Detection of Honeybee Disease: Varrosis using a Semiconductor Gas

Sensor Array

Andrzej Szczurek

1

, Monika Maciejewska

1

, Beata Bąk

2

, Jakub Wilk

2

, Jerzy Wilde

2

and Maciej Siuda

2

1

Wroclaw University of Science and Technology, Wybrzeże Wyspiańskiego 27, 50-370 Wrocław, Poland

2

Apiculture Department, Warmia and Mazury University in Olsztyn, Sloneczna 48, 10-957 Olsztyn, Poland

Keywords: Semiconductor Gas Sensor, Indoor Air, Detection, Classification, Honeybee, Disease.

Abstract: The presented study was focussed on the detection of Varroa destructor infestation of honeybee colonies,

based on gas sensor measurements of beehive air. The detection consisted in determination whether the colony

infestation rate was 0% or different. An array of partially selective gas sensors was used in measurements. It

included the following semiconductor gas sensors: TGS832, TGS2602, TGS823, TGS826, TGS2603 and

TGS2600. The sensors were exposed in dynamic conditions. The infestation detection problem was solved

using a classification approach. The basis for classification were feature vectors. They were composed of

responses of sensors, elements of the gas sensor array. The utilised responses were associated with various

parts of the sensor signal recorded during dynamic exposure and regeneration. As a reference, we used the V.

destructor infestation rate of bee colonies estimated using a flotation method. The smallest misclassification

error was 17% and it was achieved with the k-NN classifier. The experimental study was performed in field

conditions. It included honeybee colonies of various kinds, settled in beehives made of various materials,

differently located, examined in various atmospheric conditions, at different times of the day. Taking this into

consideration, the detection error at the level of 17 % is a promising result. It demonstrates the possibility to

detect varroosis using an array of partially selective sensors.

1 INTRODUCTION

Honeybees (Apis mellifera) are one of the most

recognizable domesticated insects in the world. They

are best known for their production of honey and

products, like wax, bee pollen, propolis, royal jelly,

bee venom, apilarnil, etc. However, the greatest value

of honeybees is in their service as pollinators, which

far outweigh their value as honey producers. The

honeybee is well adapted for pollination. Their sense

of smell, eyes, mouthparts and numerous branched

body hairs are ideally suited for finding food sources,

sipping nectar, and collecting and distributing pollen.

These characteristics make honeybees a most

valuable agent for cross-pollinating crops. The EU

parliament noted in 2008 (resolution T6-0579/2008)

that 79% of human food depends on honeybee

pollination. The pollination industry represents a

market of 153 billion € per year (Gallai et al., 2009).

To protect food supply, honeybee populations need to

be maintained in an optimal state of health and

afforded opportunities to grow.

Currently, honeybee populations are decreasing

due to colony collapse disorder (CCD). Bees and

beekeeping are suffering a global crisis. CCD has

been reported from many regions of the world

(Barron, 2015).

Honeybee declines are a serious threat to global

agricultural security and productivity. The CCD is

caused by multiple stressors, both abiotic and biotic

(Cox-Foster et al., 2007; Johnson et al., 2009;

Goulson et al. 2015), e.g. the use of pesticides in

agriculture, the presence of pollutants in

environment, mite infections (i.e. Varroa destructor),

fungal diseases (i.e. Nosema ceranae), viruses (i.e.

Deformed Wing Virus or Acute Bee Paralysis Virus),

climate changes, malnutrition and starvation linked to

environmental degradation. Among these, parasites

are a key driver. Disease problems in honeybees have

intensified in recent years, despite increasing

attention to address them.

Varroa destructor (Varroa mites) are the most

serious threat to honeybees (Martin, 2001; Boecking,

and Genersch, 2008). Varroa were previously known

by the species name Varroa jacobsoni. It is an

58

Szczurek, A., Maciejewska, M., B ˛ak, B., Wilk, J., Wilde, J. and Siuda, M.

Detection of Honeybee Disease: Varrosis using a Semiconductor Gas Sensor Array.

DOI: 10.5220/0007575600580066

In Proceedings of the 8th International Conference on Sensor Networks (SENSORNETS 2019), pages 58-66

ISBN: 978-989-758-355-1

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

external parasitic mite that attacks the honeybees Apis

cerana and Apis mellifera. The disease caused by the

mites is called varroosis. Varroa mites (V. destructor

and V. jacobsoni) are tiny red-brown external

parasites of honeybees. Although Varroa mites can

feed and live on adult honeybees, they mainly feed

and reproduce on larvae and pupae in the developing

brood. They cause physical damage, weaken bees and

transmit a variety of pathogens, particularly viruses.

If the Varroa mites are left untreated, the commercial

honeybee colonies will normally die within three to

five years. V. destructor is considered to be one of

multiple stress factors with the most pronounced

economic impact on the beekeeping industry,

contributing to the higher levels of bee losses around

the world. According to the USDA, 42 percent of

commercial hives in the U.S. were infested in summer

2017, and 40 percent of beekeepers said the parasite

seriously harmed their colonies (Pomeroy, 2018). By

comparison, only 13 percent reported harm from

pesticides.

V. destructor mites pose an increasing global

threat to the apicultural industry and agricultural

ecology. For that reason, it remains very important to

be able to diagnose and detect mite infection

(Ontarion.ca, 2016).

Different methods can be used to realize this task

(Bak et al., 2009, Randy, 2011). The traditional

approach is based on visual observation and manual

annotation. This method is available to bee specialists

and beekeepers. The Varroa mites, because of

characteristic features, can be found on the body

surface of adults, larvae, and pupae. All stages of the

mite are difficult to detect. In slightly infested

colonies they are mostly found in sealed brood cells.

The mites may be seen on drone and worker pupae in

sealed brood cells. It is first necessary to uncap these

cells and remove the pupae for examination. The

shriveled wings, which are frequently seen in

emerging or old bees and patchy brood patterns allow

to distinguish infected honeybees, but the effects of

mite infection are not always observable. The other

common methods used to diagnose mite infection

involve calculating the number of mites dropped onto

the bottom board of bee hives or calculating the

number of mites in a certain number of honeybees.

The visual inspection provide evidence for the level

of mite infection. Close inspection of brood,

especially drone brood, will provide the great chance

of detecting Varroa mite infections early. This

approach presents also serious shortcomings, e.g.:

it is a very time consuming and expensive

(beekeepers need to spend a certain amount of

time, labor and money);

requires long periods of observation and

sometimes specific expertise in order to be

meaningful;

the beekeeper must visit apiary and hives on a

regular basis (the location for apiary may be far

from the permanent residence of beekeepers);

leads to delays in the prevention and treatment of

infection (it results in the loss of both individual

bees and entire colonies);

the reproduction of female mites in capped brood

cells interferes with the probability of detection

and subsequent treatment.

Detection of mite infection in honeybees based on

visual inspection causes that most beekeepers treat

honeybee colonies, after they find mites or notice

abnormal appearances in honeybees using previous

experience. It is usually too late to control the mites,

when they are found in honeybee colonies. The

beekeeper has to make the necessary intervention at

the right time. Hence, it is important to diagnose and

detect mite infection before parasites have a chance

to spread rapidly and widely.

The disadvantages of visual inspection of

honeybee colonies cause that new methods are

strongly needed. They should be based on real time,

online, continuous measurements of parameters

characterizing state of a bee colony. Additionally, the

non-intrusive access to hives is required in order to

avoid modifying the bees’ work conditions. The

additional stress or unproductive activities of bees is

reflected in data. The progress in sensor and

information technology offers a chance to perform

this task (Zacepins and Karasha, 2013; Meikle and

Holst, 2015; Sánchez et al., 2015; Zacepins et al.,

2016; Gámiz-López and Luna-Rodríguez, 2017).

Practical experiments were done with:

continuous measurement of temperature (Becher

and Moritz, 2009; Stalidzans and Berzonis 2013;

Zacepnis et al. 2016);

infrared imaging (Chen et al., 2012);

air humidity (Gao, 2002);

gas content (Edwards-Murphy et al., 2016);

sound (Eskov and Toboev, 2011);

vibration of hive (Bencsik et al., 2015);

counting of outgoing and incoming bees

(Spangler, 1969);

video observation (Elizondo et al., 2003)

radio frequency identification (RFID)

(Schneider et al., 2012);

weighing of the colony (Meikle et al., 2008).

On basis of such measurements, the beekeeper can

obtain information about: swarming/pre-swarming

state, extreme nectar flow, queenless state, broodless

Detection of Honeybee Disease: Varrosis using a Semiconductor Gas Sensor Array

59

state, dead colony, starving, and first cleaning flight

in spring, diseases, including CCD (Ferrari et al.,

2008).

Nowadays, measurement systems based on

sensors and information technology are not widely

used in the apiculture, despite the importance of

honeybees for both the environment and humans.

These instrumentation is still a challenge for

researchers and various other specialists.

The aim of this study is a measurement system for

the detection of varroosis. The V. destructor mites

affect different parameters of honeybee colony (Hou

et al., 2016; Schurischuster et al., 2016). In our work,

it was assumed that varroosis is reflected in the

quality of the indoor air of a beehive. Based on this

assumption, we want to show that gas sensor array

measurements of the beehive air allow to detect the V.

destructor mite infestation of honeybee colony. In

order to extract the relevant information from the

measurement data, classification methods were used.

Based on the review of the available literature, our

work is the first attempt of applying partially selective

gas sensors to detect varroosis, based on beehive air

measurements.

2 EXPERIMENTAL PART

2.1 The Honeybee Colonies

The studied bee species was A.m. carnica. The

analysis presented in this paper was based on the

statistical sample of 44 colonies of A.m. carnica.

These honeybee colonies occupied beehives located

in four different apiaries, in one geographic region.

Beehives had various constructions and they were

made either of wood or Styrofoam.

Beehives air was examined using gas sensor

measurements and honey bee colonies were

characterised using traditional beekeeping

techniques.

In order to provide a reference for gas sensor

measurements, honeybee colonies were examined in

respect of Varroa destructor infestation rate in a

traditional manner. It was required that the time slot

between the gas sensor measurements and sampling

for V. destructor level assessment was no greater than

three days.

Several methods of Varroa destructor infestation

rate assessment are available (Dietemann et al. 2013).

In this study, a method called flotation was applied

(Fries et al. 1991). It involves collecting a sample of

bees from the honeycombs with brood and placing

them in the jar with the mixture of water and soap.

The jar should be shaken for 20 s to separate the mites

from the adult honeybees. The content of the jar

should be poured over a first sieve (aperture: 3-4 mm)

to collect all bees and let through a second sieve

(aperture < 0.5 mm), located underneath the first, to

collect the mites. The bees and mites should be

flushed with large amounts of warm water. The mites

remaining on the second sieve and the bees in the

sample should be counted. The level of infestation

with Varroa destructor is the number of mites divided

by the number of bees and multiplied by 100.

2.2 Gas Sensor Device

In order to examine the gaseous atmospheres of

beehives the measurement device based on gas

sensors was used. It was a portable, programmable,

multichannel instrument, dedicated to the continuous

recording of gas sensor signals, see Figure 1. The

construction was developed in the Laboratory of

Sensor Technique and Indoor Air Quality Studies at

Wroclaw University of Science and Technology,

Poland.

Figure 1: Gas sensor device.

Semiconductor gas sensors were installed in the

device. The commercially available products, offered

by Figaro Engineering, Japan were chosen for this

application. The following Taguchi Gas Sensors were

used: TGS832, TGS2602, TGS823, TGS826,

TGS2603 and TGS2600. The basic characteristics of

sensors is presented in Table 1.

The applied semiconductor gas sensors were

partially selective. Based on data sheets (Figaro

Engineering Inc.) they were sensitive to a wide range

of chemical substances. As shown in Table 1, the

individual sensors differed regarding the kind of the

compounds they could detect as well as in respect of

the detection range. These differences justified the

use of sensor array, which consisted of several gas

sensors. The data utilised in this study was from the

sensor array measurement.

SENSORNETS 2019 - 8th International Conference on Sensor Networks

60

Table 1: Gas sensors applied in the measurement device and

their detection ranges (Figaro Engineering Inc.).

Sensor

Detection range

TGS 823

50 ppm – 5,000 ppm Ethanol, n-Hexane,

Benzene, Acetone

TGS 826

30 ppm – 300 ppm Ethanol, Ammonia,

Isobutane

TGS 832

10 ppm – 600 ppm ethanol, R-407c, R-

134a, R-410a, R-404a, R-22

TGS 2600

1 ppm – 100 ppm Ethanol, Isobutane

TGS 2602

1 ppm – 30 ppm Ethanol, Ammonia,

Toluene

TGS 2603

1 ppm – 30 ppm Ethanol

0.1 ppm – 3 ppm Trimethyl amine,

0.3 ppm – 2 ppm Methyl mercaptan

Regarding sensor device construction, the

individual sensors were placed in their own flow-

through type chambers, inside the instrument. This

arrangement was aimed at minimizing cross-

interferences between sensors, during measurements.

The compartments were made of aluminium. The use

of this material allowed for an efficient heat

exchange, which is important for attaining constant

temperature in the direct vicinity of sensing elements.

Semiconductor gas sensors require heating. Each

sensor was connected to a voltage supplier and to a

measuring unit.

An important element of the device was a pump.

It was necessary for evoking and maintaining the gas

flow through sensors chambers. The device had eight

inlet ports and one gas outlet. The set of valves

allowed for the intermittent connection of the selected

inlet ports to all sensors chambers. The elements of

the gas sensor device, which were in contact with gas

samples, were made of chemically resistant materials.

The device was programmable. Although a

number of operating parameters could be controlled,

the most important for this study was programming

the sequence and timing of gas inlet ports connection

to sensors chambers.

The instrument was dedicated for continuous

recording of gas sensors signals with the predefined

temporal resolution of 1 s. The measurement data was

collected on the SD card. The device runs off mains

supply 230V.

2.3 Gas Sensor Measurements

Dynamic conditions of exposure are one of means of

increasing the information content of gas sensor

signal. For this reason, during beehives air

measurements sensors were exposed in dynamic

conditions.

A single measurement performed with gas sensor

device consisted of two phases: 1. gas sensors

exposure to the test gas, and 2. gas sensors

regeneration. In phase one, gas sensors were exposed

to the air drawn from a beehive. This gas was

delivered to sensors chambers using Teflon tubing.

The gas flow rate was constant. In phase two, gas

sensors were exposed to the ambient air. It was

delivered to sensors chambers at the constant flow

rate, which was the same as the flow rate of beehive

air. The exposure phase was 15 minutes long and the

regeneration phase was 15 minutes long, as well. This

duration was chosen arbitrarily, based on previous

experience with sensor measurements of

multicomponent gas mixtures.

Multiple measurements of individual honeybee

colonies were made. Depending on the colony, the

number measurements varied between 3 and 10. The

successive measurements of the particular honeybee

colony were separated by the time span. The length

of the time span (from 30 min to 3h) was determined

by the number of colonies which were monitored in

sequence with one gas sensor device. The longest

period of the measurement data collection for an

individual honeybee colony was about three days.

It should be emphasized that measurements were

performed in field conditions. The measurements and

characterization of honeybee colonies took place in

late spring, summer and early autumn 2018 (May till

September).

3 METHOD OF DATA ANALYSIS

The problem of detection of honeybee colonies

infestation with V. destructor was represented by a

problem of classification of gas sensor measurements.

Two classes were defined. Class 1 – ‘not infested’

included gas sensor measurements of air in beehives

occupied by honeybee colonies featured by the V.

destructor infestation rate equal zero. At the same

time it should be noted that the term 'not infested' was

adopted conventionally. The honeybee colonies that

are parasite free, are difficult to find in practice. The

infestation ratio of zero means, that infestation was

below the limit of quantification of the method. Class

2 – ‘infested’ included gas sensor measurements of

air in beehives occupied by honeybee colonies

featured by nonzero infestation rate.

3.1 Feature Vector

The result of gas sensor measurement was the sensor

signal. The signal was composed of two parts. The

Detection of Honeybee Disease: Varrosis using a Semiconductor Gas Sensor Array

61

first part was recorded during sensor exposure to the

beehive air. The second part was recorded during

sensor regeneration with ambient air (see Section

2.3). The signal

of the c

th

sensor, where ,

could be represented as the time series of gas sensor

responses,

.

(1)

The single response

was associated with the

time point, . The complete set of time points was

, where was the number of time points

during gas sensor exposure phase and was the

number of time points during sensor regeneration

phase. One time point was 1 s long.

Gas sensor signal was subject to pre-processing.

In our case, the pre-processing stage was constrained

to sensor signal baseline correction. Differential

correction was applied in order to eliminate the shift

of sensor baseline in the period of measurements. The

sensor response after baseline correction was

(2)

where

was the last sensor response during the

regeneration phase, which preceded the

measurement.

In this work, two facts were important for the

classification:

sensor array was used; It was composed of

several sensors, which could differently

contribute to pattern recognition;

sensor signals contain the analytical information,

therefore dynamic conditions of exposure were

chosen.

These facts caused that multiple feature vectors were

considered as the basis of classifciation.

An individual feature vector was composed of

vectors of selected responses of individual sensors,

. Responses after baseline correction were used for

this purpose.

(3)

As shown, signals of all sensors, were

utilised while constructing the feature vector.

A sequence of responses of single sensor formed

the vector

. The first elemet in the sequence,

had the time coordinate

. The coorrdinate could be

any value from the set

s.

where s and

. Therefore, the first

element of the sequence could be associated with

different parts of gas sensor signal.

Seven sequences were considered, which had the

same first element. The sequences were:

…

(4)

As shown, the individual vector

contained

between 1 (as

) and 7 (as

) gas sensor

responses. These responses included in one vector

were separated by the time interval of s. Gas

sensor response changed vividly during 5 s. The

vector

spanned over 1s and the vector

spanned over 30 s of gas sensor signal

The individual feature vector was composed of

six vectors

, or six vectors

, etc. In other

words, for the particular feature vector

and were

fixed. Multiple feature vectors were obtained, by

using different combinations of

and .

The individual feature vector was the basis for the

classification of honey bee colonies based on gas

sensor measurement of beehive air, using a classifier.

3.2 Classifier

Two kinds of classification algorithms were applied:

Linear discriminant analysis (LDA) and K-nearest

neighbors (k-NN) algorithm. Their choice was guided

by the intention of comparing the performance of a

linear and nonlinear classifier. The additional

requirement was to apply relatively simple and

computationally effective algorithms, which could be

easily embedded in the data processing unit of the

measurement device, in the future.

3.2.1 Linear Discriminant Analysis

LDA (Jain et al., 2000; Hierlemann and Gutierrez-

Osuna, 2008) is a technique of linear discrimination

between groups of data vectors. It looks for linear

combinations of variables, which best explain the

data.

In course of the analysis discriminant functions

are calculated, also called canonical variables. These

are weighted sums of the original variables, which

contribute to between group variation. Discriminant

functions are optimal combination of variables in a

sense that that the first function provides the most

overall discrimination between groups, second

provides less discrimination, and so on. Discriminant

functions are orthogonal, which means their

contributions to the discrimination between groups do

not overlap. The maximum number of functions is

SENSORNETS 2019 - 8th International Conference on Sensor Networks

62

equal to the number of groups minus one, or the

number of variables in the analysis, whichever

smaller.

Original data vectors transformed into the space

of canonical variables produce scores. The scores plot

may be used to see how discriminant functions

discriminate the data set.

Next to discriminant functions, classification

functions are calculated. The number of classification

functions equals the number of groups in the data set.

With those functions, classification scores can be

computed for each data vector and for each group.

The highest score obtained for a considered data

vector indicates which group the vector belongs to.

3.2.2 K-nearest Neighbors (k-NN)

Algorithm

K-nearest neighbors (k-NN) algorithm (Jain et al.,

2000; Hierlemann and Gutierrez-Osuna, 2008) is a

well-known classifier, willingly applied for pattern

recognition tasks of various kinds. K-NN is a non-

parametric, nonlinear, distance based method. The

non-parametric classifiers do not require assumptions

regarding the distribution of the input data. This

feature is advantageous, because in many

classification problems, in particular when the

amount of data is limited, the actual data distribution

remains unknown. K-NN is a minimum distance

classifier. The data vector assignment to the class is

based on the distance between this vector and training

vectors. The vector is assigned to the class, which

most frequently occurs among k training vectors,

nearest to it. Highly nonlinear decision boundaries

may be represented using this technique. None

classification functions have to be computed based on

the data. Training vectors are retained in the memory

and called each time the new vector is classified. K is

the only parameter of the method. It is usually chosen

by trial and error method, which allows to avoid the

lengthy process of classifier optimization. We

arbitrarily chose the k = 3.

3.3 Classification Performance

Assessment

10-fold cross-validation was chosen to examine the

performance of the classification algorithms. The

performance of classifiers was measured with

misclassification error. It was defined as the

proportion of misclassified observations averaged for

the complete run of cross-validation procedure.

4 RESULTS

The sample of examined bee colonies consisted of 15

(34%) not infested colonies and 29 (66%) infested

colonies. Considering gas sensor measurements, 111

(38%) measurements represented the class ‘not

infested’ and 181 (62%) measurements belonged to

the class ‘infested’. With such proportions the

measurement data set was slightly imbalanced in

favour of the observations of the infested honeybee

colonies.

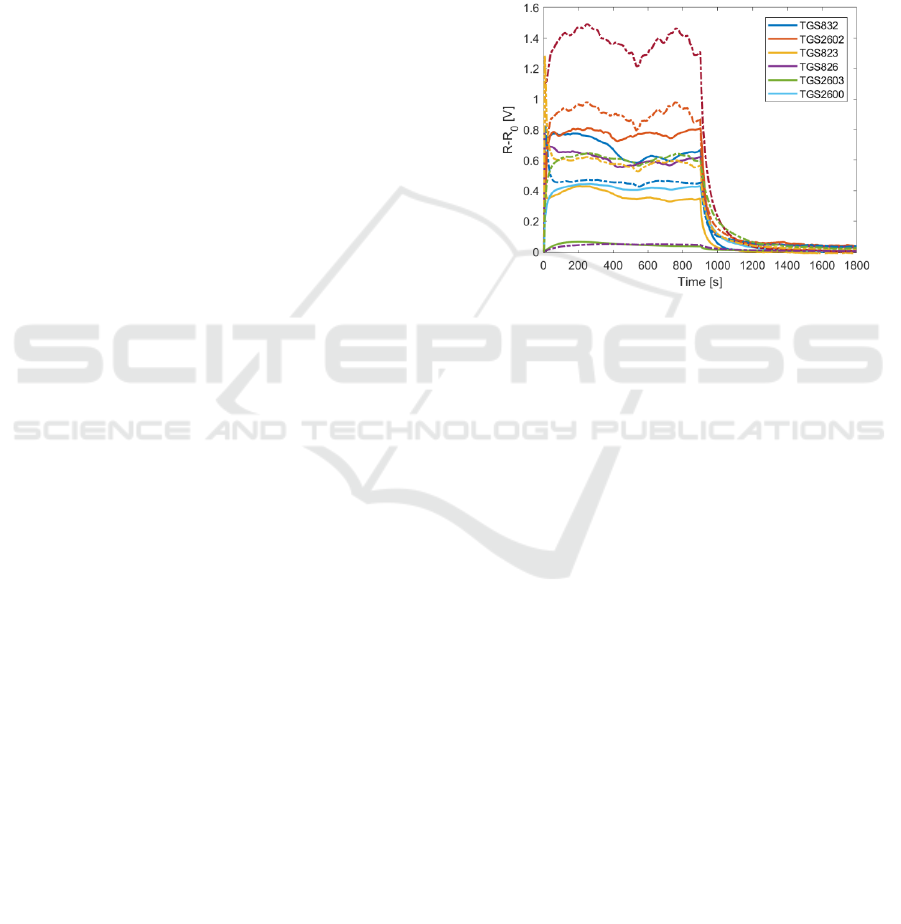

Figure 2: The exemplary signals recorded during gas sensor

measurements of the honeybee colony featured by V.

destructor infestation rate 0% (solid lines) and the

honeybee colony featured by V. destructor infestation rate

2.47% (dashed lines). The horizontal axis provides the

reference to distinguish between the gas sensor exposure

phase (0-900 s) and the regeneration phase (901-1800 s).

Figure 2 shows the exemplary signals recorded

during gas sensor measurements of two beehives. In

one of them, the bee colony was infested with V.

destructor (infestation rate 2.46 %). The other bee

colony was not infested (infestation rate 0%). Based

on Figure 2, in the case of the infested honeybee

colony, the responses of sensors to the beehive air

were higher as compared with the not infested

honeybee colony.

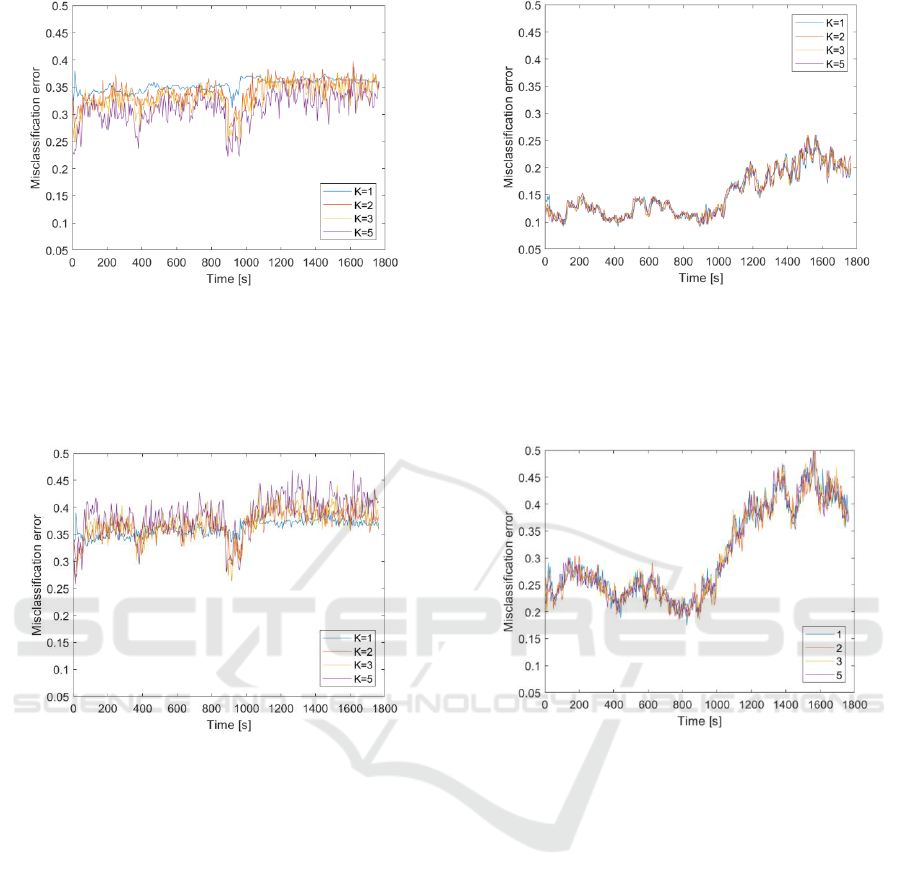

The results of classification of gas sensor

measurements are shown in figures from Figure 3 to

Figure 6. The results achieved when using LDA

algorithm are presented in Figure 3 and Figure 4. The

results obtained with k-NN algorithm are presented in

Figure 5 and Figure 6. The respective plots present

misclassification errors for the training set (Figure 3

and Figure 5) and for the test set (Figure 4 and Figure

6) when applying 10-fold cross validation. The errors

were displayed as a function of time in the time frame

of a single measurement. This allows to observe the

dependency between the misclassification error and

sensor responses included in the feature vector, more

Detection of Honeybee Disease: Varrosis using a Semiconductor Gas Sensor Array

63

Figure 3: Misclassification error for the training set when

using LDA as the classifier. The horizontal axis provides

the reference to distinguish between the gas sensor

exposure phase (0-900 s) and regeneration phase (901-1800

s), as the sources of gas sensor responses included in the

feature vector.

Figure 4: Misclassification error for the test set when using

LDA as the classifier (10-fold cross validation). The

horizontal axis provides the reference to distinguish

between the gas sensor exposure phase (0-900 s) and

regeneration phase (901-1800 s), as the sources of gas

sensor responses included in the feature vector.

precisely, their location in gas sensor signal. The

misclassification error associated with the particular

time point in time axes of Figure 3 to Figure 6 was

attained when using feature vectors, which ‘start’ at

this time point.

As shown in figures from Figure 3 to Figure 6, the

classification results obtained with LDA and k-NN

algorithms were different. In case of LDA the lowest

misclassification error for the training set was 0.16

and for the test set it was 0.26. In case of k-NN the

lowest misclassification error for the training set was

0.09 and for the test set it was 0.17. The error values

show that k-NN algorithm performed better. On

average, k-NN algorithm allowed to attain

misclassification errors smaller by 10%, as compared

with LDA.

Figure 5: Misclassification error for the training set when

using k-NN as the classifier. The horizontal axis provides

the reference to distinguish between the gas sensor

exposure phase (0-900 s) and regeneration phase (901-1800

s), as the sources of gas sensor responses included in the

feature vector.

Figure 6: Misclassification error for the test set when using

k-NN as the classifier (10-fold cross validation). The

horizontal axis provides the reference to distinguish

between the gas sensor exposure phase (0-900 s) and

regeneration phase (901-1800 s), as the sources of gas

sensor responses included in the feature vector.

The number of elements in the feature vector

differently influenced the misclassification error of

LDA and k-NN algorithms. In case of LDA, the

biggest errors were observed when the feature vector

consisted of responses of sensors collected at one

time point (k=1). The increasing dimensionality of

feature vector caused the decrease of

misclassification error for the training set (see Figure

3). In case of the test set, generally the positive

influence of dimensionality increase was not

observed. As shown in Figure 5 and in Figure 6, the

results of classification with k-NN algorithm, were

not influenced by the size of the feature vector in a

meaningful manner.

Based on figures from Figure 3 to Figure 6, the

location of sensor responses, included in feature

SENSORNETS 2019 - 8th International Conference on Sensor Networks

64

vector, in the sensor signal had an influence on the

misclassification error. Smaller errors were achieved

when responses belonged to the part of sensor signal

associated with gas sensor exposure to the beehive

air. The misclassification errors were bigger when

features belonged to the part of sensor signal

associated with gas sensor regeneration. The results

of classification obtained when using LDA draw

attention to one additional fact. In Figure 3 and in

Figure 4 there could be noticed two zones of small

values of misclassification error. The small errors

were obtained when feature vectors included gas

sensor responses collected at the beginning of the

exposure phase, and at the breakthrough between the

exposure and regeneration phase.

5 CONCLUSIONS

There was presented a study on the detection of

Varroa destructor infestation of honeybee colonies,

based on beehive air measurements using partially

selective gas sensors.

The detection consisted in determination whether

the measurement data represented the colony featured

by the infestation rate 0% or different.

The study included 44 colonies; 29 were infested

and 15 were not infested with V. destructor. Their

characterization by beekeepers and gas sensor

measurements were performed in field conditions, no

more than 2 days apart.

The gas sensor device used for measurements was

equipped with an array of semiconductor gas sensors,

including TGS832, TGS2602, TGS823, TGS826,

TGS2603 and TGS2600. Sensors were exposed in

dynamic conditions.

The V. destructor infestation detection problem

was solved using a classification approach. The basis

for classification were feature vectors composed of

responses of gas sensor array.

Based on the performed analysis, the lowest

misclassification error was 17% and it was achieved

with a k-NN classifier.

The experimental study was performed in field

conditions, it included beehives of various kinds,

made of various materials, settled in different

locations, which were examined in various

atmospheric conditions and at different times of the

day. Taking this into consideration, the detection

error at the level of 17% is a very good result.

The obtained result demonstrates the possibility to

detect varroosis using an array of partially selective

sensors. Our further work will focus on the

improvement of the detection method. It is planned to

consider other features of sensor signal as well as

different classifiers. We also think or redefining the

classification problem itself.

ACKNOWLEDGEMENTS

This work was supported by the National Centre for

Research and Development under the grant nr

BIOSTRATEG3/343779/10/NCBR/2017 “Developing

innovative, intelligent tools to monitoring the

occurrence of malignant foulbrood and elevated

levels of infestation with Varroa destructor in

honeybee colonies.”

REFERENCES

Bak, B., Wilde, J., Siuda, M., Kobylińska, M. 2009.

Comparison of two methods of monitoring honeybee

infestation with Varroa destructor mite. Annals of

Warsaw University of Life Sciences – SGGW, Animal

Science 46, 33–38.

Barron, A.B. 2015. Death of the bee hive: understanding the

failure of an insect society. Current Opinion in Insect

Science 10, no. Supplement C, 45–50.

Becher, M.A., Moritz, R.F.A. 2009. A new device for

continuous temperature measurement in brood cells of

honeybees (Apis mellifera), Apidologie 40 577–584.

Bencsik, M., Le Conte, Y., Reyes, M., Pioz, M., Whittaker,

D., Crauser, D., Delso, N.S., Newton, M.I. 2015.

Honeybee Colony Vibrational Measurements to

Highlight the Brood Cycle. PLoS One 10(11),

e0141926

Boecking, O., Genersch, E. 2008. Varroosis - the ongoing

crisis in bee keeping. Journal of Consumer Protection

and Food Safety 3, 221–228.

Chen, C., Yang, E., Jiang, J., Lin, T. 2012. An imaging

system for monitoring the in-and-out activity of

honeybees. Comput. Electron. Agric. 89, 100–109.

Cox-Foster, D.L, Conlan, S, Holmes. E.C, Palacios G., et

al. 2007. A metagenomic survey of microbes in

honeybee colony collapse disorder. Science 318, 283-

287.

Dietemann, V., Nazzi, F.,J Martin, S.J. , Anderson, D.L.,

Locke, B.,Delaplane, K.S ,Wauquiez, Q., Tannahill, C.,

Frey, E., Ziegelmann, B., Rosenkranz, P.D., Ellis, J.D.

2013. Standard methods for Varroa research. J. of

Apicult. Res. 52(1), 1-54, DOI

10.3896/IBRA.1.52.1.09

Edwards-Murphy, F., Magno, M., Whelan, P.M.,

O’Halloran, J., Popovici, E.M. 2016. b+WSN: Smart

beehive with preliminary decision tree analysis for

agriculture and honeybee health monitoring.

Computers and Electronics in Agriculture 124, 211-

219.

Detection of Honeybee Disease: Varrosis using a Semiconductor Gas Sensor Array

65

Elizondo, V.A., Bricerio, M.T., Travieso, C.M. Alonso,

B.A. 2013. Video Monitoring of a mite in honeybee

cells. Adv. Mat. Res. 2, 1107-1113.

Eskov, E.K., Toboev, V.A. 2011. Changes in the structure

of sounds generated by bee colonies during sociotomy.

Entomol. Rev. 91, 347–353.

Ferrari, S., Silva, M., Guarino, M., Berckmans, D. 2008.

Monitoring of swarming sounds in bee hives for early

detection of the swarming period. Computers and

Electronics in Agriculture 64(1), 72-77.

Figaro Engineering Inc. https://www.figaro.co.jp/en/

Fries, I., Aarhus, A., Hansen, H., Korpela, S. 1991.

Comparisons of diagnostic methods for detection of

Varroa jacobsoni in honeybee (Apis mellifera) colonies

at low infestation levels. Exp. Appl. Acarol. 10, 279-

287.

Gallai, N., Salles, J-M, Settele, J, Vaissière, B.E. 2009.

Economic valuation of the vulnerability of world

agriculture confronted with pollinator decline.

Ecological Economics 68, 810–821.

Gao, S. 2002. The effect of temperature and humidity of bee

hive on the Varroa mite. Chin. J. Anim. Husb. Vet.

Med. 4, 46-47.

Gámiz-López, V., Luna-Rodríguez, J.J. 2017. Honeybee

Colonies Remote Monitoring System, Sensors (Basel)

17(1), 55.

Goulson, D., Nicholls, E., Botías, C., Rotheray, E.L. 2015.

Bee declines driven by combined stress from parasites,

pesticides, and lack of flowers. Science 347,1255957.

Hierlemann, A., Gutierrez-Osuna, R. 2008 Higher-order

chemical sensing, Chemical Review 108, 563-613.

Hou, C.S., Li, B.B., Deng, S., Diao, Q.Y. 2016. Effects of

Varroa destructor on temperature and humidity

conditions and expression of energy metabolism genes

in infested honeybee colonies, Genetics and molecular

research: GMR 15(3), 1-13.

Jain, A.K., Dunin, R.P.W., Mao, J. 2000, Statistical pattern

recognition: A review., IEEE Transactions on Pattern

Analysis and Machine Intelligence 2(1), 4-37.

Johnson, R.M., Evans, J.D., Robinson, G.E., Berenbaum

M.R. 2009. Changes in transcript abundance relating to

colony collapse disorder in honeybees (Apis mellifera).

Proc. Natl. Acad. Sci. 35, 14790-14796.

Martin, S. J. 2001. The role of Varroa and viral pathogens

in the collapse of honeybee colonies: a modelling

approach. Journal of Applied Ecology 38(5), 1082–

1093.

Meikle, W.G, Holst, N. 2015. Application of continuous

monitoring of honeybee colonies. Apidologie 46, 10-

22.

Meikle, W., Rector, B., Mercadier, G., Holst, N. 2008.

Within-day variation in continuous hive weight data as

a measure of honeybee colony activity, Apidologie

694-707.

Ontarion.ca. 2016. Varroa Mite - Sampling and Monitoring

Infestation Levels,

http://www.omafra.gov.on.ca/english/food/inspection/

bees/Varroa-sampling.htm

Pomeroy, R. 2018. Accidental Discovery Could Save Bees

From Their Greatest Threat, Real Clear Science.

https://www.realclearscience.com/quick_and_clear_sci

ence/2018/01/15/accidental_discovery_could_save_be

es_from_their_greatest_threat.html

Randy, O., 2011. Sick Bees – Part 11: Mite Monitoring

Methods, ScientificBeekeeping.com.

Sánchez, V., Gil, S., Flores, J.M., Quiles, F.J., Ortiz, M.A.,

Luna, J. 2015. Implementation of an electronic system

to monitor the thermoregulatory capacity of honeybee

colonies in hives with open-screened bottom boards.

Comput. Electron. Agric. 119, 209–216.

Schneider, C.W., Tautz, J., Grünewald, B., Fuchs, S. 2012.

RFID tracking of sublethal effects of two neonicotinoid

insecticides on the foraging behavior of Apis mellifera.

PLoS One 7: e30023.

Spangler, H. 1969. Photoelectrical counting of outgoing

and incoming honeybee, Journal of Economic

Entomology 62, 1183-1184.

Stalidzans, E., Berzonis, A. 2013. Temperature changes

above the upper hive body reveal the annual

development periods of honeybee colonies. Comput.

Electron. Agric. 90, 1–6.

Schurischuster, S., Zambanini, S., Kampel, M., Lamp, B.

2016 Sensor Study for Monitoring Varroa Mites on

Honeybees (Apis mellifera). In Proceedings of the

Visual observation and analysis of Vertebrate And

Insect Behavior (VAIB) Workshop. Cancun/Mexico.

December 2016

Zacepins, A., Karasha, T. 2013. Application of temperature

measurements for bee colony monitoring: a review.

Eng. Rural Dev. 23, 126–131, Jelgava, Latvia.

Zacepins, A., Kviesis, A., Stalidzans, E., Liepniece, M.

Meitalovs J. 2016. Remote detection of the swarming

of honeybee colonies by single-point temperature

monitoring”, Biosystems Engineering 148, 76-80.

SENSORNETS 2019 - 8th International Conference on Sensor Networks

66