Survey about the Utilization of Open Source Arduino for Control and

Measurement Systems in Advanced Scenarios. Application to Smart

Micro-Grid and Its Digital Replica

Isaías González Pérez

a

, A. José Calderón Godoy

b

, Manuel Calderón Godoy

c

and J. Félix González González

d

Industrial Engineering School, University of Extremadura, Avenida de Elvas, Badajoz, Spain

Keywords: Open Source, Arduino, Smart Micro-Grid, Industry 4.0, ICPS, Control and Measurement System.

Abstract: The advantages of open source technology have led to their ever-growing utilization in advanced scenarios

like the Industry 4.0, the Industrial Cyber-Physical Systems (ICPSs) and Smart Grids, among others.

Concerning open source hardware, the platform Arduino receives great attention from academicians,

hobbyists and even industrial practitioners. This paper aims at providing a panoramic overview of recent

scientific literature reporting the use of Arduino in such challenging scenarios, proving its validity for control

and measurement purposes. In addition, the application of such device as part of the equipment to monitor the

operation and development of a Smart Micro-Grid and its digital replica is expounded.

1 INTRODUCTION

The digital transformation that is taking place in

different technological domains is derived from the

penetration and expansion of the Information and

Communication Technologies (ICTs) (Calderón et

al., 2018; González et al., 2019). In the industrial

environment, the Industry 4.0 is a concept of

integration of industry automation, data exchange,

and modern manufacturing technologies (Babiceanu

and Seker, 2016). It is also commonly referred to as

the fourth industrial revolution, as a consequence of

an initiative of the German government (Industrie 4.0

homepage), the Industrie 4.0. The Industry 4.0 era is

envisioned to be implemented through the so-called

Industrial Cyber-Physical Systems (ICPSs), which

enable monitoring and control of industrial physical

processes and bridge the cyber and virtual worlds

(Colombo et al., 2017).

The paradigm of Industry 4.0 involves various

challenging frameworks like the aforementioned

ICPSs, the Industrial Internet-of-Things (IIoT), Big

Data, Cloud Computing, Smart Grids, Smart Cities,

a

https://orcid.org/0000-0001-5645-3832

b

https://orcid.org/0000-0003-2094-209X

c

https://orcid.org/0000-0001-8380-8547

d

https://orcid.org/0000-0003-3531-5486

cyber-security, digital replicas and open-source

technology.

The latter one involves the utilization of hardware

and software with complete availability of

schematics, code, etc., so the user can develop and

customize the solution at deep level. This information

is publicly shared through the Internet and there are

thousands of hobbyists and professionals sharing

their projects. Moreover, commonly open source

systems have low-cost nature. For instance, there are

various single-board micro-controllers available for

less than 20 €. Indeed, most of the open source

software packages are free, promoting their usage.

Hence, open source technology is receiving

increasing attention in last years from scientists and

practitioners in a multitude of different domains. For

instance, the amount of devices within the IoT can be

increased thanks to this type of technology (Fisher et

al., 2015) and open source projects are key

accelerators for the industry adoption of IoT

(Martinez et al., 2017).

At the hardware level, according to Thames and

Schaefer (Thames and Schaefer, 2016), open source

214

Pérez, I., Calderón Godoy, A., Godoy, M. and González, J.

Survey about the Utilization of Open Source Arduino for Control and Measurement Systems in Advanced Scenarios. Application to Smart Micro-Gr id and Its Digital Replica.

DOI: 10.5220/0007830202140220

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 214-220

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

hardware (and its associated open source software) is

envisioned to lead to fast and incremental updates to

hardware platforms in future manufacturing

processes. There are various devices of this type like

Raspberry Pi, BeagleBone, Phidget, Intel Edison and

Arduino. The latter one is an inexpensive single-

board micro-controller (Arduino online) and is

considered as the flagship open source hardware. In

fact, it is a powerful tool to develop different

applications in the arenas of data acquisition,

automation and engineering in general (Calderón et

al., 2016).

Concerning the power scenario, renewable energy

sources are expected to play a vital role in the

mitigation of the greenhouse emissions effects and of

the global warming. Even more, their hybridization

with hydrogen generation and consumption

constitutes an important research field (González et

al., 2017). In particular, Smart Grids (SGs) are the

next generation of power grids, emerging as the

digital transformation applied to the energy industry,

and being an important component of the Industry 4.0

paradigm (Batista et al., 2017). SGs are defined as a

modern electric power grid infrastructure for

improved efficiency, reliability, and safety with

smooth integration of renewable and distributed

energy sources, through automated and distributed

controls and modern communication and sensing

technologies (Kilic and Gungor, 2013). These power

grids are a worthy domain where to apply open source

technology (González et al., 2017).

This paper aims at providing a panoramic survey

of recent scientific literature reporting the use of open

source hardware, namely Arduino, in advanced

technological scenarios, proving its validity for

control and measurement purposes. Indeed, as a

consequence of the benefits associated to open source

technology, its inclusion in Research and

Development (R&D) projects flows in a natural

manner. In this sense, Arduino is being incorporated

within a project dealing with the deployment and

operation of a Smart Micro-Grid and its digital

replica. This will be further commented in section 4.

The rest of the paper is organized as follows. The

second section provides an overview of the main

characteristics of the open source Arduino. Section 3

presents a survey about literature dealing with

Arduino in a number of advanced scenarios. The

application of Arduino for data sensing and

acquisition in the context of research about a Smart

Micro-Grid is reported in the fourth section. Finally,

the main conclusions of the work are addressed.

2 OVERVIEW OF ARDUINO

CHARACTERISTICS

This section is devoted to overview in a brief manner

the most relevant features of the Arduino platform.

Evidently, there is a great amount of information

available in the Internet in this regard, following the

principles of the open source philosophy.

Arduino is essentially a micro-controller mounted

on a board with the circuitry required to connect

sensors and actuators in an easy manner. In other

words, it is an embedded prototyping board designed

for electronics projects that demand repeated

execution of some tasks (Costa and Duran-Faundez,

2018). It must be noted that Arduino is not a micro-

processor/computer like for example Raspberry Pi,

therefore, it has not embedded operating system.

Arduino chips are based on micro-controllers

manufactured by Atmel, mainly of the family

ATmega. It was originally designed and

manufactured in Italy, in a project that started in 2005.

The GNU General Public License (GPL) allows the

manufacture of Arduino boards and software

distribution by anyone.

Some popular models are: Uno, Mega, Yun, Due,

Nano, Duemilanove, Extreme, Lilypad, just to name

a few. Hence, the developer is able to select the model

that fits better the application to deploy. In (Costa and

Duran-Faundez, 2018) a detailed overview and

comparison of different open source platforms,

including Arduino, can be found.

The expansion boards, called shields, provide a

number of enhancements of the Arduino

functionalities and resources. Some examples of

shields are those devoted to data storage through

Secure Digital (SD) cards, Global Positioning System

(GPS) functionality, direct connection of

sensors/actuators, etc. About connectivity options,

there are diverse shields to support communication

means both wired and wireless. Some examples or

wired links are RS-232, RS-485, and Ethernet.

Available wireless means are Bluetooth, WiFi,

ZigBee, Global System for Mobile communications

(GSM), General Packet Radio Service (GPRS), or

Radio Frequency IDentification (RFID). Figure 1

shows the aspect of an Arduino Mega and an Ethernet

shield.

Concerning the software, to program and

configure Arduino chips the open source Integrated

Development Environment (IDE) is freely available.

IDE uses a programming language based on a

simplified version of the C++ language. It runs in a

computer to which the board must be connected via

Universal Serial Bus (USB) communication. This

Survey about the Utilization of Open Source Arduino for Control and Measurement Systems in Advanced Scenarios. Application to Smart

Micro-Grid and Its Digital Replica

215

software allows designing the code for Arduino as

well as to monitor its operation through the serial port

of the computer. It includes a number of in-built

programs to facilitate the learning and development

of the applications.

Figure 1: Physical aspect of an Arduino Mega board and an

Ethernet shield.

Figure 2 shows a screenshot of the IDE with the

code to conduct reading of analogue input signals.

Apart from the IDE, there is an immense amount of

libraries in the Internet that can be used for different

purposes, from configuring an Ethernet connection to

implement fuzzy control algorithms.

Figure 2: Screenshot of the Arduino IDE.

Additionally, some software packages widely

used in scientific and industrial environments like

Matlab or LabVIEW already include communication

options to exchange data with Arduino boards. For

instance, the LabVIEW Interface for Arduino (LIFA)

toolkit enabled the data sharing between a virtual

instrument of LabVIEW and an Arduino board

through an USB connection.

There also exist web pages devoted to store,

visualize and analyse data gathered by Arduino

boards like thingspeak.com, facilitating and

promoting the integration of these boards with cloud

and IoT resources.

Among the advantages of the Arduino, the most

relevant ones are now listed:

Open source nature. Schematics, code and

documentation related to Arduino and to the

associated shields are available in the Internet.

Low-cost components. The boards of Arduino as

well as the shields and sensors/actuators are

inexpensive.

Easy-to-use. The time and effort required to

develop and deploy Arduino-based systems are

shorten due to the abovementioned availability of

information.

Community support. A large amount of tutorials,

forums and videos supports knowledge sharing,

facilitating Arduino-based projects.

New products and software continuously

released. The open source community constantly

increases resources like libraries and shields,

contributing to enhance existent arrangements or

to design novel systems.

3 LITERATURE SURVEY ABOUT

ARDUINO IN ADVANCED

SCENARIOS

In this section, among the ever-increasing literature

dealing with Arduino-based developments, recent

publications devoted to advanced trends like Industry

4.0, cyber-physical approaches and so forth have been

reviewed in order to illustrate the importance and

suitability of Arduino.

In industrial environments, diverse paradigms are

involved, like Industry 4.0, ICPSs, or cyber-

manufacturing, therefore, Arduino boards have been

widely reported as part of these scenarios. To begin

with, it must be noted that Arduino has been

identified as technology for Industry 4.0 and smart

manufacturing by different publications (Trappey et

al., 2017; Akerman et al., 2018; Chiarello et al.,

2018). In (Pisching et al., 2018) an architecture for

Industry 4.0-enabled factories is developed, where

Arduino chips are used in a TCP/IP network. A fog

computing framework for process monitoring and

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

216

prognostics in cyber manufacturing systems is

proposed in (Wu et al., 2017), measuring the

vibrations of rotating machinery through Arduino.

Another case of usage of Arduino for machine status

prediction in the Industry 4.0 era is found in (Kuo et

al., 2017).

Examples of Arduino utilization for ICPSs have

been reported in (García et al., 2016; González-Nalda

et al., 2017; Müller et al., 2017). About robotics,

interesting works dealing with robotics and Arduino

can be found in (Cela et al., 2013; Santos et al., 2016;

Tejado et al., 2016; Lupetti, 2017).

Concerning facilities integrating Renewable

Energy Sources (RES), a number of publications

report the successful applications of Arduino. For

instance, it has been used for data acquisition and

monitoring of hydrogen fuel cells in (Calderón et al.,

2016; Segura et al., 2017; Vivas et al., 2019), of

photovoltaic systems in (Fuentes et al., 2014; Gad and

Gad, 2015; Rahman et al., 2018), for weather sensing

(Morón et al., 2018) or as part of simulation

frameworks (Pagola et al., 2019). A special mention

is devoted to Smart Grids, where Arduino devices

have been used to perform measurement/sensing

tasks (Batista et al., 2014; Pereira et al., 2015; Paul et

al., 2016; Oprea et al., 2018, Raju et al., 2018).

Scenarios closely related to Smart Grids are Smart

Cities and Smart Buildings. In this context, Arduino

has been pointed out as an enabling technology for

developments in Smart Cities (Costa and Duran-

Faundez, 2018), used for the deployment of sensors

in (Trilles et al., 2017). Regarding Smart Buildings,

Arduino has been reported as means for smart energy

metering in (Viciana et al., 2018).

The impact of ICT has enabled the development

of systems that are remotely accessed and managed

through the network. An important example of this

trend is represented by remote laboratories where a

user can visualize and/or operate a physically distant

facility. A number of publications address the

utilization of Arduino boards to implement this type

of laboratories with engineering education orientation

(Prada et al., 2016; Chacón et al., 2017; Heradio et al.,

2019) or for general purposes (Mejías et al., 2017).

Cyber-security is of the utmost importance in the

advanced hyper-connected setups, from modern

manufacturing facilities to smart cities passing

through critical infrastructures like power plants. In

this sense, Arduino chips have been used to study

cyber-security issues for industrial control systems in

(Janicke et al., 2015; Bernieri et al., 2016; Alberca et

al., 2016; Sasaki et al., 2017).

In the context of the so-called digital replicas (a

virtual representation of physical assets), Arduino has

been reported as part of the physical counterpart to

perform measurement of different magnitudes in

(Wei et al., 2017; Choi et al., 2018; Liu et al., 2018;

Vrabic et al., 2018).

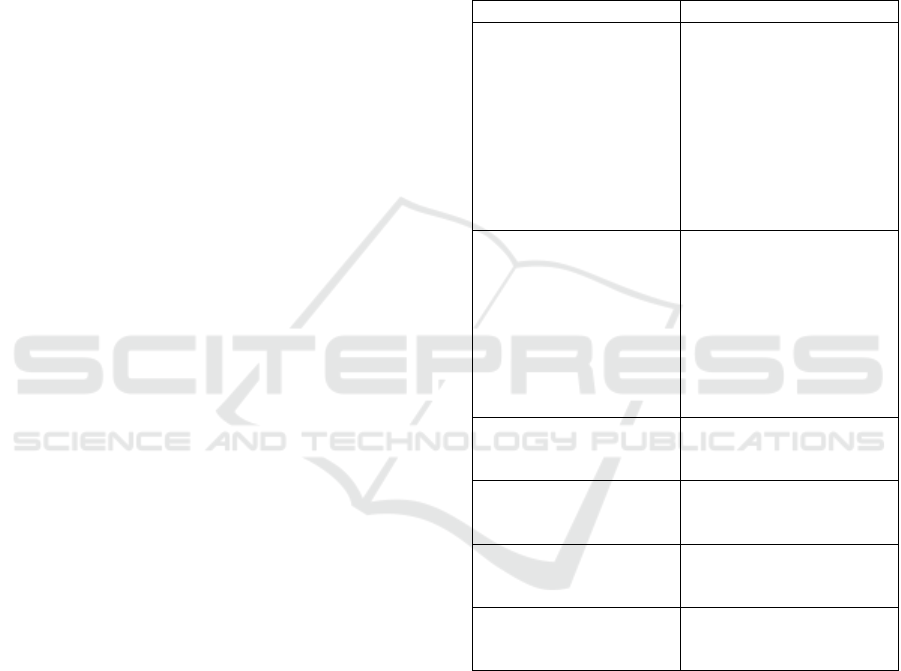

In order to illustrate the existing literature dealing

with Arduino utilization in advanced frameworks,

Table 1 summarizes the abovementioned

publications.

Table 1: Surveyed publications dealing with Arduino and

advanced scenarios.

Scenario Publications

Industry 4.0 and related

trends (ICPS, Robotics,

etc.)

Cela et al., 2013; García et

al., 2016; Santos et al., 2016;

Tejado et al., 2016, Kuo et

al., 2017; González-Nalda et

al., 2017, Müller et al., 2017;

Lupetti et al., 2017; Trappey

et al., 2017; Wu et al., 2017;

Akerman et al., 2018,

Chiarello et al., 2018;

Pischin

g

et al., 2018

RES and Smart Grids

Batista et al., 2014; Fuentes

et al., 2014; Gad and Gad,

2015; Pereira et al., 2015;

Calderón et al., 2016; Paul et

al., 2016; Segura et al., 2017;

Morón et al., 2018; Oprea et

al., 2018; Rahman et al.,

2018; Vivas et al., 2018;

Pa

g

ola et al., 2019

Smart Cities

Trilles et al., 2017; Costa and

Duran-Faundez, 2018;

Viciana et al., 2018

Remote laboratories

Prada et al., 2016; Chacón et

al., 2017; Mejías et al., 2017;

Heradio et al., 2019

Cyber-security

Janicke et al., 2015; Alberca

et al., 2016; Bernieri et al.,

2016, Sasaki et al., 2017

Digital replica

Wei et al., 2017; Choi et al.,

2018; Liu et al., 2018;

Vrabic et al., 2018

On the view of the surveyed publications, it has

been proven that Arduino constitutes a versatile tool

very valuable even for challenging scenarios.

4 APPLICATION OF ARDUINO

IN R&D PROJECT ABOUT

SMART MICRO-GRID

The present work is framed in a research project to

implement a Smart Micro-Grid (SMG) integrating

Survey about the Utilization of Open Source Arduino for Control and Measurement Systems in Advanced Scenarios. Application to Smart

Micro-Grid and Its Digital Replica

217

renewable energy sources with hydrogen and to

develop its digital replica.

SMGs can be defined as small scale SG which can

be autonomous or grid-tied (Koohi-Kamali and

Rahim, 2017). SMGs integrate physical elements in

the power grid and cyber elements (sensor networks,

communication networks, and computation core) to

make the power grid operation effective (Yang et al.,

2016).

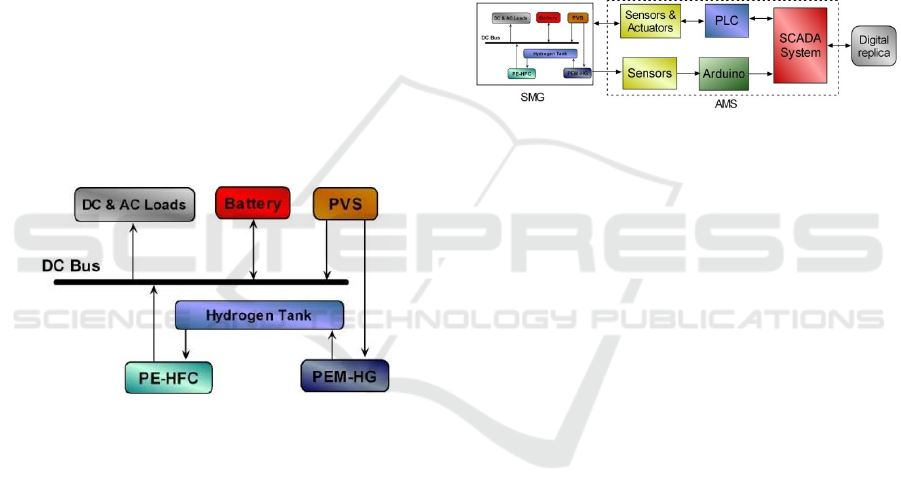

The SMG of the aforementioned project combines

photovoltaic energy and hydrogen

generation/consumption to act as a self-sufficient

eco-friendly energy system. A set of monocrystalline

photovoltaic modules compose the Photovoltaic

Subsystem (PVS). A Polymer Electrolyte Membrane

Hydrogen Generator (PEM-HG) and a Polymer

Electrolyte Membrane Hydrogen Fuel Cell (PEM-

HFC) perform the generation and consumption of

hydrogen respectively. The hydrogen is stored in a

metal hydride tank whereas an electrochemical

battery hosts the electrical flows, playing the role of

DC Bus. Finally, DC and AC loads complete the

micro-grid. A schematic diagram of the SMG is

shown in Figure 3.

Figure 3: Scheme of the SMG.

An Automation and Monitoring System (AMS)

carries out the management and surveillance of the

energy flows and interactions between the nodes of

the SMG. A Programmable Logic Controller (PLC)

and a Supervisory Control and Data Acquisition

(SCADA) system compose the AMS together with an

Arduino board and a number of sensors (temperature,

irradiance, current, voltage, etc.). The implemented

energy control strategy aims to supply the loads and

to produce hydrogen when a surplus of solar energy

is available.

To build the digital replica of the SMG, massive

data gathering is required, so Arduino boards are

considered a valuable tool to implement cost-

effective data acquisition equipment. Therefore,

Arduino is being used to retrieve data which is

considered non-critical for the automation/control

tasks, namely environmental magnitudes like

temperature and relative humidity. In the initial stage,

it is being tested to measure the temperature of one of

the photovoltaic modules through low-cost Lm35

sensors. In a previous stage, the retrieved data were

validated through the comparison with those provided

by a Pt-100 probe placed in the same module.

Particularly, an Arduino MEGA 2560 has been

chosen. It is based on a micro-controller

ATmega2560 and has 54 digital I/O as well as 16

analogue inputs. An Ethernet shield provides Ethernet

connectivity in order to share the sensor

measurements with the monitoring system. Such a

system is based in the package LabVIEW of National

Instrument and is responsible of gathering, processing

and representing the operational data of the SMG.

The structure of the AMS is depicted in Figure 4.

Figure 4: Block diagram of the AMS for the SMG.

5 CONCLUSIONS

The presence of open source systems in technological

frameworks is growing day by day. In particular,

open source hardware Arduino has become a

powerful environment to accomplish control and

measurement tasks. This paper has presented a

literature survey about recent applications of this

open source device in advanced scenarios like those

related to Industry 4.0, ICPSs, and so forth, in order

to show its suitability.

Regarding the digital transformation of the power

grids, Smart Grids, Arduino is being also successfully

used. Therefore, its inclusion in an on-going R&D

project about a SMG and its digital replica has been

expounded. Future guidelines aim to the development

of a data acquisition system based on Arduino for

massive data gathering in the SMG.

ACKNOWLEDGEMENTS

This research has been funded by the project IB18041

supported by the Junta de Extremadura in the VI Plan

Regional de I+D+i (2017-2020), co-financed by the

European Regional Development Funds FEDER

(Programa Operativo FEDER de Extremadura 2014–

2020).

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

218

Authors are grateful to the community that

supports Arduino-based developments under open

source philosophy.

REFERENCES

Akerman, M., Fast-Berglund, A., Halvordsson, E., Stahre,

J. Modularized assembly system: A digital innovation

hub for the Swedish Smart Industry. Manufacturing

Letters 2018, 15, 143-146.

Alberca, C., Pastrana, S., Suarez-Tangil, G., Palmieri, P.,

2016. Security analysis and exploitation of arduino

devices in the internet of things. ACM International

Conference on Computing Frontiers, Como, Italy.

Arduino Online. Available: www.arduino.cc (accessed on

30 January 2019)

Babiceanu, R.F., Seker, R., 2016. Big Data and

virtualization for manufacturing cyber-physical

systems: A survey on the current status and future work.

Computers in Industry, vol. 81, pp. 128-137.

Batista N.C., Melício R, Mendes V.M.F., 2014. Layered

Smart Grid architecture approach and field tests by

ZigBee technology. Energy Conversion and

Management, vol. 88, pp. 49–59.

Batista, N.C., Melício, R., Mendes, V.M.F., 2017. Services

enabler architecture for smart grid and smart living

services providers under industry 4.0. Energy and

Buildings, vol. 141, pp. 16-27.

Bernieri, G., Del Moro, F., Faramondi, L., Pascucci, F.,

2016. A testbed for integrated fault diagnosis and cyber

security investigation. International Conference on

Control, Decision and Information Technologies

(CoDIT), St. Julian's, Malta.

Calderón, A.J., González, I., Calderón, M., Segura, F.,

Andújar, J.M., 2016. A New, Scalable and Low Cost

Multi-Channel Monitoring System for Polymer

Electrolyte Fuel Cells. Sensors, vol. 16(3), pp. 349.

Calderón Godoy, A.J., González Pérez, I., 2018. Integration

of Sensor and Actuator Networks and the SCADA

System to Promote the Migration of the Legacy

Flexible Manufacturing System towards the Industry

4.0 Concept. Journal of Sensor and Actuator Networks,

vol. 7, pp. 23.

Cela, A., Yebes, J.J., Arroyo, R., Bergasa, L.M., Barea, R.,

López, E., 2013. Complete low-cost implementation of

a teleoperated control system for a humanoid robot.

Sensors, vol. 13(2), pp. 1385-1401.

Chacón, J., Saenz, J., de la Torre, L., Diaz, J.M.,

Esquembre, F., 2017. Design of a Low-Cost Air

Levitation System for Teaching Control Engineering.

Sensors, vol. 17, pp. 2321.

Chiarello, F., Trivelli, L., Bonaccorsi, A., Fantoni, G.,

2018. Extracting and mapping industry 4.0

technologies using Wikipedia. Computers in Industry,

100, 244-257.

Choi, J., Jang, I., Lee, D., Son, Y., 2018. A virtual twinning

system for user-centered eidetic human-object

interaction. IEEE International Conference on

Consumer Electronics (ICCE), Las Vegas, NV, USA.

Colombo, A.W., Karnouskos, S., Kaynak, O., Shi, Y., Yin,

S., 2017. Industrial Cyberphysical Systems. A

Backbone of the Fourth Industrial Revolution. IEEE

Industrial Electronics Magazine, vol. 11(1), pp. 6-16.

Costa, D.G., Duran-Faundez, C., 2018. Open-Source

Electronics Platforms as Enabling Technologies for

Smart Cities: Recent Developments and Perspectives.

Electronics, vol. 7, pp. 404.

Fisher, R., Ledwaba, L., Hancke, G., Kruger, C., 2015.

Open Hardware: A Role to Play in Wireless Sensor

Networks? Sensors, vol. 15, pp. 6818-6844.

Fuentes, M., Vivar, M., Burgos, J.M., Aguilera, J., Vacas,

J.A., 2014. Design of an accurate, low-cost autonomous

data logger for PV system monitoring using Arduino™

that complies with IEC standards. Solar Energy

Materials & Solar Cells, vol. 130, pp. 529-543.

Gad, H.E., Gad, H.E., 2015. Development of a new

temperature data acquisition system for solar energy

applications. Renewable Energy, vol. 74, pp. 337-343.

García, M.V., Irisarri, E., Pérez, F., Estévez, E., Marcos,

M., 2016. OPC-UA Communications Integration using

a CPPS architecture. IEEE Ecuador Technical

Chapters Meeting, Guayaquil, Ecuador.

González, I., Calderón, A.J., Andújar, J.M., 2017. Novel

Remote Monitoring Platform for RES-Hydrogen based

Smart Microgrid. Energy Conversion and

Management, vol. 148, pp. 489-505.

González, I., Calderón, A.J., Figueiredo, J., Sousa, J.M.C.,

2019. A Literature Survey on Open Platform

Communications (OPC) Applied to Advanced

Industrial Environments. Electronics, vol. 8, pp. 510.

González-Nalda, P., Etxeberria-Agiriano, I., Calvo, I.,

Otero, M.C., 2017. A modular CPS architecture design

based on ROS and Docker. International Journal on

Interactive Design and Manufacturing, vol. 11(4), pp.

949-955.

Heradio, R., Chacón, J., Vargas, H., Galán, D., Saenz, J.,

De La Torre, L., Dormido, S., 2019. Open-Source

Hardware in Education: a Systematic Mapping Study.

IEEE Access, In press.

Industrie 4.0 homepage. Available: http://www.plattform-

i40.de/I40/Navigation/EN/Home/home.html (accessed

on 25 January 2019)

Janicke, H., Nicholson, A., Webber, S., Cau, A., 2015.

Runtime-Monitoring for Industrial Control Systems.

Electronics, vol. 4(4), pp. 995-1017.

Kilic, N., Gungor, V.C., 2013. Analysis of low power

wireless links in smart grid environments. Computer

Networks, vol. 57, pp. 1192–1203.

Koohi-Kamali, S., Rahim, N.A., 2017. Coordinated control

of smart microgrid during and after islanding operation

to prevent under frequency load shedding using energy

storage system. Energy Conversion and Management,

vol. 127, pp. 623–646.

Kuo, C.J., Ting, K.C., Chen, Y.C., Yang, D.L., Chen, H.M.,

2017. Automatic machine status prediction in the era of

Industry 4.0: Case study of machines in a spring

Survey about the Utilization of Open Source Arduino for Control and Measurement Systems in Advanced Scenarios. Application to Smart

Micro-Grid and Its Digital Replica

219

factory. Journal of Systems Architecture, vol. 81, pp.

44-53.

Lupetti, M.L., 2017. Shybo. An open-source low-

anthropomorphic robot for children. HardwareX, vol.

2, pp. 50-60.

Liu, C., Xu, X., Peng, Q., Zhou, Z., 2018. MTConnect-

based Cyber-Physical Machine Tool: a case study.

Procedia CIRP, vol. 72, pp. 492-497.

Martinez, B., Vilajosana, X., Kim, I.H., Zhou, J., Tuset-

Peiró, P., Xhafa, A., Poissonnier, D., Lu, X., 2017.

I3Mote: An Open Development Platform for the

Intelligent Industrial Internet. Sensors, vol. 17, pp. 986.

Mejías, A., Reyes, M., Márquez, M.A., Calderón, A.J.,

González, I., Andújar, J.M. 2017. Easy handling of

sensors and actuators over TCP/IP Networks by Open

Source Hardware/Software. Sensors, vol. 17, 94, 2017.

Morón, C., Diaz, J.P., Ferrández, D., Saiz, P., 2018. Design,

Development and Implementation of a Weather Station

Prototype for Renewable Energy Systems. Energies,

vol. 11, pp. 2234.

Müller, M., Wings, E., Bergmann, L., 2017. Developing

Open Source Cyber-Physical Systems for Service-

Oriented Architectures Using OPC UA. IEEE 15th

International Conference on Industrial Informatics

(INDIN), Emden, Germany.

Oprea, S.-V., Bâra, A., Uță, A.I., Pîrjan, A., Căruțașu, G.,

2018. Analyses of Distributed Generation and Storage

Effect on the Electricity Consumption Curve in the

Smart Grid Context. Sustainability, vol. 10, pp. 2264.

Pagola, V., Peña, R., Segundo, J., Ospino, A., 2019. Rapid

Prototyping of a Hybrid PV–Wind Generation System

Implemented in a Real-Time Digital Simulation

Platform and Arduino. Electronics, vol. 8, pp. 102.

Paul, S., Parajuli, A., Barzegaran, M.R., Rahman. A., 2016.

Cyber physical renewable energy microgrid: A novel

approach to make the power system reliable, resilient

and secure. IEEE Innovative Smart Grid Technologies,

Melbourne, VIC, Australia.

Pereira, R., Figueiredo, J., Melicio, R., Mendes, V.M.F.,

Martins, J., Quadrado, J.C., 2015. Consumer energy

management system with integration of smart meters.

Energy Reports, vol. 1, pp. 22-29.

Pisching, M.A., Pessoa, M.A.O., Junqueira, F., Filho, D.J.,

Miyagi, P.E., 2018. An architecture based on RAMI 4.0

to discover equipment to process operations required by

products. Computers and Industrial Engineering, vol.

125, pp. 574-591.

Prada, M.A., Reguera, P., Alonso, S., Morán, A., Fuertes,

J.J., Domíngez, M., 2016. Communication with

resource-constrained devices through MQTT for

control education. IFAC-PapersOnLine, vol. 49(6), pp.

150-155.

Rahman, M.M., Selvaraj, J., Rahim, N.A., Hasanuzzaman,

M., 2018. Global modern monitoring systems for PV

based power generation: A review. Renewable and

Sustainable Energy Reviews, vol. 82(3), pp. 4142-4158.

Raju, L., Morais, A.A., Milton, R.S., 2018. Advanced

Energy Management of a Micro-grid Using Arduino

and Multi-agent System. Lecture Notes in Electrical

Engineering, vol. 446, pp. 65-76.

Santos, D., Silva Junior, A.G., Negreiros, A., Vilas Boas,

J., Alvarez, J., Araujo, A., Aroca, R.V., Gonçalves,

L.M.G., 2016. Design and Implementation of a Control

System for a Sailboat Robot. Robotics, vol. 5, pp. 5.

Sasaki, T., Sawada, K., Shin, S., Hosokawa, S., 2017.

Fallback and Recovery Control System of Industrial

Control System for Cybersecurity. IFAC-

PapersOnLine, vol. 50, pp. 15247-15252.

Segura, F., Bartolucci, V., Andújar, J.M., 2017.

Hardware/Software Data Acquisition System for Real

Time Cell Temperature Monitoring in Air-Cooled

Polymer Electrolyte Fuel Cells. Sensors, vol. 17(7), pp.

1600.

Tejado, I., Serrano, J., Pérez, E., Torres, D., Vinagre, B.M.,

2016. Low-cost Hardware-in-the-loop Testbed of a

Mobile Robot to Support Learning in Automatic

Control and Robotics. IFAC-PapersOnLine, vol. 49(6),

pp. 242-247.

Thames, L., Schaefer, D., 2016. Software-defined Cloud

Manufacturing for Industry 4.0. Procedia CIRP, 52, 12-

17.

Trappey, A.J.C., Trappey, C.V., Govindarajan, U.H.,

Chuang, A.C., Sun, J.J., 2017. A review of essential

standards and patent landscapes for the Internet of

Things: A key enabler for Industry 4.0. Advanced

Engineering Informatics, vol. 33, pp. 208-229.

Trilles, S., Calia, A., Belmonte, O., Torres-Sospedra, J.,

Montoliu, R., Huerta, J., 2017. Deployment of an open

sensorized platform in a smart city context. Future

Generation Computer Systems, vol. 76, pp. 221-233.

Viciana, E., Alcayde, A., Montoya, F.G., Baños, R.,

Arrabal-Campos, F.M., Zapata-Sierra, A., Manzano-

Agugliaro, F., 2018. OpenZmeter: An Efficient Low-

Cost Energy Smart Meter and Power Quality Analyzer.

Sustainability, vol. 10, pp. 4038.

Vivas, F.J., Heras, A., Segura, F., Andújar, J.M., 2019. Cell

voltage monitoring All-in-One. A new low cost

solution to perform degradation analysis on air-cooled

polymer electrolyte fuel cells. International Journal of

Hydrogen Energy, In press.

Vrabic, R., Erkoyuncu, J.A., Butala, P., Roy, R., 2018.

Digital twins: Understanding the added value of

integrated models for through-life engineering services.

Procedia Manufacturing, vol. 16, pp. 139-146.

Wei, C.-C., Lee, Y, Cao, K.S., Lee, W., 2017.

Implementation of a data acquisition system for

heterogeneous machines. IEEE/SICE International

Symposium on System Integration (SII), Taipei,

Taiwan.

Wu, D., Liu, S., Zhang, L., Terpenny, J., Gao, R.X.,

Kurfess, T., Guzzo, J.A., 2017. A fog computing-based

framework for process monitoring and prognosis in

cyber-manufacturing. Journal of Manufacturing

Systems, vol. 43, pp. 25-34.

Yang, Q., An, D., Yu, W., Tan, Z., Yang, X. Towards

Stochastic Optimization-Based Electric Vehicle

Penetration in a Novel Archipelago Microgrid. Sensors

2016, vol. 16, pp. 907.

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

220