Smith Predictor for Control of the Temperature Process with Long

Dead Time

Nikolajs Bogdanovs

1,2

, Romualds Beļinskis

2

, Andris Krūmiņš

3

, Ernests Petersons

2

and Aleksandrs Ipatovs

2

1

Building Automation Department, Lafivents LTD, Bauskas street 58 Street, Riga, Latvia

2

Department of Transport Electronics and Telematics, Riga Technical University, Riga, Latvia

3

Faculty of Civil Engineering, Institute of Heat, Gas and Water Technology, Riga Technical University, Riga, Latvia

Keywords: PID Regulator, Smith Predictor, Transfer Function, PLC Controller.

Abstract: The analysis of a problem of development of control systems for objects with big time delay is carried out in

this work. For such objects it is difficult to provide high-quality control, because the control is carried on the

last status of object’s output. The main setup methods of PID regulators have been examined. Based on this

analysis the technique of complete synthesis of the regulator of higher level is given in order to regulate

building’s heating system. This work offers a new method of object’s control with distributed delay. As the

test bed for the offered structure of control the valve of hot water supply in a heat-node is used. Using the

test bed the stability of the system with time delay have been studied, which is controlled by the PID

regulator assisted by Smith Predictor used to compensate the dead time.

1 INTRODUCTION

Energy saving in the field of building’s heating is

important task, considering both the criteria of

market capacity and the aspect of status of

engineering systems. In the European Union,

buildings are responsible for 40% of total energy

consumption including approximately 20% absorbed

in heating which can be effectively used in the

demand side management (DSM) strategy as a shift

able load.

Energy saving in heating systems from control

point of view is characterized by the need of stable

maintenance of air temperature for building’s

premises at adjusted comfort level in the presence of

external perturbations affecting the building. Today,

considering the development of automation

equipment and large-scale implementation of

individual thermal points, implementation of more

effective heat controlling algorithms became

possible (Altmann et al., 2005). Thermo-hydraulic

processes in the building have big momentum; have

non-linear or variable linear dynamic behaviour and

distributed nature, subjected to vast number of the

influencing factors, which direct measurements are

extremely difficult in practice.

The management with prediction models in

microclimate control algorithm allows increasing the

effectiveness of HVAC system in buildings. There is

a problem of the correct setup of the heating

equipment as excessive increase in temperature on

the heating element leads to overheating of rooms,

which results in excessive consumption of thermal

resource and decreased comfort level. At the same

time it is necessary to consider that the greatest

saving of thermal energy in heating systems of

buildings is reached by using intellectual

automation. It is explained by the fact that automatic

control allows to save heat due to accounting of

those factors, which can't be considered by

calculation methods, such as:

influence of solar radiation;

accounting of fluctuations in outside air

temperature;

heat release from people and equipment;

chaotic operating time of ventilation.

Thus, the development of intellectual management

systems for heating systems is a relevant task. The

adjustment method based on prediction is offered in

this work.

Predictive control is not a single strategy, but a

set of control methods with predictive model of the

process expressed in specific order to obtain a

Bogdanovs, N., Belinskis, R., Kr

¯

uminš, A., Petersons, E. and Ipatovs, A.

Smith Predictor for Control of the Temperature Process with Long Dead Time.

DOI: 10.5220/0007808501730179

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 173-179

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

173

control signal by minimizing objective’s function

subjection to some constraints. In building’s control,

one would aim to optimize delivered energy

subjecting to constraints. One of advantage of this

method is Smith Predictor time delay is effective

taken outside the control loop in the transfer

function relating the process output to setpoint. This

method introduces extreme instability into the

variable control system (Bogdanovs et al., 2018).

Smith Predictor control is a good decision to the

problem of controlling the time delay systems. It

approach improves the performance and reliability

of the system in the real time applications. The

Smith Predictor is a popular and effective long

compensator for stable processes. One of advantage

of this method is Smith Predictor time delay is

effective taken outside the control loop in the

transfer function relating the process output to

setpoint. This method introduces extreme instability

into the variable control system.

1.1 Related Works

The paper (Basnayake et al., 2015) in his work

offers to replace PLC controllers of building’s

automatics with new controllers designed based on

artificial intelligence. These controllers use

intellectual identification of users.

Work describes smart home systems that

decrease energy consumption by studying human

behavior pattern (Badlani and Bhanot, 2011).

Author proposed in paper simulation methods for

the temperature control systems. Work results shown

success usability of test model to use this regulation

method in PLC controller for temperature control in

buildings (Roengruen et al., 2009).

Book author describes regulation principles of

process control and regulation methods in variable

processes in building heating systems. This book

discusses different approaches for regulation loops.

It also shows the applying of Smith Predictor model

in process control (King, 2010).

Author mentions the disadvantages of the

applying the classical PID controller regulation and

tuning. The paper shows examples how to improve

system regulation with Smith Predictor. This control

method allows avoids decreasing of regulator gain

factor as result the system regulation performance

increases (Srinivas et al., 2010).

This work describes in the article compares the

use of the Smith predictor control model with the

PID regulator and the Model predictive control. The

proposed comparison allows a better understanding

of the use of models for the application of control

characteristics in industrial equipment. (Vidyamol

and Nasar, 2015).

Despite the large number of valuable research

work describing different types of management,

there is no management system, which could

increase the effectiveness in existing buildings by

using predictions. Control algorithms are developed

for such research, described below, based on Smith's

predictor, which are designed and used in building

management system.

2 FORMULATION OF THE

PROBLEM

In automation of heating, ventilation and air

conditioning (HVAC) systems the PID regulators

are used everywhere. They allow regulating

motorized air dampers and hydraulic valves,

frequency converters of pumps, fans and

compressors are regulated. The problem of

controlling inlet air temperature by direct-flow air

handling unit (AHU) with water heater is considered

in this publication. In cases when such AHU is

equipped with simple ON/OFF ventilator without

frequency converter or EC-regulator fan, the

maintenance of stable set inlet air temperature is

carried out by motorized valve through PID

regulator (Prabhakara Rao and Voleti, 2011).

Described AHU are found on outdated HVAC

systems and also in specialized systems of

production, professional kitchens, etc.

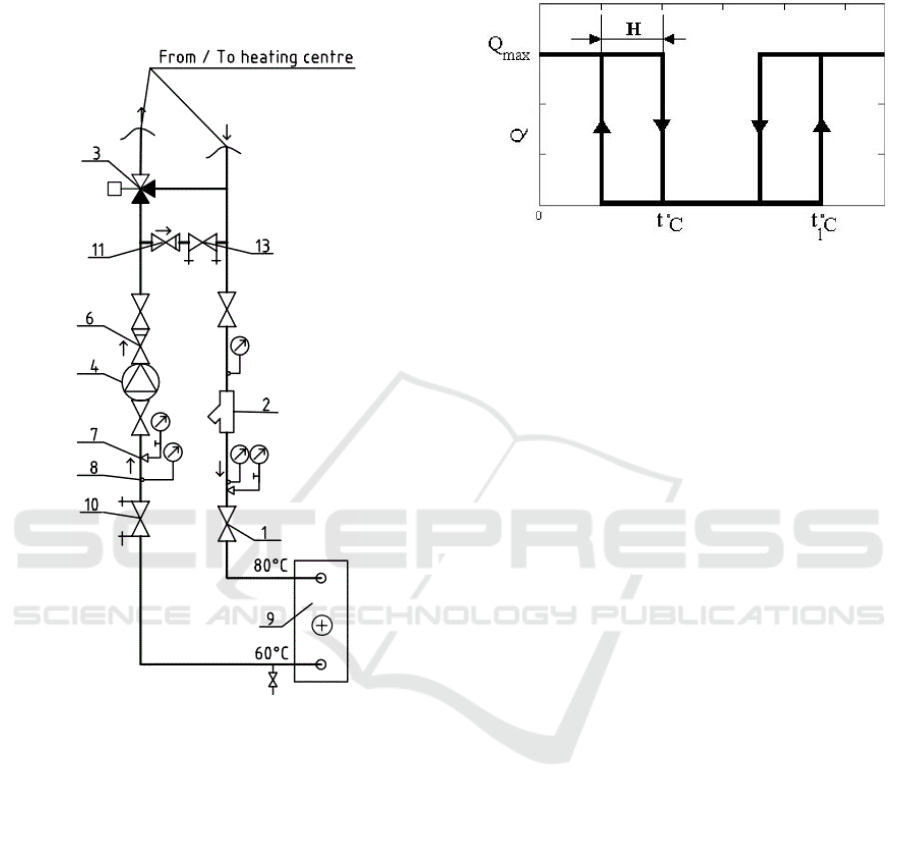

In a commonly used shunt group scheme the

circulation pump (4) is operating constantly,

ensuring freeze prevention and a steady water

temperature regulation with control valve (3). See in

Figure 1.

In the commonly, used shunt group scheme

circulation pump is operating constantly, ensuring

freeze protection and a steady water temperature

regulation with control valve, see in Figure 1.

Where:

1 – Shut off valve; 2 – Strainer; 3 – Three-way

valve with actuator; 4 – Circulation Pump; 5,6 -

Check valves; 7 – Thermometer; 8 – Manometer; 9 -

Water/Air Heat exchanger; 10,13 – Balancing

valves.

By launching such system, in order not to over

cool inlet air, the triple running valve is usually

completely opened, providing the maximum flow of

heat carrier g and respectively the heat power Q.

The problem is that inlet air temperature

undergoes strong fluctuations while the PID

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

174

regulator finds the necessary valve position for

heating the air from outside temperature to the one

that is set. It negatively reflects on thermal comfort

of people indoors and also it can influence

technological processes.

Figure 1: A typical AHU shunt group hydraulic scheme.

Heating energy transferred to the airflow by

heating coil can be calculated using formula:

( - )

cw in out

Q g p c T T

(1)

Where:

Q - heating output, kW,

g - heating fluid flow, m3/s,

ρ - heating fluid density, kg/m3,

cw

c

- heating fluid specifies heat, kJ/(kg*°C),

outin

TT ,

- supply and return flow temperatures, °C.

In three-position regulators the actuator can hold

three positions: completely open, normal (average)

or completely closed [7.8].

The value of hysteresis H affects the accuracy

temperature adjustment. Reduction the value of

hysteresis zone not only increases the accuracy of

adjustment, but also the frequency of opening the

valve that leads to a fast wear of commutation

elements.

Figure 2: Characteristics of three-position regulator.

3 ENHANCED SMITH

PREDICTOR FOR HEATING

CONTROL

Buildings’ modern heat-nodes regulating heat

consuming by the use of valves and pumps which

regulate heat supply to the building in compliance

with a desirable temperature for locations.

According to the temperature diagram and weather

conditions further regulation of the consumed

thermal energy takes place, thus, providing

comfortable conditions taking into account the

temperature of outside air. Microprocessor controller

serves as a central device, which controls operation

of valves and pumps. It allows regulating heat

carrier’s temperature according to temperature of

outside air; to automatically reduce temperature and

to control circulation pumps (Tala and Daxini,

2015). Heat carrier’s temperature control is carried

out by means of the PID regulator. Using PID

control for Building Management System (BMS) is

not effective method to control the heating system.

Thus, a considerable change in set point occurs.

Integral terms cause an overshooting error during the

rise.

Since heat-node’s temperature regulation is

carried out by means of PID regulator according to

temperature of outside air (especially in case of

sharp temperature drop), systems form the delay of

automatic control. As each link of the heat-node has

its own response time bringing the negative phase

displacement, it is capable to result in loss of

stability in regulatory system (García and Albertos,

2013; Shi et al., 2008). It is necessary to apply the

ratio between delay value and the object’s time

Smith Predictor for Control of the Temperature Process with Long Dead Time

175

constant, described by the following ratio:

)0,2...0,5(>

T+τ

τ

(2)

T - object’s time constant.

Where

- heating valve delays, depend on

weather and thermo hydraulic processes in the

building.

Time of transport delay is calculated by formula:

υ

L

ε=τ

(3)

L

- the distance from the sensor to the executing

mechanism, m.

- movement speed of the substance m/s.

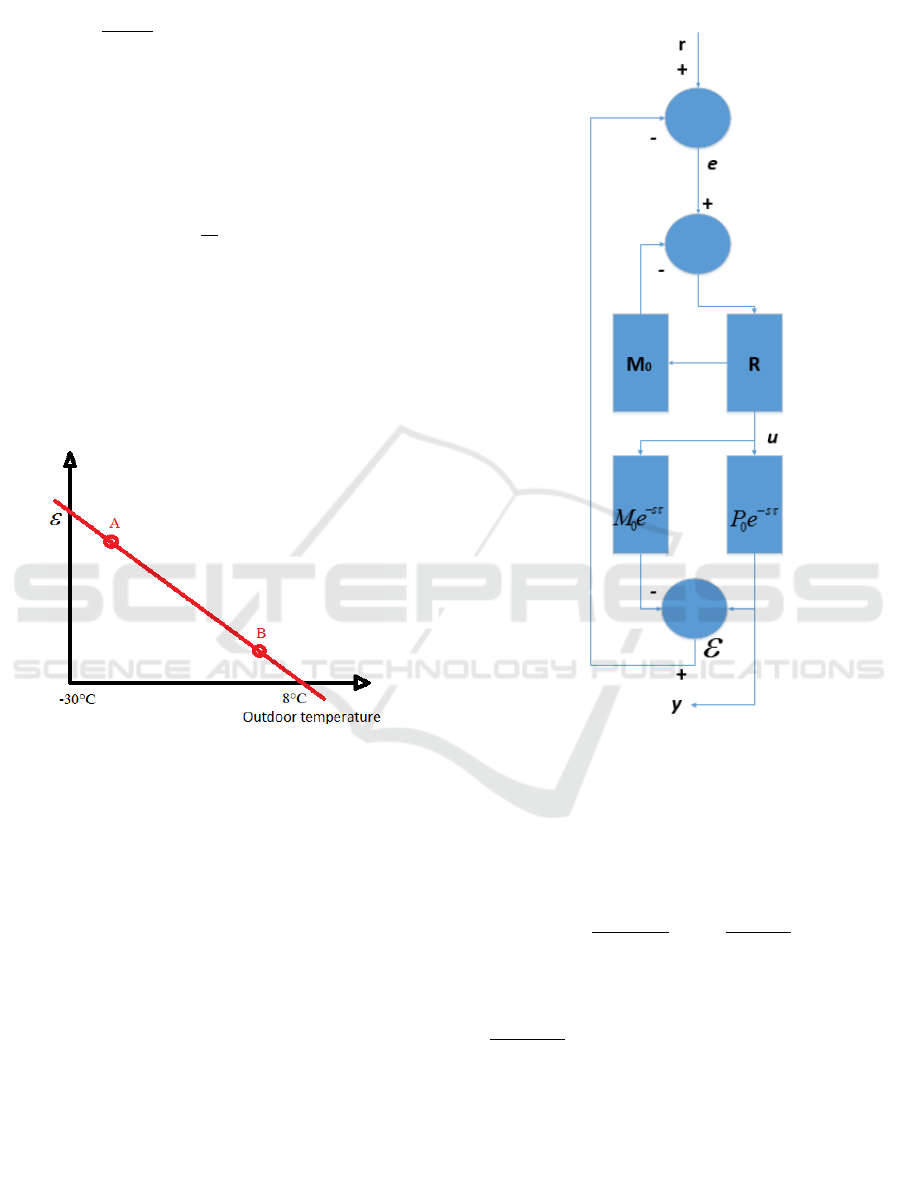

To determine dynamic characteristic

of c the

control object it is necessary to reveal the regularity

in practice as it was done in this work, see Figure 3:

Figure 3: Dynamic characteristics of time delay of outside

temperature.

The dynamic characteristic

was determined

experimentally. The best coefficient was defined at

the temperature of 8 in point A and -23 in point B. A

linear dependence was obtained after this. The linear

dependence for each heating system is separate and

it needs to be defined experimentally

The purpose of Smith’s predictor – to foretell the

signal strength at the object exit before it actually

appears there. Due to this prediction the delay factor

is excluded from the model, which allows predicting

the behaviour of an object before the moment when

signal appears at the exit.

Further, to make a prediction, it is necessary to

use the model of object’s control that consists of

fractional rational part

0

M

and delay

e

− sτ

. Here,

the R – common PID regulator,

sτ

eP

0

–

additional characteristic of the control objects (see

Figure 4).

Figure 4: Control system with Smith's predictor.

We will assume that the model is absolutely

exact. Then the difference between signals on

model’s outputs and the object will be equal to zero

(ε = 0) (Hao et al., 2011). But in that case, directly

from the diagram of Figure 4, it is possible to obtain:

sτ

00

sτ

0

e

RP+

RP

=r

RM+

R

eP=y

11

0

(4)

In this expression the member

0

0

1 RP

RP

represents a transfer function of a

system without delay. And it means that the link

with the time delay is not included in the circuit of

feedback and doesn't affect the stability and high-

speed performance of the system, which means that

there is adjustment in the circuit with the model

without delay, and the transport delay is added to

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

176

receive result (Kato et al., 2005). Due to this

prediction the delay value is excluded from the

model, which allows predicting of object’s

behaviour until the signal appears at the outlet.

Smith's predictor imitates a difference between

the process model with no sensitivity zone and a real

object. This adjusting signal is added to the

measured output signal to foretell what signal would

be at the exit if there were no delay (Dulău et al.,

2010; Zhang, 2013).

The transfer function in (4) models the way a

change in the voltage (0-10Volt) driving the water

valve opening affects the heater temperature.

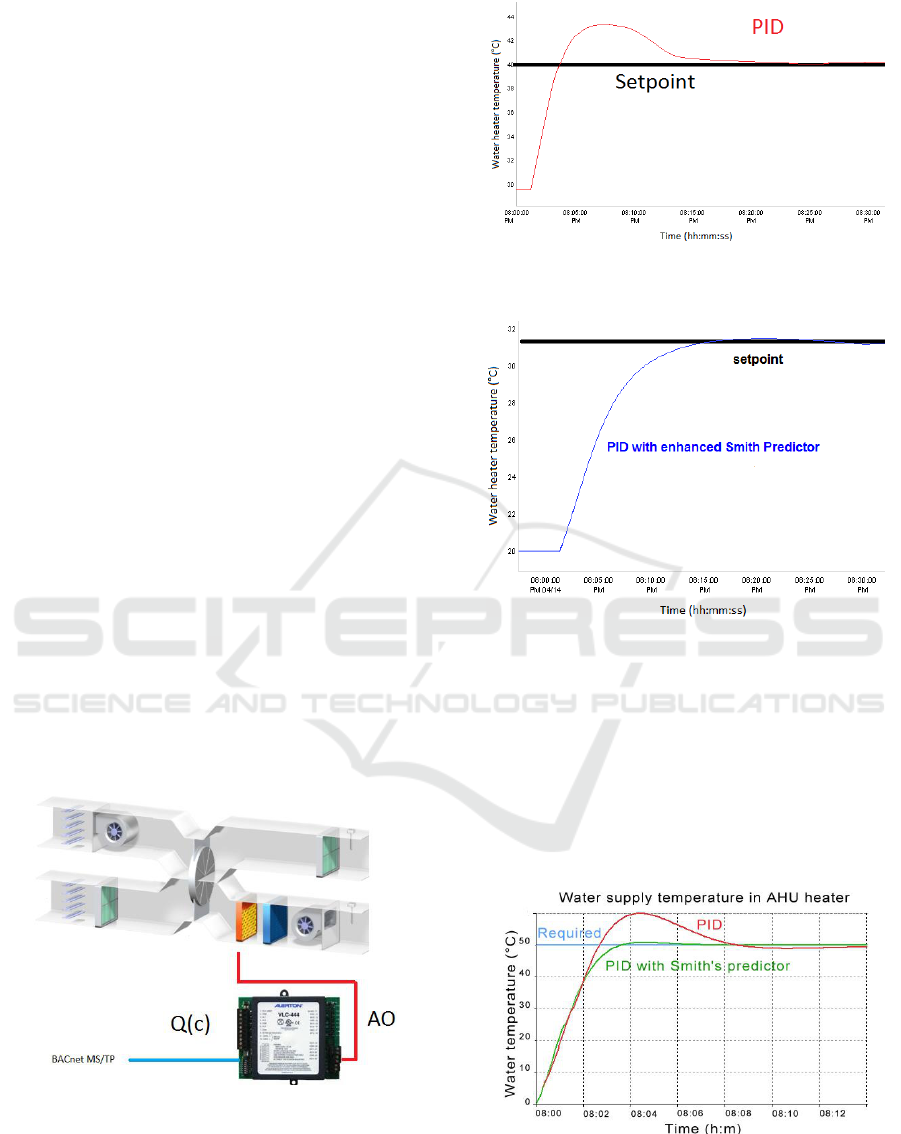

3.1 Practical Implementation of the

Enhanced Smith Predictor for

Heating Control

Simulations of the regulator in simulators based on

Smith Predictor is labour-consuming, as the dynamic

characteristics of

is stochastic and separate for

each building’s heater and it is also hardly

predictable. Simulation and laboratory conditions

can differ highly, therefore, we have to try this

adjustment method in practice and a real object was

used for this, PLC (programmable logic controller)

controller is shown in Figure 5.

The predicted value

goes to Q(c), controller,

which adjusts the controlling influence of AO

(Analog Output).

This heater of the ventilation system is controlled

with PLC controller in which software is written to

control the valve of water heater.

Figure 5: PLC Controller for AHU heater.

The controller by means of BACnet protocol is

connected to the server where archiving of data and

monitoring of the system is carried out. The water

heater valve is a one analog output system.

Figure 6: Experimental results for valve heating control

with PID for outdoor temperature -5°C.

Figure 7: Experimental results for valve heating control

with enhanced Smith Predictor for outdoor temperature -

2°C.

The Figure 6 shows that by using standard PID

regulator the precise adjustment of the heating valve

is not reached and based on this a new method of

adjustment system with great delay was studied. The

Figure 7 shows the experimental (with outdoor

temperature from 8°C to -25°C) result, received with

Smith's predictor.

Figure 8: Results for valve heating control with outdoor

temperature -8°C from PID regulator and PID with

Smith's predictor.

Smith Predictor for Control of the Temperature Process with Long Dead Time

177

The Figure 8 shows the experimental (with

outdoor temperature -8°C) result, received with

Smith's predictor. The structure of this predictor is

also given in this Figure 4.

From Table 1 it can be said that PID with Smith

Predictor gives better transient response

characteristics than PID controller for process with

constant time delay.

Table 1: Comparison of responses.

Model

Characteristics

Max. Peak

(%)

Rise

time(s)

Peak

time(s)

Settling

time(s)

PID

25

420

480

840

PID Smith's predictor

2

118

32

360

4 CONCLUSIONS

The article shows that for objects with a big value of

transport delay it is suggested to use Smith

Predictor. When compared to the usual PID, the

Smith Predictor more improves the system’s

response to set-point changes.

Finally the experimental result of the heating

control with both traditional PID regulator and PID

with Smith predictor are built in PLC

microcontroller. By comparison with traditional PID

regulator, the experimental results demonstrate the

effectiveness of the proposed methods towards the

heating valve delays and system uncertainties

integrated in the building heating control system (see

Table 1). A consistency of Smith predictor control

signals of all possible time delays can be generated

in advance and the actual delays will be

compensated. This control method is mathematically

simple implemented in PLC microcontroller with

reduce resources.

The temperature control system based on the

Smith Predictor controller can precisely control the

temperature inside the instrument. Therefore, it is

able to provide the best temperature for enzymatic

detection to ensure the accuracy of results. Should

the system under control be an integral process,

complementary outside temperature should also be

incorporated into the control system.

In future work is planned to address all above-

mentioned problems within the framework of

research by providing following solutions:

Matlab machine learning toolbox could solve the

problem of optimizing the Building Management

System algorithm by analyzing weather forecast for

the next day and sing Finite Difference Method in

self-learning model. The automation of the home or

the building has a great potential in reducing the cost

and energy consumption using, machine learning for

intelligent control.

ACKNOWLEDGMENT

The research received funding from the ERAF Post-

doctoral Research Support Program project Nr.

1.1.1.2/16/I/001 Research application “Wireless

sensor networks for a building’s energy efficiency

evaluation and data exchange with the building’s

management systems” Nr. 1.1.1.2./VIAA/1/16/228.

REFERENCES

Basnayake, B. A. D. J. C. K., Amarasinghe, Y. W. R.,

Attalage, R. A., Udayanga, T. D. I., Jayasekara, A. G.

B. P., 2015. Artificail Intelligence Based Smart

Building Automation Controller for Energy Efficiency

Improvements in Existing Building, International

Journal of Advanced Information Science and

Technology (IJAIST) ISSN: 2319:2682, Vol .4, No. 8,

pp. 85-91.

Badlani A., Bhanot S., 2011. Smart Home System Design

based on Artificial Neural Networks, ISSN: 2078-

0958 (Print); 2078-0966 (Online), Proceedings of the

World Congress on Engineering and Computer

Science, Vol. I, pp. 106-111.

Bogdanovs, N., Krūmiņš, A., Beļinskis, R., Afoņičevs, V.,

Jeralovičs, V., Ipatovs, A., 2018. Intelligence System

of Building Management System for Energy

Efficiency in the Test Facility. In: Advances in

Wireless and Optical Communications (RTUWO), pp.

1-6.

Roengruen, P., Tipsuwanporn, V., Puawade, P.,

Numsomran, A., 2009. Smith Predictor Design by

CDM for Temperature Control System, International

Journal of Electrical and Computer Engineering,

ISSN:1307:6892, Vol. 3, No. 11, pp. 2538-2542.

Altmann, W., Macdonald, D., Mackay, S., 2005. Practical

Process Control for Engineers and Technicians,

Pactical Handbook, Elsevier, Oxford, ISBN:

0750664002.

Srinivas, P., Raj, P., Rajesh, S., 2012. Modeling and

Simulation of Respiratory Controller Using Labview,

International Journal of Control Theory and

Computer Modelling (IJCTCM), ISSN: 1865-0929,

Vol. 2, No. 4 pp. 212-219.

King, M., 2010. Process Control: A Practical Approach,

Hanbook, Wiley, ISBN: 0470976661.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

178

Siroky, J., Oldewurtel, F., Cigler, J. Cigler, Prívara, S.,

2011. Experimental analysis of model predictive

control for an energy efficient building heating system,

Applied Energy 88 (9), pp. 3079-3087.

Prabhakara Rao, B., Voleti, D., 2011. A Novel Approach

of Designing Fuzzy Logic based Controller for Water

Temperature of Heat Exchanger Process Control,

International Journal of Advanced Engineering

Sciences and Technologies, Vol. 11, Issue 1, pp. 172 –

176.

Tala, A., Daxini, B., 2015. Identification of Heating

Process and Controlusing Dahlin PID with Smith

Predictor, International Journal of Engineering

Research & Technology (IJERT), Vol. 4, Issue 05, pp.

131–135.

García, P., Albertos, P., 2013. Robust tuning of a

generalized predictor-based controller for integrating

and unstable systems with long time delay, Journal of

Process Control, pp. 1205-1216.

Shi, D., Peng, G., Li, T., 2008. Gray predictive adaptive

Smith-PID control and its application, Proceedings of

International Conference on Machine Learning and

Cybernetics, Vol. 4, pp.1980 – 1984.

Dulău, M., Oltean, S., Duka, A., Gligor, A., 2010.

Behavioural study of a thermal process control under

uncertainties, IEEE International Conference on

Automation, Quality and Testing Robotics

(AQTR2010), Vol. I, pp. 198-201.

Hao. C., Zouaoui, Z., Zheng, C., 2011. A neuro-fuzzy

compensator based Smith predictive control for

FOPLDT process. Proceedings of International

Conference on Mechatronics and Automation (ICMA),

pp. 1833 – 1838.

Kato. M., Yamamoto, T., Fujisawa, S., 2005. A skill-based

PID controller using artificial neural networks,

Computational Intelligence for Modeling, Control and

Automation and International Conference on

Intelligent Agents, Web Technologies and Internet

Commerce, Vol. 1, pp. 702-707.

Xiaojing, Z., Schildbach, G., Sturzenegger, D., Morari,

M., 2013. Scenario based MPC for energy-efficient

building climate control under weather and occupancy

uncertainty. In Control Conference (ECC), pp. 1029–

1034.

Vidyamol, V., Nasar, A., 2015. Comparison between

Model Predictive Control and Smith Predictor with

PID Approach for Chamber Pressure in a Coke

Furnace, International Journal of Science and

Research (IJSR), Vol. 4, Issue 8, pp. 1148-1153.

Smith Predictor for Control of the Temperature Process with Long Dead Time

179