Load Monitoring for Orthoses with Energy Harvesting Powered

Sensor

Juan-Mario Gruber and Andreas Stahel

Institute of Embedded Systems Zurich University of Applied Sciences, Winterthur, Switzerland

Keywords: Energy Harvesting, Sensors, Force Measurement.

Abstract: A new self-powered sensor with wireless connectivity is presented. The system is powered by piezoelectric

energy harvesting from human motion. It can be implemented for example into orthoses, medical walking

aids, shoes or prostheses. Force sensors measure the weight bearing on a lower limb. The collected data is

processed and transmitted to a smartphone or computer using Bluetooth Low Energy (BLE). On the

receiving device, the data is analysed and visualized and can provide information for patients and physicians

to support healing processes. Initial tests show that the harvested energy is sufficient for a stable operation

of the embedded system.

1 INTRODUCTION

Patients with injuries on lower limbs need to reduce

the weight bearing on the leg or foot during

recovery. Over-straining can cause a delay of the

healing process or even new injuries. However, it

can be difficult for a patient, to estimate the applied

weight. An appropriate tool can help monitoring

with continuous measurements using force sensors.

It can trigger a warning, if overstraining is

imminent. Built into a cast or an orthosis, a small

and light device does not interfere with the patient in

daily life. In general, the possibility to monitor a

patient constantly over a period of time with small

effort for both patients and physicians offers new

possibilities in diagnostics or in supporting

treatment.

Usually wearable devices are powered by a

rechargeable battery (

Merrett et al., 2010). This

increases weight and size and can make the use of

the product as well as its designing more

complicated, for example with regard to

waterproofness and reliability. In addition, the

materials used for the production of batteries, as well

as their disposal at the end of the product lifetime

poses a potential risk for the environment.

Instead of using a battery, the energy needed to

operate a wearable device can be harvested from the

environment. Typical sources are light, body

temperature or mechanical forces. In recent years,

there was rapid development towards more energy

efficient devices. Therefore, there are more and

more applications, where energy harvesting is a

possible solution.

By using energy harvesting as a source of

energy, the threshold for application is lowered

compared to using a battery or accumulator. The

user does not need to perform maintenance tasks like

changing or charging a battery before use, but can

instead put the device into operation immediately.

This makes such a device convenient also for less

technically oriented users, for example elderly

people. In addition, it increases safety and reliability

of the device since it is not dependent of a limited

energy supply.

2 PIEZOELECTRIC ENERGY

HARVESTING FROM

MECHANICAL FORCES

The piezoelectric effect is used in sensor

technologies in various applications. When

piezoelectric materials are deformed, they produce a

voltage proportional to the applied force. The

preferred way to use the piezoelectric effect in

energy harvesting is to exploit vibrations with a

piezoelectric oscillator. When operated at resonance

frequency, it can produce a decent amount of power.

134

Gruber, J. and Stahel, A.

Load Monitoring for Orthoses with Energy Harvesting Powered Sensor.

DOI: 10.5220/0007253901340139

In Proceedings of the 12th International Joint Conference on Biomedical Engineering Systems and Technologies (BIOSTEC 2019), pages 134-139

ISBN: 978-989-758-353-7

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

However to keep a piezoelectric oscillator at

resonance frequency, a very steady movement or

vibration is required, which in reality is often not the

case. The power output decreases drastically, if the

oscillator is not in resonance.

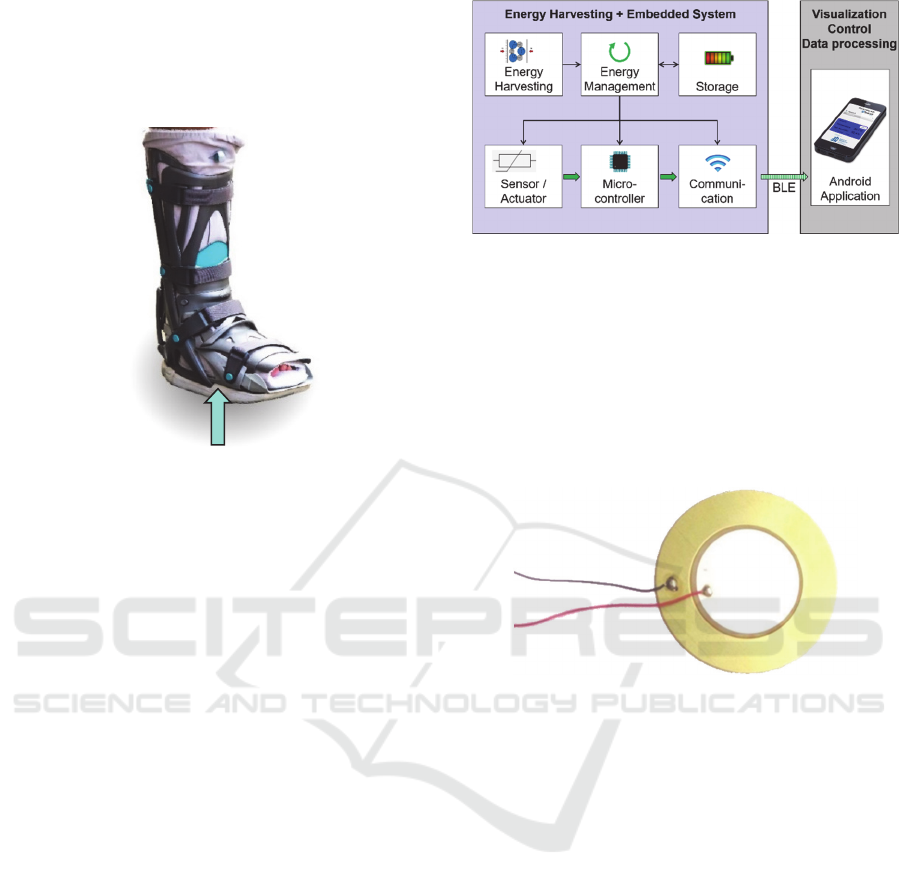

Figure 1: Impact force on the base of an orthosis, used to

deform the piezoelectric element (Source: Colourbox,

modified).

In this application, energy is harvested from

human motion like walking. Because of the low

speed of the movement and its inconsistency,

resonances cannot be exploited. Instead the events of

force impact have to be treated as single events,

from which as much energy as possible has to be

harvested.

3 OVERALL CONCEPT

The presented prototypical system showed in Figure

2 consists of an energy harvester, a microcontroller

with a BLE transmitter, a force sensor and an

Android application (Stahel and Hermann, 2017).

In the energy harvester, a piezoelectric element

transforms mechanical forces into electric energy.

The energy is stored in a capacitor, which is

monitored by an energy management unit. A step

down converter provides the voltage level for the

microcontroller.

At each program cycle, triggered by the piezo

harvester, the microcontroller evaluates the force-

sensing resistor. This data is then sent via BLE in

advertising mode and is received and visualized by

an Android application.

Figure 2: Overall concept of the presented solution.

3.1 Energy Harvesting

A piezo buzzer (Figure 3) is usually used as an

actuator to produce a sound signal by applying an

AC Voltage in a particular frequency. It is used in

cheap speakers to produce warning signals or other

low quality sounds. Thanks to their simple structure

and mass production, they are very affordable.

Figure 3: Standard piezo buzzer used for the application.

In this application, a piezo buzzer is

implemented as a generator. By deforming the

buzzer a voltage between the piezo ceramic layer

and the brass base is produced that can be harvested

by a suitable circuit.

Ideally, the piezo buzzer it is placed at a position,

where the first force impact occurs. For an orthosis,

the optimal position would on the bottom side

(Figure 1), for crutches, the buzzer can be positioned

at the tip or inside the joint in the shaft.

At every step, the device uses the first impact on

the piezo buzzer as a trigger point to wake up the

microcontroller and start the measurement routine.

For that purpose, a high-pass filter is connected to

the piezo buzzer to register the rising voltage and to

provide an input signal to the comparator of the

microcontroller.

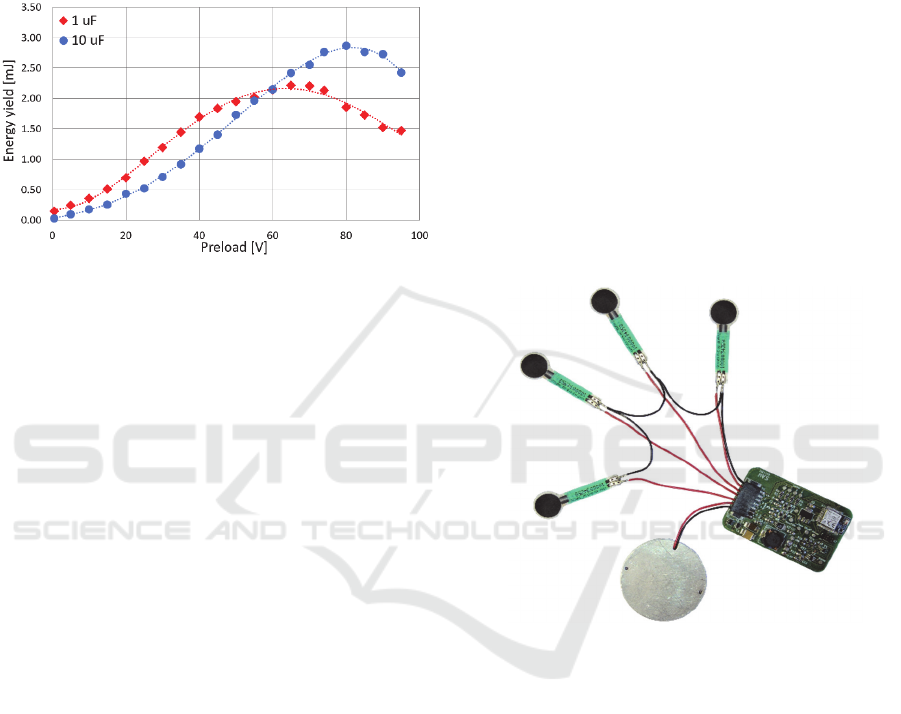

The energy yield of the piezo buzzers was

evaluated in laboratory tests. Depending on the

preload of the storage capacitor, an energy yield of

up to 3 mJ from a single stroke could be achieved

Load Monitoring for Orthoses with Energy Harvesting Powered Sensor

135

(Figure 4). Two or more piezo buzzers can also be

stacked to increase the energy yield.

For these measurements the piezo buzzers where

connected to a full bridge rectifier consisting of

BAT54 diodes and to a capacitor. The voltage level

of the capacitor after each pulse was evaluated and

the resulting energy calculated.

Figure 4: Energy yield of piezo buzzers at different

preloads and with two different storage capacitor sizes.

The main element of the harvester circuit is an

LTC3588 chip from Linear Technology. It is a

specialized chip for energy harvesting from

piezoelectric sources and consists of a rectifier and

an efficient buck converter to convert the input

voltage of the piezo buzzer into a stable output of

1.8 Volt. The input voltage of the LTC3588 is

limited to 20 Volt. Before converting, the energy is

buffered to bridge idleness.

3.2 Microcontroller and Sensors

Based on (Gugg et al., 2016) an NRF52832

microcontroller by Nordic Semiconductors was used

as a basis for the embedded system. It contains an

ARM Cortex M4 32-bit processor as well as a

2.4 GHz transceiver for BLE. To measure the

weight, force sensing resistors where implemented.

The microcontroller can evaluate them using its 12-

bit analog-to-digital converter (ADC).

With an additional ADC measurement, the

voltage level of the storage capacitor is monitored.

Depending on the available energy in the storage,

the collected data is sent via BLE. In continuous

operation, it is possible to evaluate the sensors and

send the data at every step, thanks to very low power

consumption.

The ADC measurement, including initialization,

data acquisition and data transfer with Direct

Memory Access (DMA) consumes only 1.1 μJ.

Sending the data in advertising mode on three

channels uses around 20 μJ at a transmission power

of 0 dBm. The transmission power was chosen to

ensure a stable communication, but can be reduced

to save energy. Standby phases of the

microcontroller in between two steps consume

8.1 μJ per second.

4 PROTOTYPE

A prototypic implementation of the autarkic sensor

was implemented. It consists of a harvester system, a

microcontroller with BLE transmitter and force

sensing resistors (Figure 5).

The system was fitted into an insole. Apart from

monitoring weight load, this device demonstrates a

different potential application. By spreading the

force sensors on the sole, the device measures the

weight distribution. It could be used for orthopedic

gait analysis.

Figure 5: Overview over prototypic system. The piezo

buzzer is placed inside an aluminum housing.

The system contains no moving parts. The most

stress is on the piezo buzzer that has to be deformed

at every cycle. This could potentially damage the

piezo-ceramic layer on top in the long term. To

prevent this, the piezo buzzer was placed inside an

aluminum housing. This allows limiting the maximal

bending to 2 mm. The power output is only

marginally affected this limitation. It is also largely

independent of the weight of the user. The piezo

buzzer can be bent with little force.

The complete system with piezo buzzer, four

force sensors and the microcontroller circuit board

can be fitted on an orthosis (Figure 6).

Miniaturization can presumably be achieved by a

factor of two or more, so that the autarkic sensor

system can also be used in a more limited space like

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

136

crutches. Introducing additional sensors or circuitry

is possible, provided the energy budget is taken into

account. At a weight of only a few grams, the device

does not bother the wearer during use.

Figure 6: View of a possible mounting of the system on an

orthosis. The piezo buzzer and sensors are placed at the

bottom, the microcontroller is mounted on the side

(Source: Colourbox, modified).

The bill of material of the prototype device,

excluding force sensors, adds up to around 40 USD.

This includes the piezo buzzer that is very affordable

at a price of only 2.80 USD. The used force sensing

resistors cost an additional 20 USD per piece.

4.1 Android Application

The sensor system sends the data of the force

sensors, the measured voltage value of the storage

capacitor and a step counter value using advertising

mode. Each packet has a length of ten bytes and is

sent three times successively. For processing and

visualization, the data can be received by an

application that runs on any Android smartphone

capable of BLE.

The Android application scans for advertising

data, recognizes the packets by their ID and extracts

the sensor data.

The application uses calibration data of the force

sensors to scale the measured values and display

their relative distribution by using text and color.

The step counter data and the current energy storage

level is also displayed (Figure 7).

To display the current weight load in total the

application can be modified. With the weight of the

person and the calibration data of the force sensors,

the total load can be calculated and displayed both

graphically and textually. The step counter would be

Figure 7: Sample view of the application. The color and

percentage value indicate the current weight distribution

on the foot.

of marginal interest in such an application and could

be omitted.

Signaling imminent overstraining could also be

done in a different way than via an Android

application. An acoustic or a tactile indication could

be implemented, depending on the use case and

energy budget. This way, the inhibition threshold

can be lowered further to make the device accessible

to less technically oriented users who might have

difficulties to use a smartphone.

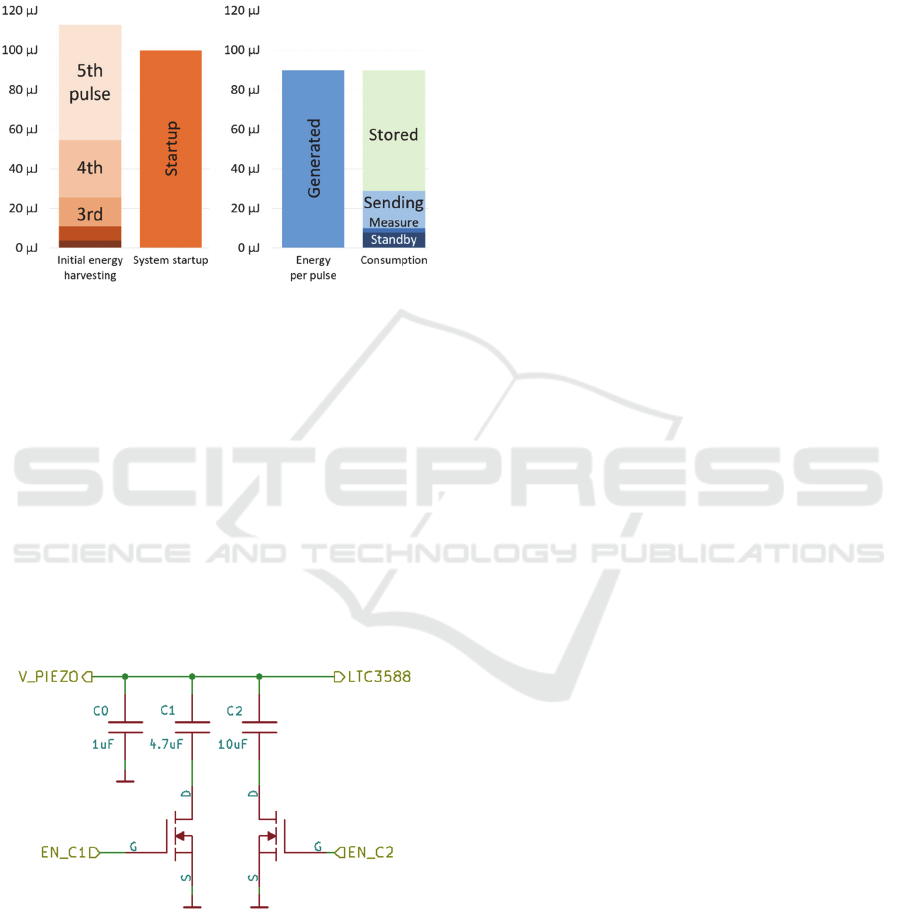

4.2 Performance

When the system is fully started up, it can be

sustained with an energy pulse frequency from the

piezo buzzer of less than 1 Hz, which corresponds

with a normal walking speed of an injured person.

Data acquisition, processing and transmitting and the

standby of the microcontroller consume around

30 μJ at each cycle. The harvesting system provides

around 90 μJ of energy at each pulse on average

(Figure 8, right side).

In conclusion, the system can store up to 60 μJ

on average at each pulse and can thus sustain

operation in standby for a certain time, while no

energy can be produced. The storage capacitors will

then eventually discharge due to leakage.

Starting up the embedded system consumes

around 100 μJ and can be done after about five

pulses from the piezo buzzer, as laboratory tests

have shown. The amount of energy produced is

Load Monitoring for Orthoses with Energy Harvesting Powered Sensor

137

significantly smaller during the first few pulses with

empty storage capacitors and improves with

increasing charge of the capacitors as shown in

Figure 4. Therefore, the initial startup of the system

poses a challenge. This is indicated in Figure 8 on

the left side.

Figure 8: Comparison between generated and consumed

energy. Left: Startup process (approximated); right:

continuous operation.

To improve the start-up procedure, an array of

storage capacitors is introduced (Figure 9). It

consists of three different capacitors in parallel that

can be enabled according to the current operating

state. At start-up, a small capacitor is used to provide

the buck converter with a high voltage as quickly as

possible. For continuous operation, additional

capacitors are activated to provide enough storage.

Due to the charge equalization that takes place when

a new capacitor is activated, the larger capacitors do

not need to be charged from an empty state, which

improves efficiency significantly.

Figure 9: Schematics of storage capacitor array.

5 APPLICATIONS

The presented system provides a wide array of

possible applications. Examples are medical walking

aids (

Merrett et al., 2009)

, supports, rails or

prostheses. It can be implemented to measure the

applied weight bearing on an injured lower limb

after a fracture or a cruciate ligament tear for

example. This way the system can help to improve

the healing process and prevent damages from

overstraining.

By recording and live reporting data about the

weight distribution on the foot, the autarkic sensor

system can be used as a tool in orthopedic gait

analysis (

Hadi

et al. 2012). For this, several force

sensing resistors can be placed on different spots on

an insole. Elderly people in need of care can be

monitored to register falls and signal for help. With

no needed maintenance, the device is very user-

friendly.

The implemented sensor types are not limited to

sensing force. Measuring temperature over a longer

period of time is a further possible scenario for

medical applications.

This autarkic sensor system can also be adapted

to other fields of application. As a safety monitoring

system, for example for firefighters, it can trigger an

alarm if no data is transmitted, meaning that the

person wearing the system is not moving. Such a

device can be used to simplify access control. Doors

can be unlocked if a person with right of access

approaches or locked otherwise. For this application,

an embedded system can be built into specialized

safety shoes or into an insole that can be inserted in

any shoe.

Another use case is a wearable fitness gadget that

counts steps or tracks position. Energy harvesting

simplifies the usage of such a gadget significantly,

since it is independent from any limited battery

lifetime.

Apart from exploiting a walking movement, the

developed system is also suitable for other

applications in which a mechanical motion is

present. Harvesting energy can also be done from an

industrial machine with moving parts, while the

autarkic sensor monitors a process or machine in the

production line.

6 CONCLUSIONS

The target of this project was to implement a sensor

to monitor and support a healing process by

measuring the applied weight on an injured lower

limb.

Several other works in this field have been done

previously. Comparable systems use batteries

(

Merrett et al., 2009)

that need to be replaced or

BIODEVICES 2019 - 12th International Conference on Biomedical Electronics and Devices

138

charged. Introducing energy harvesting as a power

supply increases the security of the system and

makes it more user-friendly. Electrical energy is

generated directly from the human motion and is

available as needed.

The presented system is preferably implemented

into foot or leg orthoses, prostheses, shoes or into

crutches since the energy harvesting system relies on

the vertical force from the weight of the wearer. The

piezoelectric element produces a voltage when being

deformed. With some adjustments, it is also possible

to apply the sensor system on other body parts, such

as the arms, provided a mechanical movement is

present that can be used to bend the piezo buzzer.

A two-part system, where energy is harvested

from the walking motion and a sensor is used to

monitor another part of the body can also be taken

into consideration. However, user-friendliness

would be reduced by a device more complicated to

apply.

The prototypic system has potential to be

optimized in future work. This includes optimizing

the harvester circuit in terms of efficiency and input

voltage range. The used LTC3588 buck converter is

limited to 20 Volts. Tests showed a significantly

higher efficiency at higher voltages of up to

80 Volts. This potential should be exploited.

The possibility to stack the piezo elements is also

worth analyzing. Two or more piezo buzzers can be

used simultaneously to increase the power output at

the cost of a larger device. Depending on the

application and the required energy, it could be a

viable solution.

An expansion of functionality is planned,

particularly with respect to the used sensor types and

construction form, to implement other applications.

REFERENCES

Merrett, G., Ettabib, M., Peters, C., Hallett, G., White N.,

2010. Augmenting forearm crutches with wireless

sensors for lower limb rehabilitation. In Measurement

Science and Technology, 21 (12), 1-10, 2010

Stahel A., Hermann A., 2017, Energieautarker,

intelligenter Schuh, Zurich University of Applied

Sciences. Switzerland.

Gugg, M., Brütsch, M., Brülisauer, C., Meli, M., 2016

Comparing the energy requirements of current

Bluetooth Smart solutions, Zurich University of

Applied Sciences. Winterthur.

Merrett, G., Peters, C., Hallet, G., White, M., 2009, An

instrumented crutch for monitoring patients’ weight

distribution during orthopaedic rehabilitation,

University of Southampton. Southampton.

Hadi, A. Razak, A., Zayegh, A., Begg, R., Wahab, Y.,

2012. Foot Plantar Pressure Measurement System: A

Review. Victoria University, School of Engineering

and Science. Melbourne.

Load Monitoring for Orthoses with Energy Harvesting Powered Sensor

139