Optimization of Gaps Resolution Strategy in Implementation of ERP

Systems

Jānis Grabis

Information Technology Institute, Riga Technical University, Kalku 1, Riga, Latvia

Keywords: Fit-gap Analysis, ERP Systems, Customization, Optimization.

Abstract: Enterprise Resources Planning (ERP) systems are packaged applications developed by their vendors. Their

functionality is not specifically tailored to particular companies implementing these systems. Differences

between provided functionality and company’s needs are identified using fit-gap analysis. The paper

develops a novel optimization model for fit-gap analysis. The model yields an optimal gaps resolution

strategy, which defines type and timing of customizations made to resolve the gaps and decisions are made

with respect to the vendor’s software evolution roadmap. Thus, the model highlights trade-offs between in-

house customization and adoption of standard features yet to be released. The optimization results are

analysed depending on the company’s customization preferences and an application example is also

provided. The model allows for understanding and evaluation of relationships between the company

implementing the ERP system and the vendor of the ERP system.

1 INTRODUCTION

Enterprise Resources Planning (ERP) systems are

large software application used by companies to run

their business processes. The ERP systems typically

are packaged applications developed by software

vendors. Their functionality is not specifically

tailored to particular companies implementing these

systems. However, they have some degree of

flexibility and customization capabilities to

accommodate specific requirements. Companies aim

to select an ERP system best suited for their needs.

ERP selection methods (Jadhav and Sonar, 2009)

and fit-gap analysis (Gulledge, 2006) are employed

to identify the most appropriate ERP system.

Nevertheless, there are gaps between

functionality and capabilities provided and the

requirements, and these gaps need to be resolved

during implementation of the ERP system. The gaps

can be resolved by customizing the ERP system.

There are various approaches to customization in

ERP systems (Aslam et al., 2012). This paper

distinguishes between low-level and high-level

modification approaches. Low-level customization is

done using low level of abstraction tools such as

programming languages while high-level

customization uses high level of abstraction tools

such as interactive development methods and

workflows. Customization allows adding business

specific features to a standard software. Several

existing works investigate a choice between

customization alternatives (Parthasarathy and

Daneva, 2016) and implications of customization on

business value and operation of ERP systems (Zach

and Munkvold, 2012).

Customization often is time-consuming and

costly and poses various risks to the ERP

implementation (Kholeif et al., 2007). In order to

reduce the amount of customization, companies

might benefit from software updates released by

ERP vendors. The updates might contain

functionality or features requested by the companies.

Information about forthcoming updates is often

published as product development roadmaps by ERP

vendors.

Therefore, it is suggested that the fit-gap analysis

and selection of customization choices should be

synchronized with the vendor’s ERP development

roadmap. In general, the fit-gap analysis should be

viewed as a more strategically oriented activity

creating an ERP evolution strategy at the

organization. A gaps resolution strategy is proposed

as a part of this overall evolution strategy in this

paper. The gaps resolution strategy specifies

selection of ERP customization methods to deal with

84

Grabis, J.

Optimization of Gaps Resolution Strategy in Implementation of ERP Systems.

DOI: 10.5220/0007710000840092

In Proceedings of the 21st International Conference on Enterprise Information Systems (ICEIS 2019), pages 84-92

ISBN: 978-989-758-372-8

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the gaps, timing of implementation of

customizations and possibilities to avoid

customization by adopting new features provided by

the ERP vendor. Depending on preferences of the

company implementing the ERP systems, the

strategy might favour customization, alignment of

development plans with the vendor’s roadmap or

redesign of business processes.

The objective of the paper is to develop a model

for optimization of the gaps resolution strategy. The

optimization model balances a trade-off between

customization effort and value, and specifically

takes into account the standard software evolution

roadmap provided by the ERP vendor. The model

allows conducting sensitivity analysis and evaluation

of different ERP implementation policies. The

specific research question of model analysis is: what

is the impact of company’s customization

preferences on the gaps resolution strategy.

Application of the model is demonstrated using an

example of customization of the lead qualification

process in a customer relationships management

module of the ERP system.

The rest of the paper is organized as follows.

Section 2 reviews background information and

related work on ERP systems and fit-gap analysis.

Section 3 defines the concept of gaps resolution

strategy. The optimization model is elaborated in

Section 4. Section 5 provides model analysis results

and the application example is explored in Section 6.

Section 7 concludes.

2 BACKGROUND

2.1 ERP Implementation Process

The ERP implementation process consists of project

planning, design and customization, implementation

and maintenance and continuous improvement

phases (Erazo et al., 2017). During the project

planning phase, key requirements are identified and

a suitable ERP system is selected. Detailed analysis

of the requirements and functionality of the ERP

system is performed in the design and customization

phase. If the enterprise chooses to adopt standard

features of the ERP system it might need to redesign

its business processes. If the enterprise opts for

retaining existing business processes, customization

of the ERP system is required. As the result

necessary changes at the enterprise and in the ERP

system are identified and the ERP system is

customized.

The important part of the implementation

process is interplay with software vendor. The

software vendor continuously evolves the software

and the recent move to software as a service mode of

software delivery implies that new features are

delivered continuously without the need for

upgrading from one version to another. The

envisioned changes are announced in advance in a

form of software development roadmap (Keizer,

2018). The development roadmap includes the

expected new features and their estimated release

dates. This way companies can take into account that

some of the currently missing features might be

delivered within a specified time period.

2.2 Fit-gap Analysis

The fit-gap analysis is a part of the planning and

design phases of the ERP implementation process.

Initially, it is performed for the high level

requirements to provide input for selection among

alternative ERP systems, and, once the ERP system

is selected, detailed fit-gap analysis is performed to

provide inputs for design of system’s

implementation.

The fit-gap analysis yields a set of fits and a set

of gaps. The gaps should be resolved for successful

implementation of the ERP systems. They can be

resolved either by customizing the ERP systems or

by adjusting the enterprise. This decision has major

implications for the organization and enterprise

adjustment leads to transformation of business

processes. These transformation decisions are

beyond the scope of this paper, which focuses solely

on software related aspects and customization

decisions. In relation to ERP evolution roadmap,

some features might be missing at the time of fit-gap

analysis, however, they might become available in

new releases of the system. If the enterprise is

willing to wait, then gaps can be resolved without

customization.

2.3 ERP Customization

ERP customization concerns modification of out-of-

the-box functionality of ERP systems using various

tools provided. It is performed in the customization

and implementation phases and is aimed at reducing

gaps between the required and provided

functionality. Aslam et al. (2012) summarize several

typologies of customizations in ERP systems. They

include configuration, bolt-ons, screen masks,

reporting, workflow development, interface

modification and package code modification.

Optimization of Gaps Resolution Strategy in Implementation of ERP Systems

85

Hustad et al. (2016) consider tailoring of reports,

interfaces, enhancements, forms, workflows and

portals. Luo and Strong (2004) developed a

framework relating technical customization and

process customization options.

There is no agreement on benefits of

customization (Aslam et al., 2012). Several authors

point out that customization is time consuming and

complicates system’s maintenance (Zach and

Munkvold, 2012). Research by Parthasarathy and

Sharma (2016) suggests that customization does not

yield expected benefits. Yet, companies have strong

desire for customization (Gool and Seymour, 2018),

and Holsapple et al. (2005) argue that customization

has a major importance on preserving value-adding

functions at companies using packaged applications.

Obviously, customization requires some

development effort and must have sufficient value or

utility for the enterprise to be considered for

implementation.

2.4 Related Work on Fit-gap Analysis

A number of fit gap analysis methods have been

developed. One group of the methods focus on

identification of gaps and another group of the

methods also consider selection of customization

choices to address the gaps.

Identification of gaps is analyzed by Wu et al.

(2007). Enterprise requirements are captured in goal,

activity and data models, which are compared with

the ERP systems to identify the differences. Yen et

al. (2011) identify misfits at the strategic level and

propose their classification framework, where the

misfits are categorized as enterprise, industry or

country specific.

Sarfaraz et al. (2012) proposed to use AHP to

evaluate technical customization choices vs process

customization choices with respect to degree of

customization. Parthasarathy and Daneva (2016)

develop a requirements prioritization framework and

a heuristic algorithm to find a justifiable degree of

customization. They consider introduction of new

standard features in future releases of the ERP

system as one of the evaluation criteria. Pajk and

Kovacic (2013) describe a detailed fit-gap analysis

process including high-level fit-gap analysis,

identification of gaps and fits, and gaps resolution.

Process adaptation, system adaption, third party

solution and workaround are identified as resolution

strategies. These and other fit-gap analysis methods

are also reviewed by Ancveire (2018).

The proposed model is an optimization model as

opposed to heuristic method used in literature and it

specifically takes into account dynamics of

introduction of new standard features by the ERP

vendor what is of particular relevance in the case of

ERP in the form of SaaS.

3 GAPS RESOLUTION

STRATEGY

The gaps resolution strategy defines selection of

customization options and their timing to reduce

gaps between the required functionality and the

functionality provided by the selected ERP system.

It takes into account vendor’s ERP development

roadmap and aims to optimize business value

achieved by satisfying requirements in the best

possible manner.

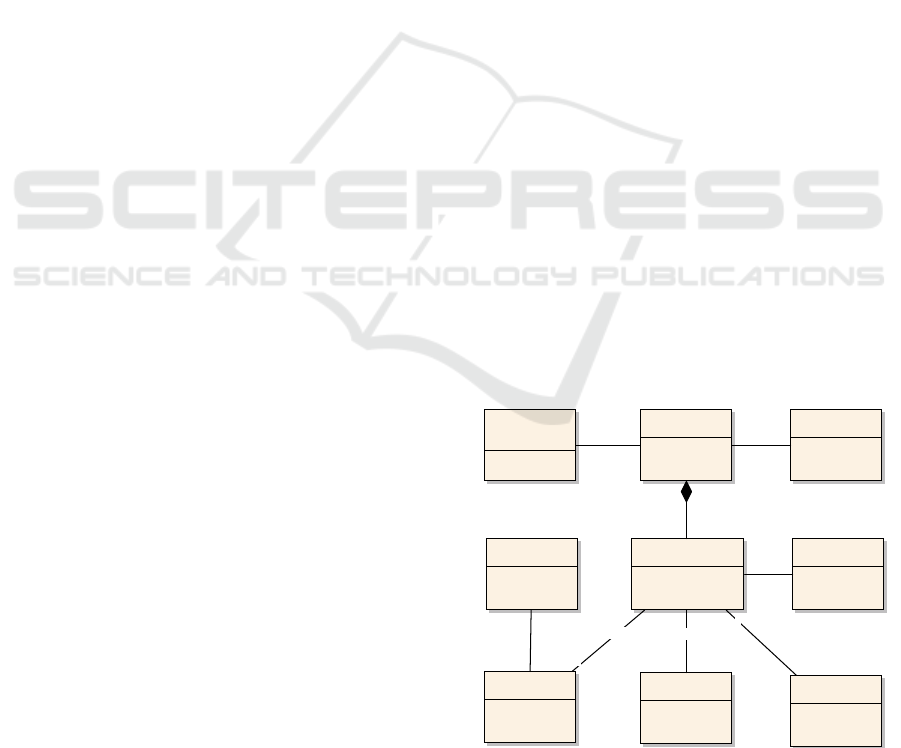

The conceptual model of the gaps resolution

strategy is shown in Figure 1. It is assumed that the

company has identified requirements towards the

ERP system. If the selected ERP package does not

satisfy some of the requirements, corresponding

gaps are identified. The strategy is driven by

company’s preferences concerning customization.

The vendor’s roadmap indicates timing of the

release of new features. The new features might

address some of the gaps though there is no

guarantee that they will be definitely delivered. The

gaps resolution strategy consists of customization

choices. The customization choice indicates when

and what gaps resolution approaches will be used.

The selection of the customization choice is made

per gap and one of the customization options is

selected. The customization options are specific to

particular ERP systems.

Figure 1: The conceptual model of the gaps resolution

strategy.

class Customization

Option

Gap

Requirement

Strategy

CustomizationChoice

Roadmap

Effort

Utility

Customization

preference

1

*

1

Used

0..*

1

Guide

1

1

1

1 1

1

Resolve

0..11..*

0..*

1

Drive

1

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

86

Figure 2: The process of establishing the gaps resolution strategy.

Every customization choice has its utility and

associated implementation effort. The utility and

effort are specific to a combination of the gap and its

resolution option. The utility characterizes business

value achieved by making a specific customization

choice. The effort characterizes the implementation

effort. The utility does not necessarily out-weight

the effort.

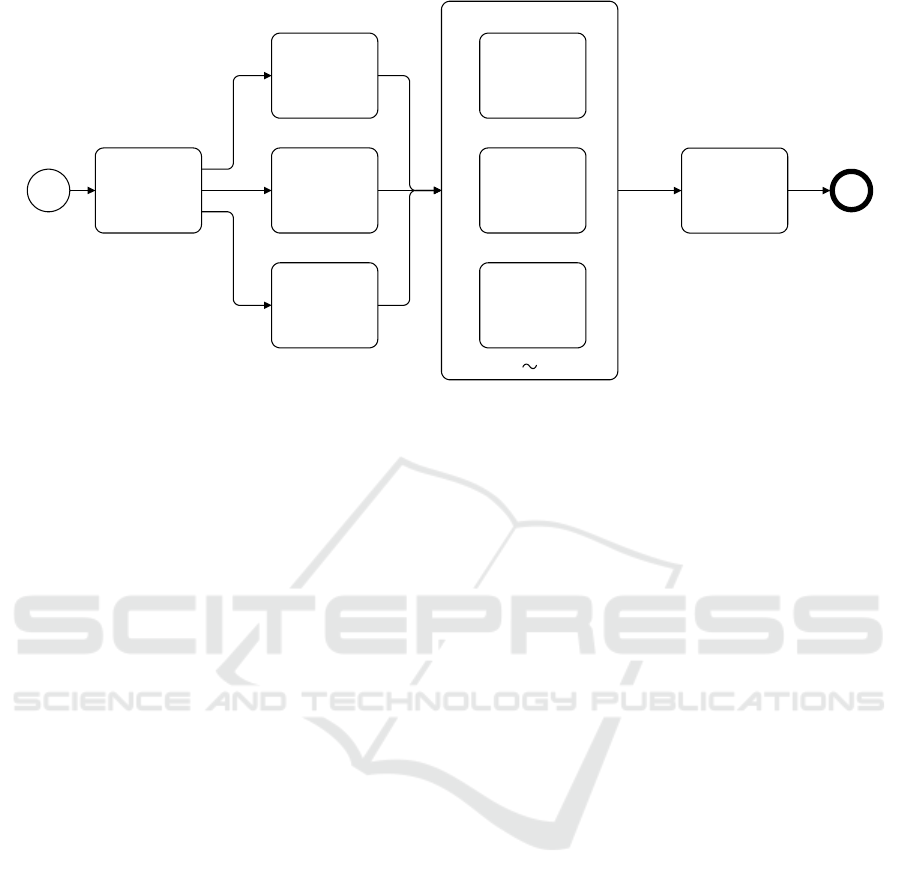

The process of establishing the gaps resolution

strategy is illustrated in Figure 2. It is assumed that

requirements towards the ERP system have been

elicited and there is sufficient information about

functionality of the ERP system. The first task of the

process is identification of gaps. The gaps can be

resolved by employing appropriate customization

options. Utility and effort associated with every

customization option are evaluated per gap. The

paper does not investigate specific methods for

estimating utility and effort, and effort estimation by

planning poker (Qureshi 2012) is adopted for

illustrative purposes. The utility can be determined

using cost of delay criterion as described by

Leffingwell (2011). If a customization option is not

suitable for the gap then modification effort is set to

infinity. Simultaneously, the vendor’s roadmap is

analyzed and opportunities for using newly released

features to resolve the gaps are identified. There is a

utility associated with adopting the new features as

well.

The utility and effort estimates, and roadmap are

inputs to gaps resolution strategy optimization. The

optimizations steps are performed in an iterative

manner. The strategy is established for a finite

planning horizon and the optimization results are

selection of customization options and timing of

implementation of the changes bundled as releases.

The optimization is performed subject to

development resource constraints. Finally, the

strategy is implemented. Implementation

adjustments might be required because of changes in

the vendor’s roadmap as well as inaccuracies in

utility and effort estimation.

4 OPTIMIZATION MODEL

As a part of the process of establishing the gaps

resolution strategy, the optimization model is

formulated. The optimization model selects

customization choices to maximize the difference

between customization utility and effort. It takes into

account expected release of new features by the

ERP’s vendor and availability of development

resources needed for customization.

4.1 Notation

i – gaps index

j – customization options index

t – time period index

TT – planning horizon

i

G

– gaps

j

O

– implementation options

ijt

X

– selected implementation option equals to 1 if

ith gap is resolved using jth option in tth period and

0 otherwise

i

– release time period of new standard feature for

ith gap

Strategy optimization

Identify gaps

Analyze

vendor’s

roadmap

Evaluate

modification

utility

Estimate

modification

effort

Select

customization

options

Plan releases

Plan resource

consumption

Implement

the strategy

Optimization of Gaps Resolution Strategy in Implementation of ERP Systems

87

ij

E

– implementation effort for gap i using option j

in points

ij

V

– unadjusted variable implementation utility for

gap i using option j in points

*

ij

V

– unadjusted fixed implementation utility for

gap i using option j in points

ij

U

– variable implementation utility for gap i using

option j in points adjusted according to

customization preferences

*

ij

U

– fixed implementation utility for gap i using

option j in points adjusted according to

customization preferences

t

R

– resources available in period t in points

– customization preference coefficient

4.2 Assumptions

The following assumptions are made in the

optimization model:

Gaps are independent;

Customizations are independent;

Tasks are small enough to be completed within

one period;

Customizations are rolled-out at the end of every

period if any;

Only one customization option can be selected

for a gap;

Effort, utility and resource capacity are measured

in points, which are appropriately scaled.

4.3 Objective

The objective function (Eq. 1) selects customization

choices that maximize customization gains expected

as the difference between customization utility and

effort. The utility is divided in two terms, namely,

variable and fixed returns. The fixed returns are

evaluated over the whole ERP life-cycle and are

accounted for regardless when the gap is resolved.

The variable returns are realized during the

strategy’s planning horizon starting with the period

when the gap is resolved.

*

1 1 1

1 1 1

()

I J TT

ij ij ijt

i j t

I J TT

ij ijt

i j t

Z TT t U U X

EX

(1)

4.4 Constraints

The optimization is performed subject to:

11

1,

J TT

ijt

jt

Xi

(2)

11

, 1,...,

IJ

ij ijt t

ij

E X R t TT

(3)

1

,,

i i t

t X i t

(4)

**

, , ,

ij ij ij ij

U V U V i j

(5)

The constraint (2) implies that every gap can be

resolved no more than just once (including using just

one customization option). The constraint (3)

represents limited availability of development

resources and total effort spent on customization

cannot exceed available resources in every period.

The constraint (4) states that the vendor’s released

features cannot be adopted before they are released.

The equation (5) adjusts the customization utility. If

the customization preference coefficient

is

increased the company has stronger incentives to

customize system. If the customization preference

coefficient is decreased the company prefers usage

of standard features and the gaps are resolved by

either changing business processes or waiting for

appropriate updates to be released by the vendor.

Thus, the equation represents company’s strategic

preference for customization or standardization.

5 MODEL ANALYSIS

Experimental studies are conducted with the model.

Their objective is to demonstrate impact of the

customization preferences on the gap resolution

strategy. A synthetic data set is used in the studies. It

is assumed that 20 gaps are identified and 5

customization options including adoption of newly

released standard features. Customization effort

varies from 0 (for standard features) to 13 points.

The utility is generated as a randomized multiple of

the effort and on average is by 20% larger than the

effort over the planning horizon. There are 12

periods within the planning horizon, and

development capacity for each period is 20 points.

The vendor releases new features after every four

periods and they are good for resolving 12 gaps

although some of the features become available

quite late in the planning horizon.

During the experimentation, the customization

preference coefficient

is varied from 0.25 to 2,

where the former value resembles company’s

preference to use standard features while the latter

value resembles company’s preference to customize.

The optimization is performed for ten different

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

88

randomly generated sets of utility values. The

optimization results (Figure 3) show that

customization choices significantly depend on the

customization preference coefficient. If

=0.25 the

enterprise opts for changing business processes or

using standard features as they become available. If

customization utility is high almost all gaps are

resolved and there are few incentives to wait for

standard features to be delivered. That, however, is

also affected by availability of development

resources (in this case resource utilization is about

70% for

=2).

The optimization model clearly allows to

identify trade-offs between customization and

adoption of standard features depending on

customization preferences of the enterprise.

Figure 4 shows an example of the gap resolution

strategy. It shows timing of implementing

customizations and adoption of newly released

standard features. If the standard features are

adopted they are introduced immediately. For Gaps

5 and 12, the optimal approach is to customize the

systems not to wait till the new standard features are

released. The customizations are introduced at

different time periods because of resources

limitations. Gap 13 is not resolved because its

resolution utility is lower than the effort.

Figure 3: The gap resolution approach chosen depending

on the customization preference coefficient

Gap

14

Gap

13

Gap

12

Gap

11

Gap

10

Gap

9

Gap

8

Gap

7

Gap

6

Gap

5

Gap

4

Gap

3

Gap

2

Gap

1

1 2 3 4 5 6 7 8 9 10 11 12

5

None

2

Std.

feature

5

Std.

feature

5

Std.

feature

Std.

feature

4

3

Std.

feature

Std.

feature

Std.

feature

Figure 4: A fragment of the sample gap resolution strategy. The second column indicates the customization approach used,

green filling indicates periods the customization is implemented and used, light read indicates availability of new standard

features and dark red indicates usage of the new standard features.

Optimization of Gaps Resolution Strategy in Implementation of ERP Systems

89

Create Lead

Find

Duplicates

Merge Lead

Records

Make

Qualification

Call

Convert Lead

Create Folow

UpTask

Update Lead

Data

Close Lead

Dublicates

found

No dublicates

Create

opportunity

Not ready

Further action

required

No further

action

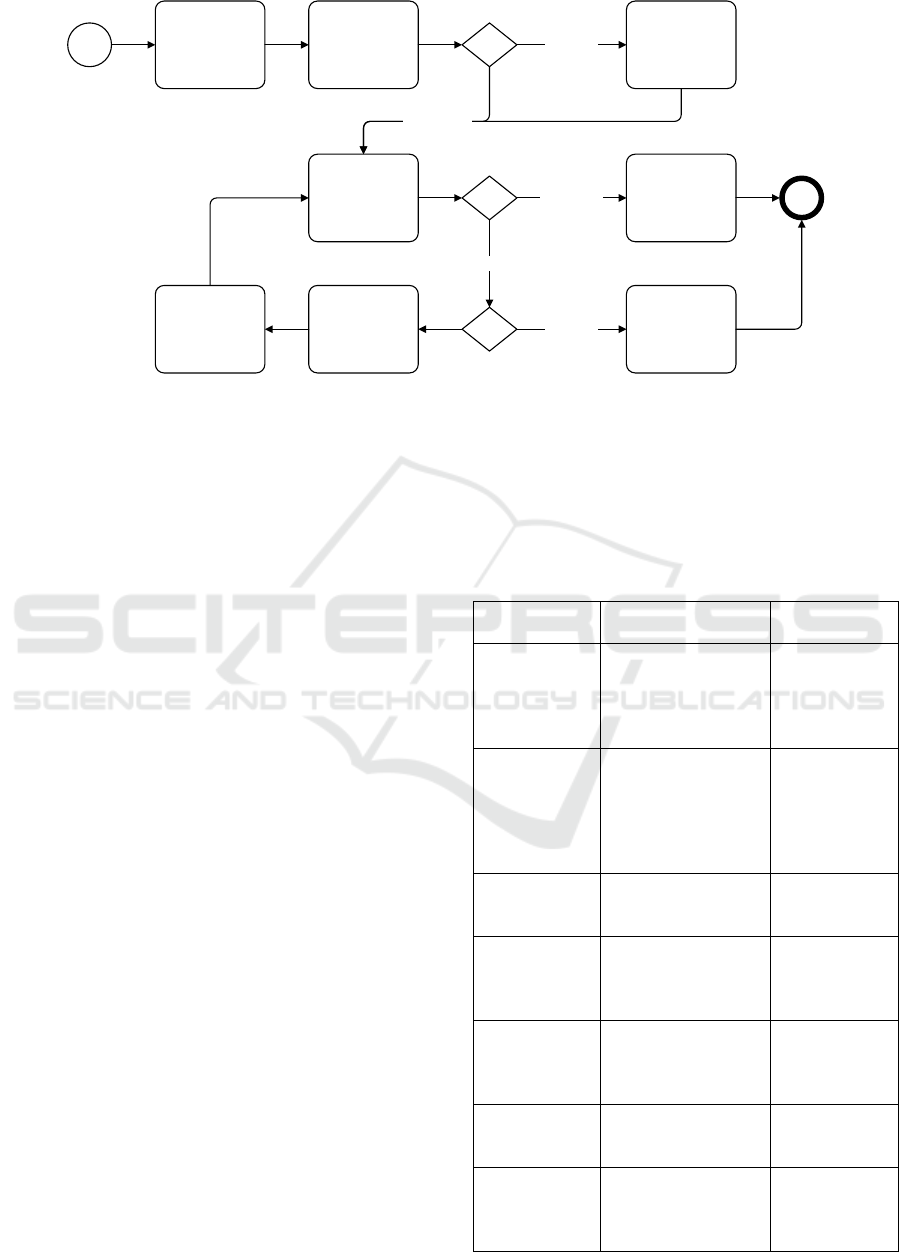

Figure 5: The lead qualification process.

6 EXAMPLE

Application of the model is demonstrated using an

example of implementing CRM module (the

functionality and available customization options are

inspired by Microsoft Dynamics 365). More

specifically, the lead qualification process (Monat

2011) is considered (Figure 5). In this process, a lead

represents a potential source of sales. Information

about lead is registered in the system. Initial

information might be incomplete and initial data

cleansing is required to identify duplicated records.

The leads are contacted by sales representatives to

gather additional data and to evaluate sales potential.

If potential customers respond positively they are

converted into opportunities. If initial contacts are

not successful, further activities are planed until the

lead is converted into an opportunity or dropped.

The number of leads can be substantial and there are

many opportunities for process automation.

The CRM application provides multiple

customization options categorized as data view, user

interface (UI) modification, custom report, different

types of workflows and add-ons. The data view

customization option provides simple improvements

for searching, filtering and performing other data

processing operations. The UI customization option

modifies the existing UI, for instance, to make data

input more efficient. Reports typically provide

analytical features. Basic processes provide process

execution guidance while workflows support task

automation and advanced process execution logics.

Add-ons are developed using low-level modification

techniques (i.e., custom code development) or

purchased from third-parties.

Table 1: Gaps identified for the lead qualification process

and available customization options.

Process tasks

Gap

Customization

options

Create Lead

G1: The data entry

is too time-

consuming due to

extra navigations

steps

Std. feature

Data view

UI

Basic process

Workflow

Find

Duplicates

G2: Provided data

are not

appropriately

tailored and a lot of

manual work

Data view

UI

Report

Basic process

Workflow

Add-on

Make

Qualification

Call

G3: The

conversation is not

scripted

Std. feature

Basic process

Workflow

Update Lead

data

G4: The update is

manual and

involves extra

navigation steps

UI

Basic process

Workflow

Create Follow

up Tasks

G5: Not all

information to

decide on follow up

tasks is available

Data view

UI

Report

Close Lead

G6: Closing is

manual

UI

Basic process

Workflow

Convert Lead

G7: Conversion is

manual

UI

Report

Basic process

Workflow

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

90

It is assumed that several gaps have been

identified (Table 1). The company aims to make

process execution more efficient and considers

changes ranging from UI modification to

introduction of automated processing. The available

customization options are also listed (not all options

are available for every gap). For instance, the report

customization option is suitable for the Update lead

data task. Six customizations options are available

for gap G2 in the Find Duplicates task. The Data

view customization provides a set of filter

facilitating manual identification of duplicates. The

UI customization emphasis data fields needed for the

task. The report customization provides analytical

data need for the task. Process defines standard steps

to be performed to find duplicates and the workflow

automates some of these tasks. The Add-on provides

a classification algorithm for merging lead according

to a set of attributes.

The effort and utility of the customization

options is determined (Table 3). Generally, it is

assumed that user interface modifications are the

simplest and development (or procurement) of add-

ons require the most effort. Similarly, usage of more

advanced and lower level customization options

Table 2: Effort and utility per customization choice.

Gap

Customization Option

Effort

Utility

G1

Std. feature

Data view

UI

Basic process

Workflow

0

1

3

3

8

10

2

3,5

3,5

10

G2

Std. feature

Data view

UI

Report

Basic process

Workflow

Add-on

0

1

3

5

3

8

13

10

1,5

4

12

4

10

25

G3

Std. feature

Basic process

Workflow

0

3

13

3

3,2

20

G4

UI

Basic process

Workflow

5

3

5

3,3

3,2

6

G5

Data view

UI

Report

1

1

5

1

1

6

G6

UI

Basic process

Workflow

3

1

5

2

2

6

G7

UI

Report

Basic process

Workflow

3

3

1

8

3,5

4

2

10

potentially yields more benefits (i.e., higher utility).

The values provided are illustrative and their actual

values are determined from case to case.

The planning horizon is six periods and

resources are available to implement 15 points worth

of customization in each period. The vendor will

provide new features for the first three gaps in the

third period. Standard features are not expected for

other four gaps. The customization preference

coefficient

=0.25.

Table 3 shows the optimized gap resolution

strategy. Gaps 4 and 5 are left unresolved. The basic

process customization option is favoured instead of

the workflow customization option because it can be

implemented sooner (due to smaller effort) and

business benefits can be realized for the whole

planning horizon.

Table 3: The gap resolution strategy for the lead

qualification process.

Gap

Customization option

Time period

G1

Std. feature

3

G2

Add-on

1

G3

Std. feature

3

G6

Basic process

1

G7

Basic Process

1

The optimization is also performed without

accounting for the vendor’s roadmap. As the result,

the value of the objective function is by 58% smaller

than initially. That indicates that using the vendor’s

roadmap as an input one can find a better strategy.

The comparison was also made with a heuristic

method following the greedy principle. The heuristic

started with implementation of customization

choices with the largest difference between effort

and utility as long as resources are sufficient for the

period. The obtained value of the objective function

was by 87% smaller than the optimal.

7 CONCLUSION

The new optimization model for resolving gaps in

implementation of ERP systems has been elaborated.

It provides dynamic view gaps resolution planning

with respect to resource availability and vendor’s

software evolution roadmap. The model can be used

to evaluate various ERP implementation policies, for

instance, impact of company’s preferences for

customization or retaining standard features. This

analysis is important because there is no consensus

Optimization of Gaps Resolution Strategy in Implementation of ERP Systems

91

on business value of ERP customization and

companies have different needs and preferences.

The optimization model can be extended in

various ways. Currently, it assumes that

maintenance considerations are captured using the

utility measure though more explicit treatment of

maintenance could be provided. The model also

does not consider relationships among gaps and

possibilities to used multiple customization options

for a single gap.

Company and vendor relationships also could be

explored further. Unfortunately, vendors change

their roadmaps frequently and this uncertainty also

should be represented in the model. Additionally,

vendors charge support fees, which include delivery

of new features. The model could be used to

evaluate whether 1) these fees are justifiable and 2)

features are delivered soon enough or the company

is better off with implementing changes on its own.

ACKNOWLEDGEMENTS

This study was funded in parts by European

Regional Development Fund (ERDF), Measure

1.1.1.5 “Support for RTU international cooperation

projects in research and innovation”. Project No.

1.1.1.5/18/I/008.

REFERENCES

Ancveire, I. 2018. Fit gap analysis methods for ERP

systems literature review, SACI 2018 - IEEE 12th

International Symposium on Applied Computational

Intelligence and Informatics, Proceedings, pp. 161.

Aslam, U., Coombs, C., Doherty, N.F. 2012. Benefits

realization from ERP systems: The role of

customization, ECIS 2012 - Proceedings of the 20th

European Conference on Information Systems.

Erazo, J., Arboleda, H., Pino, F.J. 2017. Analysis of the

software implementation process for ERP systems.

Gool, S., Seymour, L.F. 2018, Managing enterprise

resource planning system customisation post-

implementation: The case of an African petroleum

organisation, ICEIS 2018 - Proceedings of the 20th

International Conference on Enterprise Information

Systems, pp. 111.

Gulledge, T.R. 2006. ERP gap-fit analysis from a business

process orientation, International Journal of Services

and Standards, vol. 2, no. 4, pp. 339-348.

Hustad, E., Haddara, M., Kalvenes, B., 2016. ERP and

organizational misfits: An ERP customization journey.

Procedia Computer Science, 100, 429-439.

Ho, C.-., Wu, W.-., Tai, Y.-. 2004. Strategies for the

adaptation of ERP systems, Industrial Management

and Data Systems, vol. 104, no. 3, pp. 234-251.

Holsapple, C., Wang, Y., Wu, J., 2005. Empirically testing

user characteristics and fitness factors in enterprise

resource planning success. International Journal of

Human-Computer Interaction, 19(3), 325–342.

Jadhav, A.S., Sonar, R.M., 2009. Evaluating and selecting

software packages: A review, Information and

Software Technology, vol. 51, no. 3, pp. 555-563.

Keizer, G., 2018. Microsoft puts Dynamics 365 on twice-

a-year release cadence, Computerworld, July 11,

https://www.computerworld.com/article/3289388/

Kholeif, A. O., Abdel - Kader, M., Sherer, M., 2007. ERP

customization failure: Institutionalized accounting

practices, power relations and mark et forces. Journal

of Accounting and Organizational Change, vol. 3, pp.

250-269.

Leffingwell, D., 2011. Agile Software Requirements: Lean

Requirements Practices for Teams, Programs, and the

Enterprise. Addison-Wesley.

Luo, W., Strong, D.M., 2004. A framework for evaluating

ERP implementation choices. Engineering

Management, IEEE Transactions on, 51(3): p. 322-

333.

Monat, J.P., 2011. Industrial sales lead conversion

modeling. Marketing Intelligence, Planning. Vol 29,

Iss 2, pp. 178-194.

Pajk, D., Kovacic, A., 2013. Fit Gap Analysis – The Role

of Business Process Reference Models, Econ. Bus.

Rev., vol. 15, no. 4, pp. 319–338.

Parthasarathy, S., Daneva, M., 2016. An approach to

estimation of degree of customization for ERP projects

using prioritized requirements, Journal of Systems and

Software, vol. 117, pp. 471-487.

Parthasarathy, S., Sharma, S., 2016. Efficiency analysis of

ERP packages - A customization perspective.

Computers in Industry, vol. 82, pp. 19-27.

Qureshi, M.R.J., 2012. Agile software development

methodology for medium and large projects. IET

Software, vol. 6, no. 4, pp. 358-363.

Sarfaraz, A., Jenab, K., D'Souza, A.C. 2012. Evaluating

ERP implementation choices on the basis of

customisation using fuzzy AHP, International Journal

of Production Research, vol. 50, no. 23, pp. 7057-

7067.

Wu, J. H., Shin, S. S., Heng, M. S. H., 2007. A

methodology for ERP misfit analysis. Inf. Manag.,

vol. 44, no. 8, pp. 666–680.

Yen, T.S., Idrus, R. & Yusof, U.K., 2011. A framework

for classifying misfits between enterprise resource

planning (ERP) systems and business strategies. Asian

Academy of Management Journal, vol. 16, no. 2, pp.

53-75.

Zach, O., Munkvold, B.E. 2012. Identifying reasons for

ERP system customization in SMEs: A multiple case

study, Journal of Enterprise Information Management,

vol. 25, no. 5, pp. 462-478.

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

92