Modeling and Evaluation of a City Logistics System with

Freight Buses

Zheng Chang, Haoxun Chen and Farouk Yalaoui

ICD-LOSI, UMR CNRS 6281, University of Technology of Troyes, Troyes, France

Keywords: City Logistics, Freight Bus, Joint Distribution, Vehicle Routing Problem.

Abstract: Freight bus is a new public transportation means for city logistics, and each freight bus can deliver and pick

up goods at each customer/supplier location it passes. In this paper, we study the route planning problem of

freight buses in an urban distribution system. Since each freight bus makes a tour visiting a set of

pickup/delivery locations once at every given time interval in each day following a fixed route, the route

planning problem can be considered a new variant of periodic vehicle routing problem with pickup and

delivery. In order to solve the problem, a Mixed-Integer Linear Programming (MILP) model is formulated.

Based on the model, we compare a distribution system with freight buses with that without freight bus.

Preliminary numerical results on randomly generated instances show that the system with freight buses can

significantly reduce transportation costs compared with the system without freight buses.

1 INTRODUCTION

The rapid development of e-commerce has been

making urban logistics flows more and more

intensive. Driven by market demand, more and more

city freighters operated by different private third-

party logistics companies were born and circulate in

the centers of cities. This has caused serious traffic

congestion and environmental pollution problems in

large cities. To reduce traffic congestions and

improve the efficiency and time accuracy of

delivery, collaboration among third-party logistics

companies (carriers) in urban logistics is needed.

In 1973, Japanese scholar Shize (1973) first put

forward the joint distribution which has been proved

to be an effective way for city logistics. Joint

distribution promotes enterprises with similar

functions to use common facilities and equipment

such as warehouses, logistics platforms, and

vehicles, through which small orders of goods for

delivery can be consolidated into a large-volume

order to achieve the economics of scale in

transportation and other related logistics services.

Gill and Allerheiligen (1996) pointed out that

members of a distribution channel should cooperate

with each other through joint distribution, and

illustrated the effectiveness of joint distribution, and

proposed several principles for implementing it. Hao

and Su (2014) discussed the basic concepts and

operation models of joint distribution in city

logistics. Xu and Yang (2017) proposed a model for

cost sharing among small companies implementing

joint distribution.

Motivated by joint distribution, in our previous

work (Chang and Chen. 2017), we put forward the

concept of freight bus, which is a new public

transportation means for city logistics that can

replace city freighters belonging to different private

third-party logistics companies in the center of a

city. Freight bus has some advantages compared

with city freighter. Firstly, freight bus can realize

joint distribution of different third-party logistics

companies, and can thus save city logistics costs and

reduce the air pollution; Secondly, because of

having a regular schedule, freight bus can improve

the timeliness and accuracy of logistics services;

Thirdly, replacing private city freighters by freight

buses can facilitate the traffic control in a city and

reduce the traffic congestion. Finally, freight bus can

improve the utilization rate of special lanes reserved

for buses. In that article, we did not consider both

pickup and delivery of goods at each

customer/supplier location when a freight bus passes

it. However, in practice, as a new public

transportation means for city logistics, freight buses

should perform both pickup and delivery of goods at

every customer/supplier location they visit.

292

Chang, Z., Chen, H. and Yalaoui, F.

Modeling and Evaluation of a City Logistics System with Freight Buses.

DOI: 10.5220/0007362502920298

In Proceedings of the 8th International Conference on Operations Research and Enterprise Systems (ICORES 2019), pages 292-298

ISBN: 978-989-758-352-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The periodic vehicle routing problem (PVRP)

was first introduced by Beltrami and Bodin (1974)

in vehicle routing for municipal waste collection.

This is the first time that the periodicity of customer

deliveries was specifically addressed in combination

with the consideration of vehicle routing costs.

Russell and Igo (1979) named the periodic routing

problem as the assignment routing problem.

Christofides and Beasley (1984), which is well cited

by periodic routing papers, named the problem as a

period routing problem and provided the first

mathematical formulation of the problem. The first

article that uses the term “periodic vehicle routing”

appears to be Gaudioso and Paletta (1992). In the

paper entitled “Forty Years of Periodic Vehicle

Routing”, Ann and Jill (2014) discussed a wide

range of circumstances and settings in which the

PVRP has been applied and reviewed models and

solution methods developed for the PVRP, including

both exact and heuristic methods.

In this paper, we study the route planning

problem of freight buses with both pickup and

delivery in an urban distribution system. In this

system, each freight bus makes a tour visiting a set

of pickup/delivery locations once at every given

time interval in each day following a fixed route in a

city, and the route planning problem can be

considered a new variant of periodic vehicle routing

problem with pickup and delivery. To the best of our

knowledge, this problem was rarely studied in the

literature. In order to solve the problem, a Mixed-

Integer Linear Programming (MILP) mathematical

model is formulated. Based on the model, we

compare a distribution system with freight buses and

that without freight bus. Preliminary numerical

results on randomly generated instances show that

the system with freight buses can significantly

reduce transportation costs compared with the

system without freight buses.

2 FREIGHT BUS IN CITY

LOGISTICS

With the increase of freight distribution in urban

transportation, more and more private city freighters

were born in the city. Motivated by joint

distribution, in this paper, consider an urban

distribution system with freight buses, which is a

new public transport means that can replace city

freighters belonging to different private logistics

companies in the center of a city. The following two

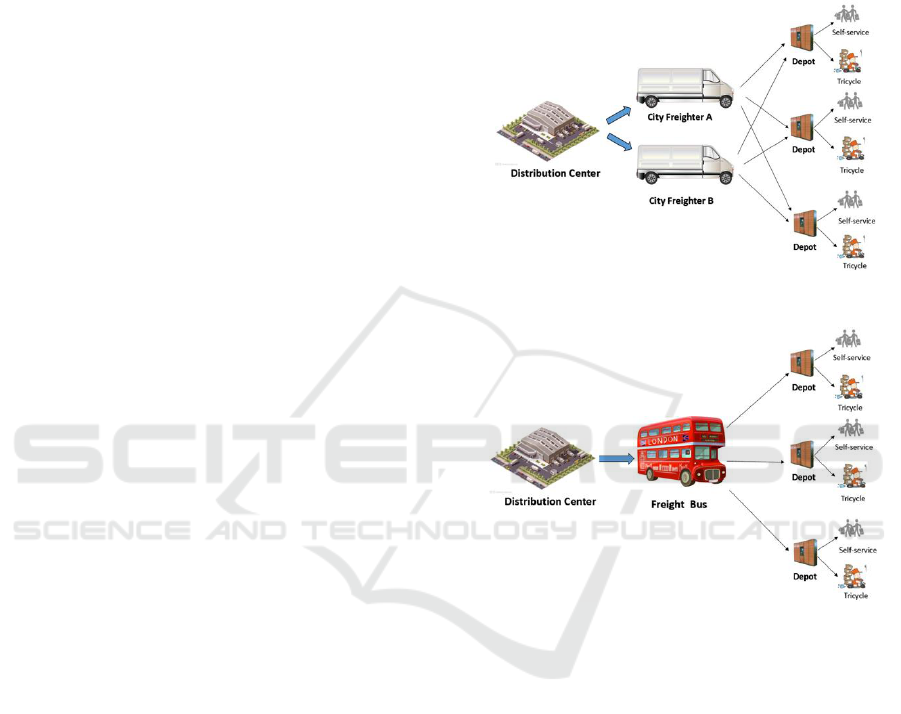

figures compare city freighters and freight buses in

an urban distribution system. We can see in Fig. 1,

there are city freighters from two companies A and

B, which separately deliver their customers'

demands from a distribution center to multiple

depots. However, in Fig. 2, freight buses are used to

deliver all the demands from the distribution center

to the depots.

Figure 1: City freighters in urban distribution system.

.

Figure 2: Freight buses in urban distribution system.

As a public service for third-party logistics

companies and customers, the use of freight buses

can achieve joint distribution. One important feature

of freight buses is that they are standardized vehicles

and have fixed time schedules. With the fixed

schedules, both shippers and customers can well

arrange their order delivery and delivery times. As

we can see from Fig. 2, each depot in such

distribution system is a freight bus station, which has

a smart cabinet (depot) for temporary storage of

goods. According to the schedules, customers can

pick up their ordered products by self-service at the

freight bus stations (depots), or ask the last-mile

delivery men to deliver the goods from a freight bus

station to their homes (Dayarian, Crainic, Gendreau,

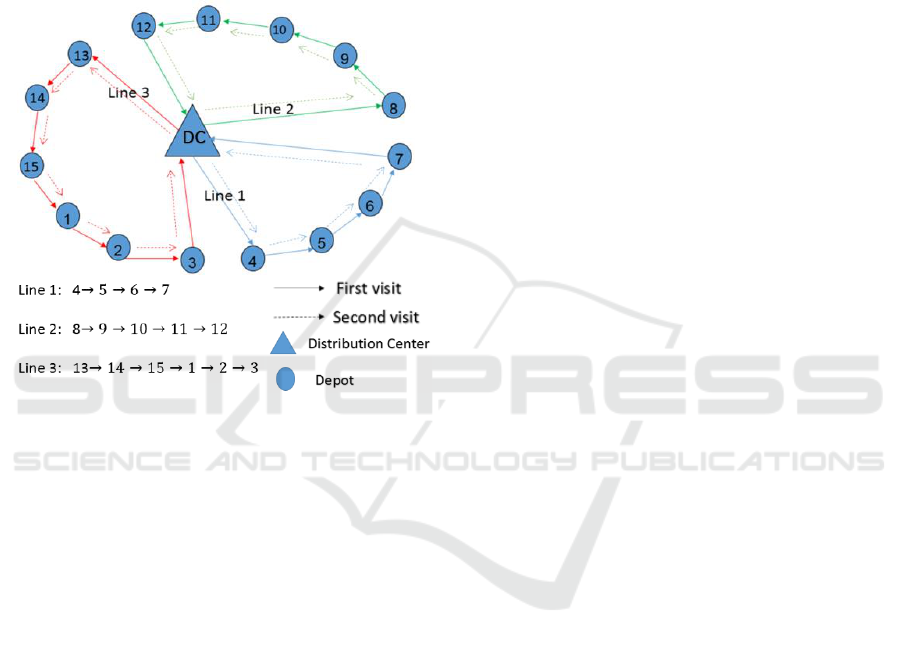

& Rei. 2015). The following figure 3 illustrates

freight bus lines, where each freight bus station is

visited and served by a freight bus line periodically.

Modeling and Evaluation of a City Logistics System with Freight Buses

293

In each run (period), each freight bus starts from a

distribution center, delivers and pick up goods at

multiple depots, and finally returns back to the

distribution center, according to a predefined route

and time schedule. Moreover, as a public

transportation means, freight buses can also enjoy

the policy of bus priority and use special lanes

reserved for buses, which can improve the timeliness

and accuracy of logistics services (Trentini, Campi,

Malhene & Boscacci, 2011).

Figure 3: An example of freight bus lines.

Freight bus has some advantages compared with

city freighter. Firstly, freight bus can realize joint

distribution of different third-party logistics

companies, and can thus save city logistics costs and

reduce the air pollution; Secondly, because of

having a regular schedule, freight bus can improve

the timeliness and accuracy of logistics services;

Thirdly, replacing private city freighters by freight

buses can facilitate the traffic control in a city and

reduce the traffic congestion. Finally, freight bus can

improve the utilization rate of special lanes reserved

for buses. Just like the birth of passenger buses, we

believe that in cities with high freight demands,

freight buses are very likely to be born in the near

future.

3 MATHEMATIC MODEL FOR

FREIGHT BUS ROUTING

In this section, we establish a mathematical model

for the vehicle routing problem of freight bus.

Each freight bus is operated (run) between a distribu-

tion center and multiple depots. Compared with the

capacitated vehicle routing problem, the vehicle

routing problem of freight bus has the following new

characteristics: 1、Each freight bus makes a tour

visiting a set of pickup/delivery locations once at

every given time interval (period) in each day. 2、

Each freight bus has a fixed vehicle route in these

periods. 3 、 Both delivery and pick up can be

operated at each depot (customer/supplier location).

4、delivery and pickup of goods can be delayed but

with penalties.

Therefore, the freight bus routing problem

considered in this paper is a multi-period vehicle

routing problem with pickup and delivery, fixed

routes, and late pickup/delivery penalties. To the

best of our knowledge, this problem was rarely

studied in the literature. In order to solve the

problem, in this section we first formulate a Mixed-

Integer Linear Programming (MILP) model for the

route planning problem of freight buses.

3.1 Problem Description

In the model, each freight bus runs between a

Distribution Center and a set of depots. For

simplicity, we don’t consider the interactions of the

freight buses with the electro-tricycles which

perform last-mile deliveries from depots to

customers. Key features of the model are first

introduced in the following.

(1)Multiple periods: We consider a time horizon

(e.g. one day) that is divided into M periods (M > 1)

and assume that each freight bus visits its served

depots once in each period, and the demand of

delivery and pickup of goods to each depot in each

period is known.

(2)Fixed routes: As passenger buses,we assume

that each freight bus has a fixed route in the time

horizon, and every depot must be served by one

freight bus in each period.

(3)Both delivery and pick up: Each freight bus

can perform pickup and deliver goods at each depot

(customer/supplier location). The freight bus arrives

at each customer/supplier location (station), unload

goods first and load goods later. During the whole

tour, the total amount of goods in the freight bus

should not exceed its capacity. So it is possible that

the delivery or the pickup demand of a depot in a

period is only partially met in this period because of

the capacity limitation of a freight bus, in this case,

the unmet demand of the period can be only met in

later periods. In other words, the goods loaded or

unloaded by the freight bus must be the pickup or

delivery demand of this period or the previous

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

294

periods that were not met due to the limitation of

vehicle capacity.

(4)Penalty of delivery/pickup delay. Delivery

and pickup of goods at a customer/supplier location

can be delayed but with penalties. There are two

types of penalty introduced in this model. One is the

penalty caused by the delay in the time horizon (e.g.

one day) of M periods, which linearly depending on

the quantity of the late delivery or pickup demands

and the number of periods delayed, with the penalty

per period and per unit of demand given by a

coefficient (In this paper, we assume late pickup

and delivery have the same penalty coefficient). The

other is the penalty for all unmet demands at the end

of the time horizon (e.g. one day) of M periods,

which linearly depending on the quantity of the late

delivery or pickup demands, with the penalty per

unit of demand given by another coefficient .

What’s more, Because of these two types of

penalty, we can assume that the operation of the

freight bus has two characteristics: 1,When the

freight bus arrives at a depot, it unloads/delivers first

and then loads/pickup the goods. (In order to free up

more capacity for pickup). 2, For delivery, the

freight bus will give priority to meeting the needs of

the previous visiting depots according to the order of

visiting; for pickup, the freight bus will try its best to

meet the loading needs of the depots according to its

maximum remaining capacity (Because late pickup

and delivery have the same penalty coefficient).

The main parameters of the model are defined as

follows:

o The distribution center where each freight

bus leaves from and returns to.

Set of freight buses.

G Set of depots.

The capacity of each freight bus.

The operating cost for a freight bus when

it travels from node i to node j (i, j ).

M The number of time periods we consider

in the route planning problem.

(k) The demand of delivery of depot i in the

k-th period, G,

.

(k) The demand of pickup of depot i in the k-

th period, G,

.

The per period and per unit late

delivery/pickup penalty cost for goods

delivered/picked up in the time horizon of M

periods.

The per unit late delivery/pickup penalty

cost for goods delivered/picked up beyound the

time horizon.

We assume that the Distribution Center o serves

all depots G in the distribution system considered.

The distance between node i and node j is denoted

by

. The operating cost of a freight bus from node

i to node j is calculated as

, where

is

the unit distance operating cost of each freight bus.

There are N (N is an integer) freight buses operated

for the Distribution Center o, and the capacity of

each freight bus is U.

In each period, each freight bus leaves from the

Distribution Center o, visits its served depots and

returns to the Distribution Center. What’s more, for

one freight bus, every period, all goods loaded at the

DC must be unloaded at its served depots before it

returns to the Distribution Center; and all goods

loaded at its served depots must be unloaded at the

Distribution Center when it returns to the DC . It is

assumed that the demand

and

(k) of each

depot i in each period

is known.

We need to plan the vehicle route for each

freight bus v, and the delivery and pickup quantity of

each freight bus at each depot in each period. The

objective is to minimize the operating costs of all

freight buses plus the late delivery and pickup

penalty costs.

We need to plan the vehicle route for each

freight bus v, and the delivery quantity of every

freight bus at each depot in each period. Our

objective is to minimize the operating costs of all the

freight buses in the M periods.

3.2 Mathematic Model

In this subsection, we propose a mathematic model

for freight buses. With this mathematic model, we

can calculate the whole operating costs of the system

with freight bus in the planning horizon. At the same

time, we can also get the optimal routes of freight

buses. In this subsection, we propose a mathematic

model for the route planning of freight buses by

considering its all characteristics. With this

mathematic model, we can optimize the total cost of

freight buses composed of their operating costs and

penalty costs for the late delivery and pickup of

goods in the planning horizon. At the same time, we

can also get the optimal routes of freight buses by

solving the model.

The detailed mathematical model for the route

planning of freight buses is given as follows:

Decision Variables

A binary variable which is equal to 1 if

the freight bus v goes from node i to j (i,

j ); 0 otherwise.

A binary variable which is equal to 1 if

and only if the depot i is served by the freighter

Modeling and Evaluation of a City Logistics System with Freight Buses

295

bus v; 0 otherwise.

(k) The unloaded quantity of the freighter

bus v at the depot i in the k-th visit k

; 0 otherwise.

(k) The loaded quantity of the freighter bus

v at the depot i in the k-th visit k

; 0 otherwise.

(k) The quantity of all goods remaining to

deliver in the freighter bus v when it just

arrives at node i during the k-th visit,

k

.

(k) The quantity of all goods picked up by

the freighter bus v when it just arrives at

node i during the k-th visit, k

.

Objective Function

The objective is to minimize the sum of all costs

including the operating costs of the freight buses and

the penalty costs for the late delivery and pickup of

goods in the planning time horizon of M periods.

Minimize Z =

+

*

+

*

+

*

+

*

(0)

Constraints

=

(1)

=

(2)

(3)

= 1

(4)

<=

-

+(1-

)

,k

(5)

k

>=

+

-(1-

)

(6)

, k

=

(7)

k

0<=

+

<=U

(8)

,

<=

*

(9)

, n

<=

*

(10)

, n

(11)

>=0 ;

>=0 ;

>=0 ;

>=0

,

,

(12)

Constraints (1) indicate that each freight bus leaves

from and returns to the DC. Constraints (2) ensure

that each freight bus arriving at a depot has to leave

it. Constraints (3) and (4) guarantee that all depots

must be served and each depot is served by at most

one freight bus. Constraints (5) (6) and (7) (8) (9)

formulate vehicle capacity constraints. Constraints

(10) (11) indicate that in each period, the delivery

and pickup of freight bus v at each depot i can only

be the demand of that period or earlier periods but

cannot be the demand of later periods. Finally,

constraints (12) define the domains of all decision

variables.

4 IMPACT OF THE JOINT

DISTRIBUTION REALIZED BY

FREIGHT BUSES

4.1 The Distribution System without

Freight Bus

In order to evaluate the impact of the joint

distribution realized by freight buses, we compare

our proposed distribution system with freight buses

with that without freight bus.

In the system without freight bus, it is assumed

that there are city freighters operated by two private

third party logistics companies and , which

separately deliver and pickup their customers'

demands from a distribution center to multiple

depots. Each city freighter of company or also

visits its served depots once during each period k∈

{1,2 … M}, and the demand of each company’s

customers at each depot i in each period must be

served by its own city freighters. In each period,

each city freighter also begins and ends its travel at

the distribution center. What’s more, and it is

possible that part of the demand of a depot in a

period is served in later periods because of the

limited capacity of a city freighter, and we also

consider two types of penalty costs for late

deliveries and pickups.

To simplify the comparison of the two distribution

systems, we assume that all city freighters operated

by company and company have the same

capacity U, the same unit distance operating cost

,

the same penalty coefficient and , and the same

number of periods M in the planning time horizon as

those of the freight buses, and all the city freighters

also have fixed vehicle routes. The objective of each

city freighter company is to minimize its total cost

which includes the operating costs and the penalty

costs of its own city freighters. With this

assumption, we can use the MILP proposed in this

paper to optimize the vehicle routes of the city

freighters of each company and get its total cost. The

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

296

total cost of the distribution system without freight

bus is thus the sum of the total costs of company

and .

4.2 Experimental Results

In order to verify the freight bus routing model

proposed in section III and evaluate the impact of

joint distribution realized by freight buses, we need

to generate instances which are representative for

both the distribution system with freight buses and

the distribution system without freight bus.

The freight bus routing problem considered in

this paper is related to the vehicle routing problem

with pickup and delivery. So when generating the

instances, we use some data from the benchmark

instances of vehicle routing problem with pickup

and delivery provided by Breedam at

http://neo.lcc.uma.es/vrp/. However, since our

freight bus routing problem involves multiple

periods, we have to generate demand data randomly

based on the benchmark data.

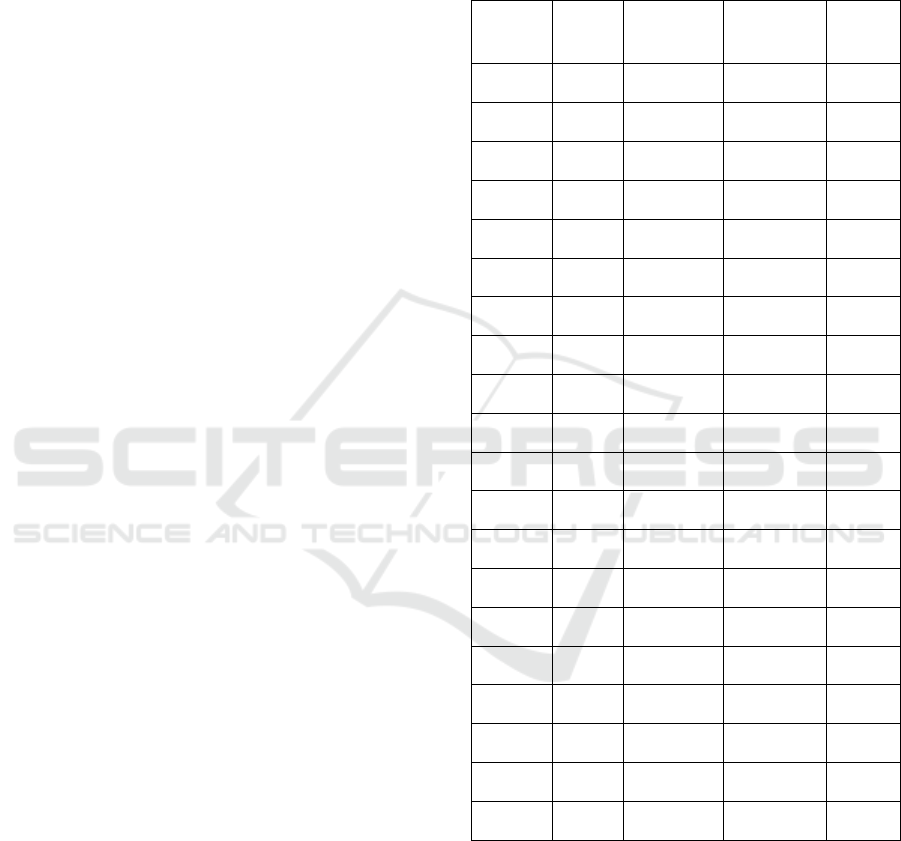

We designed 20 instances with N∈{7,13} and

M ∈ {3,5} (see Table 1). For all instances, the

following data are taken from the benchmark

instances: the coordinates of all nodes, the number

of vehicles, and the capacity of each vehicle. The

other data are generated randomly or based on the

benchmark instances: the delivery demand

(k) of

each depot in each period , the pickup demand

(k)

of each depot in each period, the number of periods

M, the unit distance operating cost

the penalty

coefficients and .

The number of periods M is set to 3 or 5. Since it

is assumed that all freight buses have the same unit

distance operating cost, we simply set

to 1 for all

instances. In order to further evaluate the impact of

the joint distribution realized by freight buses, for

the distribution system with freight buses, we

generate the demand of each depot in each period by

grouping the customer demands of two private third

party logistics companies A and B at the depot in the

period, where the demand (both the delivery and

pickup) of each company at each depot in each

period is randomly generated from [1, 20]. For the

penalty coefficient , because the ratio of to

and

to

affect the tradeoff between the operating

costs of the freight buses and the penalty costs for

late deliveries and pickups as well as the service

level to customers, i.e., the percentage of customer

orders delivered on-time, we cannot set and too

big or too small. After some tests with different

and values, in our numerical experiments we set

to 2, to 4 for all instances.

We then used CPLEX to solve the two models

for each instance with a preset time of 2 hours, and

compare the costs of the two distribution systems.

The follow table gives the experimental results.

Table 1: Experimental results of the two city logistic

systems.

Number

of depot

Visit

times

M

Cost with

Freight

bus

Cost

without

Freight bus

Cost

Saving

7

3

1067.1

1291.9

17.4%

7

3

986.6

1200.2

17.8 %

7

3

1076.9

1306.9

17.6 %

7

3

962.0

1168.9

17.7 %

7

3

1005.8

1219.2

17.5 %

7

5

1984.1

2428.5

18.3 %

7

5

1945.1

2389.6

18.6 %

7

5

1887.0

2312.5

18.4 %

7

5

1940.4

2372.1

18.2 %

7

5

1896.6

2312.9

18.0 %

13

3

1459.9

1818.1

19.7 %

13

3

1519.1

1889.4

19.6 %

13

3

1800.1

2233.4

19.4 %

13

3

1397.4

1740.2

19.7 %

13

3

2878.7

3602.9

20.1 %

13

5

3761.2

4731.1

20.5 %

13

5

3232.8

4046.1

20.1 %

13

5

3329.6

4177.7

20.3 %

13

5

3402.7

4258.7

20.1 %

13

5

3405.6

4251.7

19.9 %

From the experimental results, we can see that if

we use the proposed freight bus system, the cost

saving in percentage compared with the

corresponding system without freight bus is ranged

from 17.6% to 35.3% with the average cost saving

25.1%. Moreover, we can see that the larger the size

of the instances, the more the cost savings of the

freight bus system. The preliminary numerical

results show that the distribution system with freight

Modeling and Evaluation of a City Logistics System with Freight Buses

297

bus can significantly reduce transportation costs

compared with the system without freight bus.

5 CONCLUSIONS

In this paper, we put forward the concept of freight

bus, which is a new public transport means that can

replace city freighters belonging to different private

logistics companies operated in a city. Freight bus has

some advantages compared with city freighter.

Firstly, freight bus can realize joint distribution of

different third-party logistics companies, and can thus

save city logistics costs and reduce the air pollution;

Secondly, because of having a regular schedule,

freight bus can improve the timeliness and accuracy

of logistics services; Thirdly, replacing private city

freighters by freight buses can facilitate the traffic

control in a city and reduce the traffic congestion.

Finally, freight bus can improve the utilization rate of

special lanes reserved for buses.

We study the route planning problem of freight

buses with pickup and delivery in an urban

distribution system. At first, we have described the

operations of freight buses in city logistics. In this

system, each freight bus makes a tour visiting a set of

pickup/delivery locations once at every given time

interval in each day following a fixed route in a city,

and the route planning problem can be considered a

new variant of periodic vehicle routing problem with

pickup and delivery. To the best of our knowledge,

this problem was rarely studied in the literature. In

order to solve the problem, a Mixed-Integer Linear

Programming (MILP) model is formulated. Based on

the model, we compare a distribution system with

freight buses and the corresponding system without

freight bus. Preliminary numerical results on

randomly generated instances show that the system

with freight buses can significantly reduce

transportation costs compared with the system

without freight buses.

However, in the paper, we have not quantitatively

analyzed the timeliness of freight bus. In the future,

we need to propose an effective optimization

algorithm to solve the freight bus routing problem

proposed in this paper for large instances, and

consider more practical issues to operate freight buses

in a city.

ACKNOWLEDGEMENTS

This work is supported by the French National

Research Agency (ANR) under the project ANR-14-

CE22-0017 entitled “Collaborative Transportation in

Urban Distribution”.

REFERENCES

Amaral, R.R., and Aghezzaf, E.H, 2015. City Logistics

and Traffic Management: Modelling the Inner and

Outer Urban Transport Flows in a Two-Tiered

System. Transportation Research Procedia, 6, 297 –

312.

Ann, M. C. and Jill, H. W., 2014. Forty Years of Periodic

Vehicle Routing .Networks, 63 (1), 2-15.

Beltrami, E.J., and Bodin, L.D. ,1974. Networks and

vehicle routing for municipal waste collection.

Networks, 4 (1), 65-94.

Chang, Z., Chen, H.,2017. Freight Buses in Three-Tiered

Distribution Systems for City Logistics: Modeling and

Evaluation. 7

th

International Conference on Industrial

Engineering and Systems Management, Saarbrucken,

Germany.

Christofides, N., and Beasley, J.E. ,1984. The period

routing problem. Networks, 14 (2), 237-256.

Dayarian, I., Crainic, T.G., Gendreau, M., and Rei, W.

,2015. A branch-and-price approach for a multi-period

vehicle routing problem. Computers and Operations

Research,55, 167-184.

Gaudioso.M, and Paletta.G. ,1992. A heuristic for the

periodic vehicle routing problem. Transport Science,

26(2), 86-92.

Gill, L.E., and Allerheiligen, R.P. ,1996. Co-operation in

channels of distribution: physical distribution leads the

way. International Journal of Physical Distribution

and Logistics Management, 26(5), 49-63.

Hao, Y., and Su, Y. ,2014. The research on joint

distribution mode of the chain retail enterprises. 2014

International Conference on Mechatronics,

Electronic, Industrial and Control Engineering, MEIC

2014, 1694-1697.

Russell, R., and Igo, W. ,1979. An assignment routing

problem. Networks, 9(1), 1-17.

Shize, X. ,1973. Introductions of joint distribution.

Circulation and economic study, 8 (3), 87-94.

Trentini, A., Campi, A., Malhene, N., and Boscacci, F.

,2011. Shared passengers and goods urban transport

solutions: new ideas for milan through en international

comparison. Territorio, 59, 38-44.

Tsai, J.T., Liu, T.-K., and Chou, J.H. ,2004. Hybrid

Taguchi-Genetic Algorithm for Global Numerical

Optimization. IEEE Transactions on Evolutionary

Computation, 8 (4), 365-377.

Xu, L., and Yang, D. ,2017. Research on joint distribution

cost allocation model. Boletin Tecnico/Technical

Bulletin, 55(10), 291-297.

ICORES 2019 - 8th International Conference on Operations Research and Enterprise Systems

298