A Tool for High-level Modeling of Analog/Mixed Signal Embedded

Systems

Daniela Genius

1

, Rodrigo Cortés Porto

1,3

, Ludovic Apvrille

2

and François Pêcheux

1

1

Sorbonne Université, LIP6, CNRS UMR 7606, Paris, France

2

LTCI, Télécom ParisTech, Université Paris-Saclay, Paris, France

3

Technische Universität Kaiserslautern, Kaiserslautern, Germany

Keywords:

Embedded Systems, Analog/Mixed Signal Design, Virtual Prototyping, Code Generation.

Abstract:

Embedded systems are commonly built upon heterogeneous digital and analog integrated circuits, including

sensors and actuators. Model-driven approaches for designing software and hardware have been proposed, yet

they are generally limited to the digital parts of systems. This paper presents the extension of an integrated

modeling and simulation tool for the verification and virtual prototyping of embedded systems described at

different abstraction levels to analog/mixed-signal systems.

1 INTRODUCTION

Model-driven techniques make use of high level

models to create the specification of the software,

and then rely on model transformations to gener-

ate the corresponding source code. They have been

widely proposed for designing software and hard-

ware. Nonetheless, in most cases, these approaches

are limited to the digital part of the system, whereas

embedded systems — e.g. robotics and automo-

tive systems — are frequently built upon heteroge-

neous hardware e.g. processors, FPGAs, DSPs, hard-

ware accelerators, digital and analog analog/mixed

signal(AMS) and radio frequency(RF) circuits.

In very early design phases, rapid but less precise

exploration of the design space is required. For this

purpose, heterogeneous embedded systems require a

high-level representation that includes models of their

AMS and RF components. The problems of synchro-

nization between the time domains of the different

Models of Computation (MoC) however must be pre-

cisely considered.

This paper presents the integration of models for

analog components into an existing multi-level mod-

eling and virtual prototyping tool. In the modeling

phase, we define a way to capture both digital and

analog domains. In the prototyping phase, we propose

a way to combine a Timed Data Flow (TDF) simula-

tion with an event-based (SystemC) simulation.

Related work in the next section demonstrates the

lack of an integrated approach offering at the same

time high-level heterogeneous system modeling, for-

mal verification, correct-by-construction code gener-

ation, and cycle/bit precise simulation of both the dig-

ital and the analog parts. Section 3 presents the bases

of this work, Section 4 our contribution and Section 5

provides results for a larger case study.

2 RELATED WORK

Well established tools in analog/mixed signal design,

like Ptolemy II (Ptolemy.org, 2014), based upon a

data-flow model, address heterogeneous systems by

defining several sub domains using hierarchical mod-

els. Instantiation of elements controlling the time syn-

chronization between domains is left to the responsi-

bility of designers.

Metropolis (Balarin et al., 2003) is based on a high

level model and facilitates the separation of computa-

tion from communication concerns. Heterogeneous

systems are taken into consideration, but heterogene-

ity can only be represented using processes, mediums,

quantities and constraints. Hierarchical models are

not allowed: all processes should be implemented in

the same hierarchical level. Metro II (Davare et al.,

2007) introduces hierarchy and allows Adaptors for

data synchronization as a bridge between the seman-

tics of components belonging to different MoCs. The

model designer still has to implement time synchro-

nization. As a common simulation kernel handles all

process execution, MoCs are not well separated.

SystemC (IEEE, 2011) is a C++ class library

which makes it possible to model (digital) hardware

Genius, D., Porto, R., Apvrille, L. and Pêcheux, F.

A Tool for High-level Modeling of Analog/Mixed Signal Embedded Systems.

DOI: 10.5220/0007520804330440

In Proceedings of the 7th International Conference on Model-Driven Engineering and Software Development (MODELSWARD 2019), pages 433-440

ISBN: 978-989-758-358-2

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

433

on multiple levels of abstraction. Among the frame-

works based on SystemC are HetSC (Herrera and Vil-

lar, 2007), HetMoC (Zhu et al., 2010) and ForSyDe

(Niaki et al., 2012), all having the disadvantage that

instantiation of elements and controlling the synchro-

nization have to be managed by the designer.

SystemC-AMS extensions (Accellera Systems

Initiative, 2010) is a standard describing an exten-

sion of SystemC with AMS and RF features (Vachoux

et al., 2003). The usual approach for modeling the

digital part of a heterogeneous system with SystemC

is to rely on the Discrete Event (DE) part of SystemC

AMS extensions. The Timed data Flow (TDF) part

adds support for signals where data values are sam-

pled with a constant time step.

In the scope of the project BeyondDreams (Be-

yond Dreams Consortium, 2011), a mixed analog-

digital systems proof-of-concept simulator has been

developed, based on the SystemC AMS extension

standard. Another simulator is proposed in the

H-Inception project(H-Inception Consortium, 2015).

All of these approaches rely on SystemC AMS code

i.e. they don’t provide a high-level interface for spec-

ifying the application.

Outside the analog/mixed signal domain,

UML/SysML based modeling techniques such as

MARTE and Gaspard2 (Vidal et al., 2009; Selic

and Gérard, 2013; Gamatié et al., 2011) are popular

for capturing embedded systems, but are scarcely

used for heterogeneous system design with virtual

prototyping in mind. Furthermore, with very few

exceptions such as (Taha et al., 2010; Li et al., 2018),

they do not support refinement until a low level of

abstraction i.e. cycle bit accurate level nor provide

full-system simulation.

The B method and more recently Event-B (Abrial,

2010) model systems at different abstraction levels

and makes it possible to mathematically prove con-

sistency between refinement levels. Based on set the-

ory and the B language, the B method is well es-

tablished in large-scale public/private projects (urban

transports etc.) but less widespread in industry than

UML/SySML based approaches.

Very few works exist which bridge the gap be-

tween digital and analog aspects. One of these contri-

butions stems from the Micro-electromechanical sys-

tems (MEMS) community (Bouquet et al., 2012).

It transforms structural SysML diagrams to VHDL-

AMS code. Another is Discrete Event System Spec-

ification (DEVS (Concepcion and Zeigler, 1988)), a

modular and hierarchical formalism for modeling and

analyzing general systems that can be discrete event

or continuous state systems; the latter can be de-

scribed by differential equations, or hybrid systems.

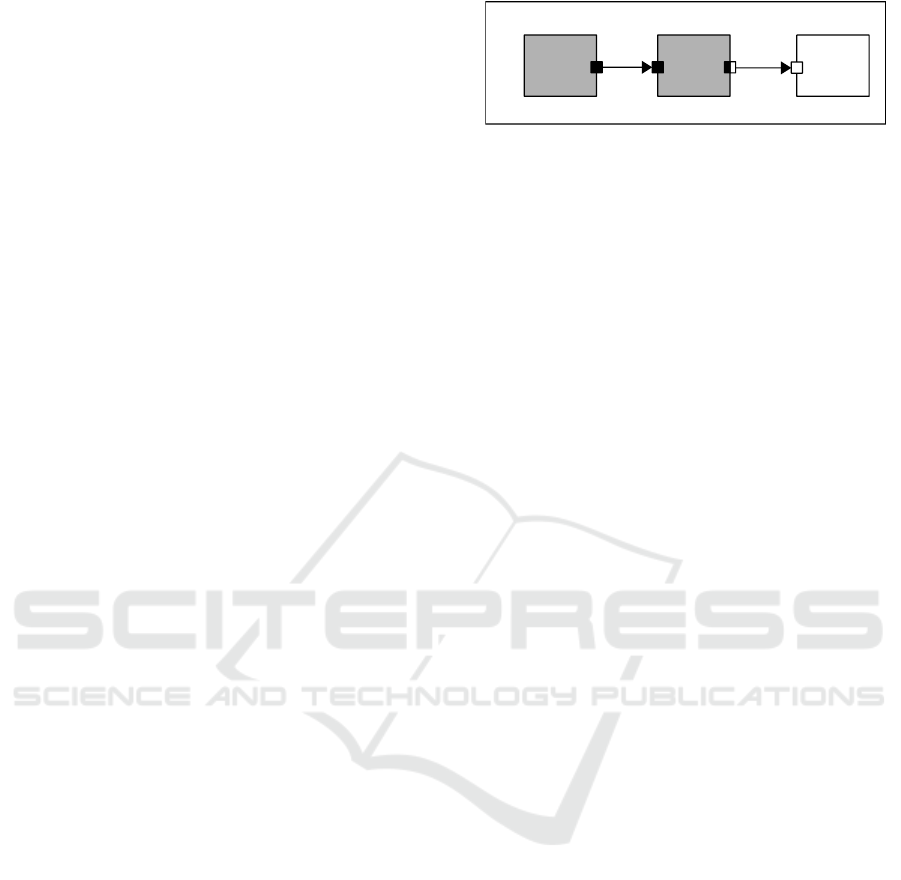

A B Y

R= 1

D= 1

Tm= 6 ms Tm= 4 ms

Tp= 4 ms

R= 3

Tp= 2 ms

D= 0

R= 2

D= 0

Tp= 2 ms

TDF Cluster

Figure 1: TDF Cluster.

3 PRELIMINARIES

Timed Data Flow. SystemC AMS uses among oth-

ers the Timed Data Flow (TDF) Model of Compu-

tation which is based on the timeless Synchronous

Data Flow (SDF) semantics (Lee and Messerschmitt,

1987b). A TDF module is described with an attribute

representing the time step and a processing function.

The processing function corresponds to a mathemat-

ical function which depends on the module inputs

and/or internal states. At each time step, a TDF mod-

ule first reads a fixed number of samples from each

of its input ports, then executes the processing func-

tion, and finally writes a fixed number of samples to

each of its output ports. TDF modules can interact

with the DE world, such as digital Multi-Processor

System-on-Chip (MPSoC) platforms, using converter

ports.

Figure 1 shows a TDF cluster. DE modules

are represented as white blocks, TDF modules as

gray blocks, TDF ports as black squares, TDF con-

verter ports as black and white squares, DE ports as

white squares and TDF signals as arrows. So-called

converter ports, shown as black-and white squares,

serve as interface between the TDF and DE MoC. The

TDF modules have the following attributes:

• Module Timestep (Tm) denotes the period during

which the module will be activated. One module

will only be activated if there are enough samples

available at its input ports.

• Rate (R). Each module will read or write a fixed

number of data samples each time it is activated.

This number is annotated to the ports and it is

known as the port rate.

• Port Timestep (Tp) is the period during which

each port of a module will be activated. It also de-

notes the time interval between two samples that

are being read or written.

• Delay (D). A delay D can be assigned to a port

to make it store a given number of samples each

time it is activated, and read or write them in the

next activation.

MODELSWARD 2019 - 7th International Conference on Model-Driven Engineering and Software Development

434

Final

software

code

Refinements

VHDL/Verilog

SystemC-

AMS

Virtual Prototype

Deployment

Hardware

design

Hardware

Abstractions

Simulation

and

Verification

Micro Kernel

MPSoC

Model

HW/SW Partitioning

Functional

Software Design

Hardware

model

Figure 2: Hardware/Software partitioning and code generation for MPSoC platforms.

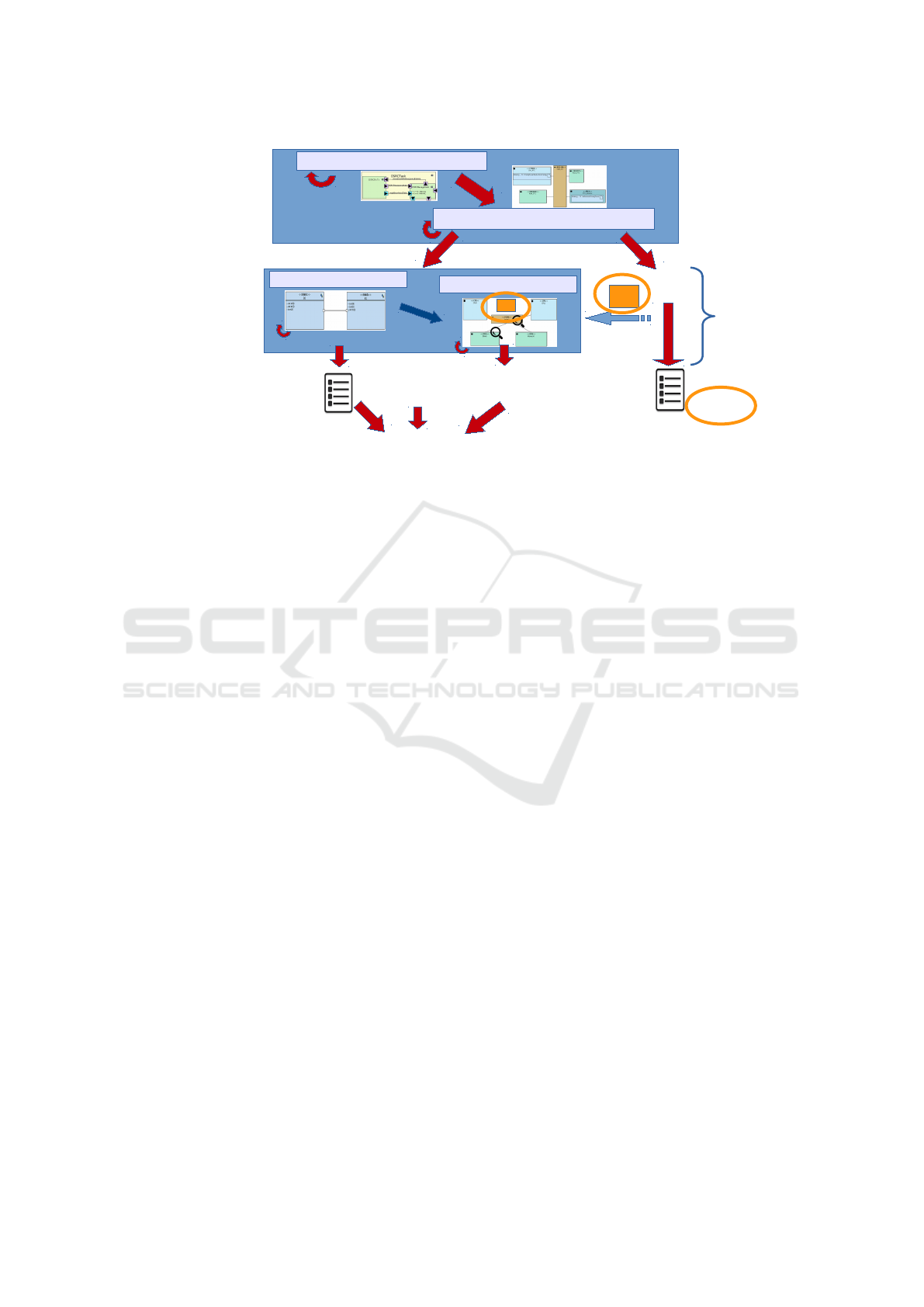

Modeling Tool. TTool (Apvrille, 2011) is a SysML

based, free and open-source software initially de-

signed for model-based engineering of (digital) em-

bedded systems at different abstraction levels: func-

tional, partitioning, software design, and deployment.

To each of these levels, as shown in Figure 2, is as-

sociated a separate panel. The method associated to

these levels explains how to take hardware/software

partitioning decisions at a high level of abstraction

and to regularly validate these decisions during soft-

ware development (Li et al., 2018).

Software tasks for the partitioning model are cap-

tured within the functional abstraction level, and soft-

ware tasks used in deployments are captured in the

software design abstraction level. In both partition-

ing and deployment, the computation part of tasks is

then deployed to processors and hardware accelera-

tors, and the communication and storage parts are de-

ployed to buses and memories.

TTool allows verification and fast simulation for

the digital part but also cycle bit accurate virtual

prototyping on a Multi-Processor System-on-Chip

(MPSoC) based on the SoCLib (SocLib consortium,

2003) public domain library written in SystemC.

As SystemC-AMS is an extension to SystemC, the

choice of this tool for integrating analog/mixed sig-

nal components was natural.

4 INTEGRATION OF ANALOG

COMPONENTS

In the following, we show how TDF concepts can be

integrated into a high-level modeling and virtual pro-

totyping tool, while maintaining as far as possible the

idea of correct-by-construction code generation. Fig-

ure 2 uses orange circles to explain how the method-

ology described above has to be adapted to AMS

components in TTool. Hardware parts, shown on the

lower right, can be simulated with a cycle-accurate

precision. Analog/Mixed Signal components are not

represented on the partitioning level, as the decision

to have them implemented in hardware or software

is not in the hands of the designer of the embedded

platforms. They must thus be visible in the deploy-

ment diagram, from which the hardware topcell and

the description of the mapping of software objects to

processors, memories and communication elements is

generated.

Our contribution is twofold: represent SystemC-

AMS components in the Deployment Diagram and

integrate the the communication between digital and

analog part of the platform in the prototyping code.

4.1 Graphical Representation of Analog

Components in TTool

TTool has been extended with an abstract way to

capture SystemC-AMS blocks with their DE, TDF

and converter ports. Each TDF cluster is designed

in its own panel because SystemC-AMS must calcu-

late a separate schedule (Accellera Systems Initiative,

2010) for each of them. When a TDF module is cre-

ated, it is possible to modify its attributes and param-

eters. The name and Timestep or Period (Tm) of a

module can be defined and time resolution selected.

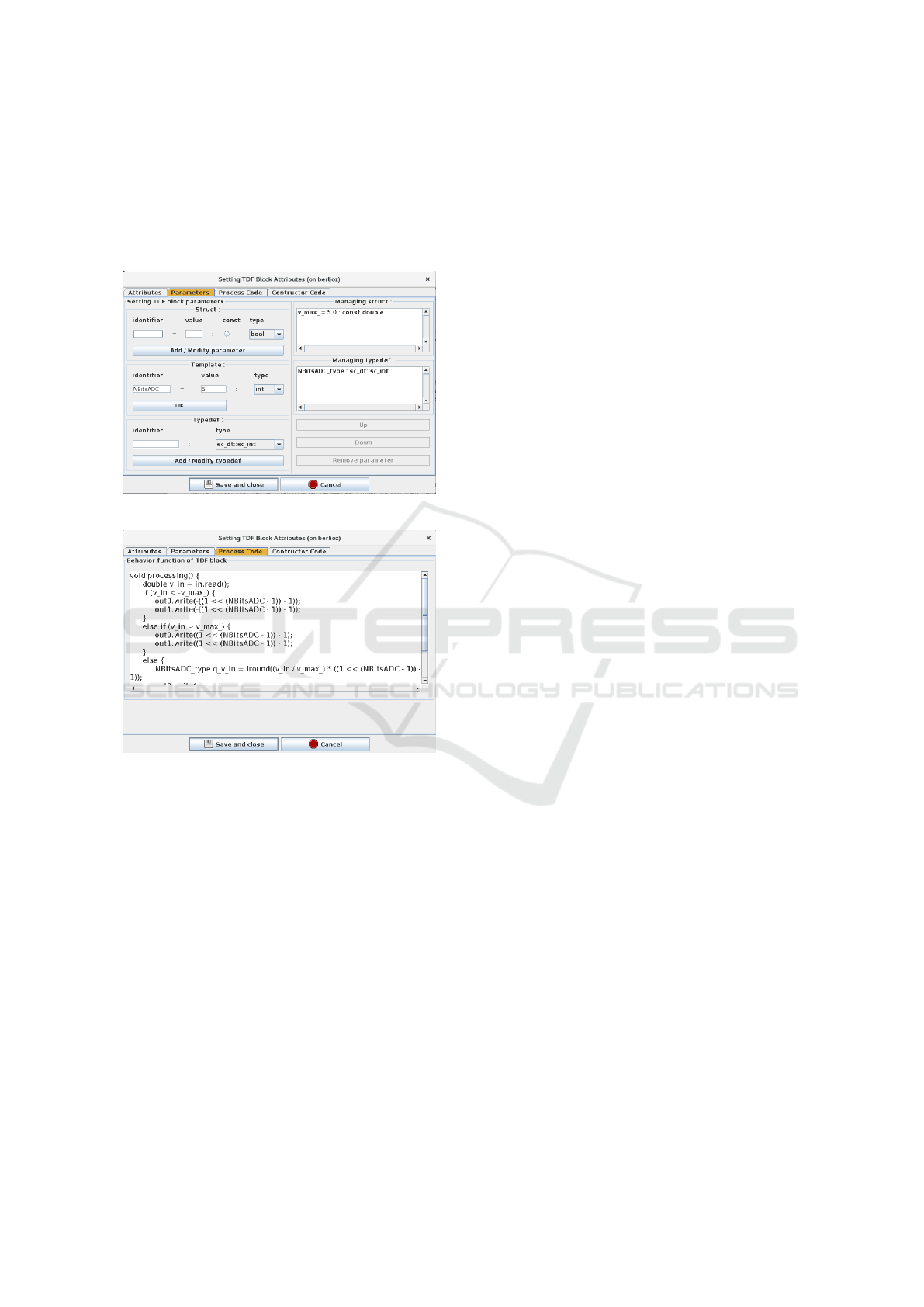

The parameters of a TDF module such as its internal

variables or template parameters can be also set up, as

A Tool for High-level Modeling of Analog/Mixed Signal Embedded Systems

435

it is shown in Figure 3.

Analog components are difficult to parameterize,

since most components are more or less unique. Our

current (and temporary) solution is to offer a dia-

log window where the SystemC-AMS processing()

function can be provided, as shown in Figure 4.

Figure 3: TDF module parameters.

Figure 4: TDF module process code.

4.2 MPSoC Virtual Prototype

If the deployment model contains only SystemC-

AMS clusters, then TTool generates SystemC AMS

TDF code of the components as well as the SystemC-

AMS top cells from the mixed graphical/textual de-

scriptions, and supplies a Makefile. In case soft-

ware code is also deployed, processors / buses /

memories must also be generated. SoCLib offers

a way to describe Multi-Processor System-on-Chip

platforms with semantics based on the shared mem-

ory paradigm, where digital components are inter-

connected with VCI (VSI Alliance, 2000) interfaces.

Components can be initiators issueing requests (typi-

cally CPUs and hardware accelerators), or targets an-

swering to requests (e.g. RAM).

In order to combine SoCLib specification with

SystemC-AMS components, we have defined generic

adaptor modules that can connect SystemC-AMS

components to VCI interfaces. An adaptor is mod-

eled as a general-purpose input/output(GPIO) tar-

get component, following the modeling rules for writ-

ing cycle-bit precise SystemC simulation models for

SoCLib.described below. GPIO components are vis-

ible in the deployment diagram, and, like the other

VCI components, their interconnection to the central

VCI interconnect is represented by an arc. Click-

ing on one of the GPIO opens the corresponding

TDF cluster. Finally, the generated topcell is thus

composed of SoCLib modules and interfaces to the

SystemC-AMS clusters.

4.3 Simulation

Due to their different Model of Computation, AMS

components require to execute their simulated behav-

ior apart from the rest of the system, but regularly

synchronize with the digital platform. The SystemC

kernel is controlling the AMS kernel: the AMS ker-

nel runs continuously until it is interrupted by and

access to a converter port by a TDF cluster. When

the TDF module accesses its input converter port, the

DE simulation time advances until it is equal to the

TDF simulation time of the input converter port. If

later an access to an output converter port occurs with

a TDF simulation time that is less than the new DE

simulation time, a time synchronization issue occurs.

To avoid this situation, the TDF simulation time of

the output converter ports always needs to be greater

or equal than the DE simulation time. This prob-

lem was exposed in (Andrade et al., 2015). Since

model-driven approaches expect to ideally provide

model validation before code generation (and thus

simulation), we propose a way to statically identify

synchronization problems (Cortés Porto, 2018). The

schedulability of the analog part is validated using

the schedulability check of SystemC-AMS (Lee and

Messerschmitt, 1987a), before code is generated.

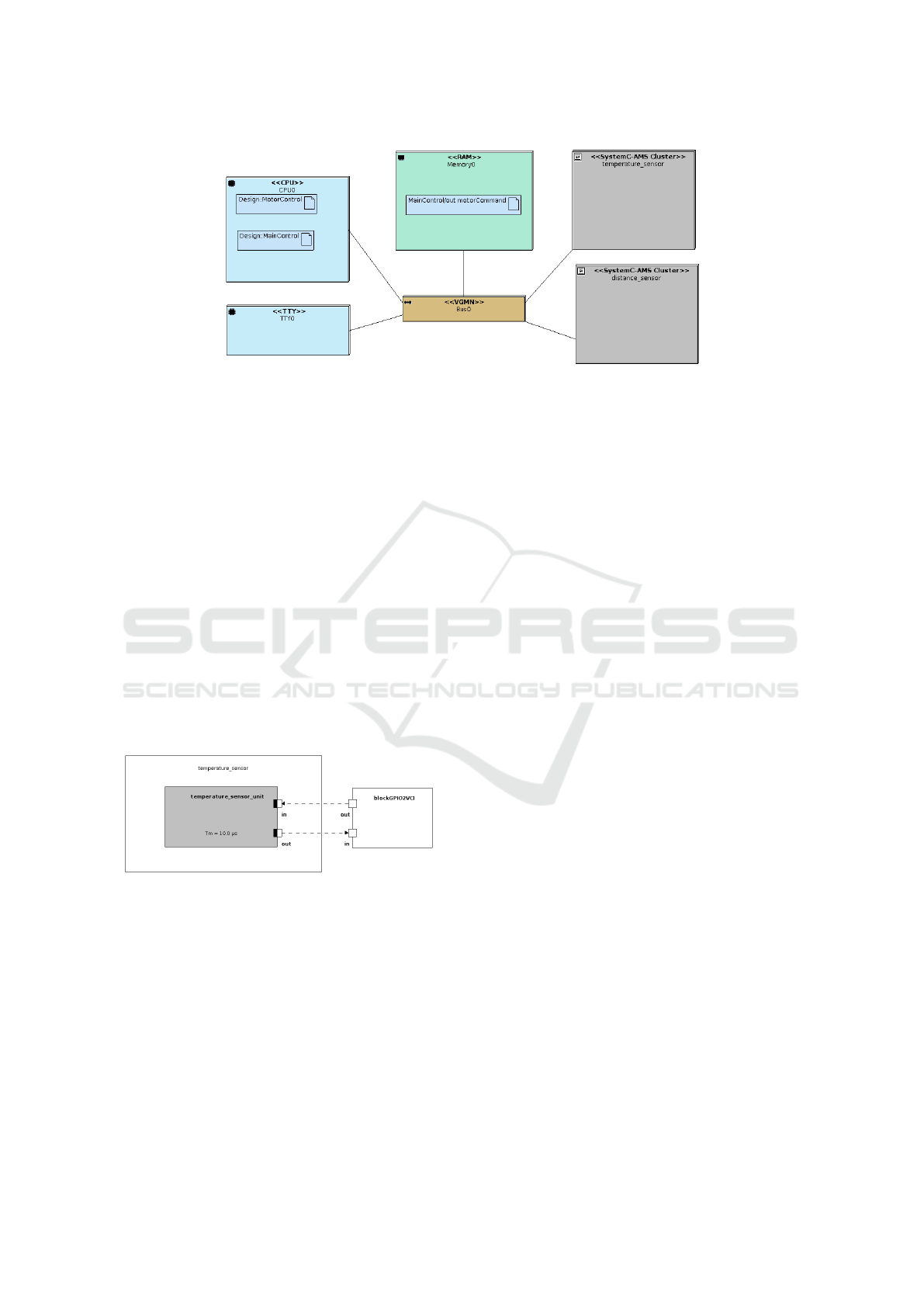

5 CASE STUDY: ROVER

A rover system, intended to assist rescuers to find vic-

tims buried in rubble, consists of four components:

central control and motor control and the two sensors,

a distance sensor and a temperature sensor.

In the rover case study already published in (Ge-

nius et al., 2018), we replace the two sensors by more

realistic analog models (TDF still being an abstraction

of the analog behavior). Central and motor control are

still modeled as digital components, whereas the two

sensors are modeled as independent TDF clusters. As

MODELSWARD 2019 - 7th International Conference on Model-Driven Engineering and Software Development

436

Figure 5: Deployment Diagram model of the rover.

the partitioning decision has already been taken for

the analog blocks, they are not part of functional and

partitioning views.

5.1 Software Design

Figure 5 shows the deployment diagram where the

two software tasks (MainControl, motorControl)

are mapped onto the CPU, the channel between the

tasks on the memory. TDF clusters appear as gray

boxes along with digital components, interconnected

to the central (digital) interconnect through GPIO

components as detailed below;

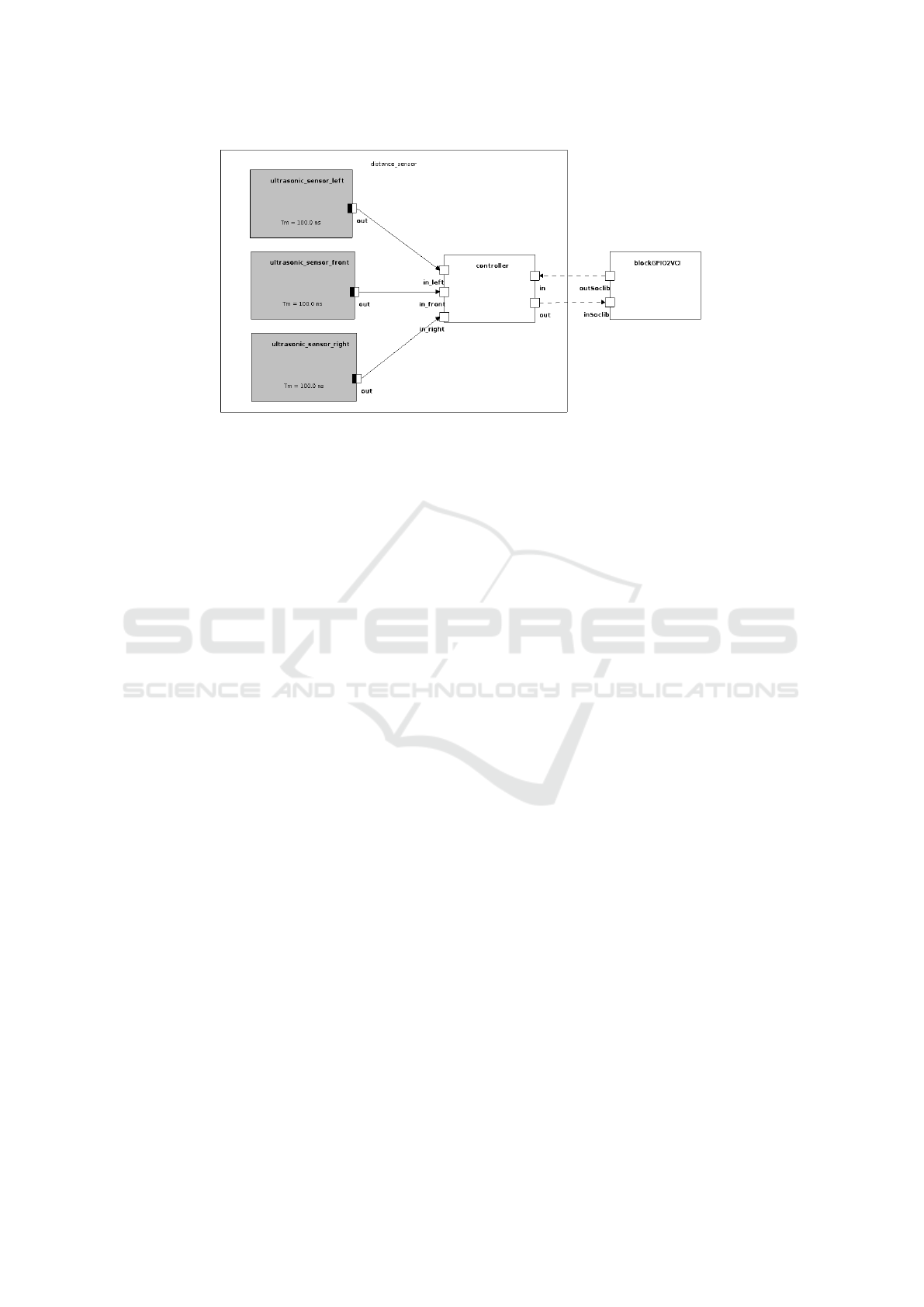

5.2 Diagrams for TDF Clusters

SystemC-AMS Component Diagram panels are

shown in Figures 6 and 7.

Figure 6: Temperature sensor model.

The temperature sensor cluster is composed of one

single TDF module. The behavior of this module,

which is a simplification of the actual behavior of

a temperature sensor, is described as SystemC-AMS

code. It depends on the value received on its input

port in, which is connected to the digital components

of the system via a GPIO2VCI component. A value of

0 means that the temperature sensor should be turned

off. If a value different from 0 is received, then the

temperature sensor will generate random integer val-

ues from 0 to 30, representing the temperature cur-

rently measured. Temperature values are written to

the output port out of the module which is also con-

nected to the GPIO2VCI component. Hence, the val-

ues will be available to be read by the digital com-

ponents of the system. The temperature sensor will

operate in timesteps of 10 µ s.

The distance sensor cluster shown in Figure 7, is

composed of three distinct TDF modules, each mod-

eling an ultrasonic sensor. These are connected to a

DE module modeling the controller which reads val-

ues from each of the ultrasonic sensors and writes a

value to the GPIO2VCI component, depending on the

value obtained from its input port in.

A value of 0 makes it read from the

ultrasonic_sensor_left, a value of 1 from

the ultrasonic_sensor_front, a value of 2 from

the ultrasonic_sensor_right. Each ultrasonic

sensor produces random values (from 0 to 12) in

timesteps of 100 ns. The behavior of this cluster is

a simplification of the behavior of a real distance

sensor, since the focus of the paper is mostly on

the communication between the digital and analog

aspects.

5.3 Interaction of Analog Blocks with

the Software Design Level

On the software side of the model, two blocks have

been created to represent the MotorControl and the

MainControl (not shown). They represent the soft-

ware design level shown on the lower left of Figure 2.

In contrast to the purely digital model of the same ap-

plication, the functional blocks pertaining to the sen-

sors are no longer represented in the block diagram,

since they are represented by analog blocks captured

in two separate SystemC-AMS panels.

Both blocks communicate with each other through

a signal motorCommand which is sent by the

MainControl to the MotorControl and contains two

parameters for the right and left velocity. The blocks

A Tool for High-level Modeling of Analog/Mixed Signal Embedded Systems

437

Figure 7: Distance sensor model.

also initialize internal attributes.

The state machine of the MotorControl block

has only one state startMotor. It receives the two

velocity parameters from the motorCommand signal

and waits for some random time between 10 and 20

clock cycles. The state machine of the MainControl

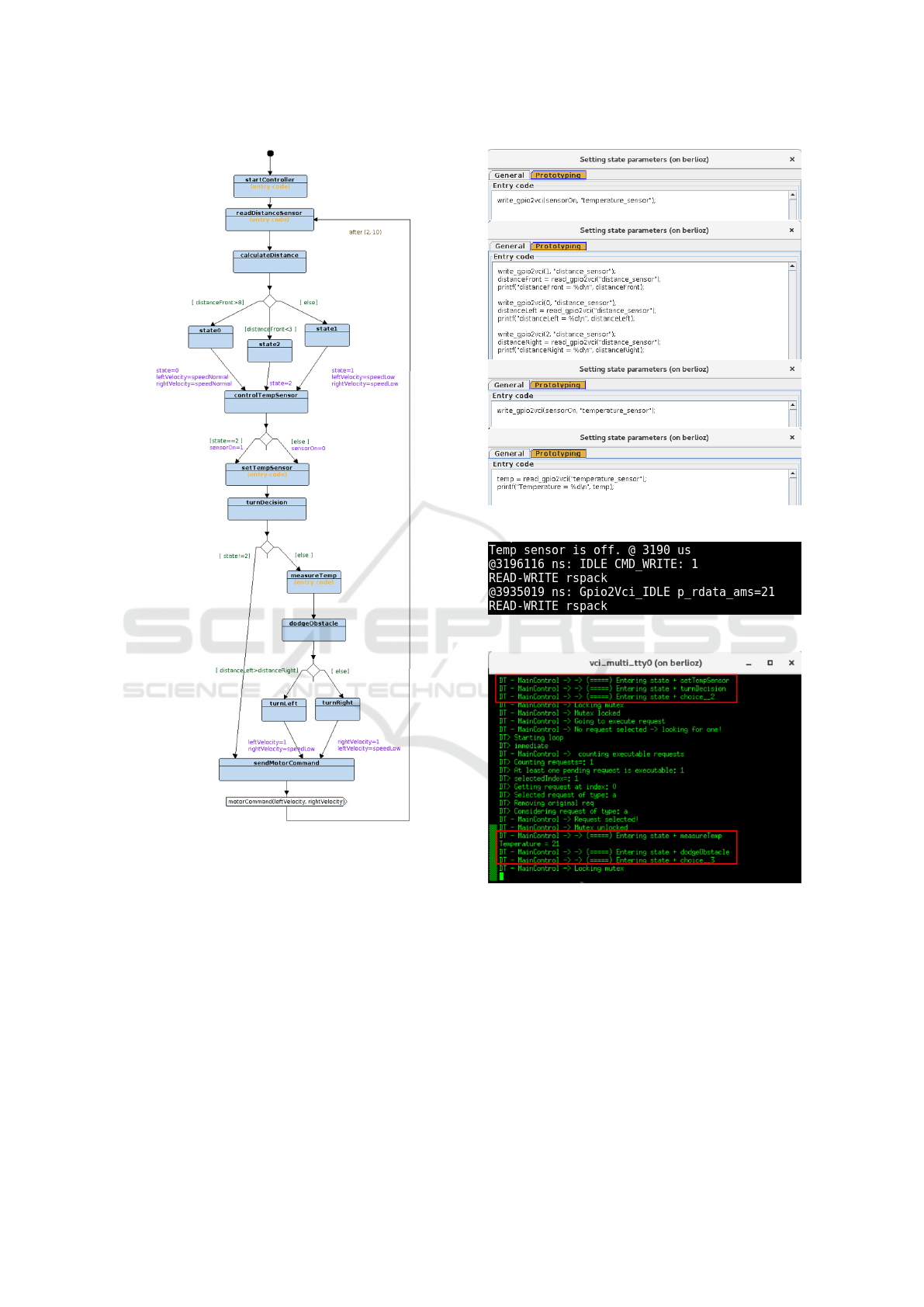

block is shown in Figure 8. In the following, we

provide a more detailed description of the states,

specially the ones that interact with the TDF clus-

ters. By executing software functions, the CPU of

the digital platform is able to write or read values

from the analog components. During the first state

startController, the variable sensorOn, initial-

ized to 0 in the MainControl block, and written to

the GPIO2VCI component connected to the temper-

ature sensor cluster. The C code inserted into the

startController state, shown in the upper part of

Figure 9, turns the temperature sensor unit module

off. Figure 10 shows the local host console output.

In the next state readDistanceSensor, each ul-

trasonic sensor is selected in turn by writing a differ-

ent value to the distance sensor cluster, then the sensor

output is read and the read value is printed to the TTY

component of the model, as shown in the code from

Figure 9.

After this, the next state calculateDistance

simulates how the velocity of the rover is calculated

based on the front distance that was read as shown

in the state diagram of Figure 8. If the distance was

large (greater than 8), the state condition will lead to

state0 and a normal speed would be set (a value of

5). If the distance was between 3 and 8, it would go to

state1 and a low speed (a value of 2) would be set.

In this case, since the front distance was 2 less than

3, the calculateDistance state condition will lead

to state2. Here the state variable is set to 2. Then

it proceeds to the controlTempSensor state, where,

sinc state = 2, sensorOn is set to 1. In the subse-

quent setTempSensor state, the temperature sensor

unit is turned on or off by writing the value of the

sensorOn variable to the temperature sensor cluster

as shown in the lowest part of Figure 9. In the output

from the local host machine, we observe that at time

3196116 ns, a value of 1 is written to the GPIO2VCI

component. At this point the temperature sensor unit

is turned on.

In the following states, the rover will measure the

temperature. Depending on the state variable, the

turnDecision state will decide if the rover needs to

turn or not. If the distance is greater or equal than 3,

then the state variable will be 0 or 1, and the rover

will neither measure temperature nor turn. In our case

the distance is 2 and the state variable is 2, so it goes

to the next state measureTemp.

In the measureTemp state, the temperature sensor

cluster is read and the temperature is printed to the

TTY, as shown in the lowest part of Figure 9. In the

local host console (Figure 10), at time 3935019 ns a

value of 21 is read. The output on the TTY is shown

in the lower red rectangle from Figure 11.

The dodgeObstacle state calculates whether the

rover needs to turn left or right, based on the distance

measured from the left and right ultrasonic sensors; it

will set the velocity of the left or right motors accord-

ingly. After turning left or right, the motorCommand

signal is sent to the motor control state machine, so

that it can adjust the velocity of the motors. Finally,

the main control state machine loops again to the

readDistanceSensor state to start a new cycle.

MODELSWARD 2019 - 7th International Conference on Model-Driven Engineering and Software Development

438

Figure 8: Main control state machine with entry

code in the startController, readDistanceSensor,

setTempSensor and measureTemp states.

6 CONCLUSION AND

PERSPECTIVES

The paper shows the integration of SystemC-AMS

(TDF) components into a multi-level modeling tool

for complex embedded systems. Virtual prototyping

can be performed from the last refinement stage, tak-

ing into account both analog and digital parts of the

system. To this end, a library was created to provide

read and write functions between the digital and ana-

log components, which can be used in State Machine

Figure 9: Entry code in the Prototyping window tab.

Figure 10: Simulation output from host machine console.

Figure 11: Simulation output from the TTY component

console - setTempSensor and measureTemp state.

Diagrams modeling software behaviors. Code gener-

ation of TTool was extended to SystemC-AMS code.

Yet, in order to use these functions, entry code in

C language needs to be inserted in the state blocks

of the TTool diagram. In the future, this should be

replaced by specific read and write operators.

The feedback of simulation results is currently

still limited to the digital part and only semi-

automatic. Automating and extending this mecha-

nism to the entire system would enable us to propose

A Tool for High-level Modeling of Analog/Mixed Signal Embedded Systems

439

a full design space exploration environment for Ana-

log/Mixed Signal systems.

REFERENCES

Abrial, J.-R. (2010). Modeling in Event-B: system and soft-

ware engineering. Cambridge University Press.

Accellera Systems Initiative (2010). SystemC AMS exten-

sions Users Guide, Version 1.0. Accellera Systems

Initiative.

Andrade, L., Maehne, T., Vachoux, A., Ben Aoun, C.,

Pêcheux, F., and Louërat, M.-M. (2015). Pre-

Simulation Formal Analysis of Synchronization Is-

sues between Discrete Event and Timed Data Flow

Models of Computation. In Design, Automation and

Test in Europe, DATE Conference.

Apvrille, L. (2011). Webpage of TTool.

Balarin, F., Watanabe, Y., Hsieh, H., Lavagno, L.,

Passerone, C., and Sangiovanni-Vincentelli, A. L.

(2003). Metropolis: An integrated electronic system

design environment. IEEE Computer, 36(4):45–52.

Beyond Dreams Consortium (2008-2011). Be-

yond Dreams (Design Refinement of Embed-

ded Analogue and Mixed-Signal Systems).

http://projects.eas.iis.fraunhofer.de/beyonddreams.

Bouquet, F., Gauthier, J.-M., Hammad, A., and Peureux, F.

(2012). Transformation of SysML structure diagrams

to VHDL-AMS. In 2012 Second Workshop on Design,

Control and Software Implementation for Distributed

MEMS, pages 74–81. IEEE.

Concepcion, A. I. and Zeigler, B. P. (1988). DEVS for-

malism: A framework for hierarchical model devel-

opment. IEEE Transactions on Software Engineering,

14(2):228–241.

Cortés Porto, R. (2018). Integration of SystemC-AMS sim-

ulation platforms into TTool. Master’s thesis, Tech-

nische Universität Kaiserslautern.

Davare, A., Densmore, D., Meyerowitz, T., Pinto, A.,

Sangiovanni-Vincentelli, A., Yang, G., Zeng, H., and

Zhu, Q. (2007). A next-generation design framework

for platform-based design. In DVCon, volume 152.

Gamatié, A., Beux, S. L., Piel, É., Atitallah, R. B., Etien,

A., Marquet, P., and Dekeyser, J.-L. (2011). A model-

driven design framework for massively parallel em-

bedded systems. ACM Trans. Embedded Comput.

Syst, 10(4):39.

Genius, D., Li, L. W., and Apvrille, L. (2018). Multi-level

Latency Evaluation with an MDE Approach. In MOD-

ELSWARD.

H-Inception Consortium (2012-2015). Hetero-

geneous Inception Project. https://www-

soc.lip6.fr/trac/hinception.

Herrera, F. and Villar, E. (2007). A framework for heteroge-

neous specification and design of electronic embedded

systems in systemc. ACM Transactions on Design Au-

tomation of Electronic Systems (TODAES), 12(3):22.

IEEE (2011). SystemC. IEEE Standard 1666-2011.

Lee, E. A. and Messerschmitt, D. G. (1987a). Static

Scheduling of Synchronous Data Flow Programs for

Digital Signal Processing. IEEE Transactions on

Computers, C-36(1):24–35.

Lee, E. A. and Messerschmitt, D. G. (1987b). Synchronous

data flow. Proceedings of the IEEE, 75(9):1235–1245.

Li, L. W., Genius, D., and Apvrille, L. (2018). Formal

and virtual multi-level design space exploration. In

MODELSWARD, Springer Communications in Com-

puter and Information Science, vol 880, pages 47–71.

Niaki, S. H. A., Jakobsen, M. K., Sulonen, T., and Sander,

I. (2012). Formal heterogeneous system modeling

with systemc. In Specification and Design Languages

(FDL), 2012 Forum on, pages 160–167. IEEE.

Ptolemy.org, editor (2014). System Design, Modeling, and

Simulation using Ptolemy II.

Selic, B. and Gérard, S. (2013). Modeling and Analysis

of Real-Time and Embedded Systems with UML and

MARTE: Developing Cyber-Physical Systems. Else-

vier.

SocLib consortium (2003). The SoCLib project: An inte-

grated system-on-chip modelling and simulation plat-

form. Technical report, CNRS. www.soclib.fr.

Taha, S., Radermacher, A., and Gérard, S. (2010). An

entirely model-based framework for hardware design

and simulation. In DIPES/BICC, volume 329 of IFIP

Advances in Information and Communication Tech-

nology, pages 31–42. Springer.

Vachoux, A., Grimm, C., and Einwich, K. (2003). Analog

and mixed signal modelling with SystemC-AMS. In

ISCAS (3), pages 914–917. IEEE.

Vidal, J., de Lamotte, F., Gogniat, G., Soulard, P., and

Diguet, J.-P. (2009). A co-design approach for embed-

ded system modeling and code generation with UML

and MARTE. In DATE, pages 226–231. IEEE.

VSI Alliance (2000). Virtual Component Interface Standard

(OCB 2 2.0).

Zhu, J., Sander, I., and Jantsch, A. (2010). Hetmoc: Hetero-

geneous modelling in systemc. In Specification & De-

sign Languages (FDL 2010), 2010 Forum on, pages

1–6. IET.

MODELSWARD 2019 - 7th International Conference on Model-Driven Engineering and Software Development

440