, F3 and F4 were not significantly

different since the PVP concentration was not as

large as F1, and the gelatine concentration was not

as large as F5. The results of the LOD value test of

granules in all formulas meet the requirements of 3-

5% (Voigt 1995). The LOD value of the granules

may affect the nature of the tablet produced. It is

concerned that the large LOD value may contribute

to the attachment of granules on the punch at the

time of printing which in turn can affect the weight

and size of the tablet produced (Siregar and Wikarsa

2010).

The results of the granule flow time test of the

five formulas met the requirements of the flow time.

While the ratio of 1:1 and 1:5 did not meet the

requirements of flow time because of the

inappropriate amount of the binding material, F1

was lack of gelatine and F5 contained too much of

gelatine. The inappropriate amount of the binder will

reduce the bonding between the granules particles

(cohesive force), consequently the particle size is not

good enough and the granules are difficult to flow

(Anwar 2002). The results showed that F3 has the

best flow properties, indicating that the 1:3 binder

ratio is the best ratio to obtain the optimal granule

cohesive force so that the granules can flow

smoothly. Flow time is also affected by the moisture

of the granules.

The repose of the angle test aimed to examine

the flow properties of the granules when subjected to

the tableting process. The angle of repose is the

fixed angle between the cone-shaped particles and

the horizontal plane. The results presented that the

angle of repose in the five formulas were different.

The difference may be affected by the cohesiveness

of the granules caused by the binder. The shape, size

and moisture of the granules influence the

magnitude of the repose angle. The value of repose

angle ranges from 25

o

to 45

o

(Siregar and Wikarsa

2010).

The five formulas met the requirements of the

repose angle. It can be concluded that the binder

ratio of F1 and F2 had decreased up to F3. However,

there was an increase in the granular repose angles

in F4 and F5 because of the lack of cohesiveness

among granules affected by the comparison of the

binder concentration. The measurement of the

granular particle size distribution to determine the

granule size and depth was necessary because it can

affect the mixing process. Based on the results of the

study, the granules left in the 18-24 sieve was the

heaviest. According to Agoes et al. (2008), the use

of gelatine solution in the formula affects the size of

the granules. The amount of gelatine solution

negatively influences the size of the granules. A

relatively small size granule has smaller internal

porosity contributing to the greater cohesion force

and causes the granules to pass the mesh size of the

larger sieve hardly. The larger particles of granules

tend to separate from the smaller particles and move

downward while small particles will rise (Lachman

et al. 2003).

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

150

The addition of gelatine concentration to F4 and

F5 did not result in smaller granule size, as shown in

Figure 5, the number of granules left increased in

18-mesh sieves. It can be concluded that the addition

of the gelatine concentration to F4 and F5 increases

the granular size caused by an unbalanced binder

ratio. The larger gelatine concentration in the binder

combination can lead to an increase in the sensitivity

of PVP as a binder (Anwar 2012), to decrease the

performance of the binder combination. The size of

the granules that generally falls on the 12-20 sieve is

840-1680 μm (Agoes 2012).

The large granule size will decrease the granule

mass density. Smaller granules can form a more

compact mass than larger granules (Banker and

Anderson 1994). The result of the granular

compressibility index test after the determination on

100 ml granule for F1 to F5 satisfied the requirement

of good flow property category, the compressibility

≤ 20% (Agoes 2012). The granular density

influences the compressibility of the granules

leading to the decreased internal porosity of the

granules to increase the hardness of the tablets

produced (Anwar 2012). The granules

compressibility of F1 was 2.7% after the addition of

4% gelatine concentration. The addition of gelatine

concentration at F2 decreased the compressibility

value to 2.6% and 2.5% in F3. The addition of

gelatine concentration in F4 and F5 further increased

the percentage of granular compressibility because

the addition of excess gelatine concentration can

disrupt the performance of PVP. Thus, the cohesive

forces between the granules and the decreased

porosity of the granules increased the

compressibility values in F4 and F5.

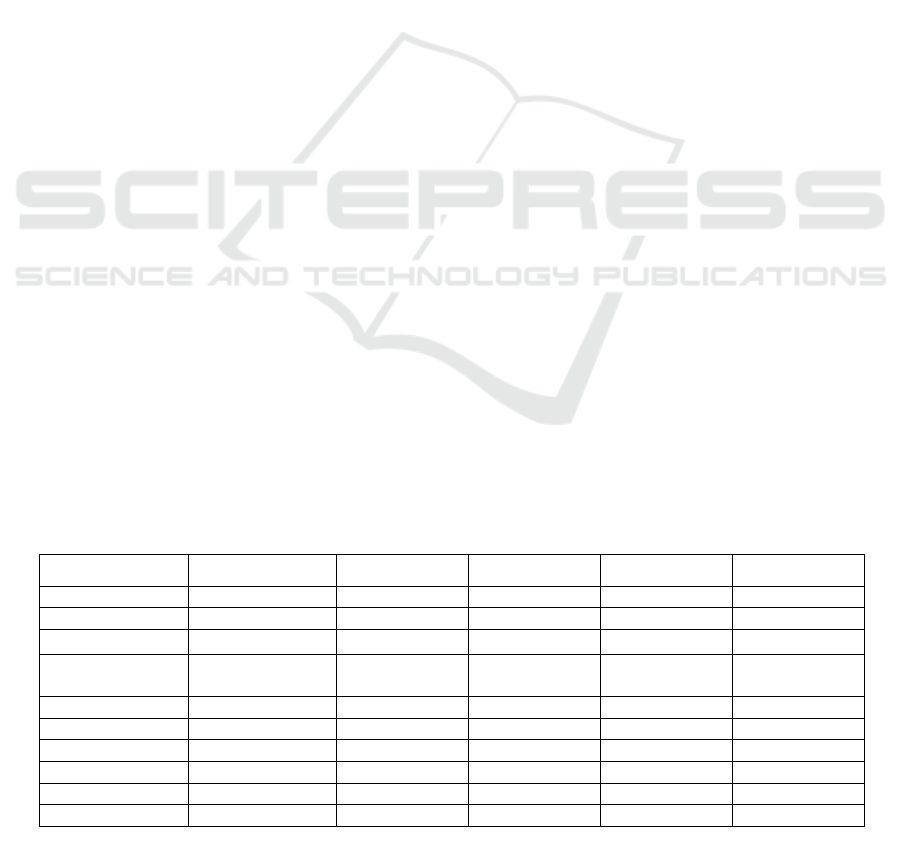

3.2 Results of Lozenge Evaluation

The purpose of the tablet evaluation is to examine

the quality of tablets in each formula concerning the

requirements of good tablets. The tablet evaluation

includes colour, shape, taste, weight uniformity,

uniformity size, tablet hardness and tablet fragility.

Details of tablet evaluation results can be seen in

Table IV.

The obtained lozenges of all formulas were

brownish white, oval and spicy-sweet. The oval

shape is adjusted to the availability of the punch for

a tablet weight of 1 gram. Tablets shape generally

are round but it can also be oval or other shapes. In

the pharmaceutical industry, tablet shape is used as a

product characteristic (Agoes 2012). Spicy taste on

lozenge was evident because of the lack use of

sweetener. In addition, the heating can change the

gingerol to be spicier yet it does not reduce the

pharmacological effects of the active substances

(Heinrich et al. 2009). Lozenges dissolve slowly

inside the mouth, so the formula having the highest

hardness lasts longer in the mouth. The spicy after-

taste of the tablets in the F3 with the hardness of

15.95 Kgf had the most unpleasant taste. F5

obtained the most delicious taste with a hardness of

12.31 Kgf and had the largest amount of gelatine.

Gelatine as a natural ingredient in the lozenge

formula can improve the characteristics and texture

of the lozenge surface when dissolving in the oral

cavity (Siregar and Wikarsa 2010).

The tablet produced showed color patches.

Striking and uniformly dispersed dark areas on the

surface of the tablet were due to the different color

of the active substance and other tablet excipients.

Such spots may arise due to the use of natural

materials in the lozenge formula (Badan Pengawas

Obat dan Makanan 2012). In addition, the use of

dextrose in the formula can contribute to the

brownish color if the temperatures given is above

37ºC (Siregar and Wikarsa 2010).

The tablet weight uniformity test was performed

by testing the weights of 20 tablets per formula. The

Table 4: The red ginger lozenge test results.

Evaluation F1 F2 F3 F4 F5

Organoleptic:

a. Shape Oval Oval Oval Oval Oval

b. Smell Specific Specific Specific Specific Specific

c. Color White Brownish

White

Brownish

White

Brownish

White

Brownish

White

Brownish

Thick

(

m

m

)

5,75 ± 0,01 5,75 ± 0,02 5,75 ± 0,01 5,75 ± 0,02 5,75 ± 0,02

Length (mm) 23,05 23,05 23,05 23,05 23,05

Width (mm) 10,45 10,45 10,45 10,45 10,45

Weigh (g) 1,008 ± 0,01 1,035 ± 0,01 1,030 ± 0,01 1,027 ± 0,01 1,025 ± 0,01

Friabilit

y

(

%

)

0,442 ± 0,01 0,674 ± 0,01 0,174 ± 0,01 0,337 ± 0,01 0,571 ± 0,01

Hardness

(

K

g

f

)

9,01 ± 0,71 14,15 ± 0,80 15,95 ± 0,76 13,45 ± 0,87 12,31 ± 0,68

The Effect of Concentration Ratio of Gelatine and Polyvinylpyrrolidone as Binders on the Physical Properties of Red Ginger (Zingiber

officinale Rosc.) Extract Lozenges

151

results of the test for F1 to F5 fulfilled the

requirement as no two tablets having a weight

deviation of 5% from the mean tablet weight and no

one tablet having weight deviation of 10% from the

average weight (Departemen Kesehatan RI 1979).

The tablet size uniformity test was performed by

measuring the width, length and thickness of the

tablet. There was no difference in length and width

of the lozenges as they were determined by the size

of the punch. If there was a difference in length and

width of the tablet, it might be due to the moisture of

granules causing a granule attached to the punch.

However, there were differences in the thickness of

the tablets due to the rise and fall of punch in the die

hole. This study used a single punch tablet machine

with only a pair of punch. The downward movement

of the bottom punch along with the up movement of

punch to a certain distance during the process of

filling the die hole resulted in the granule down due

to the gravitational effect. The distance between the

punch can be different, therefore there was a

thickness difference in the tablets produced yet it

was not significant.

The lozenge hardness requirement is 7-14 Kgf

(Hadisoewignyo and Fudholi 2013). The results

(tabble 4) reported that all formulas had different

hardness values; F2 and F3 did not meet the

requirements. The hardness of F2 and F3 exceeding

the requirement were 14.15 and 15.95 Kgf

respectively. The gelatine properties can draw water

into its bonds, resulting in a more spherical and

homogeneous granule and enhancing the cohesive

force between granular particles which in turn

increase the tablet hardness (Anwar 2012). The

characteristic of PVP is that the higher concentration

dissolved in alcohol, the stronger the liquid bridge

formed; so that the drying process of the solid bridge

formation is also stronger resulting in reduced

granular porosity increasing the greater granule

density and the tablet hardness (Siregar and Wikarsa

2010).

The addition of gelatine concentration on F4 and

F5 decreased the tablet hardness. The interaction

between PVP and gelatine in F4 and F5 can reduce

the performance of the binder because of the second

characteristic of the material. The gelatine properties

of having a low melting point, easily melt when

exposed to heat, causes the interaction with PVP

tending to be sensitive to water vaporization (Anwar

2012). When it is exposed to the pressure on the

machine, the tablet becomes moist and the bond

strength between granular particles is decreased

resulting in reduced tablet hardness (Siregar and

Wikarsa 2010).

The tablet fragility test was performed to

determine the tablet physical stability from

mechanical shock effects during the manufacturing,

packing and transportation process. The results of

tablet fragility test obtained from F1 to F5 fulfilled

the requirement that was below 0.8% (Voigt 1995)

due to the character of the binder components. The

properties of gelatine that can absorb water into its

bonds, result in a more spherical and homogeneous

granule and increase the cohesion force between

granular particles leading to increase tablet hardness

and decrease the tablet fragility value (Anwar 2012).

The PVP characteristic is that the higher the

concentration dissolved in alcohol, the stronger the

liquid bridge is formed; thus, the process of drying

solid bridge formation is also stronger which in turn

reduce the granular porosity and increase the granule

density leading to increase the tablet hardness and

reduce the tablet fragility (Siregar and Wikarsa

2010).

The addition of gelatine concentration on F4 and

F5 decreased the tablet fragility. The interaction

between PVP and gelatine in F4 and F5 decrease the

force of binding due to the gelatine (Anwar 2012).

The more gelatine leads to the less tablet fragility.

Therefore, tablet hardness decreases, and tablet

fragility increases (Siregar and Wikarsa 2010).

Based on the results of the data analysis, there is

a significant difference in each ratio of PVP and

gelatine concentration as a binder against the tablet

hardness and fragility. The results of the hardness

test identified that the increased hardness and

decreased fragility of the tablets were from the 1:1,

1:2 and 1:3 binding ratio. Also, there was a decrease

of the hardness and an increase of fragility in the 1:4

and 1:5 binder ratio.

4 CONCLUSIONS

The comparison of gelatine and PVP concentration

as the binding agent of red ginger lozenge provide

significant differences in the tablet hardness and

fragility. The ratio of gelatine and PVP

concentrations in F3 with a ratio of 1:3

concentrations identified as the highest hardness

value of 15.9 Kgf and the lowest vulnerability of

0.2%.

MICH-PhD 2018 - 1st Muhammadiyah International Conference on Health and Pharmaceutical Development

152

ACKNOWLEDGEMENTS

We would like to express our gratitude to Faculty of

Pharmacy and Sciences of Universitas

Muhammadiyah Prof. DR. HAMKA for the

contribution in the Laboratory equipment and for

joining on MICH-PHD International Seminar.

REFERENCES

Agoes G. 2008. Seri Farmasi Industri-1. Pengembangan

Sediaan Farmasi, Edisi Revisi and Perluasan. Penerbit

ITB. Bandung. Hlm. 286-335.

Agoes G. 2012. Seri Farmasi Industri-6: Sediaan Farmasi

Padat. Penerbit ITB. Bandung. Hlm. 73-79,224-

234,245.

Agubata C, Onunkwo GC, Ugwu CE, Chime SA. 2012.

Physical and mechanical effects of starch-gelatin

binary binder mixtures on sodium salicylate tablets,

Journal of Chemical and Pharmaceutical Research, 4

(3), 1625-1628.

Agus S, Sudirman I, Feranses SP. 2007. Pengaruh Ukuran

Granul terhadap Kadar Solutio Gelatin sebagai Bahan

Pengikat terhadap Migrasi Vitamin B6. Jurnal

PHARMACY, Fakultas Farmasi Universitas

Muhammadiyah Purwokerto. Purwokerto. ISSN 1693-

3591. Hlm 3-4.

Departemen Kesehatan RI. 1979. Farmakope Indonesia.

Edisi III. Jakarta: Departemen Kesehatan RI; Hlm. 6,

7, 93, 354, 378, 535, 807, 840.

Departemen Kesehatan RI. 1980. Materia Medika

Indonesia. Jilid IV. Jakarta: Departemen Kesehatan

RI; Hlm 78.

Badan Pengawasan Obat and Makanan Republik

Indonesia. 2012. Pedoman Tenologi Formulasi

Sediaan Berbasis Ekstrak. Volume 1. Jakarta: Badan

Pengawasan Obat and Makanan Republik Indonesia;

Hlm. 16- 18, 33 – 34.

Anwar E. 2012. Eksipien dalam Sediaan Farmasi

Karakterisasi and Aplikasi. Cetakan pertama. Jakarta:

PT. Dian Rakyat. Hlm.5, 26-92.

Banker GS and Anderson NR. 1994. Tablet. Editor:

Lahman L. Teori and Praktek Farmasi Industri. Edisi

III. Jilid II. Penerjemah: Suyatmi. UI Press. Jakarta.

Hlm. 643-703.

Hadisoewignyo L and Fudholi A. 2013. Sediaan Solida.

Yogyakarta: Pustaka Pelajar. Hlm.11,19,21,35.

Hamed E, Moe D. Khankari R. and Hontz J. 2005. Binder

and solvent dalam: Handbook of Pharmaceutical

Granulation Technology. Second edition. Taylor &

Francis Group. London; Hlm. 109-119.

Heinrich M, Barners J, Gibbons S, Williamson EM. 2009.

Farmakognosi and Fitoterapi. Alih bahasa Amalia H,

Hadinata. Penerbit EGC. Jakarta. Hlm. 235 – 236.

Lachman L, Lieberman HA. 2003. Pharmaceutical Dosage

Forms: Tablets Volume 2. United States of America,

New York. Hlm. 254, 299-300, 330, 714.

Liauw NR. 2012. Optimasi Formula Lozenge ekstrak

Rimpang Kencur (Kaempferia galanga L.)

menggunakan kombinasi PVP K-30 dengan Gelatin

Sebagai bahan Pengikat. Skripsi. Fakultas Farmasi

Unika Mandala, Surabaya. Hlm. 50, 51,52,96.

Moore, R., Lopes, J., 1999. Paper templates. In

TEMPLATE’06, 1st International Conference on

Mutmainah MD. 2005. Pengaruh PVP Sebagai Pengikat

Terhadap Sifat Fisik Lozenge Ekstrak Jahe (Zingiber

officinale Roxb). Skripsi. Fakultas Matematika and

Ilmu Pengetahuan Alam Universitas Islam Indonesia,

Jogjakarta.

Peters D. 1989. Medicated Lozenges, in: Lieberman HA,

Lachman L.(eds), Pharmaceutical Dosage Form.

Second edition. Volume 1. Marcel Dekker Inc. New

York. Hlm. 419, 420.

Rowe RC, Sheskey JP, Quinn ME. 2009. Handbook of

Pharmaceutical Exipient. Sixth Edition. The

Pharmaceutical Press. London. Hlm. xxviii – 917.

Sari E, Astuti IY. 2010. Formulasi Tablet Kunyah Ekstrak

Rimpang Jahe Merah (

Zingiber officinale Roxb)

dengan Bahan Pengisi Sorbitol and Laktosa and

kontrol kualitasnya. Dalam Jurnal Farmasi Indonesia.

Vol. 07 (02) ISSN 1693-3991. Hlm 67-75.

Siregar CJP, Wikarsa. 2010. Teknologi Farmasi Sediaan

Tablet Dasar-Dasar Praktis. Universitas Indonesia

Press. Jakarta. Hlm. 35, 193-195, 202, 505-523.

Voigt R. 1995. Buku Pelajaran Teknologi Farmasi. Edisi

V. Penerjemah Soendani Noerono. UGM

Press.Yogyakarta. Hlm. 160-161, 166, 168, 223, 564,

568, 570.

Zick S, Djuric Z, Ruffin MT, Litzinger AJ, Normolle DP,

Alrawi DP, Alrawi S, Feng MR, Brenner DE. 2008.

Pharmacokinetics of 6-gingerol, 8-gingerol, 10-

gingerol and shogaol and conjugate metabolites in

healthy human subjects. Cancer Epidemiol

Biomarkers Prev. 17 (8): 1930-35.

The Effect of Concentration Ratio of Gelatine and Polyvinylpyrrolidone as Binders on the Physical Properties of Red Ginger (Zingiber

officinale Rosc.) Extract Lozenges

153