Using Enterprise Modeling in Development of New Business Models

Ilia Bider

1

and Azeem Lodhi

2

1

Department of Computer and Systems Sciences, Stockholm University, Stockholm, Sweden

2

Faculty of Computer Science, Otto von Guericke University, Magdeburg, Germany

Keywords: Business Model, Enterprise Model, Business Process Architecture, Business Model Innovation.

Abstract: In the dynamic world of today, enterprises need to be innovative not only in their current line of products and

services, but also in their business models. One of the challenges in Business Model Innovation (BMI) is to

introduce radical changes in the current business model when entering new markets. Ideas for new models

can come from various sources, however each such idea needs to be analysed from the sustainability and

implementation perspectives. This paper evaluates whether enterprise modelling can help in analysis of

hypotheses for radical changes of BMI. The evaluation is carried on a particular practice of an organization.

Analysis of a new idea has been done using a so-called Fractal Enterprise Model (FEM). FEM ties various

enterprise business processes together and connects them to enterprise assets (resources) that are used and/or

are managed by the processes. FEM has been used to understand which new assets and processes should be

acquired, and which existing ones can be reused when planning the implementation of a new business model.

1 INTRODUCTION

In the dynamic world of today, enterprises need to be

innovative. The innovative power, however, cannot

be focused only on the current lines of products and

services. From time to time, companies need to revise

who they are and what they do, which means innovate

their Business Models (BM). This is needed in order

to survive in the turbulent, technology driven

business environment. For example, in the future, a

traditional manufacturing company that both designs

and manufactures their products may decide that they

would better concentrate only on one aspect of their

current business. The company then can become a

manufacturer who produces goods based on

somebody else's design, or a designer – designing

goods to be manufactured by somebody else. This

was the case in different companies where they

changed their business model like LEGO (Robertson

and Hjuler, 2009), TSMC (Su and Huang, 2006).

In light of the above, it is not a surprise that the

topics of Business Model Generation and Business

Model Innovation (BMI) have got attention from both

practitioners and researchers. On the practical side, it

is expressed by widespread usage of business model

canvas (Osterwalder and Pigneur, 2014), and its

numerous variations for communication and

brainstorming purposes. The interest on the research

side expresses itself in numerous research

publications devoted to BMI, including books

(Andreini and Bettinelli, 2017) and special issues of

journals (Mangematin et al., 2017).

Roughly, the BMI process can be divided into two

phases (Bider and Perjons, 2017): (I) generating

hypotheses – new ideas on how the new BM could

look like, and (II) assessing the hypotheses. The latter

includes defining what existing resources/capabilities

can be used in a new BMI, at what extent, and what

needs to be acquired in addition to the existing

resources. In this paper, we concentrate on the second

phase – analysis, considering that the main idea of a

new BM already exists.

Regarding the essence of BMI, we use the

classification suggested in (Giesen et al., 2007) that

differentiates three ways of innovating a BM:

1. Industry model innovation - which amounts to

changing the position in the value chain, entering

new markets, and/or other types of radical

changes.

2. Revenue model innovation - which results in

changes in how a company generates revenues,

e.g. reconfiguring offerings and/or introducing

new pricing models.

3. Enterprise model innovation – which involves

innovating the structure of an enterprise, such as

Bider, I. and Lodhi, A.

Using Enterprise Modeling in Development of New Business Models.

DOI: 10.5220/0007769205250533

In Proceedings of the 21st International Conference on Enterprise Information Systems (ICEIS 2019), pages 525-533

ISBN: 978-989-758-372-8

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

525

enterprise goals, business processes, products

and/or services.

In this paper, we focus exclusively on the first

type of BMI, i.e. industry model innovation. In

addition, we are interested only in such an innovation

that relies on the capabilities already existing in the

organization. An example of such BMI is the case of

Amazon Web Services where existing infrastructure

was used to provide services to other organizations;

this case was reconstructed in (Bider and Perjons,

2017). In comparison, we do not focus on industrial

BMI cases where a new model concerns a completely

new business activity, i.e. an activity not connected,

whatsoever, with the current ones.

The objective of this paper is to investigate

whether an enterprise model can be used for analysis

of BMI hypotheses. Here, we try only one enterprise

modelling type – Fractal Enterprise Model (FEM)

from (Bider et al., 2017), and follow the ideas drafted

in a general way in (Bider and Perjons, 2017). The

choice of modelling technique is personal, as the first

co-author of this work is part of the team engaged in

FEM development.

The question will be answered based on applying

FEM for analysis of a particular hypothesis generated

in an organization. The organization in question is a

real company to which the second co-author has been

attached for some time.

The hypothesis that we analyse can be formulated

as "becoming a provider of services that can predict

the needs for maintenance of specific machines used

in manufacturing lines". The idea itself is not

completely new in nature as it was used by Rolls

Royce in TotalCare (Rolls Royce, 2017) where

customer responsibilities were taken at supplier end.

However, the idea in our case is new in the sense that

it may not belong to the core operations of an

organization. The idea itself was created

independently of current work and FEM. We applied

FEM only to understand which existing assets and

processes of the organization could be used in a new

BM, which new assets and processes need to be

added, and what challenges exist on the way of

practically implementing the new BM.

The rest of the paper is structure in the following

way. In section 2, we give an overview of FEM so

that the reader does not need to go elsewhere to obtain

this knowledge. In Section 3, we present the business

case as it is, including parts that will be used for BMI

in the next section. This section presents also a FEM

for the important for our consideration part of the

business. In Section 4, we present the main idea of

BMI and build a FEM for a business-to-be. Then, we

analyse the difference between the two FEMs, the

current and the new one and discuss what could be

used from the existing capabilities and what needs to

be created from scratch. In section 5, we summarize

our findings and discuss the difference of our

approach to new BMs analysis from using the

standard BM canvas, and draw plans for the future.

2 OVERVIEW OF FEM

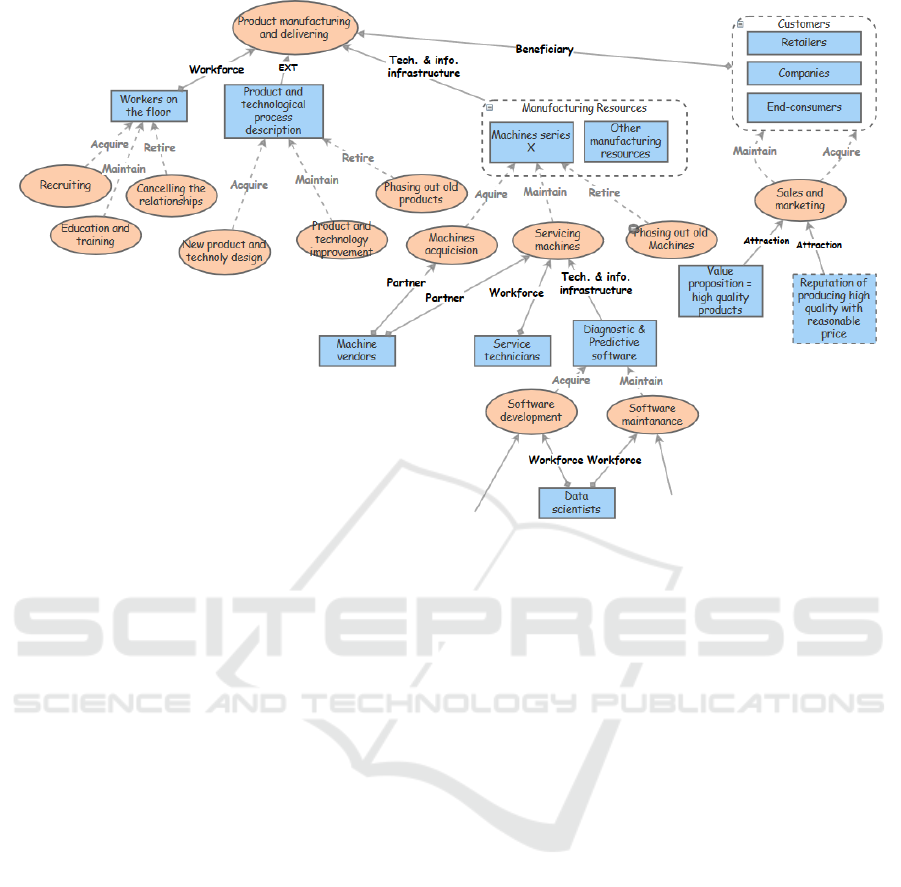

The Fractal Enterprise Model (FEM) includes three

types of elements: business processes, assets, and

relationships between them, see Fig. 1 in which a

fragment of a model is presented. The fragment is

related to a business case considered in the next

sections. Graphically, a process is represented by an

oval; an asset is represented by a rectangle (box),

while a relationship between a process and an asset is

represented by an arrow. FEM differentiates two

types of relationships. One type represents a

relationship of a process “using” an asset; in this case,

the arrow points from the asset to the process and has

a solid line. The other type represents a relationship

of a process changing the asset; in this case, the arrow

points from the process to the asset and has a dashed

line. These two types of relationships allow tying up

processes and assets in a directed graph.

In FEM, a label inside an oval names the given

process, and a label inside a rectangle names the

given asset. Arrows are also labelled to show the

types of relationships between the processes and

assets. A label on an arrow pointing from an asset to

a process identifies the role the given asset plays in

the process, for example, Workforce, Infrastructure,

etc. A label on an arrow pointing from a process to an

asset identifies the way in which the process affects

(i.e. changes) the asset. In FEM, an asset is considered

as a pool of entities capable of playing a given role(s)

in a given process(es). Labels leading into assets from

supporting processes reflect the way the pool is

affected, for example, a label acquire identifies that

the process can/should increase the size of the pool.

Note that the same asset can be used in two

different processes playing the same or different roles

in them, which is reflected by labels on the

corresponding arrows. It is also possible that the same

asset can be used for more than one role in the same

process; in this case, there can be more than one arrow

between the asset and the process, however, with

different labels. Similarly, the same process could

affect different assets, each in the same or in different

ways, which is represented by the corresponding

labels on the arrows. Moreover, it is possible that the

same process affects the same asset in different ways,

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

526

Figure 1: A fragment of FEM.

which is represented by having two or more arrows

from the process to the asset, each with its own label.

In FEM, different styles can be used for shapes to

group together different kinds of processes, assets,

and/or relationships between them. Such styles can

include using dashed or double lines, or lines of

different thickness, or coloured lines and/or shapes.

For example, a diamond start of an arrow from an

asset to a process means that the asset is a stakeholder

of the process (see the arrows Workforce in Fig. 1).

Labels inside ovals, which represent processes,

and rectangles, which represent assets, are not

standardized. They can be set according to the

terminology accepted in the given domain, or be

specific for a given organization. Labels on arrows,

which represent the relationships between processes

and assets, however, can be standardized. This is done

by using a relatively abstract set of relationships, like,

workforce, acquire, etc., which are clarified by the

domain- and context-specific labels inside ovals and

rectangles. Standardization improves the

understandability of the models.

While there are a number of types of relationships

that show how an asset is used in a process (see

example in Fig. 1), there are only three types of

relationships that show how an asset is managed by a

process – Acquire, Maintain and Retire.

To make the work of building a fractal model

more systematic, FEM uses archetypes (or patterns)

for fragments from which a particular model can be

built. An archetype is a template defined as a

fragment of a model where labels inside ovals

(processes) and rectangles (assets) are omitted, but

arrows are labelled. Instantiating an archetype means

putting the fragment inside the model and labelling

ovals and rectangles; it is also possible to add

elements absent in the archetype, or omit some

elements that are present in the archetype.

FEM has two types of archetypes, process-assets

archetypes and an asset-processes archetype. A

process-assets archetype represents which kind of

assets that can be used in a given category of

processes. The asset-processes archetype shows

which kinds of processes are aimed at changing the

given category of assets.

3 BUSINESS CASE

3.1 Overview of the Current State

The case considered in this paper concerns a company

that manufactures different lines of products. These

products can be bought by companies, retailers or

end-consumers for their usage. The company uses

different machines for producing the products. In this

paper, we focus on a particular machine that will be

referred to as Machine X.

Using Enterprise Modeling in Development of New Business Models

527

Fig. 1 presents a fragment of a fractal enterprise

model of the current business activity. In the root of

this model is a primary process of manufacturing and

delivering products. Underneath of it, there are

various assets that are needed for the process working

smart-free. Under smart-free, we mean that instances

of this process (production batches) are started with

normal frequency. As shown in FEM in Fig.1, the

process requires variety of assets such as workers on

the flour (Workforce), manufacturing equipment

(Technical and informational infrastructure) and

customers (Beneficiary). Note that the FEM fragment

in Fig.1 does not show all assets that are needed to

run the primary process, for example, a stock of

orders for producing product batches is not presented.

The choice of what to present in Fig. 1 has been made

based on the most important assets and assets that are

of interest for BMI to be considered in the paper.

After the assets of the first level (underneath the

primary process) are put in the model, the unfolding

of FEM continues by applying the asset-processes

archetype, which requires finding processes that

manage the identified assets. These processes are

connected with the asset(s) by three types of

relationships: Acquire, Maintain and Retire.

Dependent on the type of assets, the asset managing

processes have different nature. For a workforce type

of assets, they are hiring, training and retiring. For the

infrastructure type of assets, they are acquisition,

maintenance, and phasing out. For the execution

template (EXT) type of assets, they are

develop/design, maintain and phase out.

After the management processes are identified,

assets that are needed to run them are identified using

process-assets archetypes. For example, the customer

asset needs sales and marketing for both acquiring

new customers and keeping them attached to the

company, so that they continue to add orders to the

stock of orders. The equipment asset, e.g. machines

X, needs a service/maintenance process (see Fig. 1).

The process of unfolding of FEM can continue by

applying the asset-processes archetype for newly

identified assets. Thus, marketing and sales requires

well-defined value proposition and reputation that

backs it (see Fig. 1), as well as other assets (not

identified in the figure), like sales executives.

Machine X maintenance requires service technicians,

machine process experts, machine providers (partners

to provide spare parts, advice, etc.) and diagnostic

tools. As machine diagnostic and prediction is in the

focus of this work, we will look at this topic in more

details in the next sub-section.

3.2 Machine Maintenance

In a manufacturing organization, production

equipment - machines are very important resources

for production. Different Key Performance Indicators

(KPIs) related to manufacturing resources are used to

ensure the optimal usage of the machines, such as

OEE (Overall Equipment Efficiency) defined in ISO

standard (ISO, 2014a; ISO, 2014b). A stoppage in

production line due to machine failure costs a lot of

money for an organization.

In the context of Industry 4.0, maintenance is an

important area that has an enormous potential in

terms of cost saving and resource efficiency. There

are many use cases that come under the category

"maintenance 4.0", like automatic maintenance order

generation, notifications to stakeholders (users, other

machines and mobile devices), predictive

maintenance, flexible manufacturing, and support

services (augmented reality).

Normally, in an organization, maintenance is

counted as an overhead (however, a mandatory one)

on the production. In order to avoid unpredictable

costs, machines are serviced in regular intervals

(sometimes according to manufacturer

specifications). However, despite all regular services,

sometimes unplanned maintenance also has to be

carried out due to failure in machines or loss of

quality in operations carried out by the machines. If a

particular machine or its part is situated in a critical

position in the line, it has a drastic impact on the

whole production, as well as on the quality of

products delivered to the customers; thus a failure in

such an equipment affects the overall KPIs.

In a manufacturing organization, machines are

used as long as they fit for the purpose, no matter how

old they become. Several kinds of maintenance are

carried out to keep the production lines running.

These are briefly described below.

1. Planned Maintenance. The planned maintenance

is carried out according to a specific plan like after

completion of certain number of operating hours

(e.g. 20,000 hours), or after certain cycles (e.g.

2,000,000 cycles). It is carried out regularly to

avoid the unplanned (failure-based) maintenance

in order to save costs. However, this planned

maintenance is carried out sometime earlier than

completion of the operating hours in order to

avoid an extra stoppage in production when the

production line is stopped for a different reason

(like new software updates). However, an earlier

planned maintenance affects negatively the costs

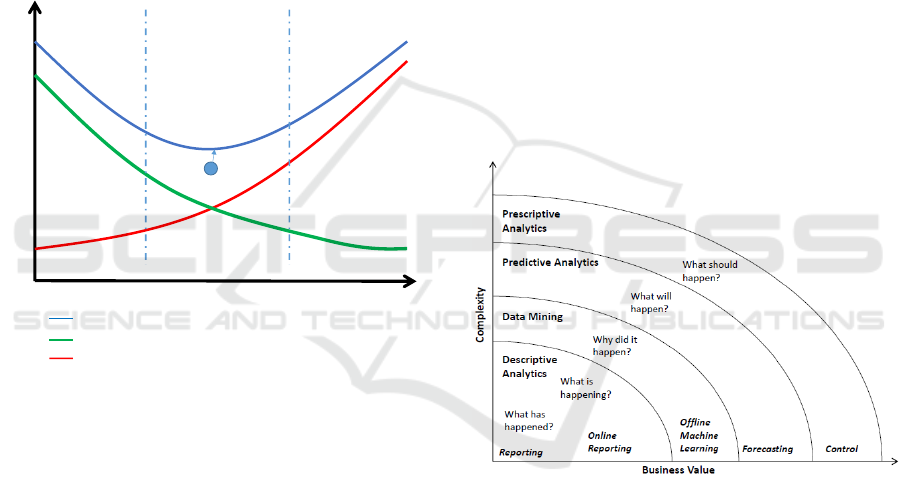

of production for an organization, as shown in Fig.

2.

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

528

2. Condition-based Maintenance. In this kind of

maintenance, certain machine parameters are

actively monitored to get information about the

health of the machine and to carry out the

appropriate actions (reducing speed, load etc.)

before situation gets out of control. This also

applies to creating maintenance orders if

necessary before a planned or unplanned

maintenance (in case of a failure or production

stoppage) occur.

3. Unplanned (problem-based) maintenance. In

unplanned maintenance, as the name suggests, the

maintenance is carried out when a problem

occurs. In this case, normally, a notification is sent

to the service team and a maintenance order is

created in case of failure.

Figure 2: The impact of maintenance on costs; adapted from

(Etia et al., 2006).

These three kinds of maintenance are common for

all manufacturers. In any kind of maintenance above,

in the first place, the internal service team is asked to

complete the required service. If they cannot carried

out the service, then the external resources are used.

The goal of any organization is to avoid unplanned

maintenances and run the production as continuously

as possible.

3.3 Improving Effectiveness of

Maintenance

As was discussed in the previous sub-section,

machine maintenance costs, direct and indirect, are

quite high. To reduce the cost of maintenance itself,

and revenue lost from unexpected breakdowns,

organizations look to applying the latest research

results in several brunches of Computer Science, e.g.

Internet of Things (IoT), data mining, machine

learning and Artificial Intelligence, which might

improve the maintenance process.

The goal of the project considered in this paper,

was to develop a tool able to detect in advance when

the machine is about to fail and take out appropriate

measures, like appropriate production and

maintenance planning. Several sub-goals were

defined to achieve the main goal in a stepwise

manner. The sub-goals included introducing

monitoring the machine status and its parameters, and

in case of deviation from the normal behaviour,

automatically sending notification to the service

technicians. Another sub-goal included analysis of

the historical data and identification of the patterns

that cause machine failure, and then using these

patterns as a basis for predictive maintenance. The

main idea of the project sub-goals is represented in

graphical form in Fig. 3, which is based on material

from (Davenport and Harris, 2007; Eckerson, 2007;

Lustig et al., 2010). The direction, the project takes is

to handle more complexity and get more business

value from the effort.

Figure 3: The goals of the project as a diagram.

3.4 Extending the Scope of Usage

The project described in the previous sub-section was

started in one plant of the organization having a

technical goal in mind, i.e. improving the

maintenance effectiveness at this plant. However,

when under the way, the project spawned the

discussion of extending the scope of the usage of its

results beyond the given plant and even beyond the

whole company. This is understandable considering

the costs of the project and the needs of establishing

a permanent team that would deal with maintaining

and further developing the software produced by the

project. The latter is represented in Fig. 1 by the sub-

tree starting from the asset node Diagnostic &

Frequency of Failures

Maintenance Costs

Total Cost (incl. production)

Prevention Cost (hours, parts)

Repair Cost

Planned

Maintenance

Condition-based

Maintenance

(Predictive)

Problem-based

Maintenance

(Reactive)

Optimal point

Using Enterprise Modeling in Development of New Business Models

529

Predictive software. This asset is used as Technical &

Informational infrastructure for the Servicing

machines process in Fig. 1.

As any other asset, Diagnostic & Predictive

software requires its managing processes, two of

which, Acquire and Maintain, are represented in Fig.

1. Continuing unfolding of the FEM structure for the

Diagnostic & Predictive software node, we will add

assets needed for these management processes, such

as Workforce represented in Fig.1. Furthermore, the

workforce asset, i.e. Data Scientists, needs its own

processes of hiring and training, etc.

As follows from the deliberation above, unfolding

node Diagnostic & Predictive software reveals quite

a complex structure that needs to be in place in order

to use the results of the project described in Section

3.3 in practice. This explains the desire to extend the

goal of the project from just improving the

effectiveness of the maintenance in one plant to

envisioning new BMs (Business Models) that could

generate additional revenues for the company. The

current discussion of extending the scope of usage

ranges from providing maintenance services to other

plants of the firm (remotely) to creating a separate

business of licencing the diagnostic software to

external companies. The latter example would be

exploited in the next section.

4 ANALYZING A NEW BM

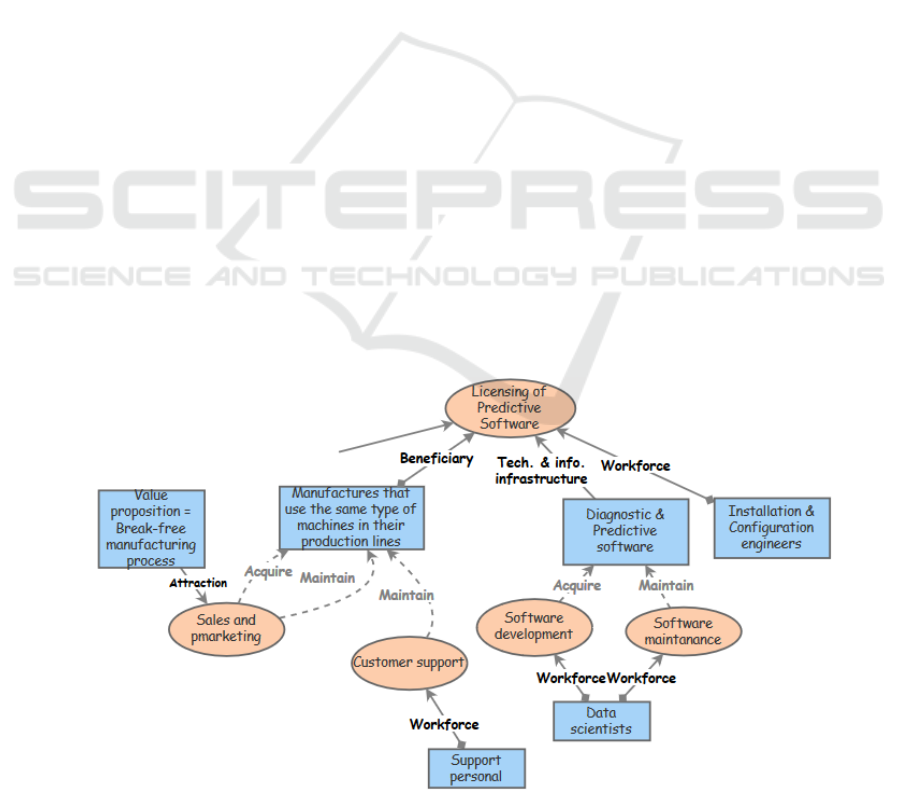

The most radical suggestion for a new business model

based on the project was to open a new business of

licensing diagnostic software to other manufacturers

that uses the same type of machines, including the

firm's competitors. To analyse the feasibility of

introducing this BM, we drafted basic FEM model

related to the new BM as presented in Fig. 4.

The primary process for the new BM becomes

Licensing of Predictive Software. It needs certain

assets to ensure that this process functions smart-free.

The central asset for this process is Diagnostic &

Predictive Software promoted from the old BM; in

Fig. 4, the whole tree related to this asset is moved

from FEM in Fig. 1. This asset serves as Technical &

information infrastructure for the main process.

Besides this asset, other assets are needed, in

particular Workforce (Installation & Configuration

Engineers) and Beneficiary (customers).

While comparing the beneficiary/customer assets

in Fig. 1 and Fig. 4, it becomes clear that these two

assets are completely different. In Fig. 1, the asset

customers has nothing to do with manufacturing, in

difference to Fig. 4. This difference becomes clearer

if we compare value propositions for both processes.

The difference means that a completely new set of

managing processes need to be added to manage the

new kind of customers. Two of such processes, Sales

and marketing and Customer support are presented in

Fig. 4. These processes and assets for them need to be

developed separately from Sales and marketing in the

current BM.

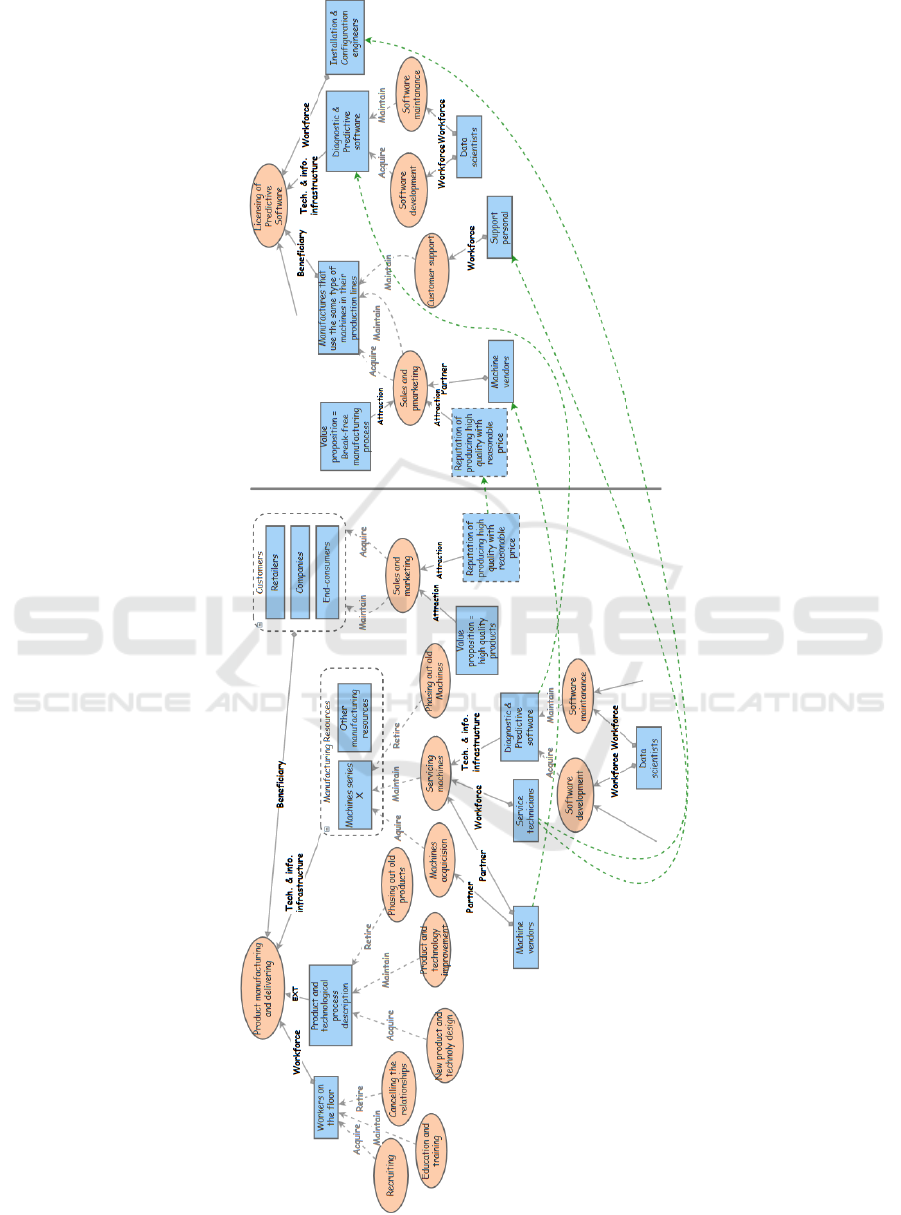

To analyse which other existing assets could be

used in the new BM, we put two FEM fragments from

Fig. 1 and Fig. 4 side by side, see Fig. 5, and continue

deliberation. To start with, we can decide that service

technicians can serve as installation and configuration

engineers on one hand and as customer support staff

Figure 4: A FEM fragment for the new BM.

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

530

Figure 5: Comparing two FEM fragments.

Using Enterprise Modeling in Development of New Business Models

531

on the other hand, which is shown by green arrow

lines drawn between these assets in Fig 5. The

experience of the service technicians in using the

software would enable them to function in another

capacity as well. However, this may help only in the

beginning, if the new BM starts producing more

customers, more Workforce will need to be hired.

The next step would be to use existing reputation

on high-level quality as an attraction in the new BM.

As many of the new customers will belong to the

company's competitors, this reputation can be

used in advertising by pointing out that the software

to be licensed is used internally in the organization.

This gives us a possibility to move asset Reputation

of producing high quality with reasonable price to the

new fragment of FEM in Fig. 5 and connect it with

the one in the old FEM fragment with a green arrow

line.

In the next step, we can consider using the

machine vendor as a partner for sales and marketing

activities, as the vendor has access to all companies

who use the machine. In Fig. 5, the machine vendor

is moved to the new FEM fragment and connected to

the one in the old FEM fragment with a green arrow

line.

The analysis above shows that some existing

assets could be used in a new BM, however,

introducing it still requires considerable efforts, e.g.

in creating different kind of sales and marketing, and

support, as well as increasing the size of some

existing assets. The latter will mean increasing the

capacity of the processes that manage these assets,

e.g. hiring and training new members of staff.

5 CONCLUSION

As follows from Section 1, the stated goal of this

paper was to investigate whether an enterprise model

could help in analysing new BM hypothesis. The

fractal enterprise model (Bider et al., 2017) was

chosen for testing; the test itself followed the

guidelines from (Bider and Perjons, 2017). The main

difference from discussion in (Bider and Perjons,

2017) and this work is that the former considered a

hypothetical scenario, while this work considers a

real business scenario. Another difference is that the

main asset chosen for building a new business

(Diagnostic software) is positioned on a much deeper

level of the FEM structure compared to the example

in (Bider et al., 2017).

The discussion in Section 4 demonstrates that

using FEM helps to detect which assets are needed for

introducing a new BM, and which ones could be

reused from the old BM. As the central asset of a new

BMI is positioned quite deep in the FEM structure,

using a standard BM canvas (Osterwalder and

Pigneur, 2014) would not be possible. Most of the

assets that could be reused in the new BM would be

outside the scope of the BM canvas, thus making it

difficult to use the canvas for deliberation.

Note that our example shows FEM advantages

only for the implementation phase of a new BM. It

does not help much in investigating whether a new

service or product will be accepted in the market

place. Other means need to be employed that can

include Business Model Canvas, SWOT, etc. This is

a limitation of FEM in relation to the BMI tasks.

The next step in this particular project would be to

deepen the analysis completed in Section 4, e.g. by

quantifying the parameters of introducing the new

model, e.g. calculating the size of assets and capacity

of processes to be introduced, at least in the

beginning. Another direction is to present the analysis

to the company management and get feedback. As far

as more general goal is concerned, we are working to

find other examples to test the idea of using enterprise

modelling in BMI.

In this, and previous examples of applying FEM

for practical tasks, we used InsightMaker (Give

Team, 2014) for drawing models. Though this tool is

not designed for FEM, it was sufficient for our cases.

For more broad use, however, a more suitable tool

should be found. Several alternatives are being

explored right now for solving this problem. One is

developing a specialized tool, for example, based on

the ADOxx meta-tool (ADOxx.org, 2017). This

alternative has an advantage in that it will allow

including special means for generating new BM

hypothesis from transformational patterns (Bider and

Perjons, 2018), and for their analysis. Another

alternative would be using some general

diagramming tool, like Archimate.

REFERENCES

ADOxx.org, 2017. ADOxx. [Online] Available at: https://

www.adoxx.org [Accessed March 2019].

Andreini, A. and Bettinelli, C., 2017. Business Model

Innovation. From Systematic Literature Review to

Future Research Directions. Springer.

Bider, I. and Perjons, E., 2017. Using a Fractal Enterprise

Model for Business Model Innovation. In BPMDS 2017

RADAR, CEUR Vol 1859., pp.20-29.

Bider, I., Perjons, E., Elias, M. and Johannesson, P., 2017.

A fractal enterprise model and its application for

business development. Software & Systems Modeling,

16(3), pp.663–89.

ICEIS 2019 - 21st International Conference on Enterprise Information Systems

532

Davenport, T.H. and Harris, J.G., 2007. Competing on

Analytics: The New Science of Winning. Harvard

Business School Press.

Eckerson, W., 2007. Predictive Analytics. Extending the

Value of Your Data Warehousing Investment. Technical

Report Q1. TDWI Best Practices.

Etia, M.C., Ogajib, S.O.T. and Probertb, S.D., 2006.

Reducing the cost of preventive maintenance (PM)

through adopting a proactive reliability-focused

culture. Applied Energy, 83(11), pp.1235-48.

Giesen, E., Berman, S.J., Bell, R. and Blitz, A., 2007. Three

ways to successfully innovate your business model.

Strategy & Leadership, Vol. 35 Issue: 6, pp., 35(6),

pp.27-33.

Give Team, 2014. Insightmaker. [Online] Available at:

http://insightmaker.com/ [Accessed 12 February 2019].

ISO, 2014a. ISO 22400-1:2014. Automation systems and

integration -- Key performance indicators (KPIs) for

manufacturing operations management -- Part 1:

Overview, concepts and terminology. Standard. ISO.

ISO, 2014b. ISO 22400-2:2014. Automation systems and

integration -- Key performance indicators (KPIs) for

manufacturing operations management -- Part 2:

Definitions and descriptions. Standard. ISO.

Lustig, I., Dietrich, B., Johnson, C. and Dziekan, C., 2010.

The Analytics Journey: An IBM View of the Structured

Data Analysis Landscape: Descriptive, Predictive and

Prescriptive Analytics. INFORMS Analytics Magazine,

(November-December), pp.11-18.

Mangematin, V., Ravarini, A.M. and Sharkey Scott, P.,

2017. Special Issue: Business Model Innovation.

Journal of Business Strategy, 38(2).

Osterwalder, A. and Pigneur, Y., 2014. Business Model

Generation: A Handbook for Visionaries, Game

Changers, and Challengers. Hoboken, NJ,US: Wiley.

Robertson, D. and Hjuler, P., 2009. Innovating a

Turnaround at LEGO. Harvard Business Review,

(September).

Rolls Royce, 2017. Power by Hour. [Online] Available at:

https://www.rolls-royce.com/media/our-stories/

discover/2017/totalcare.aspx [Accessed March 2019].

Su, Y. and Huang, S., 2006. Business Model Innovation

with Effective Innovation: An Exploratory Study on

TSMC. In 2006 IEEE International Symposium on

Semiconductor Manufacturing. Tokyo, pp. 483-486.

Using Enterprise Modeling in Development of New Business Models

533