Profile Extraction and Deep Autoencoder Feature Extraction for

Elevator Fault Detection

Krishna Mohan Mishra, Tomi R. Krogerus and Kalevi J. Huhtala

Unit of Automation Technology and Mechanical Engineering, Tampere University, Tampere, Finland

Keywords:

Elevator System, Deep Autoencoder, Fault Detection, Feature Extraction, Random Forest, Profile Extraction.

Abstract:

In this paper, we propose a new algorithm for data extraction from time series signal data, and furthermore

automatic calculation of highly informative deep features to be used in fault detection. In data extraction

elevator start and stop events are extracted from sensor data, and a generic deep autoencoder model is also

developed for automated feature extraction from the extracted profiles. After this, extracted deep features

are classified with random forest algorithm for fault detection. Sensor data are labelled as healthy and faulty

based on the maintenance actions recorded. The remaining healthy data are used for validation of the model

to prove its efficacy in terms of avoiding false positives. We have achieved 100% accuracy in fault detection

along with avoiding false positives based on new extracted deep features, which outperforms results using

existing features. Existing features are also classified with random forest to compare results. Our developed

algorithm provides better results due to the new deep features extracted from the dataset compared to existing

features. This research will help various predictive maintenance systems to detect false alarms, which will in

turn reduce unnecessary visits of service technicians to installation sites.

1 INTRODUCTION

In recent years, elevator systems have been used more

and more extensively in apartments, commercial fa-

cilities and office buildings. Nowadays 54% of the

world’s population lives in urban areas (Desa, 2014).

Therefore, elevator systems need proper maintenance

and safety. The next step for improving the safety of

elevator systems is the development of predictive and

pre-emptive maintenance strategies, which will also

reduce repair costs and increase the lifetime whilst

maximizing the uptime of the system. Elevator pro-

duction and service companies are now opting for a

predictive maintenance policy to provide better ser-

vice to customers. They are remotely monitoring

faults in elevators and estimating the remaining life-

time of the components responsible for faults. Eleva-

tor systems require fault detection and diagnosis for

healthy operation.

Fault diagnosis methods based on deep neural net-

works (Jia et al., 2016) and convolutional neural net-

works (Xia et al., 2018) feature extraction method-

ology are presented as state of the art for rotatory

machines similar to elevator systems. Support vec-

tor machines (Mart

´

ınez-Rego et al., 2011) and ex-

treme learning machines (Yang and Zhang, 2016) are

also used as fault detection methods for rotatory ma-

chines. However, we have developed an intelligent

deep autoencoder random forest based feature extrac-

tion methodology for fault detection in elevator sys-

tems to improve the performance of traditional fault

diagnosis methods.

Acceleration profile extraction for health moni-

toring is a major issue in automated industrial ap-

plications like elevator system, computer numerical

control, machinery and robotics. Although rotating

machine have been running for decades, but accel-

eration profile extraction and processing methods are

not widely available. Acceleration profile extraction

methods have applied in electric vehicles (Bingham

et al., 2012), computer numerical control systems

(Nam and Yang, 2004) and horizontal planes (Soyka

et al., 2011). Kalman filter (Wang et al., 2015) is one

of the methods being used for acceleration profile ex-

traction. However, we have developed an off-line pro-

file extraction algorithm based on low-pass filtering

and peak detection to extract elevator start and stop

events from sensor data.

In the last decade, neural networks (Calimeri

et al., ) have extracted highly meaningful statisti-

cal patterns from large-scale and high-dimensional

datasets. Neural networks has also been used to im-

Mishra, K., Krogerus, T. and Huhtala, K.

Profile Extraction and Deep Autoencoder Feature Extraction for Elevator Fault Detection.

DOI: 10.5220/0007802003130320

In Proceedings of the 16th International Joint Conference on e-Business and Telecommunications (ICETE 2019), pages 313-320

ISBN: 978-989-758-378-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

313

prove elevator ride comfort via speed profile design.

Neural networks (Lee, 2014) has been applied suc-

cessfully to nonlinear time series modeling. A deep

learning network can self-learn the relevant features

from multiple signals. Deep learning algorithms are

frequently used in areas such as signal processing

(Rivas-Perez et al., 2011), biotechnology (Sahba and

Venetsanopoulos, 2010), speech recognition (Maha

et al., 2010) and image classification (Hbali et al.,

2013). Autoencoding is a process for nonlinear di-

mension reduction with natural transformation archi-

tecture using feedforward neural network (H

¨

anninen

and K

¨

arkk

¨

ainen, 2016). Autoencoders have proven

powerful as nonlinear feature extractors. Autoen-

coders can increase the generalization ability of ma-

chine learning models by extracting features of high

interest as well as making possible its application to

sensor data. Autoencoders were first introduced by

LeCun (Fogelman-Soulie et al., 1987), and have been

studied for decades. Traditionally, feature learning

and dimensionality reduction are the two main fea-

tures of autoencoders. Recently, autoencoders have

been considered one of the most compelling subspace

analysis techniques because of the existing theoreti-

cal relations between autoencoders and latent variable

models. Autoencoders have been used for feature ex-

traction from the data in systems like induction mo-

tor (Sun et al., 2016) and wind turbines (Jiang et al.,

2018) for fault detection, different from elevator sys-

tems as in our research.

In our previous research, raw sensor data, mainly

acceleration signals, were used to calculate elevator

key performance and ride quality features, which we

call here existing features. Random forest was used

for fault detection based on these existing features.

Existing domain specific features are calculated from

raw sensor data, but that requires expert knowledge

of the domain and results in a loss of information to

some extent. To avoid these implications, we have de-

veloped an algorithm for profile extraction from the

raw sensor data rides and a generic algorithm with

deep autoencoder random forest approach for auto-

mated feature extraction from raw sensor data profiles

for fault detection in elevator systems. The rest of

this paper is organized as follows. Section II presents

the methodology of the paper including profile extrac-

tion, deep autoencoder and random forest algorithms.

Then, section III includes the details of experiments

performed, results and discussion. Finally, section IV

concludes the paper and presents the future work.

2 METHODOLOGY

In this study, we have utilised 12 different existing

features derived from raw sensor data describing the

motion and vibration of an elevator for fault detection

and diagnostics of multiple faults. We have developed

an automated feature extraction technique for raw

sensor data in this research as an extension to the work

of our previous research (Mishra et al., 2019) to com-

pare the results using new extracted deep features. In

addition, we have analyzed almost two months of the

data from five traction elevators in this research as

an extension to one elevator in our previous research.

Each elevator usually produces around 200 rides per

day. Each ride used in analysis contains around 5000

rows of the data, which proves robustness of the al-

gorithm over large dataset. We have used 70% of the

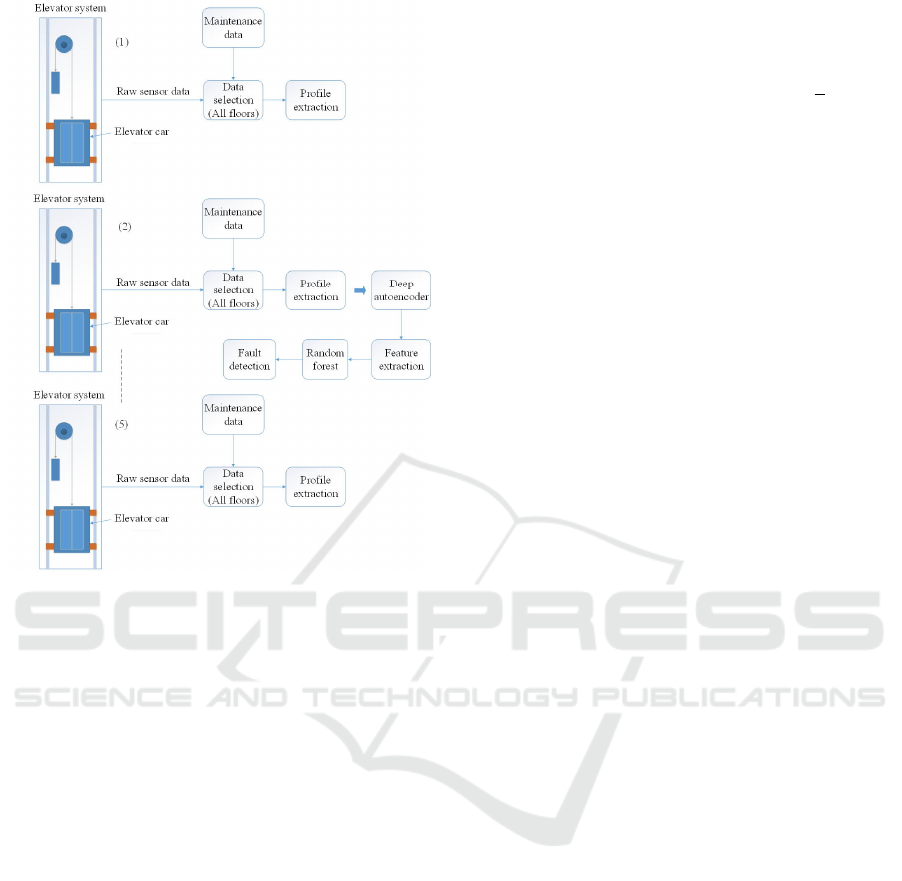

data for training and rest 30% for testing. Figure 1

shows the fault detection approach used in this pa-

per, which includes raw sensor data rides extracted

based on time periods provided by the maintenance

data from all floor patterns. Rides collected from an

elevator system are fed to the algorithm for profile ex-

traction. These extracted profiles from all five trac-

tion elevators are then fed to the deep autoencoder

model for feature extraction, and then random forest

performs the fault detection task based on extracted

deep features. We only extract start and stop profiles

from the rides because of the different lengths of rides

for each floor combination due to the constant speed

phase, which is longer when there is longer travel.

2.1 Profile Extraction Algorithm

Raw sensor data collected from elevator systems typi-

cally encompass a large collection of data points sam-

pled at high frequency. In order to feed large sensor

data to cloud-based applications, it is often desirable

to pre-process the data and perform compression be-

fore transmission, for example in the form of edge

computing performed in the device end. Here we as-

sume that raw data is in the form of a one-dimensional

time series vector with equidistant sampling times.

The goal of the proposed method is to compress the

raw time series obtained from machinery while main-

taining the information about key events, and sec-

ondly, to make the data more applicable for machine

learning.

The algorithm works in two stages. In the first

stage, the signal is pre-processed and normalized, fol-

lowed by low-pass filtering in order to reduce noise

spikes. The low-pass filtered signal is used for peak

detection, which for each elevator travel detects a lo-

cal minimum and maximum, corresponding to accel-

SIGMAP 2019 - 16th International Conference on Signal Processing and Multimedia Applications

314

Figure 1: Fault detection approach.

eration and deceleration (start and stop) events.

In the second stage, alignment and collection of

equal length profiles is performed based on window-

ing of the acceleration signal near the peak events.

In this stage, the raw acceleration signal is used in-

stead of the filtered signal. A number of time domain

alignment methods have been proposed in the litera-

ture. Dynamic time warping (DTW) has been com-

monly applied, e.g. in speech recognition (Di Mar-

tino, 1985), whereas various alignment techniques for

sensor data have been presented in (Rhudy, 2014).

Here, alignment is performed against a reference pro-

file, which is initialized to the known approximate

length of the acceleration and deceleration windows.

The reference profile is aligned against the raw data

in the window of the detected peaks. The criterion

for optimal alignment was defined as the alignment

that minimizes the sum of the Euclidean or L

2

norm.

The output from this operation is an n×m matrix of

aligned profiles describing n acceleration and decel-

eration events of length m.

In order to improve the alignment accuracy, the

reference profile is updated iteratively following each

run. Each sequence in the profile matrix is of the same

sample size and closely synchronized in time and can

hence be considered a repetition of the same signal.

Using signal averaging, the new reference profile is

calculated as the mean of the n extracted profiles. This

both maintains the main characteristics of the signal

and reduces the noise. Assuming white noise and per-

fect synchronization, signal averaging improves the

signal-to-noise ratio (SNR) by a factor of

√

n. The ref-

erence profile is updated on-line during the alignment

stage or in batch mode by multiple iterations through

the same dataset.

The off-line profile extraction algorithm is de-

scribed as follows.

Off-line Profile Extraction Algorithm.

Pre-procession

1. Read a vector of raw acceleration data contain-

ing k elevator travels. Define the zero mean trans-

formed dataset as X.

2. Perform low-pass filtering on X and obtain de-

noised dataset Y.

Initialization

3. Define parameters for reference profile. Set

window length to m samples and height h to the 99th

percentile of the low-pass filtered dataset.

4. Set threshold limit t for triggering peak detec-

tion as a fraction of h.

5. Define alignment window size a and set k=1.

Iteration

6. From Y(k), detect peak acceleration points y

min

and y

max

satisfying abs(y

min

,

max

) ≥t

7. Align reference profile R against raw dataset X

in the vicinity of detected peaks by minimizing the L

2

norm according to

min

a/2

∑

i=−a/2

m

∑

j=1

[−r

j

−x

min+i+j

]

2

(1)

min

a/2

∑

i=−a/2

m

∑

j=1

[r

j

−x

max+i+j

]

2

(2)

8. Add aligned data points from X(k) as rows into

an n×m profile matrix, alternatively separate matrices

according to direction of travel (min/max).

9. Set travel window k=k+1 and repeat steps 6-8

until end of dataset.

10. Update reference profile with the signal-

averaged profile obtained from the column-wise mean

of the new profile matrix. Set k=1 and continue with

new batch iterations by repeating steps 6-9.

2.2 Deep Autoencoder

The deep autoencoder model is based on deep learn-

ing autoencoder feature extraction methodology. A

basic autoencoder is a fully connected three-layer

feedforward neural network with one hidden layer.

Profile Extraction and Deep Autoencoder Feature Extraction for Elevator Fault Detection

315

Typically, the autoencoder has the same number of

neurons in the input and output layer and reproduces

its inputs as its output. We are using a five layer deep

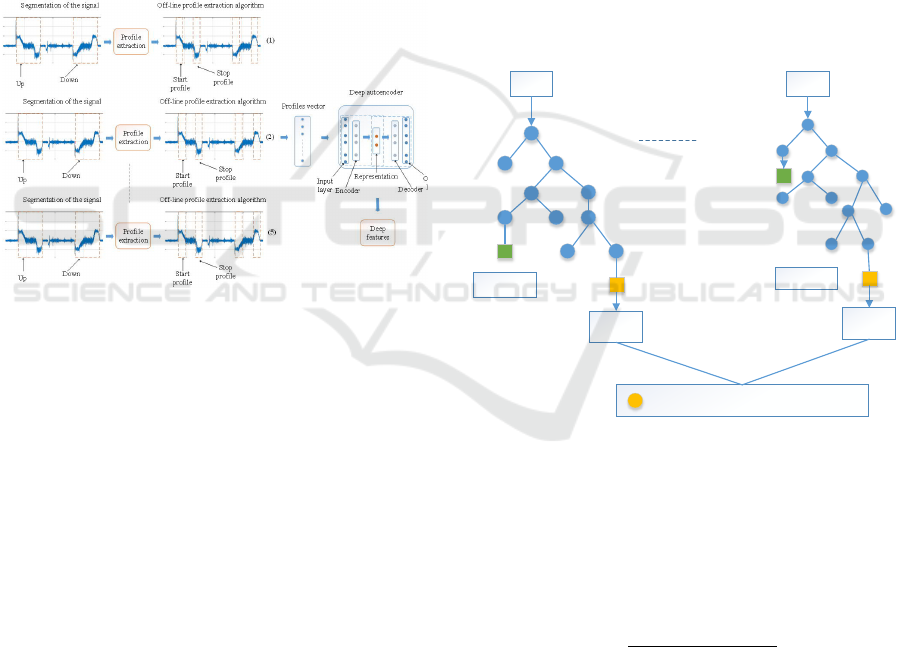

autoencoder (see Figure 2) including input, output,

encoder, decoder and representation layers, which is

a different approach than in (Jiang et al., 2018), (Vin-

cent et al., 2008). In our approach, we first analyze

the data to find all floor patterns and then feed the

segmented raw sensor data windows in up and down

directions separately to the algorithm for profile ex-

traction. Extracted profiles are fed to the deep autoen-

coder model for extracting new deep features. Lastly,

we apply random forest as a classifier for fault detec-

tion based on new deep features extracted from the

profiles. We have combined healthy and faulty pro-

files as a vector from all five traction elevators before

feature extraction.

Figure 2: Off-line profile extraction and deep autoencoder

feature extraction approach.

The encoder transforms the input x into corrupted

input data x

’

using hidden representation H through

nonlinear mapping

H = f (W

1

x

’

+ b) (3)

where f(.) is a nonlinear activation function as the

sigmoid function, W

1

∈R

k*m

is the weight matrix and

b ∈ R

k

the bias vector to be optimized in encoding

with k nodes in the hidden layer (Vincent et al., 2008).

Then, with parameters W

2

∈ R

m*k

and c ∈ R

m

, the

decoder uses nonlinear transformation to map hidden

representation H to a reconstructed vector x

”

at the

output layer

x

”

= g(W

2

H + c) (4)

where g(.) is again nonlinear function (sigmoid func-

tion). In this study, the weight matrix is W

2

=W

1

T

,

which is tied weights for better learning performance

(Japkowicz et al., 2000).

2.3 Random Forest

Random forest includes an additional layer of ran-

domness to bagging. It uses different bootstrap sam-

ples of the data for constructing each tree (Breiman,

2001). The best subset of predictors is used to split

each node in random forest. This counterintuitive

strategy is the best feature of random forest, which

makes it different from other classifiers as well as ro-

bust against overfitting. It is one of the most user-

friendly classifiers because it consists of only two

parameters: the number of variables and number of

trees. However, it is not usually very sensitive to their

values (Liaw and Wiener, 2002). The final classifi-

cation accuracy of random forest is calculated by av-

eraging, i.e. arithmetic mean of the probabilities of

assigning classes related to all the produced trees (e).

Testing data (d) that is unknown to all the decision

trees is used for evaluation by the voting method (see

Figure 3).

Vote 1

Vote e

Tree 1

Tree e

Assign Class (Majority Vote)

d d

Figure 3: Classification phase of random forest classifier.

Specifically, let sensor data value v

l

e

have training

sample l

th

in the arrived leaf node of the decision tree

e ∈ E , where l ∈ [1,...,L

e

] and the number of train-

ing samples is L

e

in the current arrived leaf node of

decision tree e. The final prediction result is given by

(Huynh et al., 2016):

µ =

∑

e∈E

∑

l∈[1,...,L

e

]

v

l

e

∑

e∈E

L

e

(5)

All classification trees providing a final decision

by voting method are given by (Liu et al., 2017):

H(a) = argmax

y

j

∑

i∈[1,2,...,Z]

I(h

i

(a) = y

j

) (6)

where j= 1,2,...,C and the combination model is H(a)

, the number of training subsets are Z depending on

SIGMAP 2019 - 16th International Conference on Signal Processing and Multimedia Applications

316

which decision tree model is h

i

(a) , i ∈ [1,2, ...,Z]

while output or labels of the P classes are y

j

, j=

1,2,...,P and combined strategy is I(.) defined as:

I(x) =

(

1, h

i

(a) = y

j

0, otherwise

(7)

where output of the decision tree is h

i

(a) and i

th

class

label of the P classes is y

j

, j= 1,2,...,P .

2.4 Evaluation Parameters

Evaluation parameters used in this research are de-

fined with the confusion matrix in Table 1.

Table 1: Confusion matrix.

Predicted (P) (N)

Actual (P) True positive (TP) False negative (FN)

(N) False positive (FP) True negative (TN)

The rate of positive test result is sensitivity,

Sensitivity =

T P

T P + FN

∗100% (8)

The ratio of a negative test result is specificity,

Speci f icity =

T N

T N + FP

∗100% (9)

The overall measure is accuracy,

Accuracy =

T P + T N

T P + FP + T N + FN

∗100% (10)

3 RESULTS AND DISCUSSION

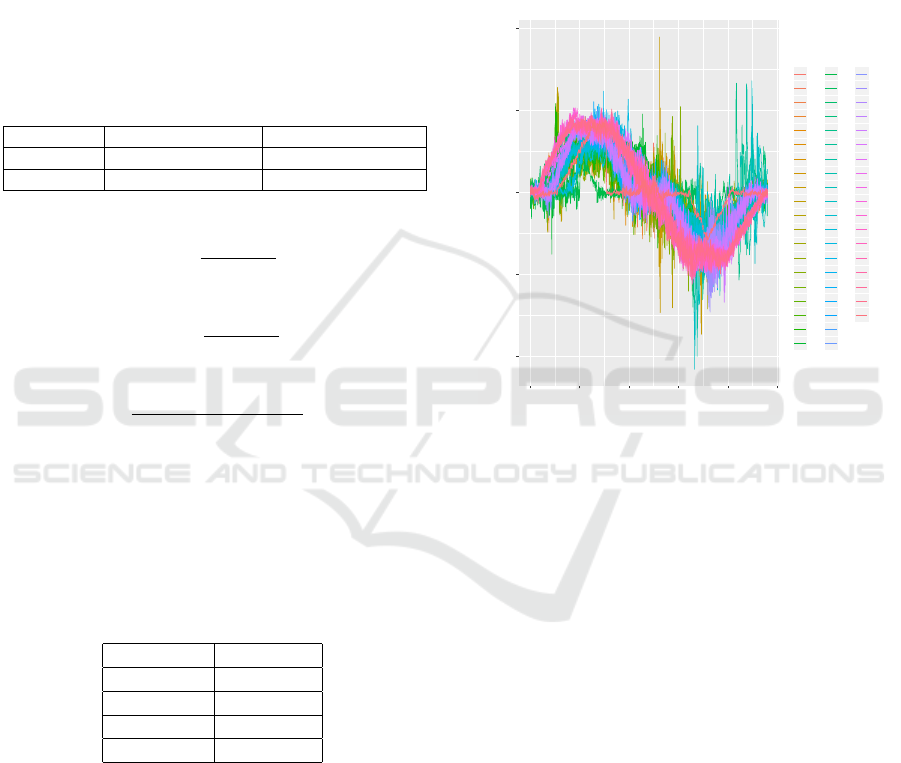

In this research, we first selected all floor patterns like

floor 2-5, 3-8 and so on from the data, some of which

are shown in Table 2.

Table 2: Floor patterns.

Start floor Stop floor

0 1

2 5

3 8

4 6

The next step includes the selection of faulty rides

from all floor patterns based on time periods provided

by the maintenance data. An equal amount of healthy

rides are also selected. Only the vertical component

of acceleration data is selected in this research be-

cause it is the most informative aspect, consisting of

significant changes in vibration levels as compared to

other components. Healthy and faulty rides are fed to

the algorithm for profile extraction separately. Start

and stop profiles are of equal length, irrespective of

floor combination.

3.1 Up Movement

We have analyzed up and down movements separately

because the traction based elevator usually produces

slightly different levels of vibration in each direction.

First, we have selected faulty rides based on time pe-

riods provided by the maintenance data, including all

floor patterns, which is fed to the algorithm for profile

extraction, as shown in Figure 4.

-2000

-1000

0

1000

2000

0 250 500 750 1000 1250

Samples

Acc vertical

variable

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V15

V16

V17

V18

V19

V20

V21

V22

V23

V24

V25

V26

V27

V28

V29

V30

V31

V32

V33

V34

V35

V36

V37

V38

V39

V40

V41

V42

V43

V44

V45

V46

V47

V48

V49

V50

V51

V52

V53

V54

V55

V56

V57

V58

All floor faulty profiles-up

Figure 4: Profiles from faulty rides (Acc represents acceler-

ation signal).

Then we have selected an equal number of rides

for healthy data, and the extracted profiles are shown

in Figure 5.The next step is to label both the healthy

and faulty profiles with class labels 0 and 1 respec-

tively. Healthy and faulty profiles with class labels are

fed to the deep autoencoder model and the generated

deep features are shown in Figure 6. These are called

deep features or latent features in deep autoencoder

terminology, which shows hidden representations of

the data. In Figure 6, we can see that both features

with class labels are perfectly separated, which results

in better fault detection.

Extracted deep features are fed to the random for-

est algorithm for classification, and the results pro-

vide 100% accuracy in fault detection in Table 3. We

have compared accuracy in terms of avoiding false

positives from both features and found that new deep

features generated in this research outperform the ex-

isting features. We have used the remaining healthy

rides for extracting profiles to analyze the number of

false positives. These healthy profiles are labelled as

class 0 and fed to the deep autoencoder to extract new

deep features from the profiles, as shown in Figure 7.

These new deep features are then classified

Profile Extraction and Deep Autoencoder Feature Extraction for Elevator Fault Detection

317

-2000

-1000

0

1000

2000

0 250 500 750 1000 1250

Samples

Acc vertical

variable

V1

V2

V3

V4

V5

V6

V7

V8

V9

V10

V11

V12

V13

V14

V15

V16

V17

V18

V19

V20

V21

V22

V23

V24

V25

V26

V27

V28

V29

V30

V31

V32

V33

V34

V35

V36

V37

V38

V39

V40

V41

V42

V43

V44

V45

V46

V47

V48

V49

V50

V51

V52

V53

V54

V55

V56

V57

V58

All floor healthy profiles-up

Figure 5: Profiles from healthy rides.

0.0

0.1

0.2

-0.2 0.0 0.2

Feature axis 1

Feature axis 2

class

0

1

Deep features-up

Figure 6: Extracted deep autoencoder features (visualiza-

tion of the features w.r.t class variable).

with the pre-trained deep autoencoder random forest

model to test the efficacy of the model in terms of

false positives. Table 3 presents the results for up-

ward movement of the elevator in terms of accuracy,

sensitivity and specificity. We have also included the

accuracy of avoiding false positives as an evaluation

parameter for this research. The results show that the

new deep features provide better accuracy in terms

of fault detection and avoiding false positives from

the data, which is helpful in detecting false alarms

for elevator predictive maintenance strategies. It is

extremely helpful in reducing unnecessary visits by

maintenance personnel to installation sites.

-0.4

0.0

0.4

-0.5 0.0 0.5

Feature axis 1

Feature axis 2

class

0

Features from the remaining healthy profiles-up

Figure 7: Extracted deep features (only healthy profiles).

Table 3: Fault detection analysis (False positives field re-

lated to analyzing remaining healthy profiles after the train-

ing and testing phase).

Deep features Existing features

Accuracy 1 0.50

Sensitivity 1 0.53

Specificity 1 0.47

False positives 1 0.43

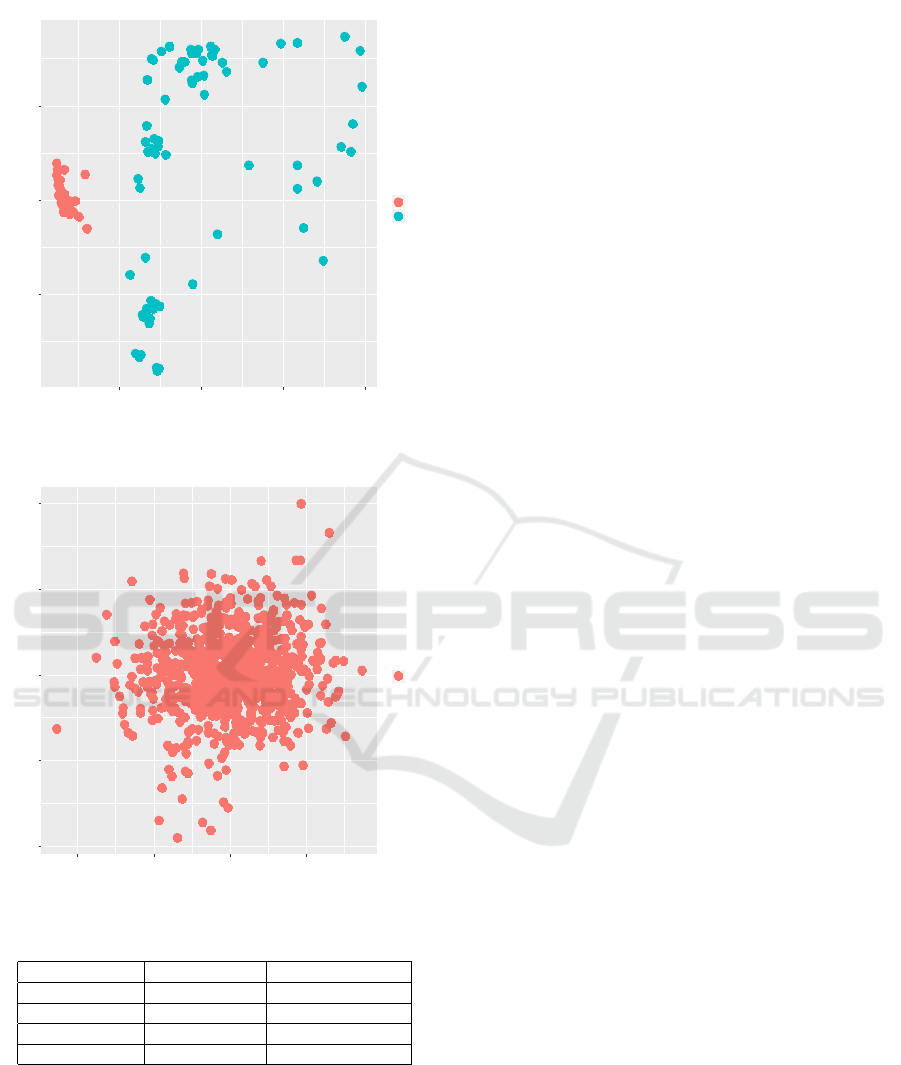

3.2 Down Movement

For downward motion, we have repeated the same

analysis procedure as in the case of upward motion.

We feed both healthy and faulty profiles with class la-

bels to the deep autoencoder model for the extraction

of new deep features, as shown in Figure 8.

Finally, the new extracted deep features are clas-

sified with random forest model and the results are

shown in Table 4. After this, the remaining healthy

rides are used to analyze the number of false positives.

The extracted deep features are shown in Figure 9.

Table 4 presents the results for fault detection with

deep autoencoder random forest model in the down-

ward direction. The results are similar to the upward

direction but we can see significant change in terms

of accuracy of fault detection and when analyzing the

number of false positives with new deep features.

SIGMAP 2019 - 16th International Conference on Signal Processing and Multimedia Applications

318

-0.5

0.0

0.5

-0.5 0.0 0.5 1.0

Feature axis 1

Feature axis 2

class

0

1

Deep features-down

Figure 8: Extracted deep features.

-0.6

-0.3

0.0

0.3

0.6

-0.50 -0.25 0.00 0.25

Feature axis 1

Feature axis 2

class

0

Features from the remaining healthy profiles-down

Figure 9: Extracted deep features (only healthy profiles).

Table 4: Fault detection analysis.

Deep features Existing features

Accuracy 1 0.41

Sensitivity 1 0.36

Specificity 1 0.46

False positives 1 0.54

4 CONCLUSIONS AND FUTURE

WORK

This research focuses on the health monitoring of ele-

vator systems using a novel fault detection technique.

The goal of this research was to develop generic mod-

els for profile extraction and automated feature ex-

traction for fault detection in the health state monitor-

ing of elevator systems. Our approach in this research

provided 100% accuracy in fault detection and also

in the case of analyzing false positives for all floor

combinations with new extracted deep features. The

results support the goal of this research of developing

generic models which can be used in other machine

systems for fault detection. The results are useful

in terms of detecting false alarms in elevator predic-

tive maintenance. The approach will also reduce un-

necessary visits of maintenance personnel to installa-

tion sites if the analysis results are utilized to allocate

maintenance resources. Our developed models can

also be used for different predictive maintenance so-

lutions to automatically generate highly informative

deep features for solving diagnostics problems. Our

models outperform others because of new deep fea-

tures extracted from the dataset as compared to ex-

isting features calculated from the same raw sensor

dataset. The automated feature extraction approach

does not require any prior domain knowledge. It

also provides dimensionality reduction and is robust

against overfitting characteristics. The experimental

results show the feasibility of our generic models,

which will increase the safety of passengers as well

as serve the public interest.

In future work, we will extend our approach on

other real-world big data cases to validate its potential

for other applications and improve its efficacy.

REFERENCES

Bingham, C., Walsh, C., and Carroll, S. (2012). Impact of

driving characteristics on electric vehicle energy con-

sumption and range. IET Intelligent Transport Sys-

tems, 6(1):29–35.

Breiman, L. (2001). Random forests. Machine learning,

45(1):5–32.

Calimeri, F., Marzullo, A., Stamile, C., and Terracina, G.

Graph based neural networks for automatic classifica-

tion of multiple sclerosis clinical courses. In Proceed-

ings of the European Symposium on Artificial Neural

Networks, Computational Intelligence and Machine

Learning (ESANN 18)(2018, forthcoming).

Desa (2014). World urbanization prospects, the 2011 revi-

sion. Population Division, Department of Economic

and Social Affairs, United Nations Secretariat.

Di Martino, J. (1985). Dynamic time warping algorithms

for isolated and connected word recognition. In New

systems and architectures for automatic speech recog-

nition and synthesis, pages 405–418. Springer.

Fogelman-Soulie, F., Robert, Y., and Tchuente, M. (1987).

Automata networks in computer science: theory and

Profile Extraction and Deep Autoencoder Feature Extraction for Elevator Fault Detection

319

applications. Manchester University Press and Prince-

ton University Press.

H

¨

anninen, J. and K

¨

arkk

¨

ainen, T. (2016). Comparison

of four-and six-layered configurations for deep net-

work pretraining. In European Symposium on Artifi-

cial Neural Networks, Computational Intelligence and

Machine Learning.

Hbali, Y., Sadgal, M., and Fazziki, A. E. (2013). Mark-

erless augmented reality based on local binary pat-

tern. In Signal Processing and Multimedia Applica-

tions (SIGMAP), 2013 International Conference on,

pages 137–141. IEEE.

Huynh, T., Gao, Y., Kang, J., Wang, L., Zhang, P., Lian,

J., and Shen, D. (2016). Estimating ct image from

mri data using structured random forest and auto-

context model. IEEE transactions on medical imag-

ing, 35(1):174.

Japkowicz, N., Hanson, S. J., and Gluck, M. A. (2000).

Nonlinear autoassociation is not equivalent to pca.

Neural computation, 12(3):531–545.

Jia, F., Lei, Y., Lin, J., Zhou, X., and Lu, N. (2016). Deep

neural networks: A promising tool for fault character-

istic mining and intelligent diagnosis of rotating ma-

chinery with massive data. Mechanical Systems and

Signal Processing, 72:303–315.

Jiang, G., Xie, P., He, H., and Yan, J. (2018). Wind turbine

fault detection using a denoising autoencoder with

temporal information. IEEE/ASME Transactions on

Mechatronics, 23(1):89–100.

Lee, C.-C. (2014). Gender classification using m-estimator

based radial basis function neural network. In Signal

Processing and Multimedia Applications (SIGMAP),

2014 International Conference on, pages 302–306.

IEEE.

Liaw, A. and Wiener, M. (2002). Classification and regres-

sion by randomforest. R news, 2(3):18–22.

Liu, Z., Tang, B., He, X., Qiu, Q., and Liu, F. (2017).

Class-specific random forest with cross-correlation

constraints for spectral–spatial hyperspectral image

classification. IEEE Geoscience and Remote Sensing

Letters, 14(2):257–261.

Maha, C., Maher, E., Mohamed, K., and Chokri, B. A.

(2010). Dct based blind audio watermarking scheme.

In Signal Processing and Multimedia Applications

(SIGMAP), Proceedings of the 2010 International

Conference on, pages 139–144. IEEE.

Mart

´

ınez-Rego, D., Fontenla-Romero, O., and Alonso-

Betanzos, A. (2011). Power wind mill fault detection

via one-class ν-svm vibration signal analysis. In Neu-

ral Networks (IJCNN), The 2011 International Joint

Conference on, pages 511–518. IEEE.

Mishra, K. M., Krogerus, T., and Huhtala, K. (2019). Fault

detection of elevator systems using deep autoencoder

feature extraction. In Research Challenges in Infor-

mation Science (RCIS), 2019 International Confer-

ence on. IEEE.

Nam, S.-H. and Yang, M.-Y. (2004). A study on a

generalized parametric interpolator with real-time

jerk-limited acceleration. Computer-Aided Design,

36(1):27–36.

Rhudy, M. (2014). Time alignment techniques for experi-

mental sensor data. Int. J. Comput. Sci. Eng. Survey,

5(2):1–14.

Rivas-Perez, M., Linares-Barranco, A., Jimenez-

Fernandez, A., Civit, A., and Jimenez, G. (2011). Aer

spike-processing filter simulator: Implementation of

an aer simulator based on cellular automata. In Signal

Processing and Multimedia Applications (SIGMAP),

2011 Proceedings of the International Conference on,

pages 1–6. IEEE.

Sahba, F. and Venetsanopoulos, A. (2010). Breast mass de-

tection using bilateral filter and mean shift based clus-

tering. In Signal Processing and Multimedia Appli-

cations (SIGMAP), Proceedings of the 2010 Interna-

tional Conference on, pages 88–94. IEEE.

Soyka, F., Giordano, P. R., Beykirch, K., and B

¨

ulthoff,

H. H. (2011). Predicting direction detection thresh-

olds for arbitrary translational acceleration profiles in

the horizontal plane. Experimental brain research,

209(1):95–107.

Sun, W., Shao, S., Zhao, R., Yan, R., Zhang, X., and Chen,

X. (2016). A sparse auto-encoder-based deep neural

network approach for induction motor faults classifi-

cation. Measurement, 89:171–178.

Vincent, P., Larochelle, H., Bengio, Y., and Manzagol, P.-

A. (2008). Extracting and composing robust features

with denoising autoencoders. In Proceedings of the

25th international conference on Machine learning,

pages 1096–1103. ACM.

Wang, X., Wu, S., and Wang, K. (2015). A run-to-run

profile control algorithm for improving the flatness of

nano-scale products. IEEE Transactions on Automa-

tion Science and Engineering, 12(1):192–203.

Xia, M., Li, T., Xu, L., Liu, L., and de Silva, C. W.

(2018). Fault diagnosis for rotating machinery us-

ing multiple sensors and convolutional neural net-

works. IEEE/ASME Transactions on Mechatronics,

23(1):101–110.

Yang, Z.-X. and Zhang, P.-B. (2016). Elm meets rae-elm:

A hybrid intelligent model for multiple fault diagnosis

and remaining useful life predication of rotating ma-

chinery. In Neural Networks (IJCNN), 2016 Interna-

tional Joint Conference on, pages 2321–2328. IEEE.

SIGMAP 2019 - 16th International Conference on Signal Processing and Multimedia Applications

320