Software 2.0 for Scrap Metal Classification

Manuel Robalinho

1 a

and Pedro Fernandes

2 b

1

Portucalense University Infante D. Henrique, Dr. Ant

´

onio Bernardino de Almeida 541, Porto, Portugal

2

ISR-UC - Institute of Systems and Robotics, University of Coimbra, Coimbra, Portugal

Keywords: Software 2.0, Scrap Metal Classification, Spectral Images.

Abstract:

Software 2.0 and its approach to the processing of multi-spectral images helping to perform an automatic clas-

sification of metal scrap is the subject of this research. The use of Machine Learning and Deep Learning tools

contribute to the development of intelligent systems, allowing to achieve relevant results in the classification

of images, particularly of metal scrap. In this research, tests will be performed with a multi-spectral chamber

to obtain images of aluminum, iron, copper, brass, stainless steel, simulating an environment of metal scrap.

The aim is to obtain the classification of these metals through the development of software and to perform a

multi-spectral analysis of the obtained images. Preliminary tests were made in a controlled environment, with

a small sample of these materials. Studies to implement a prototype in a Brazilian steel industry will follow.

1 INTRODUCTION

Steel is the world’s most important engineering and

construction material. It is used in every aspect of our

lives. There are more than 3,500 different grades of

steel with many different physical, chemical, and en-

vironmental properties. The European environmen-

tal initiative on raw materials (Parliament and Coun-

cil, 2003) has recently promoted the efforts in recy-

cling and recovery of metal alloys. Recycling of scrap

plays an important role in the conservation of energy

because the remelting of scrap requires much less en-

ergy than the production of iron or steel products from

iron ore (Javaid and Essadiqi, 2003).

In Brazil, the collection of recyclable metal ma-

terials is carried out by a fleet of about 15 thousand

trucks throughout the country. There are 1.5 million

people directly and indirectly involved in the collec-

tion, selection, preparation and distribution of recy-

clable metal materials, including in this total 800,000

pickers (Vasques, 2009).

The objective of this work is the research of spec-

tral images of scrap steel to perform an efficient clas-

sification using Machine Learning techniques. One

of the goals is to facilitate a current visual and time-

consuming human work, with many classifications

that are dependent on personnel and fallible apprecia-

a

https://orcid.org/0000-0001-9063-4258

b

https://orcid.org/0000-0002-1260-9820

tion only.

Each year, U.S. industry discards tens of billions

of pounds of non-ferrous metals as waste because it

is either impractical or uneconomical to recover this

material using current technology. Many alloys are

downgraded in value due to contamination that can-

not be cost effectively removed. In addition, bil-

lions of pounds of non-ferrous metals are shipped

overseas to China and elsewhere, for separation into

higher value scrap grades using low cost labor for vi-

sual identification and hand sort. Traditionally, metals

businesses, including recycling, are slow in adopting

new technologies. There are ongoing projects in US

to transform this industry, by replacing old methods

of manual selection and visual identification by fully

automated, high-efficiency methods using computers,

robotics, and other automation systems for material

handling. This will have positive effects throughout

the entire scrap industry chain. Scrap recyclers will

be able to monetize the scrap value with a better and

faster rating. The industries that use it, will be able

to profit from the greater availability and quality of

scrap, which will bring more competitive prices in the

market. It is these reasons that lead government agen-

cies in the United States, such as the National Insti-

tute of Standards and Technology (NIST) and the Na-

tional Science Foundation (NSF) to develop new tech-

nologies aimed at advancing scrap processing tech-

666

Robalinho, M. and Fernandes, P.

Software 2.0 for Scrap Metal Classification.

In Proceedings of the 16th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2019), pages 666-673

ISBN: 978-989-758-380-3

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

nology. Projects in this scope developed Spectramet

1

,

a platform of technologies for rapid identification that

allows the unambiguous separation of non-ferrous

mixed scrap according to the type of alloy (Spencer,

2005).

Steel is 100% recyclable, making it one of the

most sustainable materials in the world. Even a sheet

totally taken by the rust can be sent to processing

in a steel mill gaining new possibilities of use (Za-

parolli, 2014). Thus, recycling scrap iron and steel

has remarkable economic and environmental advan-

tages. The example of the steel industry is not unique,

similar figures can be obtained with other materials,

whether metallic or not. However, given its impor-

tance in the Brazilian economy, the values related to

the steel industry really impress.

Recycling of scrap in new iron and steel products

is advantageous, because in order to obtain a metal-

lic product from iron ore (iron oxide) it is necessary

to react it at high temperatures with coal, which in

general removes the oxygen and isolates iron. This

process has a very high energy expenditure, since it

is necessary that certain regions of the furnace reach

more than 2,000 degrees Celsius, the process gen-

erates many gases, particulates, solid wastes (called

slag) and pig iron in liquid form. In order to produce

steel from scrap, in general terms it is only necessary

to melt the scrap (close to the same 2,000 degrees

Celsius) and to correct the composition. These are

relevant arguments in that recycling is much more ad-

vantageous, in relation to the production of the same

material from iron ore, considering the consumption

of raw material, generation of solid waste and gaseous

effluents, necessity (usually for cooling, washing and

heat treatment) and energy expenditure. Regarding

this latest point, the energy expenditure, it is esti-

mated that to make a kilogram of metal from the

scrap, only 2/3 of all the energy that is consumed in

the manufacture of a kilogram of steel from the ore

is needed. Other interesting points are that recycling

of scrap produces only 3% of the particulate matter

and 30% of the solid waste that is produced with the

production of steel from the ore, not counting very

interesting gains in the gaseous emissions of nitroge-

nous and sulfur compounds, as well as simpler liquid

effluents to be treated (Mancini, 2013).

Scrap iron arrives at steel mills in a large trucks,

with cargo well accommodated, which makes it diffi-

cult to classify the cargo visually. Usually the heavy

scrap is placed down and the small and mixed scrap

1

The initial system is located at Spectramet’s techni-

cal research center in Greenfield, Mass., and will be ded-

icated to processing mixed non-ferrous metals from various

sources.

is placed over, for reasons of load optimization. This

makes it difficult to verify the type of scrap shipped

and the type of material that is below the visible

load. In addition, purely personal and financial fac-

tors can influence the people who make the classifi-

cation, leading to financial losses in the acquisition

of scrap. It is intended that this task of classification

be optimized in time and credibility, so that financial

gains are obtained and improve the quality of the clas-

sification and separation of metallic scrap. Machine

Learning

2

(ML) techniques will be studied, using im-

ages to obtain classification parameters that will help

to classify metals. The application in the steel indus-

try was taken into account both in the classification

of the discharge of metal scrap acquisitions and in the

preparation of scrap production, for use in the produc-

tion of iron ingots.

The use of ML techniques for multi-spectral im-

ages is being used, due to the high cost of hyper-

spectral equipment. Although hyper-spectral equip-

ment has valuable information in the images they pro-

duce, in most cases of study and implementation it is

difficult to create proofs of concept, taking into con-

sideration the price of the equipment. Also in the case

of iron scrap materials, the issue of industrial secrecy

creates legal obstacles to accessing images and infor-

mation on similar projects, which are developed in

other universities and research centers.

In a steel environment, there is a great need for

correct sorting of scrap. The incorrect classification

impairs the quality of the steel production, since it is

cheaper to produce steel from scrap, the scrap should

also be of good quality and with the quantities of suit-

able ferrous steel. In a steel production the incorrect

selection of materials to go to the production of the

pig iron can bring danger of explosion.

2 RELATED WORK

The author (Andrej Karpathy, 2018), a research sci-

entist at OpenAI

3

, was the first that use the term Soft-

ware 2.0 on November 2017.

(Sikka, 2018) describes Sotware 2.0 as using the

concepts of programming, mathematics, and statistics

to develop the concept of ML, and put the machine

into large-data reasoning. The results are presented

2

Machine Learning is a field of computer science that

uses statistical techniques to give computer systems the

ability to ”learn” with data, without being explicitly pro-

grammed.

3

OpenAI is a non-profit AI research company, discov-

ering and enacting the path to safe artificial general intelli-

gence.

Software 2.0 for Scrap Metal Classification

667

as predictive behaviours of a given set of data, and

can combine multiple characteristics, making it supe-

rior to human reasoning. This is the concept of ML

as the basis of Software 2.0 and differs from the cur-

rent standard in an important way: it is cantered on

weights of neural networks

4

, not explicit algorithms.

According to (Andrej Karpathy, 2018), neural net-

works are not just another classifier, they represent the

beginning of a fundamental shift in how we write soft-

ware. They are Software 2.0. The same author states

that Software 2.0 platforms, must have a great devel-

opment in the coming years, since their goal is not to

replace but improve processes that the human being

develops, or processes of analysis where the human

being can’t perceive the result, in cause of their com-

plexity.

The author (Andrej Karpathy, 2018) says that, per-

haps it is this human inability to understand some of

the results made available by this Software 2.0 tech-

nology, which is its main disadvantage, according to

the author, because in the event of system failure, it

is presented as a ”silent failure” that may also not be

noticeable to the human being and to provoke a catas-

trophe without culprits.

According to (Domingos, 2015), we live in the

age of algorithms. Few years ago, mentioning the

word algorithm would have drawn a blank from most

people. The same thing would happen to AI

5

, who

scarcely a few years ago frightened the citizen and

the businessmen, with the presumption that AI would

put the machines in command of the Earth.

According to the same author, it is necessary for

people to be aware of ML, so that this learning of the

computers will serve them, for me to decide and not

others to decide for me.

The authors (Wilson et al., 2019), say that the re-

cycling industry has been slow to adopt automated

methods of sorting such metallic scraps. How-

ever, with the advent of hyper-spectral cameras and

robotic-based picking and sorting methods, such pro-

cedures can now be performed automatically, reliev-

ing workers of laborious tasks while at the same time

improving the efficiency of sorting metallic alloys.

Since the automation process is more effective, scrap

providers can produce more recycled material thus in-

crease their profitability. According to the same au-

thors, using automated systems, 40-50% of the steel

that comes from recycled material and 30% of other

metals can be sorted by magnetic drums or induction

4

Artificial neural networks (ANN) are computing sys-

tems inspired by the biological neural networks that consti-

tute human brains.

5

AI, in computer science is artificial intelligence.

or Eddy current separators

6

, respectively. One of the

greatest challenges in developing more sophisticated

systems is sorting various non-ferrous metals such as

aluminum, copper, silver, brass, lead, stainless steel,

silver and gold.

A project that implement this concepts, was de-

scribed by (Barnab

´

e et al., 2015). The project uses

spectral imaging to scrap classification and was ref-

erenced to the conception of a prototype combining

two hyper spectral cameras, one ranging from vis-

ible to near-infra-red and the other covering short-

wave infra-red, is presented. The prototype aims at

the characterization of millimetre sized metallic al-

loys particles, originating from end-of-life vehicles

and waste electrical and electronic equipment recy-

cling.

Another work was published in a paper by (Ku-

tila et al., 2005) and presents a novel automatic scrap

metal sorting system which employs a colour vision

based optical sensing system and an inductive sensor

array sensor array.

Recently in 2017, the work in PICK-IT project,

about Hyper spectral imaging in the VNIR

7

, devel-

oped by a team, and described by (Braibant et al.,

2017), has nevertheless proven to be an efficient tech-

nique to identify aluminum, zinc, copper, brass al-

loys and stainless steel. The same authors, describes

an Hyper-spectral imaging in the VNIR has never-

theless proven to be an efficient technique to iden-

tify aluminum, zinc, copper, brass alloys and stainless

steel (e.g., Barnab

´

e et al., 2015, Kutila et al., 2005).

The efficiency of hyper-spectral classification how-

ever depends on the surface conditions of the alloy

fragments.

At USA, (Paul, Torek; Benjamin, Aubuchon;

Kalyani, 2016) patented in 2016 a system and a

method of sorting scrap particles, which includes

imaging a moving conveyor containing scrap particles

using a vision system to create an image. A computer

analyzes the image as a matrix of cells, identifies cells

in the matrix containing a particle, and calculates a

color input for the particle from a color model by de-

termining color components for each cell associated

with the particle.

6

Eddy current separator, it’s a parasitic chain separa-

tor uses a powerful magnetic field to separate non-ferrous

metals from the waste after all ferrous metals have been re-

moved earlier by some magnet arrangement.

7

The visible and near-infrared (VNIR) portion of the

electromagnetic spectrum has wavelengths between ap-

proximately 400 and 1400 nanometers (nm).

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

668

3 BACKGROUND, MATERIALS

AND METHODS

In the experiments already carried out, the materi-

als used were aluminum, brass, copper, iron, stain-

less steel and painted iron materials to obtain multi-

spectral images. For the analysis of these multi-

spectral images, ML techniques were used, imple-

mented with Python programming in the Anaconda

platform. The images were obtained during the study

design in different light conditions and distance for

the photographed materials. The batches of images

were cataloged according to the conditions of their

obtaining.

3.1 Background

This study is based on multi-spectral image analysis

techniques, applying a ML process that allows the ob-

tention of marks that help making the classification of

metals. Some of the techniques tested are the analysis

of the RGB

8

band length, the color and the histogram

of the image. The transformation of the image into

matrix form, allows the use of multiple enhancement

techniques, for improving image quality, such as:

- Contrast stretch;

- Density slicing;

- Edge enhancement;

- Spatial filtering;

- Noise reduction;

- Improve contrast image;

- Extract RGB information;

- Removing background;

- Image histogram information.

A multi-spectral image of the used materials is a set

of several monochrome images of the same material,

each obtained with a different sensor. Each image is

referred to as a band RGB. A multi-spectral image is

an RGB color image that is composed of a R-red, G-

green, and B-blue image each obtained with a sensor

sensitive to a different wavelength.

All single-band imaging operations can also be

applied to multi-spectral images by processing each

band separately. Using the matrix of a multi-spectral

image, we can detect the edges on each band to ex-

tract an image from each band. If we want to go back

to the original image, we simply assemble three im-

ages using mathematical calculation of the matrices

that make up each image.

The transformation of the RGB bands of an im-

age into matrices and lists allows an approach with

8

RGB is the acronym of the additive color system

formed by the initials of the colors Red, Green and Blue.

ML, and the differences between the spectral bands

of the different materials can be exploited mathemati-

cally. Several libraries available for image processing

allow an exploration at the level of the representative

matrices of an image, its color and the reflectance as

exposed to the incidence of light. Some of the ap-

plied techniques are of marking objects in the images

and extraction so that the analysis is not influenced by

noise.

To explore the additional information that is con-

tained in the various bands, we must consider the im-

ages as a multi-spectral image and not as a set of

monochromatic gray scale images. The overall goal

of image sorting is to categorize automatically all pix-

els of an image in classes. The multi-spectral data

are used to perform the classification and spectral pat-

tern within the data for each pixel is used as the nu-

merical basis for categorization. The different types

of resources manifest different combinations of num-

bers based on in their inherent spectral reflectance and

emission properties.

3.2 Materials

The used equipment is a multi-spectral machine,

ADC Lite (COMPUTAR, 2009), which is a

lightweight (198 grams) version of ADC Air Cam-

era. The camera and its accompanying software,

PixelWrench2, is used to capture and process multi-

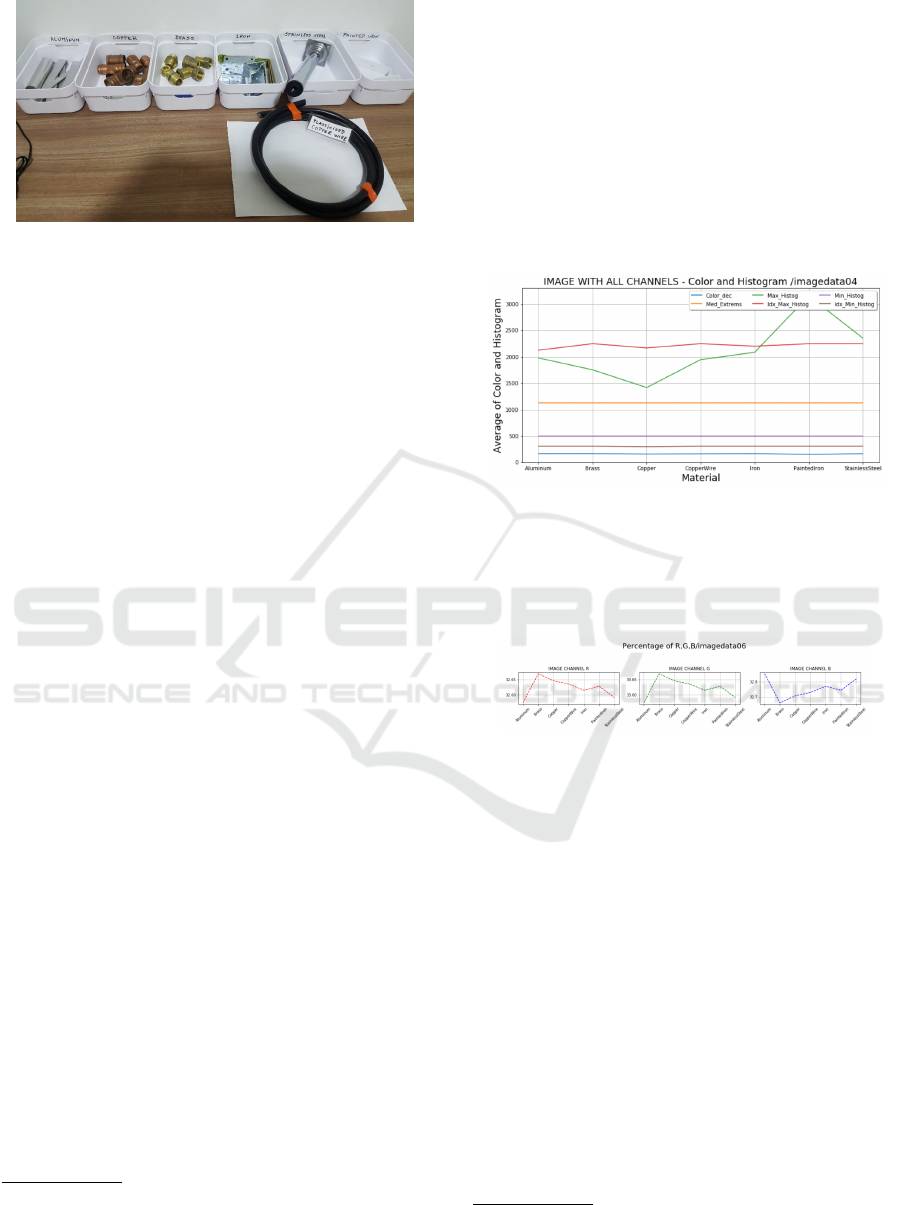

spectral images. The Figure 1 has the equipment used.

Figure 1: Equipment used in the tests.

The equipment can be used manually or coupled

to a drone to obtain the images in an outdoor environ-

ment, as with industrial scrap. The method used con-

sists of capturing images in a controlled lighting envi-

ronment and to clean the artefacts used in the images.

The chosen materials were iron, copper, brass, alu-

minum, stainless steel and copper wire. These mate-

rials represent metallic materials, which must be sep-

arated from the scrap yard in a steel industry. The

workbench is presented bellow, at Figure 2.

The Anaconda framework was installed to use

Software 2.0 for Scrap Metal Classification

669

Figure 2: Working environment and samples of metallic

material.

Jupyter with Python programming. The exploration

of the bands of the images focuses on the analysis of

the matrices of the images, in order to obtain clas-

sification parameters for the different materials. An-

other approach could be to use Google’s Collabora-

tory, which provides a Python virtual machine in the

cloud and can also use the GPU’s

9

environment.

Applied techniques used need Python libraries in-

stalled, such as: Pillow, Opencv, Openpyxl, Color-

math, Webcolors, Numpy and Matplotlib, provide a

set of facilities that allow us to analyse different issues

and compose a specific approach to each problem.

3.3 Methods

For the study, several photos of all materials were

generated and stored in separate folders, identified

by each type of conditions of image acquisition. In

each batch of images, the following conditions were

changed: the lighting conditions, background image

of the place where the images were taken and the dis-

tance between the camera and the materials. The im-

ages are generated in TIF

10

format and converted to

other formats using the PixelWrench2 software, pro-

vided with the Tetracam machine.

All the images were classified according to the

type of material, so as to be able to have a database

of multi-spectral images, that can be used in future

ML processing.

A Python program was developed to read all im-

ages from a folder and submit each image to various

techniques, to retrieve image characterization infor-

mation. Following are examples of information ob-

tained:

- Extract each channel image;

- Maximum and minimum histogram values;

- Histogram plotting;

- Spatial filtering;

9

GPU, Graphics Processing Unit.

10

Tagged Image File Format (TIFF) is a standard file for-

mat used in the publishing and printing industry.

- Contrast stretch;

- Edge enhancement;

- Removing Background;

- Extract RGB information;

- Obtain delta from colors;

- Most common colors;;

- Image histogram information;

- Extremes from each band spectrum.

This information is stored in a Pandas DataFrame

table, for each analysed image. Some information

from the table, are printed in Figures 3 and 4.

Figure 3: Plot the information about materials.

Classifications can be obtained by combining sev-

eral parameters and are stored in a database. This

database will be the basis of the training system for

future classifications.

Figure 4: Analysis from image material bands.

After its processing, the information in the Pan-

das

11

table is stored in a database, and will serve as

a basis for ML processing the information about the

analysed materials. Figure 5 presents the database.

4 ANALYSIS AND DISCUSSION

The techniques studied address several problems of a

steel environment: materials that are in dispersed po-

sitions and in external environments, influence of the

luminosity, image noise caused by the external envi-

ronment, or by the factory floor, painted or dirty ma-

terial and material with a lot of reflectance normally

shown for example in stainless steel.

For suppressing images and background colors,

and also suppressing colors in the environment where

11

Pandas is a software library written for the Python pro-

gramming language

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

670

Figure 5: Database obtained by automatic processing of images with Python.

Figure 6: Image noise removal technique using brass.

the images are obtained, there are some issues resul-

tant from changes on each environment. As an exam-

ple, the influence of the floor colors of the scrap yard

must be configured in the system to be disregarded

from the analysis. Some of this techniques are pre-

sented in Figures 6 and 7.

Figure 7: Techniques for area detection for copper metal

analysis.

The use of mathematical computations in multi-

spectral array of images is a process that demands

a lot of computer power in terms of processing and

memory. One approach was to use Google’s Colabo-

ratory, with the project using the cloud and the GPU

provided in that environment. The transfer of images

between the source environment and the cloud should

be scoped, because the large amount of information in

the images generates a large volume of data traffic to

the cloud. Another approach is to install the software

on a computer with a fair amount of memory and pro-

cessing power and with a performant GPU. This was

the approach used in the study. This facilitated the

handling of images in large quantities and with the

required speed, in terms of what is expected in the

implementation of the prototype.

The similarity of color between various materials

and the perception of color noise to the surrounding

area, needs algorithms that make a tolerance in the

color detected. The algorithm implements a color dif-

ference to understand which it is the color sought.

Colormath libraries provide features that allow us to

work in this area using Python. In this case the

conversion between color formats, decimal and other

forms of expression require functions developed us-

ing mathematical expressions with Numpy Python li-

braries. Normally we do not look for a fixed form of

the spectrum, but an approximate color. That depends

on the conditions of luminosity in which the images

were obtained and the level of dirt of the materials.

In a first step, the image was submitted to tech-

niques that improves contrast. Contrast stretching or

normalization, is one such operation applied on im-

ages, which improves the contrast of the image so that

the details present in the image can be clearly seen.

See Figure 8, produced with this technique.

Figure 8: Contrast enhancement technique for better image

analysis.

After that step, we extract the analysis area in an

image, detecting its contours, extracting the relevant

Software 2.0 for Scrap Metal Classification

671

part, thus removing the influence of its background.

This technique makes up Edge Enhancement, that de-

lineates the edges surrounding various objects of in-

terest and makes the shapes and details comprising the

image more conspicuous and perhaps easier to anal-

yse. Figure 9 presents this technique.

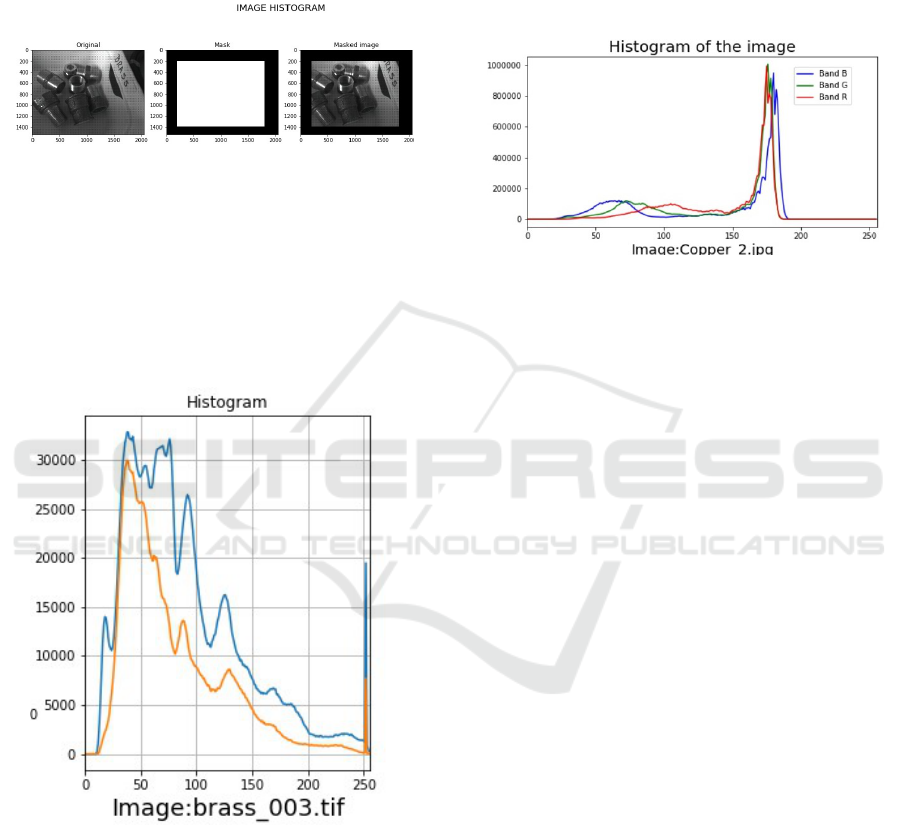

Figure 9: Plotting extract area to brass histogram.

The background of the image was removed using

techniques of delineation of the contour of the materi-

als, and an auto background with expressive color was

generated. In this case, the color red was used. Tech-

niques were applied to the image obtained from the

contour, disregarding the colors that remained in the

middle of the materials. This eliminates noise in the

image and obtains more assertiveness in the analysis.

Figure 10: Plotting brass histogram.

The Opencv libraries for Python have functionalities

directed to these imaging techniques. The features

have been developed so that they can be adjusted to

the background and context colors where image tech-

niques can be applied. For example, in a black floor

scenario, the colors at the threshold of black should

be considered as image noise. Figure 10, presents this

technique, using Opencv.

Using the histogram image information we can

obtain more technical and visual information. His-

tograms plots how often each intensity value in the

image occurs. Histograms help detect image acquisi-

tion problems, like:

- Over and under exposure;

- Brightness;

- Contrast;

- Dynamic range.

Figure 11: Copper histogram analysis.

Some point operations can be used to alter histogram,

e.g: Addition, Multiplication, Exp and Log and Inten-

sity Windowing (Contrast Modification).

Another issue to consider is the color list used in

the algorithms. Depending on the library used and

the algorithms to implement, each library has its list

of colors. Colour analysis can be made using Mat-

plotlib, or Webcolors colors as a list of valid colors, to

give two examples of used libraries that already have

color lists. For development purposes, a fixed color

list defined was implemented. This color list has the

purpose of serving the color search algorithms in the

context of what is sought.

5 ONGOING WORK

The parameters with higher information were ob-

tained from the histogram of the image. Each ma-

terial has its signature in terms of the spectral image,

both the intensity of its brightness and the positions

of the spectrum, where that maximum is presented.

The minimum values’ positions of the spectrum also

show variations in some materials. This information

is obtained by removing each band of the image. Af-

ter we analysing the maximum value of the spectrum

matrix and its position, in the list of values obtained

(position in the spectrum). The visualization of this

information for copper and brass, can be observed in

Figures 10 and 11, where the difference in the param-

eters is verified in particular in: MaxHistog, IdxMax-

Histog and IdxMinHistog. At the level of the spectral

analysis of each of the bands we have differences be-

tween the band R (Red) and B (Blue) that could be

ICINCO 2019 - 16th International Conference on Informatics in Control, Automation and Robotics

672

observed after a more accurate analysis of the values

of the spectrum, obtained by multiplying its values by

a thousand. The projection of these values presents a

relevant difference, which would not be observed in

Figure 4.

6 CONCLUSIONS

We have already some ML techniques that may al-

low to sectorially develop processes of classifica-

tion of metals. Not all metals have the same ap-

proach and some require several parallel approaches

to achieve classification. Depending on some types

of metal scrap grading requirements, some techniques

will only be possible using Deep Learning. In this

case, the classification of metals is inserted in the ac-

quisition process, where the technique must be dif-

ferent given the large volume of metal that is to be

inspected, and given that it is loaded by truck.

With this approach of ML applied to the images,

it is intended to obtain its classification in terms of the

type of metal used in its composition. Additional ML

methods allowing an analysis of the materials color

are used, so that a phased classification of the mate-

rials can be done. One of the factors to be consid-

ered is the conditions of luminosity in obtaining the

images, and the cleaning of the materials involved in

the images. In an industrial scrap environment, it will

not always be easy to obtain optimum results for the

imaging process, so industrial prototype application

studies should address this issue.

ACKNOWLEDGEMENTS

Thanks to Portucalense University for sharing infor-

mation, contents and follow up of the works on the

theme proposed in this work.

REFERENCES

Andrej Karpathy (2018). Software 2.0 – Andrej Karpathy –

Medium.

Barnab

´

e, P., Dislaire, G., Leroy, S., and Pirard, E. (2015).

Design and calibration of a two-camera (visible to

near-infrared and short-wave infrared) hyperspectral

acquisition system for the characterization of metallic

alloys from the recycling industry. Journal of Elec-

tronic Imaging, 24(6):061115.

Braibant, L., Barnab

´

e, P., Leroy, S., Dislaire, G., and Pi-

rard, E. (2017). Non-ferrous scrap metals classifica-

tion by hyperspectral and multi-energy X-ray trans-

mission imaging. Shaker Verlag - 8th Conference on

Sensor-Based Sorting and Control (SBSC), pages 1–9.

COMPUTAR (2009). Adc lite.

Domingos, P. (2015). The Master Algorithm: How the

Quest for the Ultimate Learning Machine Will Remake

Our World. Perseus Books Group.

Javaid, A. and Essadiqi, E. (2003). Final Report on Scrap

Management, Sorting and Classification of Steel.

Report No. 2003-23(CF) Gouvernment of Canada,

23(August):22.

Kutila, M., Viitanen, J., and Vattulainen, A. (2005). Scrap

metal sorting with colour vision and inductive sensor

array. In International Conference on Computational

Intelligence for Modelling, Control and Automation

and International Conference on Intelligent Agents,

Web Technologies and Internet Commerce (CIMCA-

IAWTIC’06), volume 2, pages 725–729.

Mancini, S. (2013). As vantagens da sucata - 26/11/13 -

ARTIGOS - Jornal Cruzeiro do Sul.

Parliament, T. E. and Council (2003). Directive 2002/96/ec

of the european parliament and of the council. Official

Journal of the European Union.

Paul, Torek; Benjamin, Aubuchon; Kalyani, C. (2016).

Scrap sorting system. US Patents.

Sikka, H. (2018). Democratizing Machine Learning for

Software 2.0 – Medium.

Spencer, D. B. (2005). IDENTIFICAC¸

˜

AO E

CLASSIFICAC¸

˜

AO DE SUCATAS N

˜

AO-

FERROSAS. Fundic¸

˜

ao e Servic¸o -Ano 15 - N

o

.

156.

Vasques, A. C. (2009). Reciclagem de Metais no Brasil.

Technical report, MINIST

´

ERIO DE MINAS E EN-

ERGIA.

Wilson, A., Editor, E., and Systems, V. (2019). Multisen-

sor imaging aids non-ferrous scrap metal sorting. Sys-

tems, Vision, pages 1–7.

Zaparolli, D. (2014). Sider

´

urgicas diversificam meios de

obter sucatas e reaproveitar o ac¸o.

Software 2.0 for Scrap Metal Classification

673