The Stray Light Absorption and Anti-photobleaching Capacity of

Matting Materials on Optical System

Rou-Jhen Chen, Chun-Han Cho, Chia-lien Ma, Liang-Chieh Chao, Kuo-Cheng Huang

and Yu-Hsuan Lin

Instrument Technology Research Center, National Applied Research Laboratories, Hsinchu, Taiwan

Keywords: Matting Materials, Stray Light, Anti-photo Bleaching.

Abstract: Eliminating stray light is a very important item in optimizing optical systems. The typical method is to use

matting materials to coat onto the optomechanical component. However, the material will deteriorate or

bleaching after being exposed to long periods of time and high UV energy. The performance of the optical

system will be therefore affected. In this study, the anti-photobleaching capacity of matting materials on

various substrates was discussed. A high intensity UV source was used to radiate the samples for long time.

The changes of the morphology and relative reflectance of sample were observed and analysed. Also, a 355

nm pulsed laser was used to perform the surface modification on samples. An improvement of the matting

performance was expected. This study succeeded in establishing a comparing procedure, which enabled the

characteristic comparison between the various experimental conditions. This study provides a useful

database for the development of matting material technology.

1 INTRODUCTION

Optical systems are widely used in various fields

such as imaging, illumination, and spectral

detection. The modules of its extension are very

versatile and closely related to people's modern life.

In the development process of various consumer and

professional-grade optical systems, the

specifications focused on are often different.

Therefore, it should be optimized for the demand

during the optical design. For example, cameras

require high-quality resolution, light sources require

uniform light field distribution, display systems

require high collimation, and so on. However, all

optical systems always have the same requirement,

that is, less stray light. (Cheng, 2018) (Buisset,

2015) (Williams, 2018). The reason is that these

undesired beams often interfere with the original

ideal optical system. Typical examples are camera

produces ghost and illumination becomes uneven.

They result in a significant drop in optical quality.

Sources of stray light often come from the edges of

optical systems with limited dimensions or the

imperfect lens quality. The beam is constantly

reflected in the system and deviates from the optical

path that was originally expected. This problem can

be overcome by the anti-reflective film coated on the

lens surfaces and the matting materials processed on

the optomechanical component (Patterson, 2003)

(Benjamin, 1962). The anti-reflection coatings were

a common and mature technology, we notice that the

matting process on the optomechanical surface is a

topic worth studying. Generally, it is not difficult to

achieve high-quality stray light elimination under a

low-brightness optical system, but a high radiation

optical system (such as an photo lithographer)

requires a much higher level of extinction capability.

In addition, the matting material also needs to have

excellent anti-bleaching properties in order to make

the optical system have a long service life.

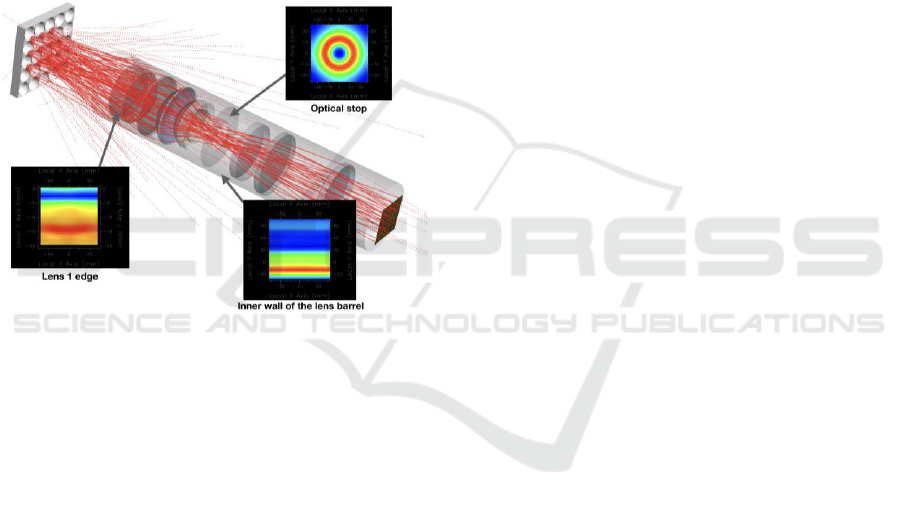

In figure 1, the stray ray distribution of the lens

edge, stop and barrel inner wall of the lithography

light source system by the optical simulation

software was analyzed. The simulation model was

traced by ten million samples. It can be seen from

the figure that since the illuminating light source

cannot be perfectly spatially symmetrical, the

irradiated intensity of the lens edge will be uneven.

If the edge of each lens provides a slight

contribution to the intensity difference, the entire

system will be affected by a non-negligible noise.

This represents a need for matting at the edge of the

lens. For the vicinity of Stop, since the energy is

Chen, R., Cho, C., Ma, C., Chao, L., Huang, K. and Lin, Y.

The Stray Light Absorption and Anti-photobleaching Capacity of Matting Materials on Optical System.

DOI: 10.5220/0007377300590065

In Proceedings of the 7th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2019), pages 59-65

ISBN: 978-989-758-364-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

59

concentrated in the middle of the hole, the beam that

has not been successfully passed will expose the

edge of the hole to form a donut-like shape. This

part of the energy is very high (red area). Therefore,

even though the surface of the Stop has been matted,

it is still prone to failure due to photo bleaching

effect. Finally, the matte treatment of the inner wall

of the lens barrel is inevitable because of it always

encounter a mount of stray lights. In general low-

brightness optical systems, most of them are treated

with black fluffs or black paint. This is not the case

in high-brightness systems, which the scorched

fluffs might contaminate the lens surface. High-

brightness optical systems often use complex surface

modification process, and require good anti-

photobleaching capacity.

Figure 1: Optical intensity distribution of stray light on the

lens edge, stop and inner wall of lens barrel.

In general, the matting treatment on the surface

of the object is divided into two types, one is coating

of the light absorbing material, and the other is

surface modification to form a scattering structure.

A wide variety of light absorbing materials was

formulated for the wavelength match. Some people

created the coating with high melting point and high

absorbance characteristics (Suzanna, 2015)

(Draggoo, 1986) (Jürgen, 2008). The advantages of

these kinds of coating are easily manufacturing and

low cost. The disadvantages of them are that the

absorbances usually lower than 90% and easy to

increase the optical element temperature. The other

people design the diffuser structure on the

optomechanical surface to reduce the effects of stray

ray (Amemiya, 2015) (Mohammad, 2018). A rough

and irregular structure was obtained by destroying

the flatness of the material surface. The specular

reflection behaviour will be converted into diffuse

behaviour, meaning that the directionality of the

light beam will be attenuated by optical scattering.

The advantage of this method is that the extinction

effect is good, but the processing cost is high and

has the risk to damage the optomechanical accuracy.

Surely, the really best way is to combine the two to

achieve a balance between performance and cost. In

this study, a self-made high-intensity UV source was

used to radiate several kinds of matting materials.

The matting materials were coated onto the glass

and metal substrate, and the light exposure time was

over 8 days. By analysing the changes of the surface

structures and relative reflectance, the anti-

photobleaching capacity could be estimated. In

addition, we also try to directly surface-modify these

materials by a UV pulse laser. A novel method was

proposed to increase the matting performance with

the advantages of simple, fast processing and low-

cost. We believe that this study provides a useful

database for matting processing technology.

2 EXPERIMENTAL SETUP AND

SAMPLE PREPARTION

In order to avoid the deterioration of the optical

quality caused by the stray light generated at the

"inner wall of the optical tube" and the "edge of the

lens", a proper design of the matting treatment is

necessary. There are two typical matting treatments,

one is surface modification and the other is black

painting. The former is to manufacture a high-rough

surface to achieve a large amount of optical

scattering, that is, to achieve the extinction by means

of optical diffusion (Diffuse). The effect is very

obvious, but has the disadvantage of high processing

costs. The latter achieves extinction by using an

absorbing material for the wavelength, which is

performance acceptable and inexpensive, but has the

disadvantage of easily accumulating energy to cause

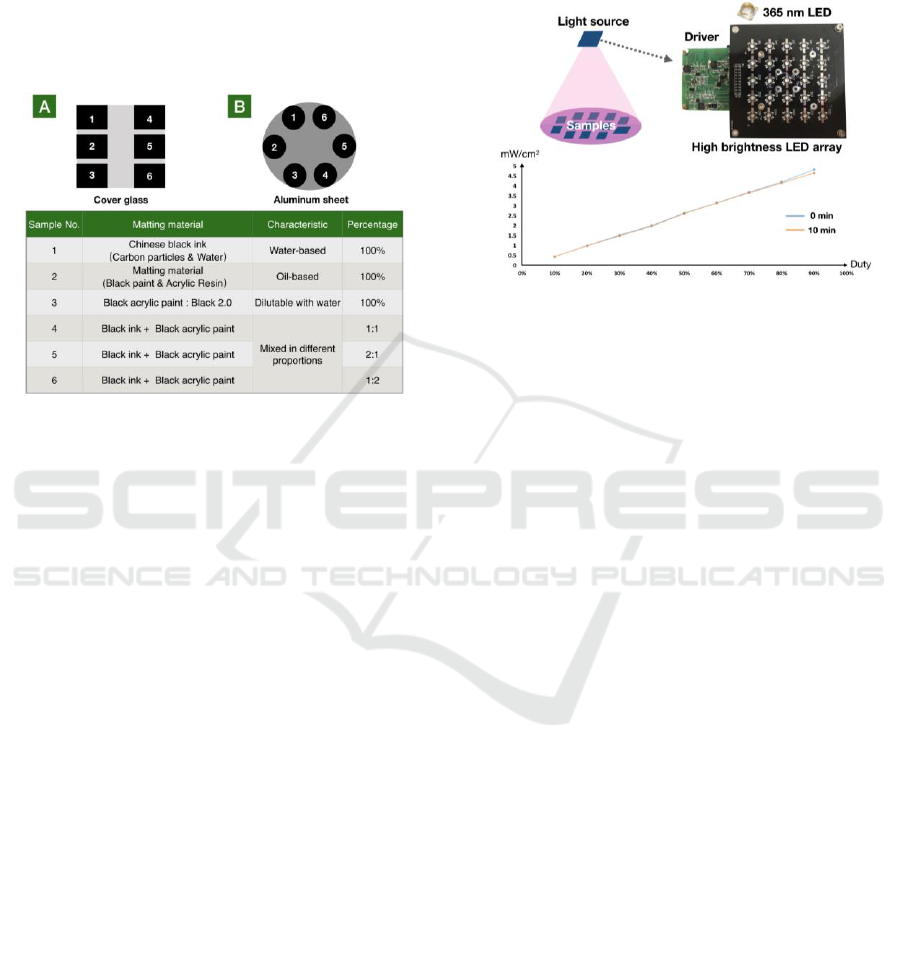

deterioration of the material. In this paper, we

prepared six types of materials as experimental

samples, and were coated on the two types of

substrates. The material information are shown in

Figure 2, where numbers 1~3 are pure matting

materials, and numbers 4~6 are materials mixed in

different proportions. The material types,

characteristics and proportions are also shown in

Figure 2. There are two types of substrates, matte

glass and aluminium metal, which are used to

simulate the "edge of the lens" and the "inner wall of

the optical tube" respectively. The materials was

applied to the substrate in the same manner, and the

position was as shown in the top of Figure 2. The

entire sample has a size of about 10 mm, and the six

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

60

materials are sustained the similar luminance values

during the optical exposure experiment. When

various materials are applied to the substrate, they

will form a slightly rough surface due to cohesive

force, but the contribution of the extinction mainly

comes from the light absorbing ability of the

material. In the second experiment, a pulsed laser

was used to try to form a highly scattering surface

structure on the matting materials.

Figure 2: Configuration diagram of the matting material

and substrate type.

Figure 3 shows the experimental setup. The light

source is a high brightness LED array with a

wavelength of 365 nm. Arranging 25 LEDs in a

square shape makes the illumination more uniform.

The 100mm * 100mm panel size provides a stable

and a large exposure environment. The samples

prepared in Figure 2 are placed in the middle of the

projected range. Before performing the exposure

experiment, the stability of the light source was

verified. As shown in the lower figure in Figure 3,

the linear characterises and intensity did not change

or drift after gradually increasing the electric power

and starting in ten minutes. This plot was measured

when the distance between the sample and the

sensor is 30 cm. The extinction material experiment

was performed for 192 hours, that is, the samples

were exposed to continuous high-intensity

ultraviolet light for 8 days. Each sample receives an

illumination value of approximately 100mW / cm2

and the distance between the sample and the light

source is about 10 mm. Subsequently, the surface

degradation of the material was observed by

confocal optical microscopy to analyse and estimate

the anti-photobleaching capacity of the material. The

confocal microscope used in this study has an axial

resolution of up to 1 μm. Further, in order to make

the matting material have both optical absorption

and structural scattering characteristics, this study

also uses 355 nm pulsed lasers to perform a surface

modification to achieve a better matting

performance. This approach allows for faster and

lower cost surface processing and also can directly

improve the quality of the optical system.

Figure 3: Experimental setup and light source stability test

for anti-photobleaching experiment.

3 RESULTS AND DISCUSSION

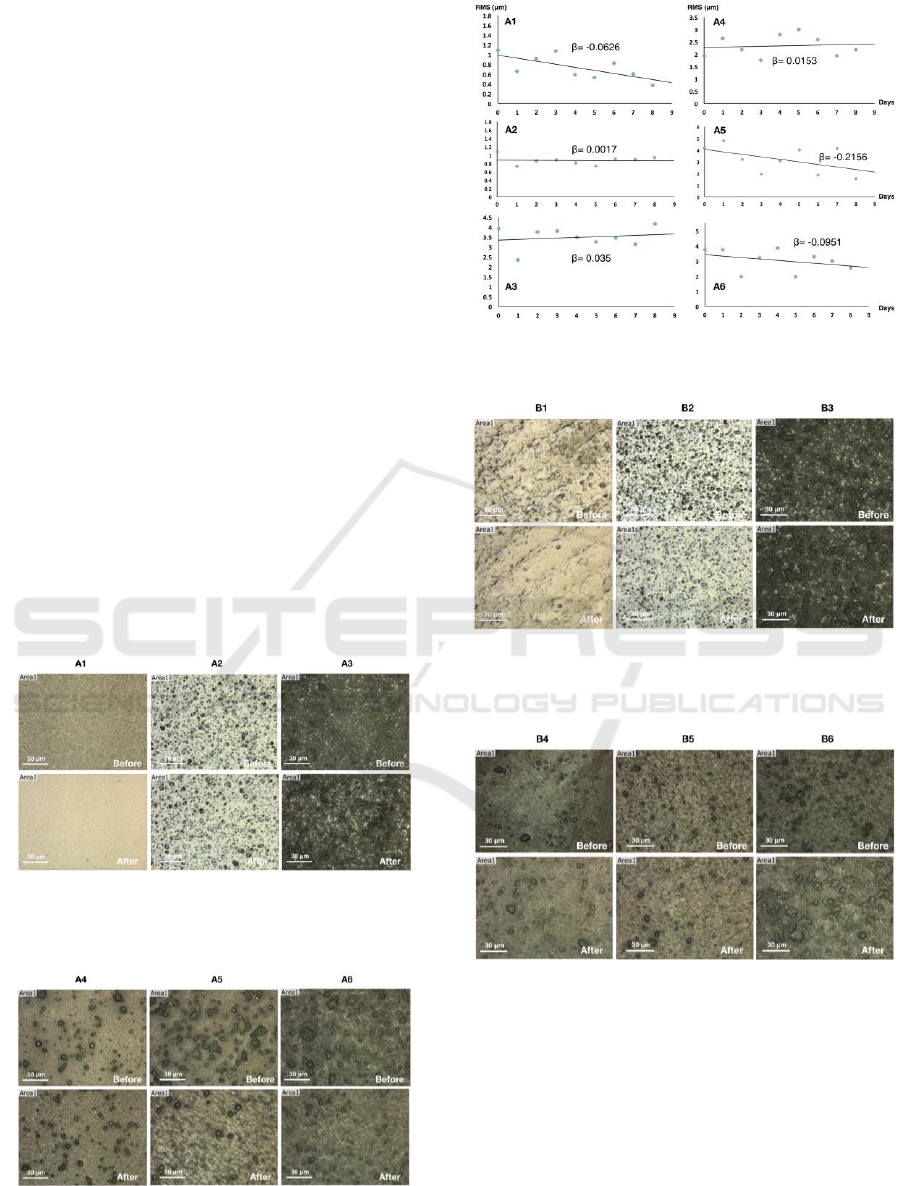

To understand the change of the matting material

with time under the exposure of high-intensity

ultraviolet light, an optical confocal microscope was

used to obtain the roughness of the surface of the

sample. The surface morphology of the 12 samples

(two kinds of substrates) were measured after each

day of light exposure. The samples were illuminated

for a total of 8 days, so a total of 96 sets of data were

obtained after the end of the experiment. Figure 4

and Figure 5 show the morphologies of the sample

surface before and after light exposure (8 days). The

symbol A indicates the use of a glass substrate, and

No. 1 to 6 individually represents the matting

material shown in figure 3. The measurement results

show that different materials have different particle

and pore distributions. The surface of the sample A1

is fine-grained after light exposure, and therefore it

leads to an increase of the reflected light. The

morphology changes of sample A2 and A4 are not

significant. The sample A3 has a tendency to

increase the particles on surface, and A5 and A6

have significantly less particles. Obviously, the

surface changes of various materials after light

exposure are different.

The surface roughness of the sample determines

the characteristics of light extinction. In general, the

higher the roughness, the better the matting

performance. In the experiment, root mean square

(RMS) roughness of each sample surface was

measured and analysed, as shown in figure 6. The

The Stray Light Absorption and Anti-photobleaching Capacity of Matting Materials on Optical System

61

horizontal axis is the number of exposure days, and

the vertical axis is the measured RMS roughness

value. Since the sample would still be slightly

uneven in each area during the fabrication process,

the change in sample roughness over time should be

represented by a trend line. The β value indicates the

slope of the trend line. We assume that the change is

nearly linear. It can be found that the surface of the

sample A1 has a significantly flattened appearance,

and thus its matting efficiency is lowered. This is

consistent with the results in Figure 4. The surface

morphology of sample A2 is almost unaffected by

the high intensity light exposure, and therefore can

be considered as a matting material with the most

anti-photobleaching characteristics. Although the

sample A3 slowly increase the roughness, it was not

obvious. The samples mixed in different proportions

can theoretically adjust the desired effect. The

sample A5 has a higher contribution of water-based

black ink, so its trend line is similar to the sample

A1. However, it become flatten because it is affected

by the influence of the sample A3. The sample A6

was flatter than A5 because the contribution of the

sample A3 is increased. The most appropriate

proportion may be A4 because its flatness is closest

to A2 and ignore the influence of light exposure. It

means that the sample A4 also has the good anti-

photobleaching capacity.

Figure 4: The morphology changes of the matting

materials (#1~3) on glass substrate after high intensity

light exposure.

Figure 5: The morphology changes of the matting

materials (#4~6) on glass substrate after high intensity

light exposure.

Figure 6: The roughness of different matting materials on

glass substrate varies with exposure time.

Figure 7: The morphology changes of the matting

materials (#1~3) on metal substrate after high intensity

light exposure.

Figure 8: The morphology changes of the matting

materials (#4~6) on metal substrate after high intensity

light exposure.

Figure 7 and Figure 8 show the morphologies of

the sample surface before and after light exposure (8

days). The symbol B indicates the use of a metal

substrate (aluminium), and No. 1 to 6 individually

represents the matting material shown in figure 3.

The measurement results show that different

materials have different particle and pore

distributions. The surface distribution of sample B1

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

62

has lower frequency structures after light exposure.

The morphology changes of sample B2 are still not

significant. The samples B3 and B6 show an

increased phenomenon on surface roughness. The

surface change of sample B4 and B5 cannot be

judged by image observation, thus software was

used to perform the surface structural analysis. The

metal substrates have a higher capacity of heat

dissipation, so it will benefit the anti-bleaching

performance of the matting materials.

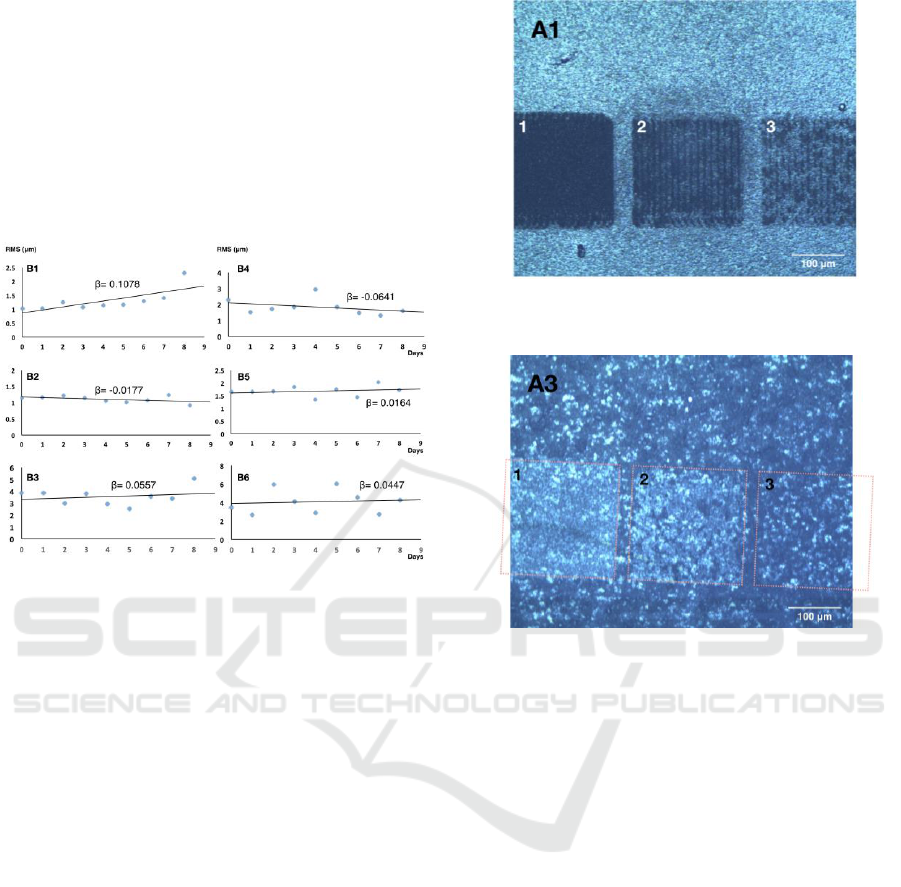

Figure 9: The roughness of different matting materials on

metal substrate varies with exposure time.

Figure 9 shows the roughness of different

matting materials on metal substrate varies with

exposure time. The surface of the sample B1 was

gradually roughened, which was completely

opposite to the case of the A1. This means that the

stability of the water-based black ink is not very

good. The sample B2 is still unaffected by the light

exposure and is the most stable material for anti-

photobleaching. Although sample B3 slowly

increase the roughness, it wasn't obvious. The result

was completely consistent with sample A3. The

results also show that the morphologies of the

sample B4, B5 and B6 are only slightly affected by

the water-based black ink. Their characteristics are

very similar to those of the B3. That is, the increase

and decrease in roughness are not significant. The

experimental results show that the matting materials

on the metal substrate have good anti-

photobleaching capacity, except for the water-based

black ink. Therefore, experimentally, it is necessary

to perform a longer light exposure or higher light

intensity to see an obvious difference in the anti-

photobleaching capacity of the matting material on

the metal substrate.

The matting materials in this experiment all have

good optical absorption characteristics, but the

Figure 10: Laser surface modification of the A1 matting

material.

Figure 11: Laser surface modification of the A3 matting

material.

scattering efficiency contribution of their surface

roughness is not actually significant. Then a 355 nm

pulsed laser was used to perform a surface

modification on them. The matting ability was

expected to be further increased. The experimental

results show two typical effects:First type is that

the surface modification of the sample generates a

highly scattering surface structure. The second type

is that the surface modification forms a photo

bleaching effect. Figures 10 and 11 show the

experimental results of surface modification

performed lasers on samples A1 and A3. Zone 1, 2

and 3 in Fig. 10 and 11 represent the morphology

and brightness of the sample processed by the laser

power of 3W, 1W and 0.5W, respectively. The

brightness change of the zones in image

demonstrates that different matting materials under

laser processing have two type results : Some

materials can increase their extinction by laser

modification, while the others only have the

opposite effect. It means that the laser surface

modification do not necessarily increase the

performance of the matting materials.

The Stray Light Absorption and Anti-photobleaching Capacity of Matting Materials on Optical System

63

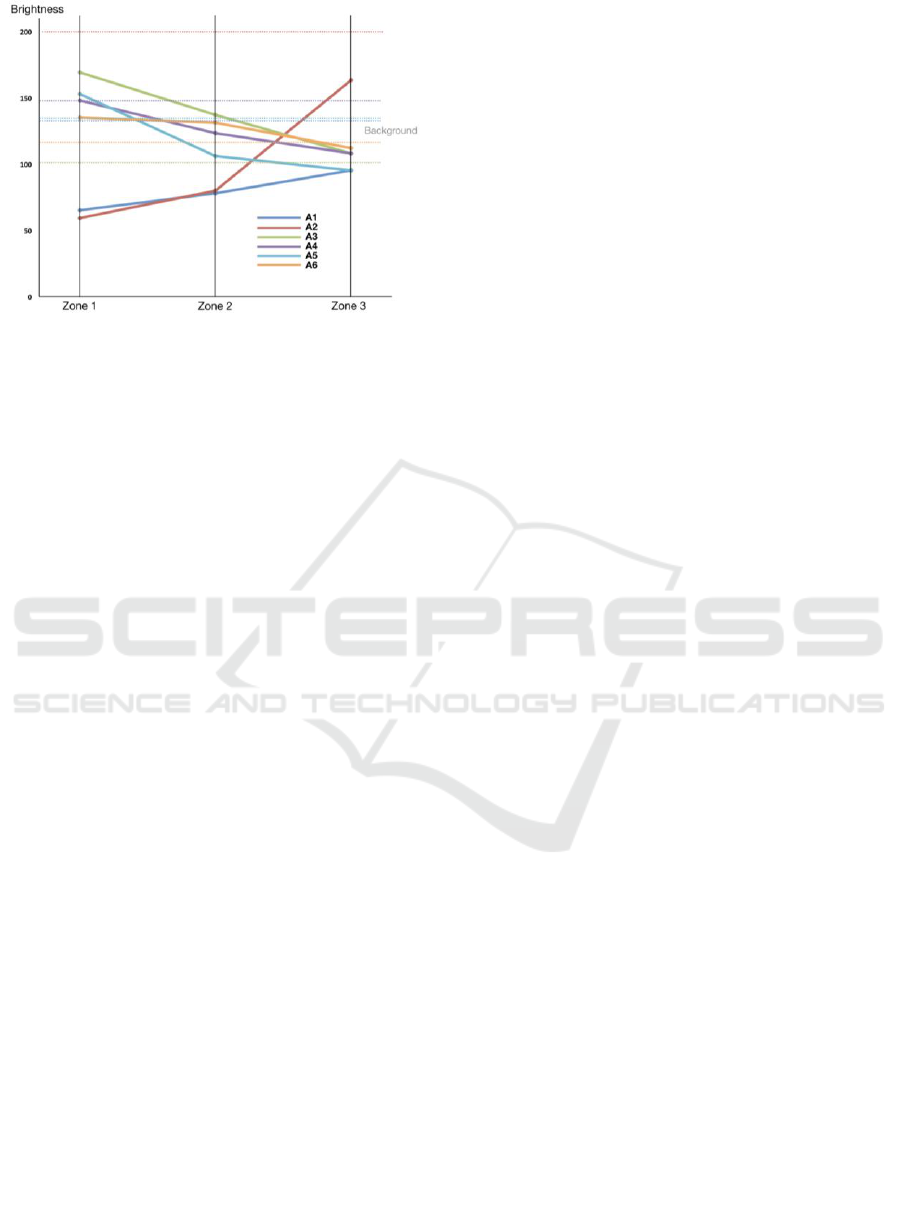

Figure 12: Reflected brightness change of the different

matting materials after laser surface modification.

Figure 12 shows the reflected brightness change

of the different matting materials after laser surface

modification. The horizontal axis is the surface

modification area under different laser powers. The

smaller the zone number, the greater the power. The

vertical axis is the relative brightness value. The

values are obtained by averaging the brightness in

the processing area. The dotted lines represent the

original brightness values of the matting samples.

They are relative reflectance before laser processing.

The experimental results show that both samples A1

and A2 become darker after laser treatment.

Conversely, the samples A3~6 become brighter. The

sample A2 has not only been demonstrated its ability

to resist photobleaching in previous experiments, but

also it has significantly increased its light extinction

capacity after laser surface modification. We can

therefore believe that it is the highest quality matting

material among these materials. This study proposes

a procedure for testing and analysing the matting

material quality. The performance of the materials in

optical absorption and anti-photobleaching could be

accordingly determined.

4 CONCLUSIONS

This study succeeded in developing a simple, rapid

and relative accurate method for the quality

estimation of the matting materials on glass and

metal substrate. A high intensity UV light source

with a wavelength of 365 nm was used to irradiate

the prepared matting materials for 8 days. With the

optical observation of experimental results, many

samples have the reflectance and morphology

changes. Roughness and brightness analysis allows

us to understand the anti-bleaching capacity of the

samples. The experimental results shows that the oil-

based matting paints and 1:1 mixed materials are the

most stable materials that have good anti-

photobleaching characteristic. A UV pulsed laser

was further used to try to improve the matting

performance of the materials. However, only some

materials can benefit from it. The other materials

have become less effective. This study procedure is

compatible with the other matting materials and can

be applied to various optical systems. This study

provides a useful database for optical matting and

anti-photobleaching technology.

ACKNOWLEDGEMENTS

The authors would like to express their appreciation

for financial aid from the Ministry of Science and

Technology, R.O.C under grant numbers MOST

107-2622-E-492-019-CC3. The authors would also

like to express their gratitude to the Instrument

Technology Research Center of National Applied

Research Laboratories for the support.

REFERENCES

Cheng, Y., Cheng D., Wang Y., 2018. “Design and stray

light analysis of a lenslet-array-based see-through

light-field near-eye display.” Digital Optics for

Immersive Displays. Vol. 10676. International Society

for Optics and Photonics.

Buisset, C., Prasita, A., Leckngama, A., Lépineb, T.,

Poshyajindaa, S., Soonthornthuma, B., Irawatia, P.,

Richichia, A., Sawangwita, U., Dhillonc,d, V., Hardy,

L. K., 2015, “Progress on the prevention of stray light

and diffraction effects on the Thai National

Telescope.” Optical Systems Design 2015: Optical

Design and Engineering VI. Vol. 9626. International

Society for Optics and Photonics.

Williams, E. A., Withington, S., Goldie, D. J., Thomas, C.

N., Chen, J., Ade, P. A. R., Sudiwala, R., Walker, I.

K., Trappe, N. A., 2018, “Ultra-low-noise transition

edge sensors for far infrared wavelengths: optical

design, measurement and stray light

control.” Millimeter, Submillimeter, and Far-Infrared

Detectors and Instrumentation for Astronomy IX. Vol.

10708. International Society for Optics and Photonics.

Patterson, B. A., Wells, M., 2003, “Analysis of scattered

light for VISTA.” Specialized Optical Developments

in Astronomy. Vol. 4842. International Society for

Optics and Photonics.

Benjamin, C., 1962, “Light loss and image formation in

optical systems, with special reference to endoscopic

instruments.” spiral.imperial.ac.uk.

PHOTOPTICS 2019 - 7th International Conference on Photonics, Optics and Laser Technology

64

Suzanna, A., Cohen, R., Magdassi, S., 2015, “Wet

deposition of carbon nanotube black coatings for stray

light reduction in optical systems.” Surface and

Coatings Technology, (262), 21-25.

Draggoo, V. G., Morton, R. G., Sawicki, R. H., Bissinger,

H. D., 1986, “Optical coating absorption measurement

for high power laser systems.” High power and solid

state lasers. Vol. 622. International Society for Optics

and Photonics.

Jürgen, I., 2008, “Micro patterning of fused silica by laser

ablation mediated by solid coating

absorption.” Applied Physics A, (93.1), 65-68.

Amemiya, K., Koshikawa, H., Yamaki, T., Maekawa, Y.,

Shitomi, H., Numata, T., Kinoshita, K., Tanabe, M.,

Fukuda, D., 2015, “Fabrication of hard-coated optical

absorbers with microstructured surfaces using etched

ion tracks: Toward broadband ultra-low

reflectance.” Nuclear Instruments and Methods in

Physics Research Section B: Beam Interactions with

Materials and Atoms, (356), 154-159.

Mohammad, A., Eslamimajd, A., Hajghassem, H., 2018,

“Stray light analysis, baffle, and optical design of a

high-resolution satellite camera.” Journal of Applied

Remote Sensing, 12(2), 026009.

The Stray Light Absorption and Anti-photobleaching Capacity of Matting Materials on Optical System

65