IoT based Driver Information System for Monitoring the

Load Securing

Jurij Kuzmic

1

, Günter Rudolph

1

, Walter Roth

2

and Michael Rübsam

2

1

Department of Computer Science, TU Dortmund University, Otto-Hahn-Str. 14, Dortmund, Germany

2

Dept. of Computer Science, South Westphalia University of Applied Sciences, Frauenstuhlweg 31, Iserlohn, Germany

Keywords: Load Securing System, Load Cell Sensor, VL6180X Proximity and Ambient Light Sensing Module,

CNY70 Reflective Optical Sensor, Miniature Snap-Action Switch, Wireless Technology, Encryption of

Transmitted Data, Development and Analysis of 433 MHz Radio Link, Power Supply of the Electronic

Cargo Strap Systems, Back End, Front End, Practical Real World Tests.

Abstract: This paper presents an electronic cargo strap system for monitoring load securing in trucks and car trailers.

Various measuring techniques and sensors for measuring the force on lashing belts are investigated. In

addition, a data access layer (back end) and a presentation layer (front end) have been developed for the

system in order to be able to monitor the load while driving. Moreover, radio data transmission, encryption

of transmission data and power supply of the systems has been realized. Furthermore, some prototypes have

been created in order to test the developed systems. A series of practical tests have been performed to test

the electronic cargo strap systems under real-world conditions.

1 INTRODUCTION

Many accidents and road closures occur due to non-

monitored load securing during transportation of

loaded goods in heavy goods vehicles, also causing

transport damages of the loaded goods, which

further increases the costs. To counteract this

problem, this paper introduces a system for

monitoring the load securing in trucks and car

trailers.

Various measuring methods and sensors have

been investigated. The sensors for measuring the

force on the lashing belt have been analysed and

tested. To prove the long-term stability, all sensors

were operated in continuous long-term tests. The

cost of the individual sensor must be very low for

this application because there are many lashing

straps used on a typical truck. Monitoring and

display of measured data has been implemented as a

mobile application running on an Android tablet.

Furthermore, power consumption of our

electronic cargo strap systems including sensor and

microcontroller has been investigated. Additionally,

a power supply suitable for real world use featuring

easy replacement of batteries has been developed.

Long service life of these systems without replacing

the batteries is highly desirable.

The radio data transmission between the data

access layer (back end) and the electronic cargo

strap systems has been examined. Here it is

important that the radio link requires very little

energy in order to be able to run the electronic cargo

strap systems with the same energy supply for years.

A simple encryption of the data has been

implemented to address the need not to transmit

clear text data via the radio link.

Most of the work in this project was done at the

South Westphalia University of Applied Sciences in

Iserlohn (Kuzmic A1, 2018). Furthermore, several

prototypes of the electronic cargo strap systems were

produced in order to test them in real-world

deployments.

To the best of our knowledge, there is no other

research in this area. For this reason, the references

are tutorials and sensor datasheets, and therefore not

related scientific work. According to our research,

no product exists on the market for monitoring the

load securing so far. There is only one patent

(Bruhn, 2014) for a similar system which describes

other sensors.

262

Kuzmic, J., Rudolph, G., Roth, W. and Rübsam, M.

IoT based Driver Information System for Monitoring the Load Securing.

DOI: 10.5220/0007710302620269

In Proceedings of the 4th International Conference on Internet of Things, Big Data and Security (IoTBDS 2019), pages 262-269

ISBN: 978-989-758-369-8

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 SYSTEM ARCHITECTURE OF

LOAD SECURING SYSTEM

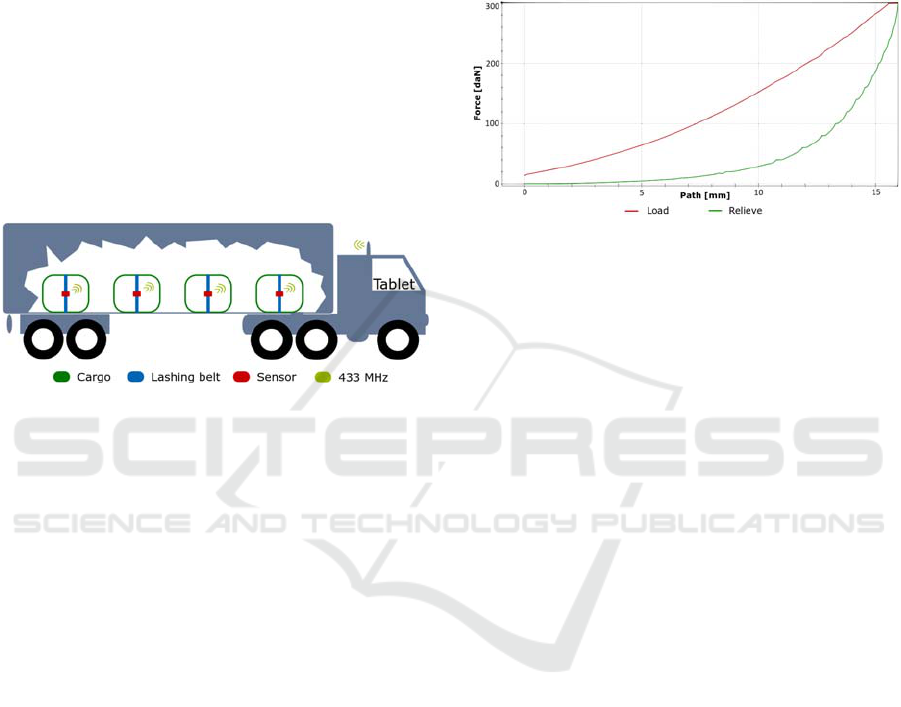

The system architecture describes the interactions

between developed components. Load is secured in

the vehicle using lashing belts and is monitored by

the electronic cargo strap systems. The data

measured by the sensors attached to the lashing belt

are transmitted from the truck semi-trailer to a truck

cabin via 433 MHz radio link. Data are displayed for

the truck driver on a tablet in the cab (Fig. 1). The

conversion from raw analog sensor value to force on

the lashing belt is performed by the microcontroller

of the sensor-transmitter unit. The mechanical

DoMess2 force meter (Dolezych, 2018) is used as a

starting point for the electronic cargo strap systems.

Figure 1: System architecture (interaction between truck

semi-trailer and truck cabin).

During development of the electronic cargo strap

systems, a hysteresis of measured values was

recognized. This is due to the physical assembly of

the DoMess2 force meter and the stretching of the

lashing belt and the built-in compression springs

(Rudolph, 2017). It can be seen in the diagram (Fig.

2) created by the pull-off force machine that the path

is not identical during increasing and relieving the

force on the lashing straps. When increasing the

force on the DoMess2 force meter, the force of 200

daN is reached at a position of about 12 millimetres.

However when relieving, the same force is reached

at 15 millimetres. The stretching of the lashing strap

and the mechanics are included in this diagram. daN

is the abbreviation for the unit of force Dekanewton

(10 Newtons). This corresponds approximately to

the weight of one kilogram (Wikipedia.org A1,

2018).

However hysteresis plays a minor role in the

development of the electronic cargo strap systems.

Because the relieving curve is relevant when

verifying force during transport, only the relieving

curve must be examined. Furthermore Figure 2

shows, that while relieving the DoMess2 force meter

the distance from 200 to 300 daN is only about 0.9

millimetres. This means that the sensor must be very

sensitive in order to be able to perceive minimal

changes of the distance. Optimizing the larger spring

forces may reduce the hysteresis, but this was not

tested. The steps in the relieving curve diagram

result from stopping at different levels of force on

the pull-off force machine. The force was held in

these conditions for ten seconds at each step.

Figure 2: Hysteresis of load and relieve the lashing strap.

3 ANALYSIS OF SENSORS

The following sections examine four possible

sensors for measuring the force on the lashing belts.

Arduino Pro Mini microcontrollers (Rohner, 2015)

are used to read the sensors.

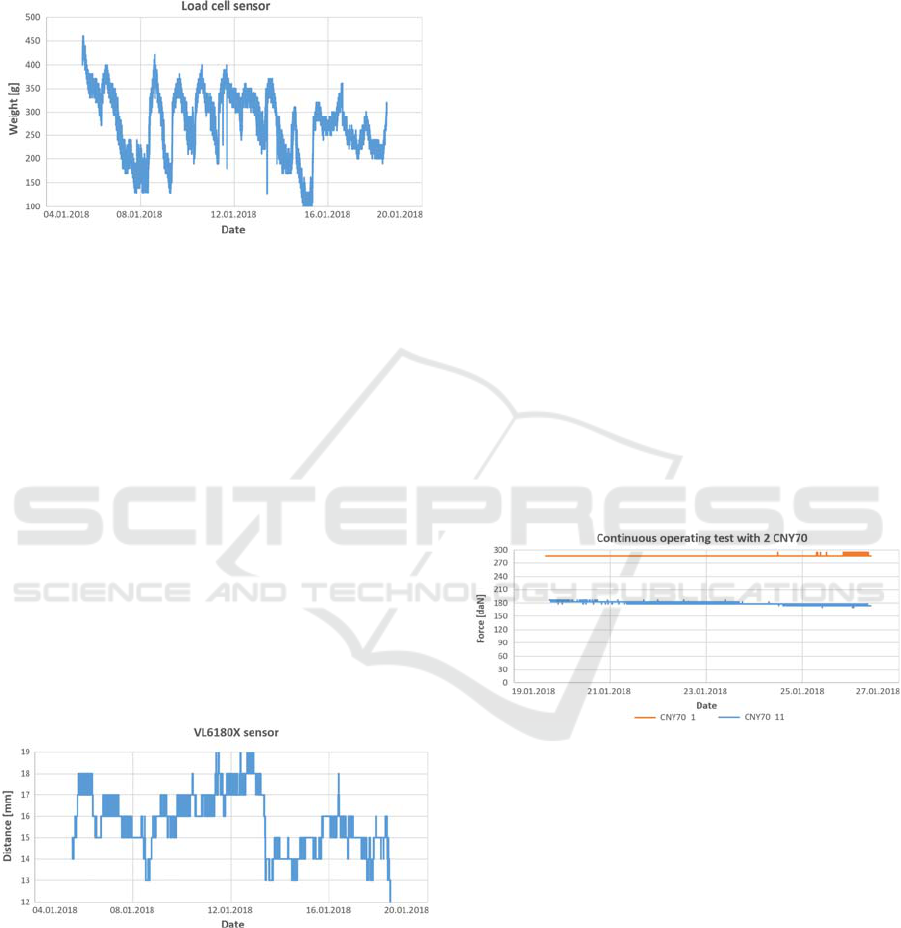

3.1 Load Cell Sensor

The load cell sensor is the standard measuring

device installed in commercial digital personal

scales (Instructables.com A1, 2018). This sensor

contains two strain gauges, which change their

resistance during compression or stretching (Al-

Mutlaq, 2018).

This type of sensor needs a load cell

amplifier, because the changes of resistance are very

small. The breakout board HX711

(Forum.arduino.cc, 2018) can be used for this. It

contains all components required for amplification

of the resistance changes. To obtain correct readings

for two load cell sensors, two half Wheatstone

bridges (dual half bridge) have to be constructed

(Youtube.com, 2016). This type of circuit is

commonly used to measure small ohmic resistance

changes. After some short-term measurements, the

question arises as to whether the load cell sensors

are long-term stable. To answer this question, a

continuous operating test was run for about two

weeks. The starting weight in this test was 410

grams. As can be seen in next figure (Fig. 3), the

reading values vary significantly over time. The

deviation in this case is up to 76 percent. Although

these sensors are ideal for a short measurement in a

IoT based Driver Information System for Monitoring the Load Securing

263

digital personal scale, they can not be used for

continuous operation. For this reason, load cell

sensors are inappropriate for measuring forces on

lashing belts.

Figure 3: Continuous operating test of load cell sensor.

3.2 VL6180X Proximity and Ambient

Light Sensing Module

The next type of sensor investigated was the

VL6180X Time-of-Flight proximity and ambient

light sensor. Because the VL6180X uses infrared

pulses for measurement, it is widely independent of

colour and surface properties of the target (Pololu,

2018).

After wiring and programming (Github.com,

2016) of the components, a distance measurement

test was performed with this sensor. From this test, it

was found out that the VL6180X sensor is suitable

for measuring distances in the mm range. It provides

a digital read out of the distance to the object in

millimetres. To determine whether this sensor can be

used permanently for the electronic cargo strap

system, a continuous operating test with three

sensors for about two weeks was carried out (Fig. 4).

Figure 4: Continuous operating test of one of three

VL6180X sensors.

The three continuous operating tests were

executed in parallel. All three VL6180X sensors

fluctuate between 4-7 millimetres. The minimum

resolution of the sensor is one millimetre, which is

within the requirements for measuring lashing belt

forces. Nevertheless, the discovered fluctuations

make these sensors too inaccurate with regard to

long-term stability. The VL6180X sensors are

therefore not suitable for measuring the force on

lashing belts because the maximum lift of the

mechanical DoMess2 force meter used is only ten

millimetres and the fluctuations of the sensors were

4 mm, equivalent to 40% of the measuring range.

However, the measuring range is in centimetres,

VL6180X sensors may be used.

3.3 CNY70 Reflective Optical Sensor

with Transistor Output

This chapter investigates the usability of the CNY70

reflective optical sensor with transistor output

(Mischnick and Mischnick, 2007) for the electronic

cargo strap system. In order to check whether the

sensor is suitable for measuring, it was installed in a

syringe in the first step. The syringe was taped with

black tape, so that the outside light did not affect the

light from the sensor’s LED. Because each of these

analog sensors shows different measured values with

the same applied voltage, they must be calibrated

before measuring. In principle, these sensors are

suitable for measuring distances. They passed the

continuous operating tests very well, showing

excellent long-term stability (Fig. 5).

Figure 5: Continuous operating test of two CNY70

sensors.

An average function is used to convert the raw

analog value of the sensor voltage to the force on the

lashing belt (Dekanewton). Because the curve

progression of the sensors is identical, the measured

ratio of the sensor can be represented on a

percentage basis on this average curve. For this only

the start and end values of the measurement range

determined during calibration of the sensor are

required. During test measurements and continuous

operating tests it turned out that although CNY70

sensors are suitable for measuring the distance in the

DoMess2 force meter, they are very sensitive to

external light and mechanical impact. Furthermore,

it has been noticed that material and colour of the

reflective surface play a major role in the

IoTBDS 2019 - 4th International Conference on Internet of Things, Big Data and Security

264

measurement. However, because of the good results

of test measurements and continuous operation tests,

several prototypes were produced for field tests in

the real world.

3.4 Miniature Snap-action Switch

Another possibility for monitoring load securing is

the miniature snap-action switch known from

electrical engineering. These switches are nowadays

a standard component in many electrical appliances.

A great advantage of micro switches is their working

temperature range between - 25°C and + 85°C. In

addition, they support up to a million operations

(Produktinfo.conrad.com, 2018). Micro switches can

be used in different ways. Using all three existing

connections, the electrical switch can be wired as a

changeover contact. If only two connections of the

micro switch are used, it acts as a NO (normally

open) or NC (normally closed) (Wikipedia.org A2,

2018) device. In the electronic cargo strap system,

the micro switch is used as a normally open switch.

Because the micro switches behave like security

contacts, and load security requires a certain

minimum force on the lashing belts, they are well

suited for monitoring load securing when their

trigger point is set to this minimum force. This point

can be adjusted on a pull-off force machine. For this

reason, two such prototypes are created.

4 WIRELESS TECHNOLOGY

The 433 MHz wireless technology was chosen as

radio technology for the system. WLAN (wireless

local area network) wireless technology was used

successfully in a previously created prototype

(Kuzmic A2, 2017) with ESP8266 microcontrollers

(not discussed in this paper). Based on this, it was

known that a WLAN connection is indeed stable and

secure due to WPA2 encryption, but it requires a lot

of energy. Therefore, WLAN wireless technology

with the ESP8266 can not be used when operating

with batteries as in this paper. Another alternative

investigated was Bluetooth wireless technology.

Previous projects revealed that this technology has

range problems using less transmission power

(powering with batteries), but this was not explicitly

tested in this project. Therefore, it can not be used in

the development of the electronic cargo strap

system. In the two previously presented wireless

technologies, a permanent connection between

transmitter and receiver is established. Thus, the

transmission process lasts longer and uses a lot of

energy. In 433 MHz wireless technology, however,

no connection between the transmitter and the

receiver is established. Messages are sent without

knowing whether they have actually arrived at the

receiver, like User Datagram Protocol (UDP).

Therefore, 433 MHz radio technology requires much

less energy and can achieve long range in optimal

conditions. For this reason, this wireless technology

was used in our system.

4.1 Encryption of Transmitted Data

To ensure that messages are not transmitted in plain

text over the 433 MHz radio link, the transmission

data is encrypted with an enhanced Caesar

encryption. This should show in principle the

possibility of cryptography. Of course, in the next

step the primitive Caesar algorithm needs to be

replaced with a state of the art encryption like the

Rabbit stream cipher, which requires only a rather

small extra amount of code.

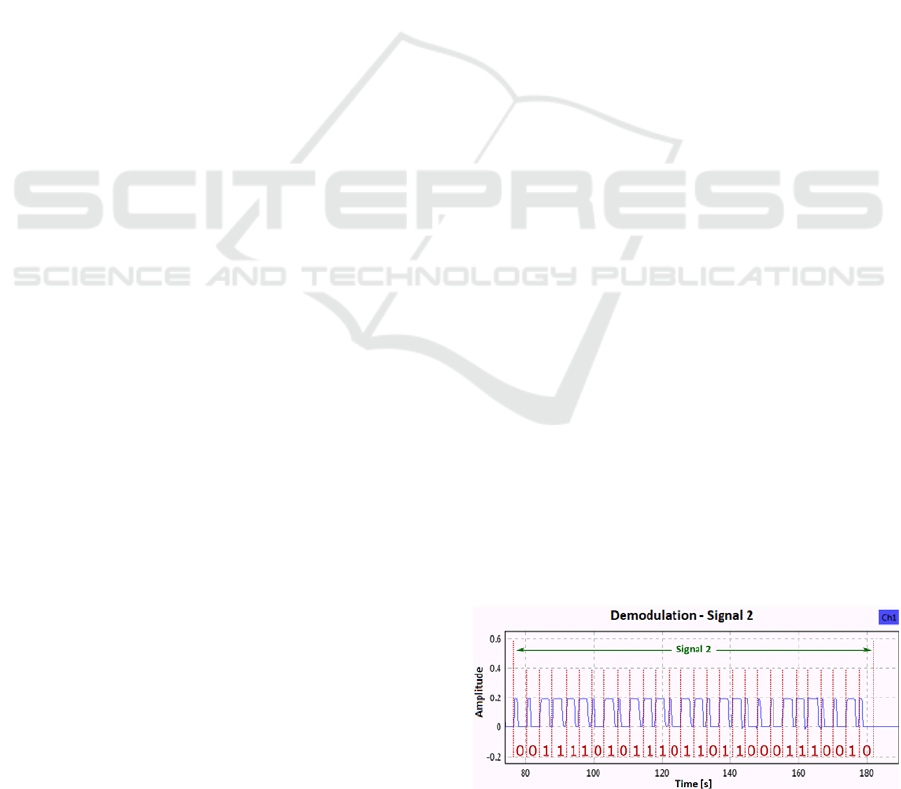

4.2 Analysis of 433 MHz Radio Link

To understand what really happens on the 433 MHz

radio link between transmitter and receiver, the 433

MHz radio link was analysed (Instructables.com A2,

2018; Rtl-sdr.com, 2013) using software-defined

radio (SDR) technology. This analysis uses digital

signal processing. Coding of the bits in a 433 MHz

connection is as follows: 0 = 100 and 1 = 110

(Pérez, 2013). The 433 MHz transmitter and the 433

MHz receiver modules (FS1000A and XD-RF-5V)

for Arduino use amplitude-shift on-off keying

(ASK-OOK) (Mietke, 2018). This is a form of

amplitude modulation (AM) (Wikipedia.org A3,

2018). To check what the binary code on the radio

link looks like, a test message is sent. The bit

sequence of this message looks like this:

"1111010111011011000111001".

After demodulating the signal, the same bit

pattern can be successfully detected from the air.

The next figure (Fig. 6) shows this demodulation

(Rascagnères, 2015).

Figure 6: Diagram of bit sequence from signal two.

IoT based Driver Information System for Monitoring the Load Securing

265

During testing the transmission range of the

systems, the messages of all ten test systems could

be received at a distance of ten metres from the

transmitter to the receiver. This test was carried out

without any obstacles between transmitter and

receiver. To increase the transmission distance,

professional antennas could be installed. If this does

not solve this problem, 433 MHz repeaters can be

installed on the truck semi-trailer.

5 POWER SUPPLY

According to a market analysis, the Arduino Pro

Mini microcontrollers are known to consume very

little power and are often used as microcontrollers

for powering with batteries (Wikipedia.org A4,

2018). Due to the fact that these microcontrollers

consume very little energy in sleep mode (Deep

Sleep) compared to other microcontrollers, they can

be operated for years without changing batteries

(Home-automation-community, 2018). For this

reason, these microcontrollers were chosen for the

electronic cargo strap system. Of course, the final

power consumption is also affected by the connected

sensors and actuators. Furthermore, Arduino Pro

Mini microcontrollers do not require an external

low-dropout (LDO) regulator. This is already

installed on the standard demo board

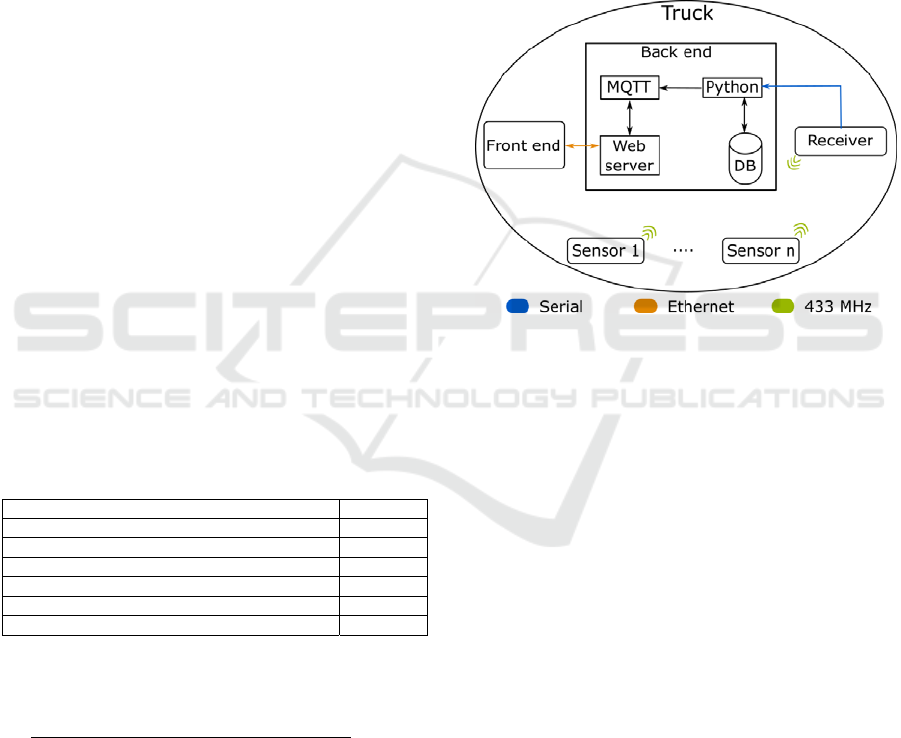

(Cdn.sparkfun.com, 2018). The following table

(Tab. 1) illustrates the key data for an example

calculation of continuous operation.

Table 1: Key data for battery life.

Battery

t

ype NiMH

Capacity of a battery (mAh) 2500

Power consumption in sleep mode (mA) 0,03293

Power consumption in normal mode (mA) 21,08

Interval duration (s) 600

Duration in sleep mode (s) 598

Duration in normal mode (s) 2

The following shows an example of the

theoretical calculation of the battery life:

2500 ∗ 600

21.08 ∗ 2 0.03293 ∗ 598

24261.4

33.2

(1)

Every ten-minute interval (600 seconds), the

microcontroller switches from sleep mode to normal

mode. In normal mode two seconds are needed for

reading the sensor and transmitting the sensor’s

value via the 433 MHz interface. During the

remaining 598 seconds of a 600 second interval the

microcontroller is in sleep mode (Deep Sleep). This

calculation (Eq. 1) refers to the CNY70 sensors

currently installed in the electronic cargo strap

system. This also shows that theoretical battery life

is approx. 3 years in continuous operation.

6 SOFTWARE ARCHITECTURE

Software architecture (Fig. 7) describes the

interaction of the sensors with the presentation layer

(front end) and the data access layer (back end).

Figure 7: Software architecture of the monitoring system.

The electronic cargo strap systems transmits the

measured data over a 433 MHz radio link. Data are

received by a 433 MHz receiver connected to the

data access layer (back end). Next, the received data

are streamed to a Python script in the back end.

Received data are evaluated in this Python script and

stored in the database. Furthermore, the analysed

data and alarm messages are passed from the Python

script to the MQTT broker and thus to the

presentation layer (front end). In the next step,

incoming data are displayed in an Android

application via the web server.

Communication between back end and front end

is realized via a REST interface, working via

Ethernet over USB (Universal Serial Bus), because a

cable connection is more stable and less susceptible

to interference. Of course, this connection can also

be a wireless connection.

6.1 433 MHz Receiver

The microcontroller for the 433 MHz receiver (XD-

RF-5V) uses the demo board NodeMCU ESP8266.

This board contains all components necessary for

Plug and Play (PnP). The internal serial adapter

IoTBDS 2019 - 4th International Conference on Internet of Things, Big Data and Security

266

provides access to the back end via USB.

6.2 Back End

The back end of the software includes the

components Apache HTTP server, MariaDB

relational database, Mosquitto MQTT broker and a

Python script. These run on a Raspberry Pi 3 with a

solid-state drive (SSD) (Raspberry.tips, 2017). After

the back end system is started, the Python script is

executed as a service (Wiki.ubuntuusers.de, 2018).

This service connects to the MQTT broker and in the

next step checks using an endless loop whether data

have arrived from the 433 MHz receiver via the

serial interface.

Once data are available, they will be reviewed

first. After review and evaluation of the message,

metrics and alerts are forwarded to the front end. If

errors occur in the function, in the receiver or in the

transmitter, these are sent to the surface additionally.

Moreover, each measured value, alarm message and

error message is stored permanently in the database

for possible further evaluations.

6.3 Front End

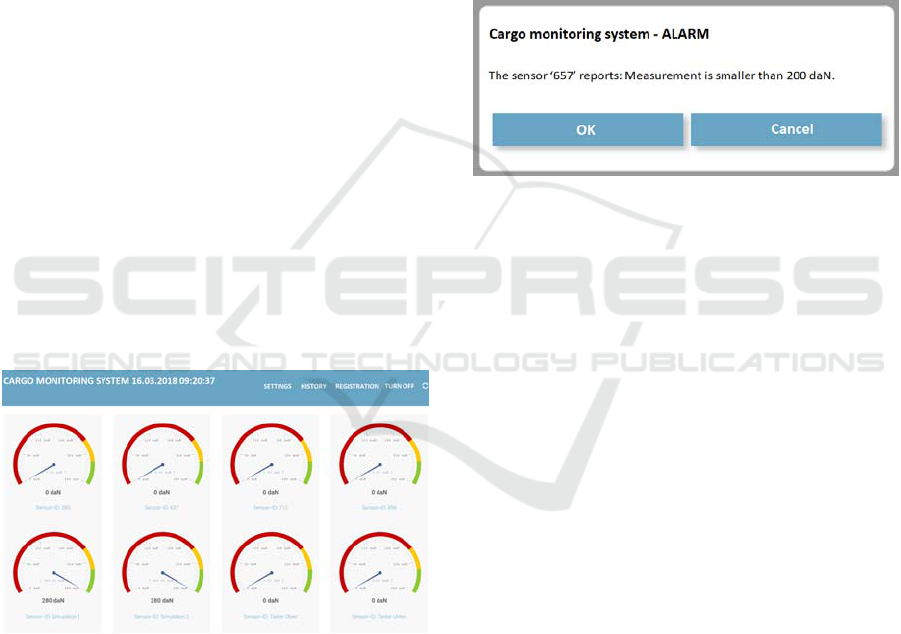

The user interface of the front end consists of an

Android application that displays the data in a

WebView (Fig. 8). The data for the display are

provided by the HTTP web server.

Figure 8: User interface of the monitoring system with

eight monitored sensors (translation from German).

As soon as measured values of the electronic

cargo system arrive on the monitoring page, a new

JavaScript gauge for this system is created and

displayed. If the JavaScript gauge exists already for

a particular sensor, the measured values of this

sensor are updated and displayed as daN. If an error

message is forwarded from the back end to the front

end, it will appear on the monitoring page

immediately. As soon as measured values of a

lashing belt fall below the minimum allowable force

predefined in the settings, an alarm message appears

on the monitoring page (Fig. 9) including the

system’s sensor identification number. If a name

was manually set when registering the electronic

cargo strap system, this name will be displayed on

the monitoring page instead of the sensor

identification number.

In addition to the visual notification, the user is

warned by an audible warning signal from the

Android device. If this alarm is ignored or not

confirmed, the notification will be displayed again

when the next measured value of the system is

received.

Figure 9: Alarm message on the monitoring page

(translation from German).

7 PRACTICAL TESTS

For practical tests of the developed systems, four

real-world deployments were carried out.

7.1 Lashing Belt Elongation Test

For this test a metal box weighing about 600

kilograms and filled with scrap metal, was fastened

on a car trailer using the developed electronic cargo

strap system. Because the metal box can not be

compressed by the lashing strap, it was possible to

measure the elongation of the lashing strap

successfully while driving. After about 1.3

kilometres, the lashing strap had completely

extended and had to be retightened. It had also been

proven that driving in curves and acceleration has an

effect on the measured force on the lashing belt.

7.2 Crucial Test

To detect whether the developed electronic cargo

strap system notifies users even when the lashing

belt tear (Lasiportal.de, 2018), a successful

emergency test was performed (Fig. 10).

IoT based Driver Information System for Monitoring the Load Securing

267

Figure 10: Alarm message during the crucial test. Left:

Intact lashing belt. Right: Torn lashing belt.

7.3 Pressure Test

Another possible scenario (Fig. 11) for load securing

is the transport and attachment of pallets with soft

material. Because in these cases the load seems to be

secured at first glance, but over the time of driving,

the soft material may compress and the cargo will no

longer be secured.

Figure 11: Alarm message during the pressure test. Left:

Closed cap of the canister. Right: Opened cap of the

canister.

7.4 Transmission Test

A final and important practical test for the electronic

cargo strap systems was the transmission test. In this

test, it was observed that vehicle speed have a

negative effect on the transmission of the sensor

data. The use of more professional antennas would

significantly improve the result in our opinion.

8 CONCLUSIONS

Overall, the driver information system for

monitoring the load securing worked well. The

CNY70 reflective optical sensors were used

successfully. However, it was noticed that they are

very sensitive to the colour and the material of a

reflective surface. It was also noticed that ambient

light and slight impact affect the measurement.

In order to achieve a greater range for the

transmission of the measured data, more

professional antennas are recommended. These

should point to different directions. The antennas

could look like a wireless router, which usually

contain three antennas for sending and receiving

from different directions. An alternative would be to

install 433 MHz repeaters on the truck semi-trailer.

Another option for wireless data transmission could

be Zigbee (Wikipedia.org A5, 2018). This data

transfer technology can achieve long ranges and is

often used on various Internet of Things (IoT)

devices. For improved receipt in the cab of the truck,

the receiver antenna should be mounted outside the

cab. It should be noted that the maximum cable

length of USB connection is not exceeded. If

necessary, it makes more sense to extend the 1-Wire

connection (Maxim Integrated Products, 2008) to the

Arduino receiver module rather than the USB

connection (Wikipedia.org A6, 2018) from the

receiver to the back end system.

A second option for the sensor for the electronic

cargo system is a miniature snap-action switch. The

fact that this micro switch can be installed in a

simple mechanical device can quickly turn this

prototype into a product. In addition, the micro

switches do not respond to ambient light,

temperature and slight impact like other analysed

sensors. However, it is still a long way to a

successful product.

REFERENCES

Al-Mutlaq, S., 2018. Getting Started with Load Cells,

Sparkfun.com. [online]. Available at:

https://learn.sparkfun.com/tutorials/getting-started-

with-load-cells.

Bruhn, D., 2014. Electronic monitoring of load securing of

vehicles, Patents.google.com. [online]. Available at:

https://patents.google.com/patent/DE102014012508A

1/en?oq=DE102014012508A.

Cdn.sparkfun.com, 2018. Arduino Pro Mini 8MHz/3.3V,

Sparkfun.com. [online]. Available at:

https://cdn.sparkfun.com/datasheets/Dev/Arduino/Boa

rds/ProMini8MHzv1.pdf.

Dolezych, 2018. DoMess 2 Vorspannkraftmessgerät,

Dolezych.de. [online]. Available at:

https://dolezych.de/domess-2-vorspannkraftmessgerat-

dolezych.

Forum.arduino.cc, 2018. HX711 – Bild, Arduino.cc.

[online]. Available at: https://forum.arduino.cc/

index.php?action=dlattach;topic=486101.0;attach=216

741

IoTBDS 2019 - 4th International Conference on Internet of Things, Big Data and Security

268

Github.com, 2016. VL6180X library for Arduino,

Github.com. [online]. Available at:

https://github.com/pololu/vl6180x-arduino.

Home-automation-community, 2018. Arduino Low Power

- How To Run ATmega328P For a Year On Coin Cell

Battery, Home-Automation-community.com. [online].

Available at: http://www.home-automation-

community.com/arduino-low-power-how-to-run-

atmega328p-for-a-year-on-coin-cell-battery/.

Instructables.com A1, 2018. Arduino Bathroom Scale

With 50 Kg Load Cells and HX711 Amplifier,

Instructables.com. [online]. Available at:

http://www.instructables.com/id/Arduino-Bathroom-

Scale-With-50-Kg-Load-Cells-and-H/.

Instructables.com A2, 2018. RTL-SDR FM Radio Receiver

With GNU Radio Companion, Instructables.com.

[online]. Available at: http://www.instructables.com/

id/RTL-SDR-FM-radio-receiver-with-GNU-Radio-

Companion/.

Kuzmic A1, J., 2018. Driver information system for

monitoring the load securing (German:

Fahrerinformationssystem zur Überwachung der

Ladungssicherung), Master’s thesis, South Westphalia

University of Applied Sciences.

Kuzmic A2, J., 2017. Prototyping of a microcontroller-

based wireless sensor system for central monitoring

the force in lashing straps (German: Entwicklung des

Prototypen eines Mikrocontroller basierenden Funk-

Sensorsystems zur zentralen Überwachung der

Vorspannkraft von Zurrgurten), Master’s project,

South Westphalia University of Applied Sciences.

Lasiportal.de, 2018. Ladung durch einen (zerrissenen)

Zurrgurt gesichert, Lasiportal.de. [online]. Available

at: https://www.lasiportal.de/seminare-und-

schulungen/bilder/mangelhafte-

ladungssicherung/brisante-ladung-durch-einen-

zerrissenen-zurrgurt-gesichert/

Maxim Integrated Products, 2008. Guidelines for Reliable

Long Line 1-Wire Networks, Maximintegrated.com.

[online]. Available at:

https://www.maximintegrated.com/en/app-

notes/index.mvp/id/148

Mietke, D., 2018. Amplitudenumtastung – ASK,

Elektroniktutor.de. [online]. Available at:

https://elektroniktutor.de/signalkunde/ask.html

Mischnick, S., Mischnick, J., 2007. 1.2.12 Der

Reflexkoppler CNY 70, Strippenstrolch.de. [online].

Available at: http://www.strippenstrolch.de/1-2-12-

der-reflexkoppler-cny70.html

Pérez, X., 2013. Decoding 433MHz RF data from wireless

switches. The data, Tinkerman.cat. [online]. Available

at: https://tinkerman.cat/decoding-433mhz-rf-data-

from-wireless-switches-the-data/

Pololu, 2018. VL6180X Time-of-Flight Distance Sensor

Carrier with Voltage Regulator, 60cm max,

Pololu.com. [online]. Available at:

https://www.pololu.com/product/2489

Produktinfo.conrad.com, 2018. DG sub-subminiature

switch, Conrad.com. [online]. Available at:

http://www.produktinfo.conrad.com/datenblaetter/700

000-724999/705504-da-01-en-SUBSUBMINIATUR_

DG23_B1LA_0_05A_30V.pdf.

Rascagnères, P., 2015. 433MHz ASK signal analysis,

Bytebucket.org. [online]. Available at:

https://bytebucket.org/rootbsd/433mhz-ask-signal-

analysis/raw/5f4937e4efb2198abcc375b8aefee414219

41fca/pdf/433MHz_ASK_sginal_analysis-Wireless_

door_bell_adventure-1.0.pdf.

Raspberry.tips, 2017. Raspberry Pi von SSD Festplatte

booten, Raspberry.tips. [online]. Available at:

https://raspberry.tips/raspberrypi-tutorials/raspberry-

pi-von-ssd-festplatte-booten/.

Rohner, A., 2015. How to make the Watchdog timer work

on an Arduino Pro Mini by replacing the bootloader,

Andreasrohner.at. [online]. Available at:

https://andreasrohner.at/posts/Electronics/How-to-

make-the-Watchdog-Timer-work-on-an-Arduino-Pro-

Mini-by-replacing-the-bootloader/

Rtl-sdr.com, 2013. Tutorial: Creating an FM Receiver in

GNURADIO using an RTL-SDR source, Rtl-sdr.com.

[online]. Available at: https://www.rtl-

sdr.com/tutorial-creating-fm-receiver-gnuradio-rtl-sdr/

Rudolph, D., 2017. Resultierende Kraft / Kräfte zerlegen,

[online]. Available at: https://www.frustfrei-

lernen.de/mechanik/kraefte-zerlegen-resultierende-

kraft.html.

Wikipedia.org A1, 2018. Newton (Einheit), Wikipedia.org.

[online]. Available at: https://de.wikipedia.org/

wiki/Newton_(Einheit)

Wikipedia.org A2, 2018. Mikroschalter, Wikipedia.org

URL: https://de.wikipedia.org/wiki/Mikroschalter

Wikipedia.org A3, 2018. Amplitudenumtastung,

Wikipedia.org. [online]. Available at:

https://de.wikipedia.org/wiki/Amplitudenumtastung

Wikipedia.org A4, 2018. Mignon (Batterie),

Wikipedia.org. [online]. Available at:

https://de.wikipedia.org/wiki/Mignon_(Batterie)

Wikipedia.org A5, 2018. Zigbee, Wikipedia.org. [online].

Available at: https://en.wikipedia.org/wiki/Zigbee

Wikipedia.org A6, 2018. Universal Serial Bus,

Wikipedia.org. [online]. Available at:

https://de.wikipedia.org/wiki/Universal_Serial_Bus

Wiki.ubuntuusers.de, 2018. Service Units,

Ubuntuusers.de. [online]. Available at:

https://wiki.ubuntuusers.de/systemd/Service_Units/

Youtube.com, 2016. Load Cell, Youtube.com. [online].

Available at: https://www.youtube.com/watch?v=

0Lwdzpr_TxM

IoT based Driver Information System for Monitoring the Load Securing

269